Introduction

Navigating the world of equipment rentals can often feel overwhelming, especially when it comes to specialized tools like acetylene torches. For those embarking on welding projects, understanding the intricacies of renting this essential equipment is crucial to ensuring both safety and efficiency. From identifying the right torch for specific needs to adhering to safety protocols and maintenance practices, each step plays a vital role in the successful execution of a project.

This guide will illuminate the key considerations and best practices for renting an acetylene torch, empowering users to tackle their tasks with confidence and competence.

Step-by-Step Process for Renting an Acetylene Torch

- Identify Your Needs: Begin by assessing the specific requirements of your project to determine the type of gas welding tool that best suits your needs. Consider factors such as size, capacity, and any additional accessories that might enhance functionality.

- Research Local Suppliers: Utilize online platforms and local directories to identify tool leasing companies in your area that provide acetylene torch rental near me. Pay close attention to customer reviews and ratings to measure the reliability and reputation of potential suppliers.

- Compare Leasing Options: Reach out to several suppliers to evaluate their leasing rates, equipment availability, and leasing terms. Options may vary from daily to weekly or monthly agreements, so choose the one that aligns best with your project schedule and budget. For example, the starting price for a cylinder is approximately $29.24, which can help you gauge costs.

- Check Availability: Verify the availability of the acetylene torch you intend to rent. It is wise to make an advance reservation, particularly during peak seasons when demand is high.

- Review Lease Agreement: Before committing to the arrangement, meticulously read through the lease agreement. Key points to focus on include the lease duration, associated fees, and any potential charges for damages or late returns.

- Inspect the Equipment: At the time of pickup, conduct a thorough examination of the gas cutting tool. Look for signs of wear or damage, and ensure that all necessary components, such as hoses and regulators, are present and in good condition. Be aware of challenges related to tank recertification; tanks that have deteriorated significantly may not be suitable for use.

- Receive Safety Instructions: Interact with the supplier to acquire necessary safety guidelines and operational advice for the gas cutting tool. As Franny K. aptly states, "Heat & beat, to fit" should stay an old joke, not become a work method due to a -misperceived, mistaken- cost reduction. Familiarizing yourself with safety protocols is critical to mitigate risks and prevent accidents on the job site.

- Return the Equipment: Upon completion of your project, return the gas welding tool in accordance with the agreed terms. Ensure that it is clean and in the same condition as when it was rented to avoid incurring additional charges. Keep in mind, as mentioned by a Calgary member, larger oxygen tanks are often more effective since users generally use three tanks of oxygen for each tank of gas when cutting, making it essential to be aware of your tool usage throughout the rental process.

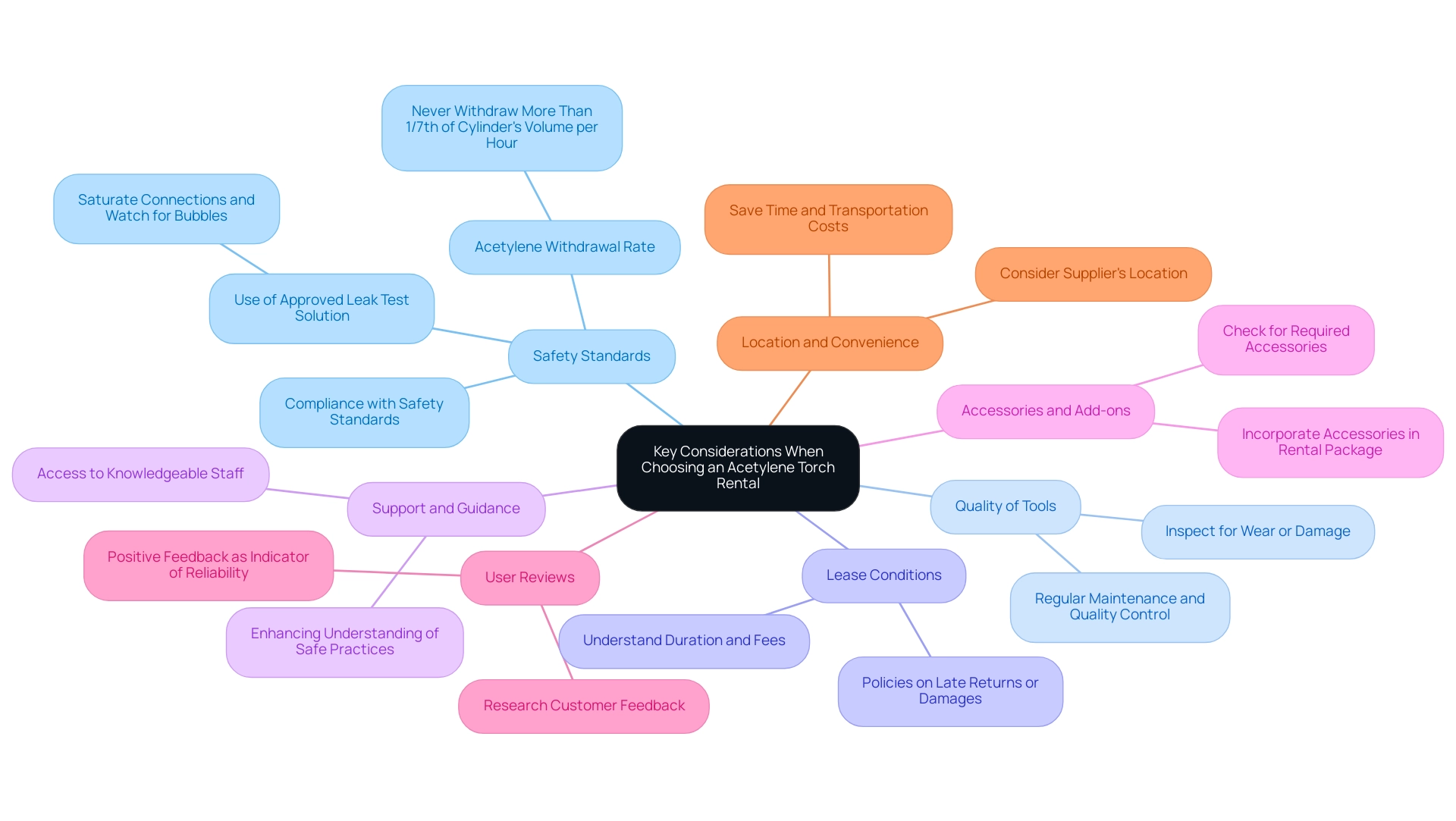

Key Considerations When Choosing an Acetylene Torch Rental

- Safety Standards: It is vital to ensure that the gas torch you select complies with all pertinent safety standards. Opt for equipment that has undergone thorough inspection and certification for safe use. As emphasized in recent training sessions on gas welding safety, comprehending the risks linked to welding, particularly when utilizing oxygen, is essential for avoiding accidents. Participants in these sessions learn the importance of safety precautions, proper storage, and handling of gas cylinders to prevent accidents. Always remember,

when using acetylene torch rental near me, the acetylene withdrawal rate is critical for safe use; never withdraw more than 1/7th of the cylinder’s volume per hour. Additionally, using an approved leak test solution to check for leaks by saturating connections and watching for bubbles is essential for ensuring safety when using acetylene torches. - Quality of Tools: Selecting a provider with a reputation for superior tools is crucial. Before concluding your lease, inspect the torch for any signs of wear or damage. Regular maintenance and quality control measures are critical for ensuring that the equipment functions safely and effectively.

- Lease Conditions: Familiarize yourself with the lease conditions, including the duration, associated fees, and policies regarding late returns or damages. Grasping these terms is essential to preventing unforeseen expenses and guaranteeing a seamless leasing experience.

- Support and Guidance: Choose a leasing company that provides comprehensive support and guidance, particularly if you lack experience with acetylene torch rental near me. Access to knowledgeable staff can significantly enhance your understanding of safe practices and equipment usage, ensuring a safer working environment.

- Accessories and Add-ons: Assess whether you require additional accessories, such as hoses or cutting tips, for your welding projects. Verify that the leasing company can supply these items or incorporate them in the package to prevent any last-minute issues.

- User Reviews: Conduct thorough research on customer feedback and testimonials regarding the leasing company. Positive feedback can be a strong indicator of reliability and service quality, giving you confidence in your choice of supplier.

- Location and Convenience: Finally, consider the location of the rental supplier. Selecting a conveniently located supplier can save significant time and transportation costs, particularly if you need to return the equipment frequently. This logistical consideration can enhance your overall project efficiency.

Understanding Safety Protocols for Acetylene Torch Use

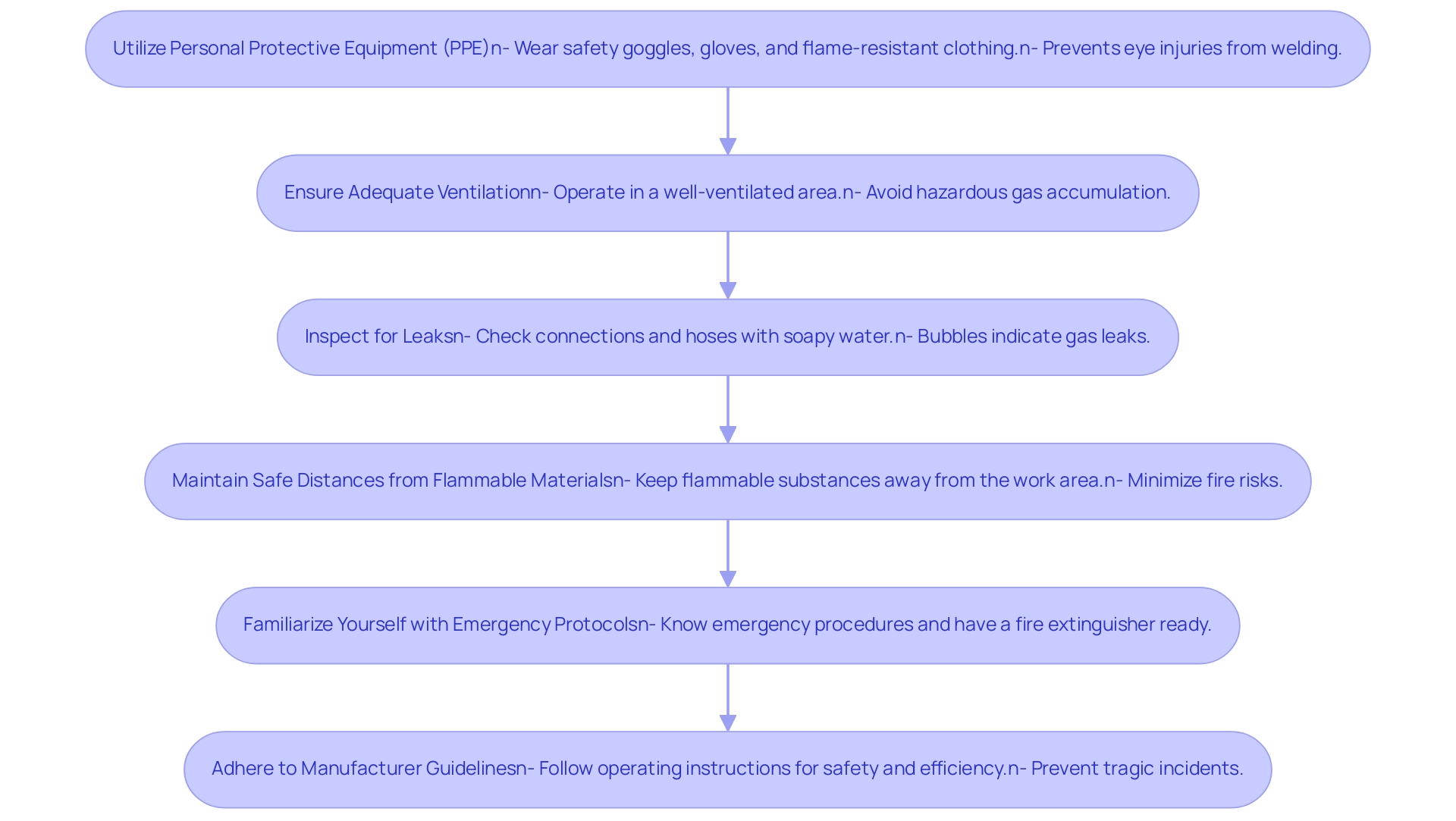

-

Utilize Personal Protective Equipment (PPE): It is critical to always wear the appropriate PPE, such as safety goggles, gloves, and flame-resistant clothing. Notably, burns to the eyes from welding account for nearly 6 percent of all construction-related eye injuries, highlighting the necessity of proper eye protection.

-

Ensure Adequate Ventilation: Operate the gas welding tool in a well-ventilated area to avoid the accumulation of hazardous gases that can pose serious health risks.

- Inspect for Leaks: Prior to use, meticulously check all connections and hoses for leaks. A soapy water solution is effective for this purpose; bubbles will form at any points of gas escape, alerting you to potential hazards.

-

Maintain Safe Distances from Flammable Materials: Keep flammable substances well away from your work area when using the heating device. This practice is essential to minimizing fire risks and ensuring a safer working environment.

-

Familiarize Yourself with Emergency Protocols: It's vital to know the emergency procedures relevant to your work. Always have a fire extinguisher on hand in the event of an emergency, ensuring you can respond quickly and effectively.

-

Adhere to Manufacturer Guidelines: Following the manufacturer's instructions for operating the gas torch is crucial for both safety and efficiency. As emphasized by Anil Aggrawal, who examines the conditions leading to cylinder explosions, proper adherence to guidelines can prevent tragic incidents and ensure safe operations. Furthermore, a review of literature on fatalities resulting from gas cylinder explosions reinforces the importance of these safety protocols. In light of recent studies examining nonstandard forms of employment and worker disability status, it is evident that implementing robust safety measures is essential in protecting workers across various employment situations.

Tips for Maintaining the Acetylene Torch During Rental

- Clean After Use: It is essential to clean the acetylene device and its associated components after each use. This helps to remove any debris or residue, which can affect performance. Using clean compressed air to blow out the device is a recommended practice to ensure optimal functionality.

- Store Properly: When the device is not in use, keep it in a secure, dry location. Proper storage not only safeguards the tools from physical harm but also prevents contamination from dust and debris. Ensure that the torch is positioned safely away from areas where it could be knocked over or exposed to moisture.

- Inspect Regularly: Throughout the leasing duration, periodically examine the tools for signs of wear or damage. If any issues are detected, report them to the rental supplier immediately to avoid further complications. Regular inspections can prevent accidents and prolong the lifespan of the equipment. For instance, Deeg expressed concern about the lack of flashback protection on their device, prompting a discussion on the importance of flashback arrestors, which can significantly enhance safety during operation.

- Handle with Care: Take extra care when managing the light source and its components. Avoid dropping or knocking the devices against hard surfaces, as this can lead to accidental damage. As Travis Ham, a senior product manager for gas tools, advises, always shut off the torch oxygen valve before closing the torch fuel valve to ensure safety during handling. Additionally, consider pushing the oxygen up to 30 psi for optimal performance, as recommended by industry experts.

- Follow Usage Guidelines: Adhere strictly to the operational guidelines provided by the acetylene torch rental near me. Following these instructions is crucial for using the equipment correctly and safely, especially if you are considering an acetylene torch rental near me, and it ensures compliance with best practices in the industry. Furthermore, be mindful of ongoing conversations in the community about cutting methods, like using a cutting device with an additional lever for oxygen adjustment, which may influence cutting efficiency.

By applying these best practices, you can preserve the integrity and performance of your rented gas cutting tools, such as those from acetylene torch rental near me, ensuring safe and effective operation throughout your construction projects.

Returning the Acetylene Torch: Best Practices

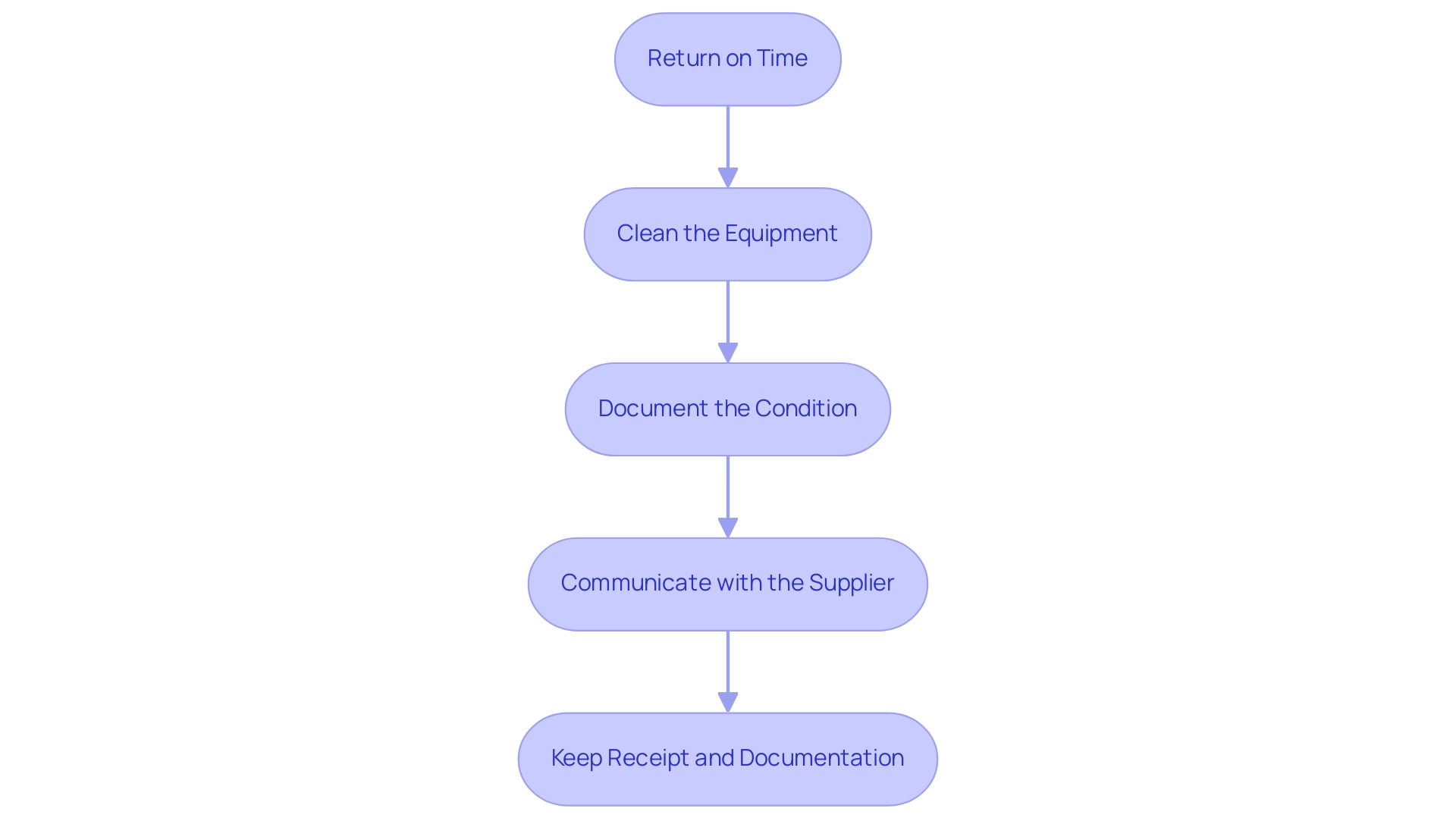

- Return on Time: Adhering to the agreed-upon return date for your acetylene torch rental near me is essential. Late returns can incur significant fees, which can impact your project's budget. It's advisable to review the lease agreement for specific terms regarding late fees when you are looking for an acetylene torch rental near me. As Denym Bird, CEO of Paidnice, notes, managing accounts receivable effectively can help avoid such late fees, ensuring a smoother rental experience.

- Clean the Equipment: Before returning the light and its accessories, ensure they are thoroughly cleaned. Rental companies often impose additional cleaning charges if equipment is returned in less-than-ideal condition, which can add unexpected costs to your project.

- Document the Condition: To safeguard against any disputes over damage claims, document the condition of the torch and accessories by taking clear photographs at the time of return. This practice can provide you with the necessary evidence should any issues arise.

- Communicate with the Supplier: Effective communication with your leasing supplier is crucial. Inform them of your return and ensure that they inspect the equipment upon its arrival. This proactive method enables prompt resolution of any concerns and fosters a relationship with the leasing company, as highlighted in the case study 'Feedback and Future Rentals.' Such connections can result in enhanced service and possibly more favorable conditions for future leases.

- Keep Receipt and Documentation: Retaining all related receipts and documentation of the lease is important for your records. This information can be invaluable in resolving discrepancies or misunderstandings about the rental terms, especially in light of Ahearn Equipment’s 40 years of experience in the industry, which underscores the importance of clarity and communication in rental agreements.

Conclusion

Navigating the process of renting an acetylene torch can be simplified by following a structured approach. Identifying specific project needs, researching local suppliers, and comparing rental options are essential first steps. Ensuring safety through proper equipment selection and understanding rental terms will help avoid unexpected costs and complications. It is crucial to engage with rental companies that provide quality equipment and support, as this can greatly enhance the overall experience and ensure safety during operation.

Understanding and adhering to safety protocols is paramount when using an acetylene torch. Utilizing personal protective equipment, ensuring proper ventilation, and regularly inspecting for leaks are vital practices to minimize risks. Additionally, maintaining the torch during the rental period by cleaning, storing correctly, and inspecting regularly ensures optimal performance and safety.

Finally, returning the equipment in good condition and on time is essential to avoid additional fees and maintain a positive relationship with rental suppliers. Documenting the condition of the equipment upon return and retaining all related paperwork can protect against potential disputes. By following these guidelines, individuals can confidently rent and utilize acetylene torches, ensuring both project success and safety.

Frequently Asked Questions

What should I do first when considering gas welding tool rental?

Begin by assessing the specific requirements of your project, including factors such as size, capacity, and any additional accessories that may enhance functionality.

How can I find local suppliers for acetylene torch rental?

Utilize online platforms and local directories to identify tool leasing companies in your area. Pay attention to customer reviews and ratings to assess the reliability and reputation of potential suppliers.

What factors should I compare when evaluating leasing options?

Reach out to several suppliers to evaluate their leasing rates, equipment availability, and leasing terms. Consider the duration of the lease, which may vary from daily to weekly or monthly agreements, to find the best fit for your project schedule and budget.

How can I ensure the availability of the acetylene torch I want to rent?

Verify the availability of the acetylene torch by checking with suppliers and consider making an advance reservation, especially during peak seasons when demand is high.

What should I look for in the lease agreement before renting?

Carefully read through the lease agreement, focusing on key points such as lease duration, associated fees, and any potential charges for damages or late returns.

What should I inspect when picking up the rented equipment?

Conduct a thorough examination of the gas cutting tool for signs of wear or damage, and ensure that all necessary components, such as hoses and regulators, are present and in good condition.

Why is it important to receive safety instructions from the supplier?

Acquiring necessary safety guidelines and operational advice is critical to mitigate risks and prevent accidents while using the gas cutting tool.

What should I do when returning the rented equipment?

Return the gas welding tool in accordance with the agreed terms, ensuring that it is clean and in the same condition as when rented to avoid additional charges.

What safety standards should I consider when selecting a gas torch?

Ensure that the gas torch complies with all pertinent safety standards and has undergone thorough inspection and certification for safe use.

How can I assess the quality of the tools offered by a supplier?

Before concluding your lease, inspect the torch for any signs of wear or damage and choose a provider with a reputation for superior tools.

What lease conditions should I familiarize myself with?

Understand the lease duration, associated fees, and policies regarding late returns or damages to prevent unforeseen expenses and ensure a seamless leasing experience.

Why is support and guidance important when renting an acetylene torch?

Access to knowledgeable staff can significantly enhance your understanding of safe practices and equipment usage, ensuring a safer working environment.

Should I consider additional accessories when renting a gas welding tool?

Yes, assess whether you require additional accessories, such as hoses or cutting tips, and verify that the leasing company can supply these items to avoid last-minute issues.

How can user reviews influence my choice of a leasing company?

Conduct thorough research on customer feedback and testimonials regarding the leasing company, as positive feedback can indicate reliability and service quality.

What logistical considerations should I keep in mind when selecting a rental supplier?

Consider the location of the rental supplier, as choosing a conveniently located supplier can save time and transportation costs, enhancing overall project efficiency.