Overview

Renting a torque wrench is a practical choice for DIYers and contractors who need high-quality tools for occasional use, as it offers cost savings and eliminates maintenance and storage concerns. The article supports this by outlining a step-by-step guide for renting, including assessing project needs, checking local availability, and understanding lease terms, which collectively ensure that users can efficiently access the right tools for their tasks without the long-term financial commitment of purchasing.

Introduction

In the construction and DIY world, having the right tools can make all the difference between a successful project and a costly mistake. Among these tools, the torque wrench stands out as a vital instrument for ensuring fasteners are tightened to the precise specifications required.

However, for many, the decision to rent rather than buy can lead to significant savings and convenience. This article delves into the advantages of renting torque wrenches, offering a comprehensive guide on how to navigate the rental process effectively.

From understanding the various types available to identifying common pitfalls and tips for optimal usage, readers will gain valuable insights that empower them to make informed decisions for their projects.

As the rental market continues to evolve, embracing this approach not only enhances project efficiency but also aligns with the growing trend of cost-effective tool management.

Understanding Torque Wrenches: Why Rent Instead of Buy?

A turning tool is a vital precision instrument created to apply a specific rotational force to fasteners, ensuring they are neither too loose nor too tight. For construction supervisors and DIY fans in Dallas, the option to rent a torque wrench often appears as a more cost-effective choice than buying, especially for one-time tasks or occasional use. This method not only offers access to high-quality, professional-grade tools without the financial obligation of ownership but also enhances efficiency by enabling optimal execution while conserving time and money.

Furthermore, renting alleviates concerns regarding storage space and eliminates ongoing maintenance costs. When assessing requirements, consider the frequency of use:

- If a torque wrench is anticipated to be used across multiple tasks, purchasing may offer long-term value.

- However, for sporadic applications, to rent a torque wrench is a practical, budget-friendly solution that perfectly aligns with the needs of cost-conscious contractors and DIY tasks in 2024.

The trend towards leasing is emphasized by recent developments in the leasing market, including Sunbelt Rentals’ acquisition of 33 companies since 2022, showcasing a commitment to enhancing product offerings. Furthermore, innovations such as Snap-on's break-over torque wrenches and Norbar's electronic torque wrenches illustrate the continuous progress in the industry, emphasizing the benefits of renting a torque wrench as a practical choice for contemporary tasks. In Dallas, the availability of trailers for rent further complements the benefits of tool rentals, enabling managers to efficiently transport equipment and materials, thereby streamlining their operations.

Step-by-Step Guide to Renting a Torque Wrench

-

Identify Your Needs: Start by determining the specific requirements for your project. Consider the torque range and the type of torque wrench you need, including options to rent torque wrench models like click, beam, or digital. This initial assessment is vital for securing the right tool for your task, as precision and reliability are crucial in construction projects.

-

Find Local Leasing Locations: Next, explore services in Irving, TX, such as those offering a variety of equipment including boom lifts, mini excavators, forklifts, and other machinery. Local businesses can supply specialized tools, so consider both hardware stores and dedicated equipment leasing services that cater to the DFW Metroplex.

Check Availability and Pricing: Once you've identified potential leasing locations, contact them to verify the availability of your desired rent torque wrench. Inquire about leasing prices, which can typically range from $20 to $80 per day depending on the model and specifications. Keep an eye out for any necessary deposits, which can help you budget effectively. For context, consider that purchasing an Air Hydraulic Pump can cost around $5,200.00, making renting a cost-effective option for short-term projects.

-

Review Lease Terms: Before concluding your agreement, scrutinize the contract thoroughly. Pay close attention to the rental duration, late fees, and any stipulations regarding damage or loss, such as insurance requirements or maintenance responsibilities. Understanding these terms will help prevent unexpected costs and liabilities.

-

Inspect the Tool: After choosing your adjustable tool, carry out a thorough examination. Look for any visible damage or signs of wear. Ensure it operates correctly—if you have any doubts, don’t hesitate to ask a staff member for assistance, as their expertise is invaluable.

-

Ask for Instructions: If you’re not well-versed in using a torque wrench, seek guidance. Request a brief tutorial from the rental staff or look for instructional materials online. Proper usage is crucial for accuracy, especially in tasks where precision is paramount.

Return the Tool Quickly: Lastly, after finishing your task, return the socket tool on time to prevent incurring late charges. Clean the tool if necessary and ensure it is in the same condition as when you borrowed it, preserving a positive relationship with the leasing service for future endeavors.

Case Study: JM Test Systems provides a leasing service for high-quality tools, catering to clients needing equipment for short-term tasks without long-term investment. Customers benefit from cost-effective access to calibrated and well-maintained equipment, supported by JM Test Systems’ expertise, which is crucial for industries requiring precision and reliability. Additionally, they offer a variety of other equipment leases, including boom lifts and excavators, ensuring you have access to necessary machinery across the DFW Metroplex.

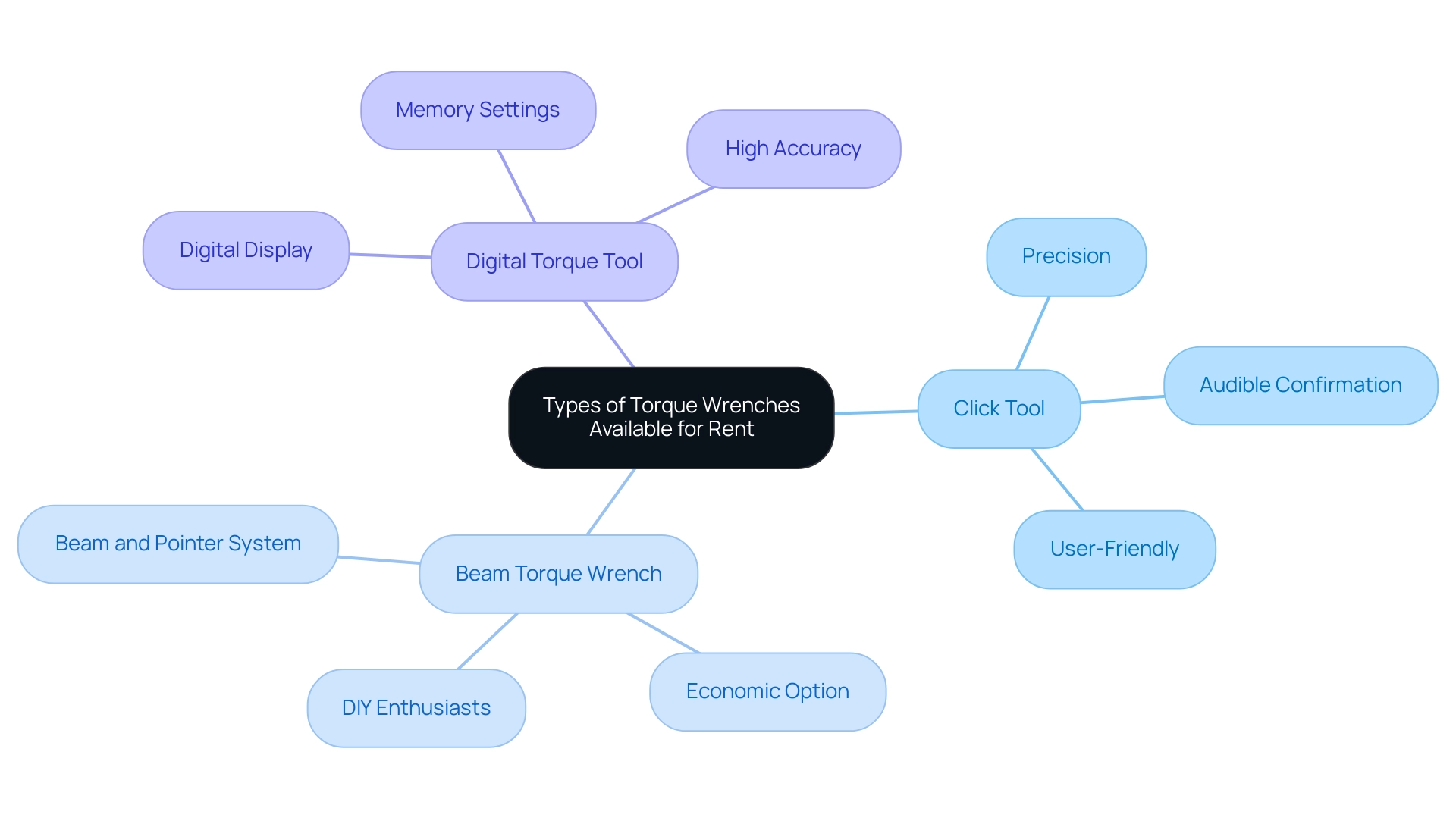

Types of Torque Wrenches Available for Rent

When evaluating tool rentals, it's crucial to grasp the unique varieties available, each serving different task requirements:

- Click Tool: Known for its precision, this type produces a clicking noise upon achieving the designated force level, offering an intuitive and audible confirmation. Its user-friendly nature makes it a favorite among professionals who prioritize precision in their work.

- Beam Torque Wrench: This traditional option relies on a beam and pointer system to indicate force levels. While less common in commercial uses, it remains an economic instrument for DIY enthusiasts and smaller projects because of its simplicity and affordability.

- Digital Torque Tool: Featuring a digital display, this device not only shows force values but often includes features like memory settings and notifications for improved functionality. It is especially beneficial for tasks needing high accuracy and consistency, rendering it a perfect option for complex projects.

Recent product launches have unveiled innovations in tools, such as Snap-on's new line of break-over tools and Norbar Torque Tools' electronic tools. These advancements aim to enhance safety and efficiency in fastening applications, addressing the risk of over-tightening fasteners. With the market for torque tools expected to expand considerably, comprehending the market share of various types of torque wrenches is essential for making informed choices.

Choosing the suitable rent torque wrench depends on several factors, including specifications of the task, your previous experience with the tool, and budget limitations. Engaging with rental staff can provide valuable insights and recommendations tailored to your specific needs. As Vinayak Bali, a Senior Research Analyst at Cognitive Market Research, notes,

Through collaboration with cross-functional teams, I played a pivotal role in shaping business strategies rooted in robust research.

This collaborative approach can equally apply to choosing the right tools for your tasks, ensuring efficiency and safety.

Common Mistakes to Avoid When Renting a Torque Wrench

-

Misunderstanding Force Specifications: One of the most critical errors is not fully grasping the force requirements necessary for your undertaking. This oversight can lead to the use of inappropriate tools, compromising the integrity of the work. Always consult your guidelines to determine the correct torque values before using a rent torque wrench.

-

Overlooking Leasing Policies: Each leasing company operates under different policies concerning deposits, late fees, and damage liabilities. Failing to familiarize yourself with these terms can result in unexpected costs or disputes. Carefully review the lease agreement to avoid any surprises that could impact your budget and project timeline.

-

Neglecting Tool Inspection: Skipping the inspection of the torque wrench before you rent it can lead to significant setbacks if you end up with a faulty tool. Always conduct a thorough check for any visible damage or operational issues before finalizing your lease. Proper inspection can greatly enhance your leasing satisfaction and prevent costly delays. For instance, outdated inventory records can cause inefficiencies like double bookings and poor customer service due to inaccurate tracking of equipment availability. Automating the inventory updating process with QR code labels allows for real-time tracking of equipment status, reducing errors and improving customer satisfaction.

-

Not Asking Questions: If there’s any uncertainty regarding how to rent a torque wrench, reach out to the staff for assistance. Their expertise can provide crucial insights and operational tips that can enhance your efficiency on the job site. For instance, Jordan Frasca, a satisfied customer, remarked,

Very Quick and Efficient! Would definitely use again,

highlighting the benefits of seeking assistance when needed.

-

Returning the Tool Late: Timely returns are essential to avoid incurring additional fees. Carefully plan your timeline to ensure that you return the tool as scheduled. This foresight not only assists in managing your budget but also nurtures a positive connection with suppliers, which can be advantageous for future endeavors. Understanding your cash flow and taking actionable steps to finance projects is crucial for construction project managers when considering tool rentals, especially with the potential costs involved.

Tips for Using a Torque Wrench Effectively

-

Calibrate the Tool: Proper adjustment of your force measuring device is critical before use. Refer to the manufacturer's guidelines for calibration procedures to ensure accuracy. Studies highlight that effective tool calibration not only prevents inaccuracies but also enhances overall performance. For instance, the risk calculator for predicting the onset of bipolar disorder in youth was well calibrated in the validation sample, showing a range of predictions from 0.00 to 0.24. This statistic underscores the importance of calibration in achieving reliable results. As noted by Schmid & Griffith,

In selecting a predictive model, it is important that calibration be high for a new data set and not just for the training data set — a principle that applies equally to tool calibration.

-

Use Smooth, Even Pressure: When applying rotational force, do so gradually and evenly. This technique helps to prevent over-tightening, which can lead to damage of fasteners or components, ensuring the integrity of your work.

-

Avoid Using a Tightening Tool as a Breaker Bar: Utilizing your tightening tool as a breaker bar can severely harm its internal mechanisms. Always utilize the tool as intended to achieve the best results and maintain its functionality over time.

-

Store Properly After Use: After finishing your tasks, it’s crucial to return the tool to its case and adjust it to the minimum setting. This practice not only preserves its accuracy but also prolongs the tool's lifespan, making it ready for your next project.

-

Keep the Tool Clean: Regular maintenance, such as wiping down the instrument after use, is vital. Removing dirt or grease helps prevent performance issues during future applications. By adhering to these best practices, you can ensure that your rent torque wrench remains reliable and effective.

Real-World Example: Consider the case study of Tangram Vision's approach to calibration, which highlights how incorporating accuracy and precision metrics into the calibration process can enhance overall quality and reliability. This real-world application demonstrates the tangible benefits of diligent calibration practices.

Conclusion

Renting a torque wrench presents a strategic and economical solution for both construction professionals and DIY enthusiasts. By understanding the specific types of torque wrenches available, such as:

- Click

- Beam

- Digital models

Individuals can select the right tool tailored to their project needs. The step-by-step guide emphasizes the importance of:

- Identifying project requirements

- Exploring local rental options

- Reviewing rental terms to avoid common pitfalls

Moreover, being aware of frequent mistakes—like misunderstanding torque specifications or neglecting tool inspections—can lead to smoother project execution and enhanced outcomes. Implementing best practices for using and maintaining the wrench ensures not only accuracy in work but also prolongs the lifespan of the tool.

Ultimately, renting a torque wrench not only saves money but also aligns with the growing trend of cost-effective tool management. As the rental market evolves, embracing this practice allows project managers and DIYers to focus on executing their tasks efficiently while avoiding the burdens of ownership. By making informed decisions and leveraging available resources, individuals can enhance their project outcomes, ensuring success in every endeavor.

Frequently Asked Questions

What is a torque wrench and why is it important?

A torque wrench is a precision instrument used to apply a specific rotational force to fasteners, ensuring they are neither too loose nor too tight. It is vital for maintaining the integrity of construction and DIY projects.

Why might someone choose to rent a torque wrench instead of buying one?

Renting a torque wrench is often more cost-effective for one-time tasks or occasional use, providing access to high-quality tools without the financial obligation of ownership. It also saves on storage space and maintenance costs.

When should I consider purchasing a torque wrench instead of renting?

If you anticipate using a torque wrench frequently across multiple tasks, purchasing may offer long-term value. However, for sporadic applications, renting is a practical and budget-friendly option.

What are some recent trends in the tool rental market?

The leasing market has seen developments such as Sunbelt Rentals acquiring 33 companies since 2022, indicating a commitment to enhancing product offerings. Innovations in torque wrenches, like Snap-on's break-over and Norbar's electronic models, also highlight the benefits of renting.

What should I consider when identifying my needs for a torque wrench?

Determine the specific requirements for your project, including the torque range and the type of torque wrench needed, such as click, beam, or digital models. This assessment is crucial for securing the right tool for your task.

How can I find local leasing locations for a torque wrench?

Explore services in areas like Irving, TX, that offer various equipment, including specialized tools. Check both hardware stores and dedicated equipment leasing services in the DFW Metroplex.

What should I do to check availability and pricing for renting a torque wrench?

Contact potential leasing locations to verify availability and inquire about rental prices, which typically range from $20 to $80 per day. Be aware of any necessary deposits to budget effectively.

What should I review before signing a lease agreement?

Scrutinize the contract for rental duration, late fees, and stipulations regarding damage or loss, including insurance requirements and maintenance responsibilities, to avoid unexpected costs.

How should I inspect a torque wrench before renting it?

Examine the tool for visible damage or signs of wear and ensure it operates correctly. If in doubt, ask a staff member for assistance to ensure its reliability.

What should I do if I need help using a torque wrench?

Seek guidance from rental staff or look for instructional materials online. Proper usage is crucial for accuracy in tasks requiring precision.

What should I do when returning the rented torque wrench?

Return the tool promptly to avoid late charges, clean it if necessary, and ensure it is in the same condition as when borrowed to maintain a positive relationship with the leasing service.