Introduction

In the realm of construction, the choice of equipment can significantly impact the success of a project. Among the various tools available, the sheepsfoot roller stands out for its unique design and effectiveness in compacting cohesive soils.

This article delves into the purpose and functionality of sheepsfoot rollers, exploring their advantages and limitations, as well as practical considerations for rental and operation.

From enhancing road stability to optimizing embankment construction, understanding the capabilities of this essential machinery is crucial for project managers aiming to achieve optimal compaction and durability in their work.

With insights into best practices and applications, this guide aims to equip professionals with the knowledge needed to leverage sheepsfoot rollers effectively in their construction endeavors.

Understanding the Sheepsfoot Roller: Purpose and Functionality

A sheepsfoot compactor is a vital tool in construction designed for compressing earth, gravel, and asphalt. Its distinctive design, characterized by rounded feet, allows for a kneading action that effectively compresses the material underneath. This type of equipment excels at attaining high-density consolidation in cohesive materials, which is essential for projects like road construction, embankments, and foundational work.

Significantly, attaining a density level of 95 percent signifies that the ground has achieved 95 percent of its potential density, highlighting the machine's ability in improving stability. However, it’s important to acknowledge that while specialized compactors are effective in cohesive materials, they face difficulties with granular soils, often resulting in a rough surface finish and necessitating multiple passes for sufficient densification. For example, as observed in Louisiana, materials such as crushed seashells or clinker from coal-fired power plants may be utilized alongside specialized compaction equipment.

Additionally, while effective, these devices generally operate at slower speeds compared to smooth drums or vibratory machines, necessitating multiple passes for sufficient compaction. Comprehending the functionality and limitations of specialized compaction tools is crucial for construction project managers, as this knowledge directly affects the selection of equipment and ultimately the stability and durability of the built surface.

Renting a Sheepsfoot Roller: Key Considerations and Rental Options

When leasing a sheepsfoot roller for rent, it’s essential to take into account several important factors to guarantee a successful project. First, assess the rental duration; determine how long the equipment will be necessary. Short-term options might suit smaller tasks, offering daily or weekly rates, while longer projects could benefit from monthly agreements.

Significantly, specialized compaction equipment is designed with 72 pads, which improve their efficiency for deep compaction, especially on cohesive earth. Next, focus on rental providers; conduct thorough research on local equipment rental companies. Prioritize those with positive reviews and a reputation for dependable service to avoid disruptions on-site.

In terms of cost, be diligent in comparing rental prices for a sheepsfoot roller for rent and factor in any potential additional fees, such as delivery charges or insurance. It's also crucial to examine the equipment state before rental—ensuring the compactor is in optimal working order can prevent expensive delays and safety risks. For projects in Hawaii, consider renting a sheepsfoot roller for rent like the CT 48P compactor, which is specifically designed to handle the region's diverse ground conditions and features articulating steering for maneuverability in tight construction zones.

Lastly, inquire about support services; check if the rental company offers operational training or assistance, which can be invaluable for effectively utilizing the equipment and ensuring your project runs smoothly. Additionally, referencing case studies on the sheepsfoot compactor's characteristics can illustrate its benefits for filling trenches in narrow spaces, further emphasizing the importance of selecting the right equipment for your specific project needs.

Pros and Cons of Using Sheepsfoot Rollers

Advantages of Sheepsfoot Rollers

-

Efficient Compression: Sheepsfoot machines excel in achieving superior density in cohesive materials, a crucial aspect for projects requiring stable foundations. Their unique design, especially when using a sheepsfoot roller for rent, allows for improved penetration into the ground, ensuring a dense and reliable base.

Significantly, recent studies suggest that the effective depth for attaining a dry density ratio of 95% with eight passes of the impact device is approximately 1.3 meters, highlighting their efficiency in compaction and establishing them as a vital tool for construction project managers.

-

Versatility: These devices are adaptable for a variety of applications, ranging from road construction to embankments and utility trenching.

This flexibility makes them a valuable asset on diverse job sites, allowing project managers to utilize a sheepsfoot roller for rent for multiple tasks.

-

Reduced Risk of Ground Disturbance: The kneading action of sheepsfoot rollers minimizes ground disturbance, preserving the integrity of the material being compacted.

M. B. Jaksa from the School of Civil, Environmental and Mining Engineering emphasizes this benefit, stating that a contour plot developed quantified the influence zone at various stress levels, providing further evidence of their effective densification capabilities. This ability to maintain earth structure is particularly beneficial for project success. Moreover, improvements in GPS technology increase the efficiency of specialized equipment like a sheepsfoot roller for rent by offering real-time spatial visibility of measurement values, enabling more accurate density processes.

Disadvantages of Sheepsfoot Rollers

- Restricted Application on Non-Cohesive Materials: While specific compactors are effective for cohesive types, their efficiency decreases on granular or loose substances. This limitation can require project managers to consider alternative compaction methods when dealing with certain soil types.

- Higher Rental Costs: Leasing compactors can be pricier compared to other types of equipment, which may affect project budgets. A thorough cost comparison is necessary to determine the most economical choice for specific project requirements.

- Operational Complexity: The effective use of sheepsfoot compaction equipment often necessitates trained operators, which can increase overall project costs. Ensuring that operators are adequately trained and experienced is essential to maximize the benefits of these devices while minimizing potential inefficiencies.

Applications of Sheepsfoot Rollers in Construction Projects

Sheepsfoot machines are essential tools in numerous construction uses because of their distinctive design and efficiency in attaining density in cohesive materials, which are marked by fine-grained and high clay content. Research indicates that cohesive soils can possess a moisture content of up to 20%, which significantly influences their densification behavior. Their primary applications include:

- Road Construction: These machines excel in compacting subgrade and base layers, establishing a solid foundation crucial for roadway stability and longevity. As stated by a construction supervisor at a prominent company, 'Utilizing specialized compactors has enhanced our density rates by more than 30% relative to conventional techniques.'

- Embankment Construction: In creating earth embankments, specialized compactors deliver the crucial compression required to avoid settling, thus maintaining structural integrity over time.

- Trenching: They are particularly effective at compacting backfill material in utility trenches, which is vital for ensuring long-term stability and minimizing future ground movement.

- Landfill Operations: Sheepsfoot machines play a critical role in compacting refuse material within landfill sites, maximizing available space and reducing settlement issues. The recent innovation of specialized landfill compactors from padding technology is a testament to the ongoing advancements in this field.

Overall, the use of specialized compactors, such as a sheepsfoot roller for rent, significantly improves road construction efficiency, as demonstrated by the difficulties encountered in projects like the Knox-Yellow Pine Road, where manual methods may not deliver the required compaction. The ongoing advancement of these devices into specialized landfill compactors further highlights their versatility and significance in contemporary construction practices.

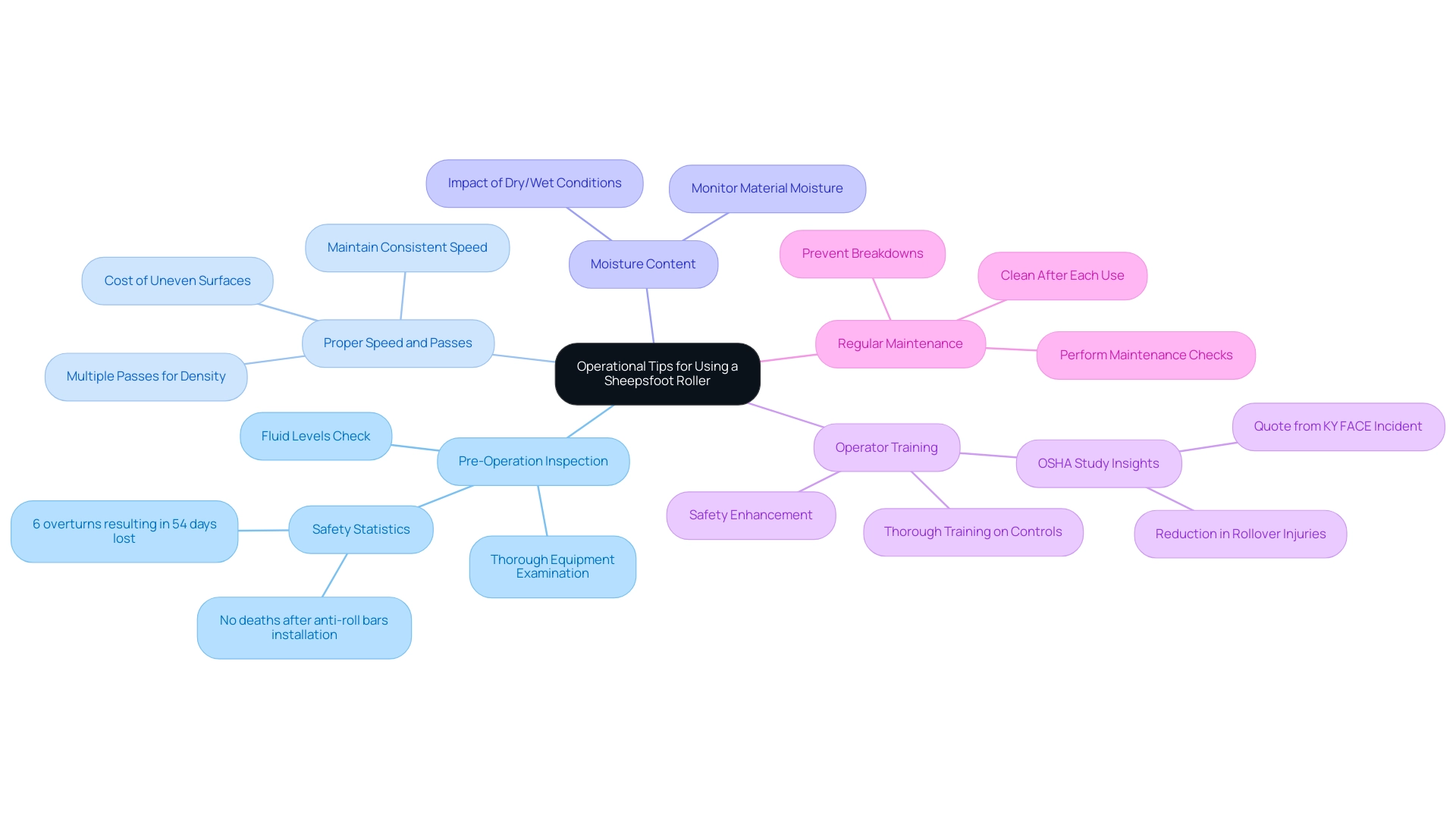

Operational Tips for Using a Sheepsfoot Roller Effectively

To ensure effective operation of a sheepsfoot roller, adhere to the following best practices:

- Pre-Operation Inspection: Conduct a thorough examination of the equipment for any signs of damage or wear before each use. Pay attention to fluid levels and ensure that all components are functioning correctly, as neglecting this step can lead to serious safety hazards. As highlighted by the statistic regarding anti-roll bars, during the two years after their installation, no operators died from a tractor rollover, despite six overturns resulting in 54 days of lost time. This underscores the critical nature of pre-operation inspections.

- Proper Speed and Passes: Maintain a consistent speed while operating the roller. Typically, slower speeds produce better results in packing, and multiple passes may be required to achieve the desired density. This approach minimizes the risk of uneven surfaces, which can lead to costly repairs.

- Moisture Content: Monitor the moisture content of the material being compacted. Achieving the right moisture balance is crucial; overly dry or excessively wet conditions can significantly compromise the effectiveness of compaction.

- Operator Training: Ensure that operators are thoroughly trained in the specific controls and functions of the sheepsfoot compactor. Proper training not only maximizes efficiency but also enhances safety on the job site. As highlighted in a study by Woodward Associates for OSHA, proper equipment handling can lead to a significant reduction in injuries related to vehicle rollovers. Additionally, the quote from KY FACE illustrates the risks involved: "In another incident, a ROPS-equipped compactor slid sideways along a roadside, dropped over a 17-foot high underpass wall, and rotated 270° in midair before impacting the ground." This reinforces the necessity of proper equipment handling.

- Regular Maintenance: After each use, clean the device and perform necessary maintenance checks to maintain optimal working condition. Regular upkeep prevents breakdowns and ensures that the sheepsfoot roller for rent is ready for future rentals.

These practices are vital not only for the efficiency of compaction tasks but also for the safety of operators on site. As emphasized by industry experts, investing in operator training can lead to smoother operations and fewer accidents, addressing the challenges that arise from the complexities of using sheepsfoot rollers. Furthermore, the OSHA study on ROPS retrofits provides evidence that such safety measures significantly reduce injuries and deaths related to vehicle rollovers, reinforcing the importance of adhering to these best practices.

Conclusion

The sheepsfoot roller proves to be an indispensable tool in the construction industry, particularly for projects involving cohesive soils. Its unique design facilitates effective compaction, ensuring stability and durability in foundations, roadways, and embankments. Understanding its operational capabilities, including the importance of proper speed, moisture management, and pre-operation inspections, can significantly enhance project outcomes.

However, it is equally important to recognize the limitations of sheepsfoot rollers, especially when dealing with non-cohesive soils. Project managers must weigh the advantages against potential challenges, such as higher rental costs and the necessity for trained operators. By considering these factors, one can make informed decisions that optimize resource allocation and project efficiency.

Ultimately, leveraging the strengths of sheepsfoot rollers, while being mindful of their limitations, can lead to successful project execution. As the construction landscape continues to evolve, embracing best practices and innovative uses of this equipment will remain crucial in achieving high-quality results and addressing the complexities of modern construction challenges.

Frequently Asked Questions

What is a sheepsfoot compactor and what is its primary use?

A sheepsfoot compactor is a vital construction tool designed for compressing earth, gravel, and asphalt. Its distinctive design with rounded feet allows for a kneading action that effectively compresses the material underneath, making it ideal for projects like road construction, embankments, and foundational work.

How effective is a sheepsfoot compactor in achieving density in materials?

A sheepsfoot compactor can achieve a density level of 95 percent, indicating that the ground has reached 95 percent of its potential density, which is crucial for improving stability in cohesive materials.

Are there limitations to using a sheepsfoot compactor?

Yes, while sheepsfoot compactors are effective in cohesive materials, they struggle with granular soils, often resulting in a rough surface finish and requiring multiple passes for adequate densification.

What factors should be considered when leasing a sheepsfoot roller?

When leasing a sheepsfoot roller, consider the rental duration, the reputation of rental providers, rental costs and any additional fees, the condition of the equipment, and the availability of support services such as operational training.

How can the rental duration affect the leasing decision for a sheepsfoot roller?

Short-term rental options may suit smaller tasks and are often available at daily or weekly rates, while longer projects could benefit from monthly agreements for better cost efficiency.

Why is it important to research rental providers for sheepsfoot rollers?

Thorough research on local equipment rental companies is essential to find those with positive reviews and a reliable reputation, which helps prevent disruptions on-site during the project.

What should be checked regarding the condition of the sheepsfoot compactor before renting?

It is crucial to examine the equipment's state before rental to ensure it is in optimal working order, which can prevent expensive delays and safety risks during the project.

What specific model is recommended for projects in Hawaii?

The CT 48P compactor is recommended for projects in Hawaii as it is specifically designed to handle the region's diverse ground conditions and features articulating steering for maneuverability in tight construction zones.

What additional support services should be inquired about when renting a sheepsfoot roller?

Inquire whether the rental company offers operational training or assistance, which can be invaluable for effectively utilizing the equipment and ensuring a smooth project execution.