Overview

This article serves as an essential step-by-step guide for project managers seeking to rent a milling machine. It underscores the critical importance of thoroughly understanding project needs, evaluating rental companies, and effectively managing the rental period. By identifying specific steps such as:

- Pinpointing requirements

- Researching potential providers

- Maintaining open lines of communication with the rental company

project managers can ensure a seamless leasing experience that leads to successful project execution.

Key Highlights:

- Milling machines are crucial in various sectors, with 70% of manufacturing expected to rent them by 2025.

- Types of milling machines include vertical, horizontal, and CNC, each suited for specific tasks.

- Applications of milling machines span road construction, metal fabrication, and woodworking.

- Understanding cutting processes is vital for optimising milling machine usage.

- The rental process involves identifying needs, researching providers, requesting quotes, inspecting equipment, reviewing agreements, and finalising leases.

- Key criteria for evaluating rental companies include reputation, equipment quality, customer service, lease conditions, and support for machine operation.

- Effective management of the rental period includes planning schedules, maintaining communication with providers, conducting inspections, training operators, and timely equipment return.

Introduction

Milling machines are pivotal tools in various industries. Projections indicate that by 2025, approximately 70% of manufacturing sectors will choose to rent these machines for their operations. This shift underscores the growing necessity of comprehending the intricacies of milling machine rentals, from selecting the appropriate type for specific tasks to navigating the rental process itself.

With numerous options available and the stakes of project success on the line, project managers must ensure they make the best choices when renting such crucial equipment. This guide explores the essential steps and considerations for effectively renting a milling machine, empowering managers to optimize their projects and avoid common pitfalls.

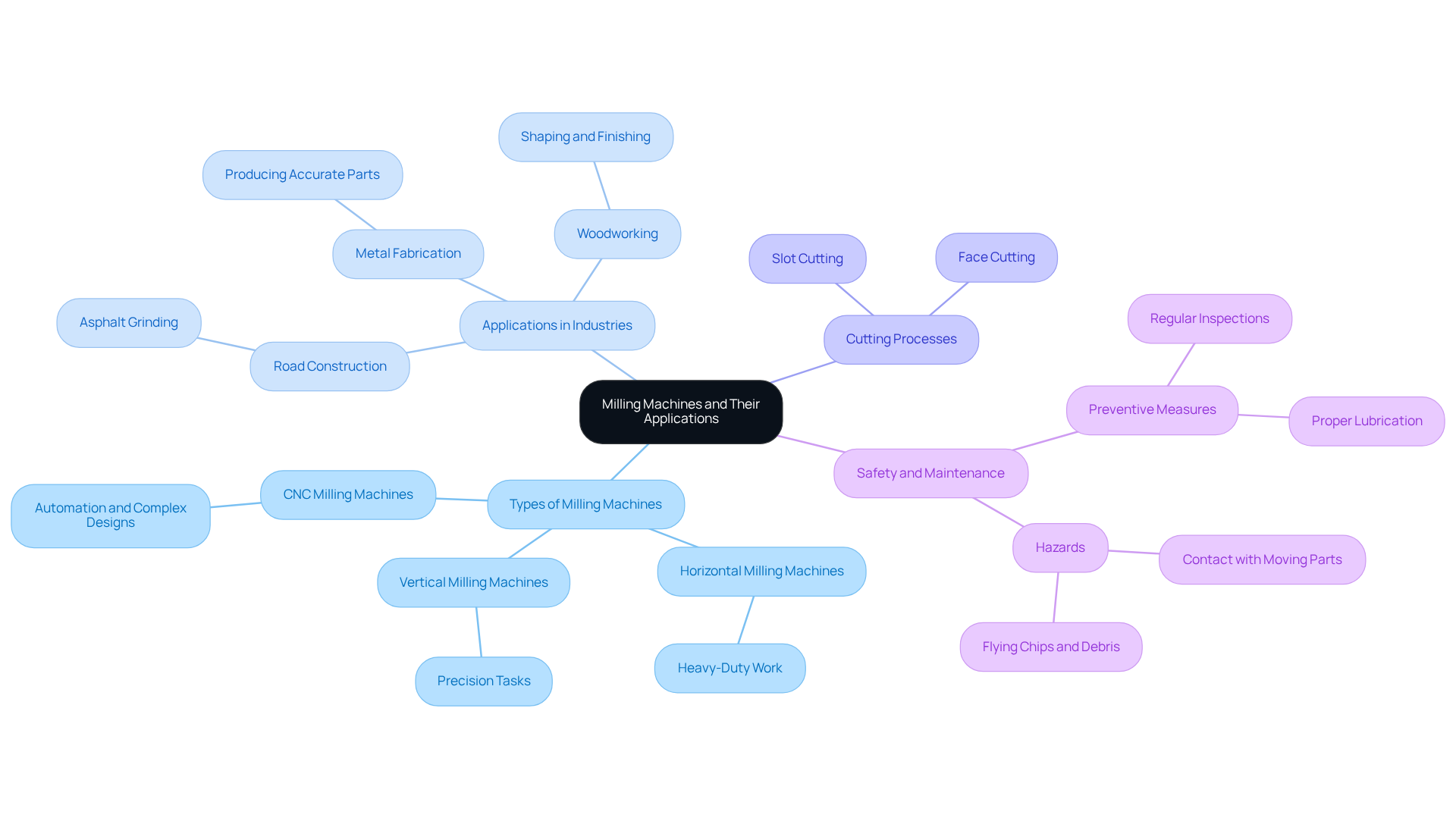

Understand Milling Machines and Their Applications

Milling devices are indispensable instruments across various sectors, and to achieve precision in shaping and cutting materials, one can rent a milling machine. By 2025, approximately 70% of manufacturing sectors are projected to rent a milling machine as part of their processing tools, underscoring their critical role in production. These devices, including vertical, horizontal, and CNC types, can be utilized when you rent a milling machine, as each is tailored for specific applications. For example, vertical mills are renowned for their precision tasks, while CNC devices automate complex designs, thereby enhancing efficiency and accuracy.

It is vital for project managers to understand the applications of machining tools, especially when they need to rent a milling machine. In road construction, these tools are employed for asphalt grinding, a crucial process for repairing and maintaining road surfaces. In metal fabrication, cutting tools are essential for producing accurate parts, ensuring high-quality output. Moreover, the woodworking industry utilizes these devices for shaping and finishing wooden products, demonstrating their versatility.

A comprehensive understanding of cutting processes, such as face cutting and slot cutting, is essential for optimizing results. As industry leaders assert, 'Quality is never an accident; it is always the result of intelligent effort.' This statement emphasizes the importance of comprehending the various types of equipment and their specific applications to guarantee the successful execution of tasks. By grasping the capabilities and limitations of machining tools, managers can effectively organize their tasks and allocate resources, ultimately leading to improved outcomes.

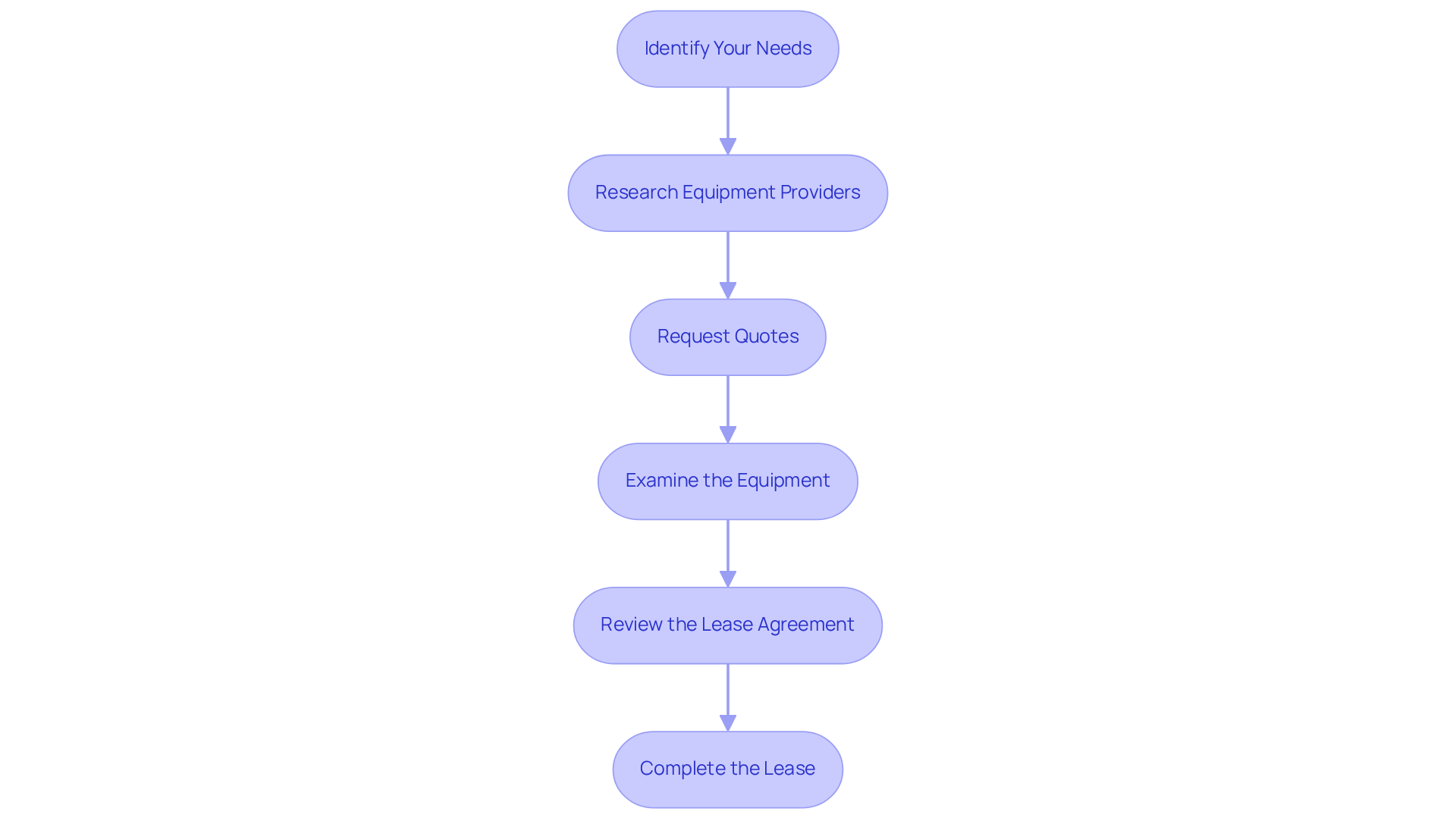

Follow the Step-by-Step Rental Process

Renting a milling machine involves several key steps that ensure a successful leasing experience:

-

Identify Your Needs: Begin by determining the specific type of milling machine required based on your project specifications. It is essential to consider factors such as the material to be milled, the size of the project, and the desired precision.

-

Research Equipment Providers: Next, look for reputable machinery leasing companies in your area. Assess their inventory for the type of milling machine you need and read customer reviews to gauge their reliability and service quality.

-

Request Quotes: Subsequently, contact multiple leasing companies to obtain quotes. Comparing lease rates, terms, and conditions will help you identify the best deal available.

-

Examine the Equipment: Before finalizing the lease, inspect the milling machine for any signs of wear or damage. It is crucial to ensure that it meets safety standards and is in good working condition.

-

Review the Lease Agreement: Take the time to carefully read the lease contract, paying close attention to the duration, fees, and responsibilities for maintenance and repairs. This diligence will prevent misunderstandings later on.

-

Complete the Lease: Finally, once you are satisfied with the terms, finalize the leasing agreement and arrange for the delivery or pickup of the equipment.

By following these steps, managers can ensure a seamless experience when they rent a milling machine while avoiding potential problems. Engaging with reliable equipment providers not only enhances project efficiency but also fosters long-term partnerships in the industry.

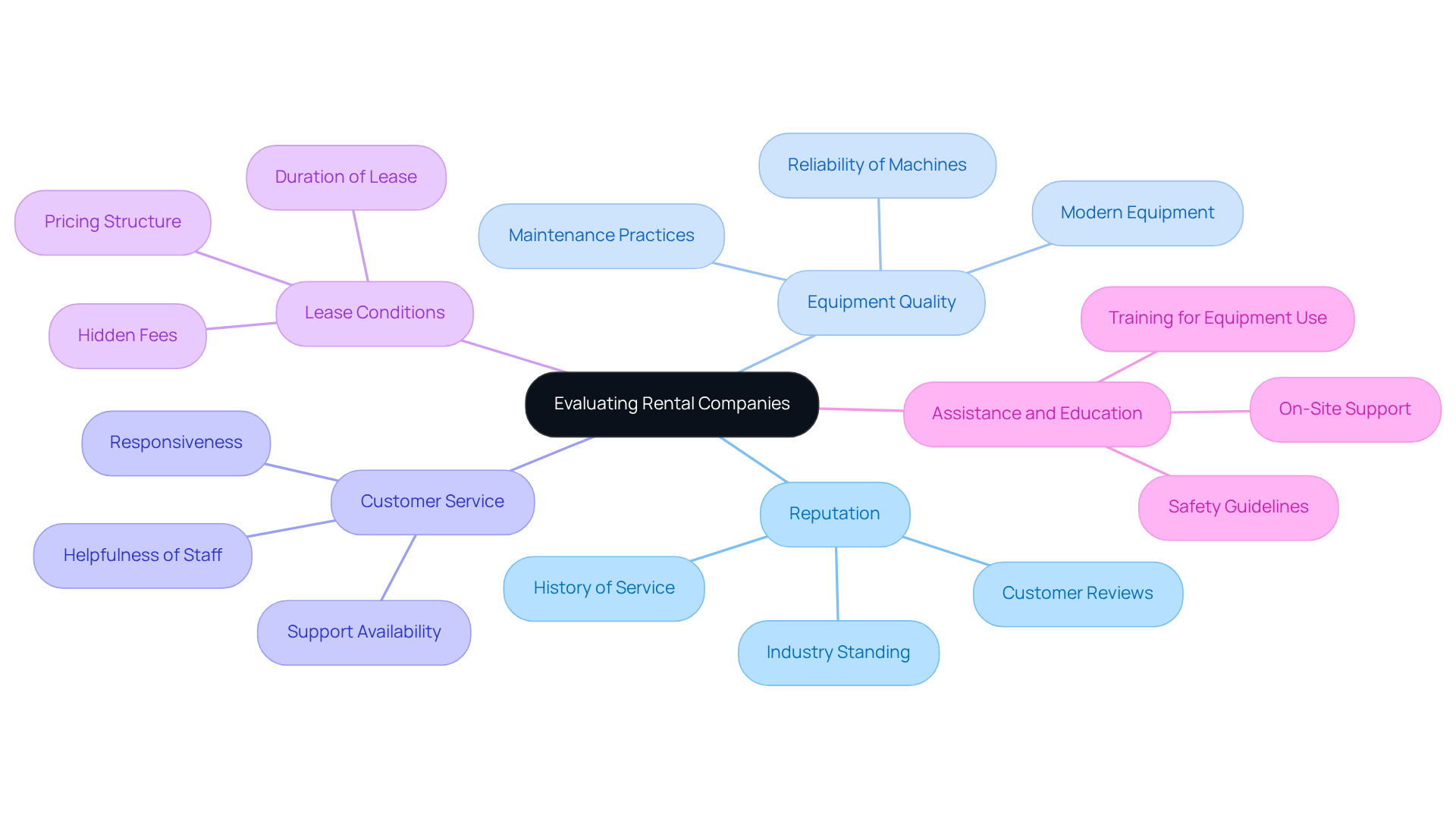

Evaluate Rental Companies for Quality and Reliability

When evaluating rental companies to rent a milling machine, it is essential to consider several key criteria that can significantly impact your decision-making process.

-

Reputation is paramount. Investigate the company's history and standing within the industry. Look for customer reviews and testimonials to gauge their reliability and service quality. A rental provider with a large and diverse fleet is more likely to have the solutions you need for your projects, especially if you want to rent a milling machine.

-

Next, assess the Equipment Quality. Confirm that the company offers well-maintained and modern milling devices. Inquire about their maintenance frequency and practices to ensure the equipment is in optimal condition. Remember, newer machines typically offer higher reliability due to fewer service hours, which can directly affect your project's success.

-

Customer Service is another critical factor. Evaluate the responsiveness and helpfulness of the company's staff. Outstanding customer service can greatly enhance your leasing experience and facilitate smoother operations, making it easier to address any issues that may arise.

-

Additionally, carefully review the Lease Conditions. This includes pricing, duration, and any additional fees. Be vigilant for hidden costs that could impact your budget and project timeline. With leasing penetration in the US reaching 56.4%, understanding these terms is crucial in a competitive market.

-

Lastly, ascertain if the leasing firm provides Assistance and Education for those who want to rent a milling machine to process materials. This support can be crucial, particularly for complex machinery, ensuring safe and effective use.

By thoroughly assessing these factors, managers can select a leasing partner that meets their specific requirements, ultimately leading to successful project outcomes.

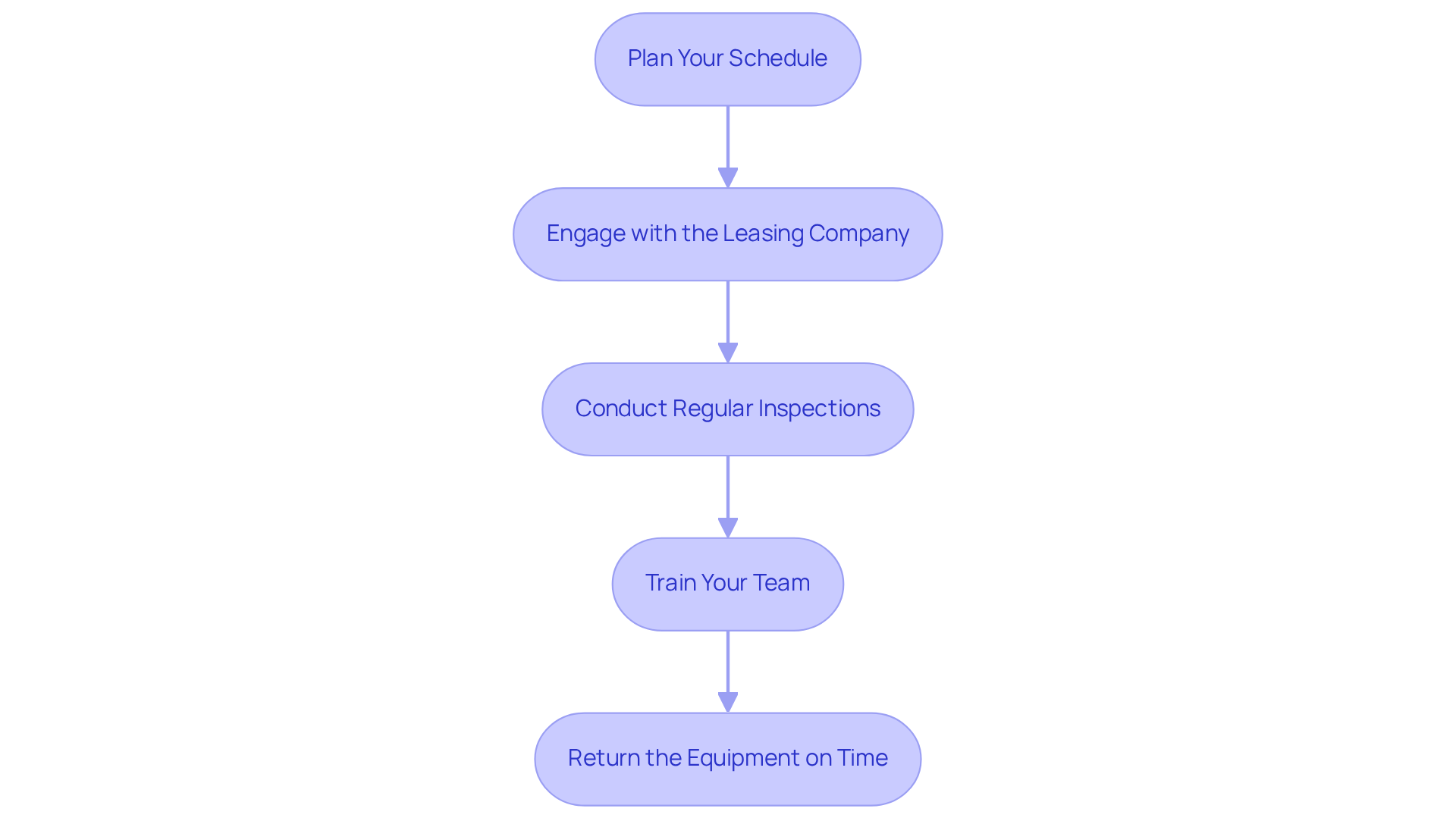

Manage Your Rental Period Efficiently

To manage your milling machine rental period efficiently, consider these essential strategies:

-

Plan Your Schedule: Begin by creating a detailed timeline that encompasses the leasing duration. Verify the equipment's availability to prevent any potential delays in your project.

-

Engage with the Leasing Company: Maintain open communication with your leasing provider. Promptly inform them of any adjustments to your project timeline or changes in equipment requirements to ensure alignment and avoid misunderstandings.

-

Conduct Regular Inspections: Carry out routine checks on the processing equipment throughout the leasing period to confirm its operational state. Reporting any issues to the leasing company promptly facilitates timely resolutions, ensuring continuous productivity.

-

Train Your Team: Ensure that all operators receive comprehensive training on the safe and effective use of the milling equipment. This proactive measure minimizes the risk of accidents and equipment damage, thereby enhancing overall safety on-site.

-

Return the Equipment on Time: Adhere to the agreed-upon return date to avoid incurring late fees. If an extension is necessary, communicate with the rental company well in advance to arrange for additional rental time.

By implementing these strategies, project managers can optimize how they rent a milling machine, ultimately contributing to the successful execution of their projects.

Conclusion

Renting a milling machine is a strategic decision that can significantly impact project outcomes across various industries. Understanding the intricacies of milling machines, from their diverse applications to the detailed rental process, is essential for project managers aiming to maximize efficiency and precision. By following the outlined steps, one can navigate the complexities of renting machinery with confidence, ensuring that the right equipment is secured for specific project needs.

Throughout this discussion, key insights have been shared, including:

- The importance of identifying project requirements

- Researching reputable rental companies

- Thoroughly evaluating equipment quality and lease conditions

Furthermore, effective management of the rental period, including communication with providers and regular equipment checks, has been emphasized as vital for maintaining productivity and avoiding unnecessary costs.

Ultimately, the significance of renting a milling machine extends beyond mere access to equipment; it encompasses the ability to enhance operational efficiency and achieve high-quality results. By embracing best practices and leveraging the right partnerships, project managers can not only streamline their workflows but also contribute to the overall success of their projects. Taking proactive steps in the rental process will ensure that every project is equipped for success, paving the way for future accomplishments in the field.

Frequently Asked Questions

What are milling machines and why are they important?

Milling machines are essential instruments used in various sectors for shaping and cutting materials. They are projected to be rented by approximately 70% of manufacturing sectors by 2025, highlighting their critical role in production.

What types of milling machines are available for rent?

The types of milling machines available for rent include vertical mills, horizontal mills, and CNC (Computer Numerical Control) machines. Each type is tailored for specific applications.

What are the applications of vertical and CNC milling machines?

Vertical mills are renowned for precision tasks, while CNC machines automate complex designs, enhancing efficiency and accuracy in production.

How are milling machines used in road construction?

In road construction, milling machines are employed for asphalt grinding, which is crucial for repairing and maintaining road surfaces.

What role do milling machines play in metal fabrication?

In metal fabrication, milling machines are used with cutting tools to produce accurate parts, ensuring high-quality output.

How are milling machines utilized in the woodworking industry?

The woodworking industry utilizes milling machines for shaping and finishing wooden products, demonstrating their versatility across different sectors.

Why is it important for project managers to understand machining tools?

It is vital for project managers to understand machining tools to optimize results, effectively organize tasks, and allocate resources, ultimately leading to improved outcomes.

What cutting processes should be understood for optimizing milling results?

A comprehensive understanding of cutting processes such as face cutting and slot cutting is essential for optimizing results when using milling machines.