Overview

Renting an aluminum welder effectively requires careful consideration of project specifications, rental duration, and equipment suitability to ensure optimal performance and cost-effectiveness. The article outlines essential steps and common pitfalls in the rental process, emphasizing the importance of thorough research, understanding lease terms, and inspecting equipment to avoid unexpected costs and ensure a successful welding experience.

Introduction

Renting an aluminum welder can be a daunting task, especially with the myriad of options available and the specific requirements of each project. Whether it's for a one-time job or a longer-term endeavor, understanding the nuances of equipment rental is crucial for achieving optimal results. Key considerations such as:

- Project specifications

- Welder types

- Rental agreements

can significantly impact both performance and budget. By navigating these factors thoughtfully, individuals can avoid common pitfalls that lead to unnecessary expenses and project delays. This article delves into essential insights and practical steps to ensure a smooth rental experience, empowering welders to make informed decisions that align with their unique needs.

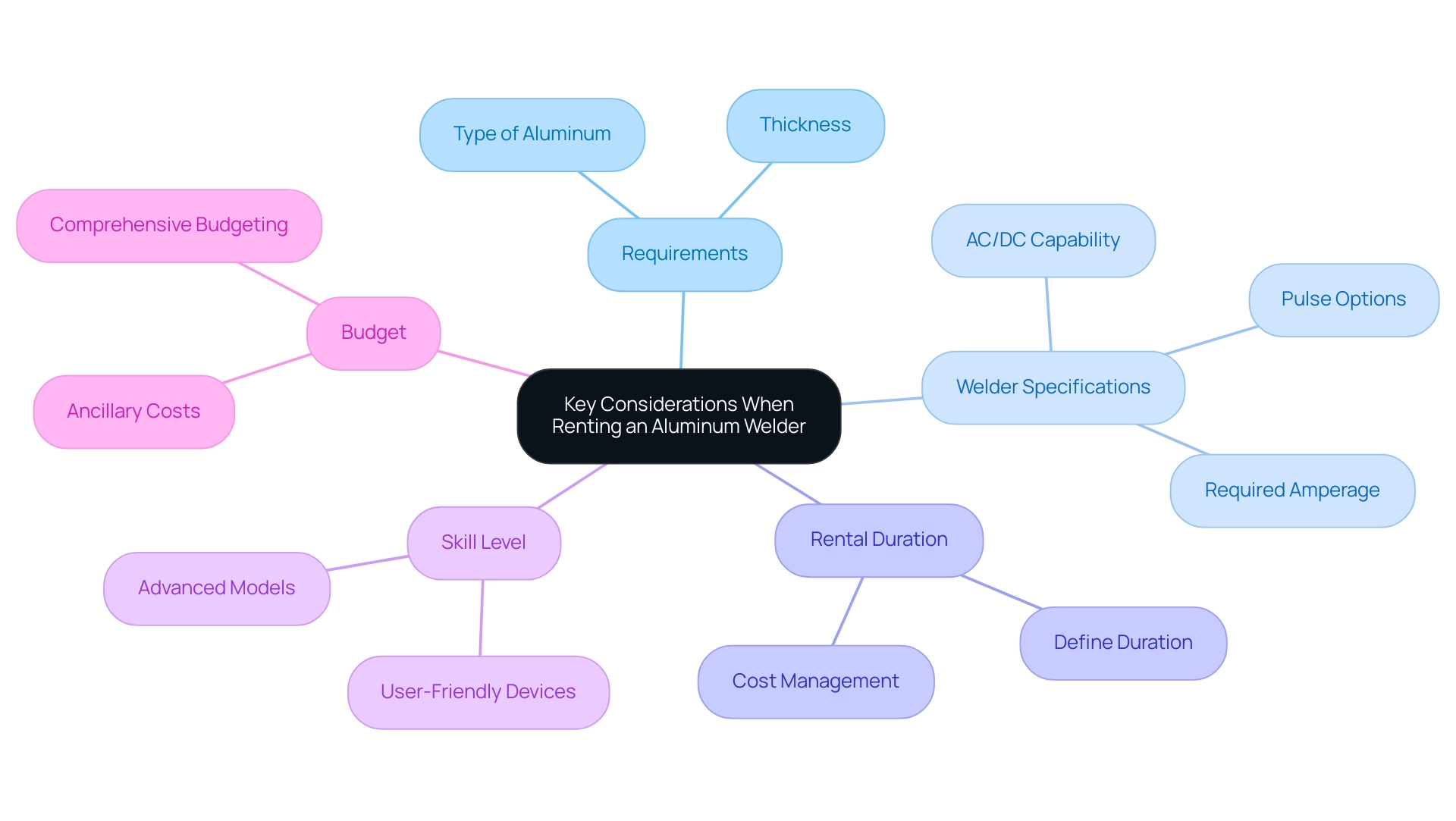

Key Considerations When Renting an Aluminum Welder

When considering aluminum welder rental, several key factors should be evaluated to ensure optimal performance and cost-effectiveness.

- Requirements: Understand the specific demands of your endeavor, including the type and thickness of aluminum to be welded. Different applications may require distinct joining techniques, impacting the choice of equipment.

- Welder Specifications: Choose welders that fulfill your project’s specifications, especially concerning required amperage and characteristics such as AC/DC capability and pulse options. These technical aspects are crucial for achieving quality welds on aluminum.

-

Rental Duration: Clearly define the rental duration to avoid incurring excess costs associated with prolonged rentals.

Precise planning will help optimize your budget and resources.

-

Skill Level: Assess your welding proficiency. If you are less experienced, you might prefer a user-friendly device, while advanced users may benefit from more sophisticated models that offer greater versatility.

- Budget: Establish a comprehensive budget for the lease, including any ancillary costs such as accessories or protective gear. This financial foresight is essential for managing expenses effectively.

In 2024, the market for aluminum welder rental is projected to grow significantly, driven by increasing consumer demand and technological advancements. This growth trend underscores the importance of making informed decisions when renting equipment. As mentioned in a recent case study, aligning objectives and fostering open communication is essential; as one expert stated, 'Make decisions that satisfy both the board and executives by fostering open communication, aligning goals, and using a decision-making framework.'

By thoroughly evaluating these considerations, you can make a more informed decision that aligns with the unique requirements of your aluminum fabrication project, including the option of aluminum welder rental, ensuring both efficiency and cost-effectiveness.

Step-by-Step Process for Renting an Aluminum Welder

To successfully rent an aluminum welder, follow these essential steps:

- Research Equipment Providers: Start by identifying reputable equipment leasing companies in your vicinity that specialize in welding tools. Focus on those with a strong track record and customer reviews that highlight their reliability and service quality. Significantly, four of the top five companies on the IRN100 are US-based firms, boasting an average growth rate of 14%, indicating a healthy leasing market.

- Compare Options: Review the variety of aluminum welder rental machines that are available. Pay close attention to specifications, including power output and features, as well as pricing to ensure you choose the best fit for your requirements.

- Check Availability: Reach out to your chosen rental companies to confirm the availability of the specific equipment you need for your intended rental period. This proactive step can save you time and potential delays in your project schedule.

- Ask Questions: Don’t hesitate to inquire about the welder’s condition, its maintenance history, and whether any additional equipment or accessories are required for operation. As Ollie Hodges, Publisher, observes, "Under the Sammons umbrella are Briggs Industrial Solutions, providing equipment, leasing, service, and design products to clients with 21 locations in six states through four distinct business units." Understanding these details can prevent unforeseen issues during use.

- Finalize the Rental: Once you’ve made your choice, complete the rental agreement. Be prepared to provide necessary documentation, such as identification and payment information, to facilitate a smooth transaction.

- Inspect the Equipment: Before taking possession of the equipment, conduct a thorough inspection for any damages or operational issues. Documenting the individual's condition can protect you from liability for pre-existing damages.

- Read Instructions: Familiarize yourself with the operation manual of the welder to ensure you are well-versed in its use. Understanding the specific operational guidelines is crucial for safe and effective welding.

By following these steps, you can simplify the leasing process and significantly minimize the risk of facing common pitfalls associated with equipment leasing. Additionally, technology, such as the RapidCount inventory management solution launched by Wynne Systems, is enhancing inventory efficiency in rental companies, further improving the overall rental experience for project managers.

Exploring Different Types of Aluminum Welders for Rent

When choosing an aluminum specialist for rent, it’s essential to understand the different types available and their specific applications:

- MIG Welders: Often recommended for beginners, MIG welders stand out for their user-friendly operation. They utilize a continuous wire feed, making them highly efficient for larger projects and suitable for various aluminum thicknesses. As emphasized by industry experts,

Get your chops up, and all your welds will look clean regardless of whether you use [the MIG, TIG](https://protoolreviews.com/comparing-mig-tig-stick-welding), or Stick process. This versatility, combined with a maximum joint strength of 89 MPa, makes MIG a frequent choice in construction settings. - TIG Welders: For precision work, TIG welders are unparalleled. Although they require a higher skill level, they produce exceptionally high-quality welds, making them ideal for thin materials and intricate designs. This method is particularly advantageous when working with aluminum, as it allows for greater control over the joining process, ensuring superior joint integrity. Notably, insights from Habba et al. highlight the economic benefits and joint evaluation of TIG welding, reinforcing its position as a reliable choice for high-quality applications.

- Stick Welders: While not the most common choice for aluminum, stick welders can still be utilized effectively with specific electrodes designed for this material. Their portability makes them suitable for outdoor tasks, although they may require more practice and technique to achieve optimal results. It's worth mentioning that the typical hardness value for FSW joints in the stir zone is approximately 10% lower compared to the base metal, which can affect the selection of joining technique based on requirements.

- Multi-Process Welders: These versatile machines can perform multiple joining processes, including MIG, TIG, and stick methods. They are an excellent choice for construction endeavors where diverse joining tasks are needed, permitting adaptability without requiring several machines.

By thoughtfully evaluating an aluminum welder rental that best fits your needs, you can enhance both the quality of your joints and the efficiency of your work, ultimately resulting in better outcomes in your construction endeavors.

Understanding Rental Agreements and Terms

When reviewing rental agreements for welding equipment, it is crucial to pay attention to several key terms that can impact your project’s success:

- Lease Duration: Clearly define the start and end dates of the lease period, along with any grace periods for late returns. Utilizing an aluminum welder rental will help you manage project timelines effectively.

- Pricing Structure: Understand the full scope of costs for aluminum welder rental, which may include daily, weekly, or monthly rates, as well as additional fees for damages or late returns. This clarity can assist in budgeting and financial planning for an aluminum welder rental.

- Liability: Be aware of your responsibilities regarding the condition of the aluminum welder rental throughout the leasing period. This includes regular maintenance and repair obligations, which are essential to ensure the aluminum welder rental equipment remains in top condition. For instance, if renting an aluminum welder rental, specifically a Welder Rack, 280 Amp, it’s important to keep it in good working order to avoid additional charges.

- Insurance Options: Investigate whether the company provides insurance for the aluminum welder rental equipment and if additional coverage is required. Insurance can mitigate financial risks associated with potential damages.

- Return Policy: Familiarize yourself with the return process, including any specific requirements for cleaning or refueling the equipment before its return. Understanding this can prevent unexpected charges and ensure a smooth return experience.

Additionally, it’s worth noting the statistic regarding the Cold Jet Aero C100 Dry Ice Cleaning System, which has a hopper dry ice capacity of 100 lb (45.5 kg) and a feed rate of 0-7 lb/min (0-3.2 kg/min). This information can be valuable when considering the capabilities of the equipment you wish to rent.

As the quote from a construction expert aptly indicates, "The choice to rent, buy or own fabrication equipment seems like it can be a hard decision." I loved that rule of thumb to buy if you’re using the equipment 60% of the time or more. By understanding these essential leasing terms, including the aluminum welder rental, you can navigate the process with confidence and avoid unforeseen complications that could affect your project's progress.

Common Pitfalls to Avoid When Renting an Aluminum Welder

To ensure a successful rental experience with welding equipment, it's essential to be aware of these common pitfalls:

- Neglecting Research: Many contractors overlook the significance of investigating leasing firms, which can lead to inferior service or unforeseen hidden charges. A thorough assessment can save both time and money. Statistics indicate that rental firms with superior service quality ratings frequently result in improved outcomes.

- Ignoring Specifications: Each assignment comes with its own requirements. Renting a tool that doesn’t align with project specifications can lead to inadequate performance and wasted resources, impacting overall project timelines.

- Overlooking Lease Terms: It's vital to fully understand lease agreements. Ignoring the details can lead to unforeseen costs or liabilities that could have been avoided with careful scrutiny.

- Skipping Inspection: Always inspect the welder before completing the agreement. Failing to do so may result in being held accountable for pre-existing damages, which could incur unnecessary costs. For instance, a case study titled "Failing to Maintain the Tool" highlights how neglecting tool upkeep can lead to additional charges and project delays.

- Rushing the Process: In the fast-paced construction environment, it’s tempting to rush the rental process. However, taking shortcuts can lead to significant mistakes. Always take the time to read agreements thoroughly and ask any questions needed for clarity.

Additionally, ensure access to a reliable power source, as this is crucial when renting fabrication machines. Depending on material thickness, you may require 220V or 120V power options. Contractors with limited or no electricity access should consider an aluminum welder rental along with a generator.

By being aware of these pitfalls and taking the necessary precautions, you can improve your rental experience and achieve optimal outcomes in your welding tasks. As noted by experts,

Ignoring these instructions can lead to accidents and injuries.

Prioritizing these steps not only promotes safety but also contributes to the success of your projects.

Conclusion

Navigating the rental process for an aluminum welder can seem challenging, but with a clear understanding of the essential considerations, individuals can make informed choices that optimize both performance and budget. Key factors such as project requirements, welder specifications, and the rental duration play a vital role in ensuring the right equipment is selected for the task at hand. Additionally, assessing one’s skill level and establishing a comprehensive budget are crucial steps that can prevent unnecessary costs.

Following a structured approach when renting an aluminum welder can streamline the experience significantly. Researching rental companies, comparing options, and thoroughly inspecting the equipment before use are all necessary steps that reduce the likelihood of encountering common pitfalls. Understanding the specifics of rental agreements, including pricing structures and liability terms, further empowers individuals to manage their projects effectively.

Ultimately, by taking the time to evaluate these aspects and avoid common mistakes, welders can enhance the quality of their work and achieve successful project outcomes. The growth of the aluminum welder rental market emphasizes the importance of making educated decisions that align with project goals. With the right preparation and knowledge, a rewarding rental experience is within reach, paving the way for high-quality results in aluminum welding endeavors.

Frequently Asked Questions

What key factors should be evaluated when considering aluminum welder rental?

Key factors include understanding specific project requirements, welder specifications (amperage, AC/DC capability, pulse options), rental duration, skill level, and budget.

Why is it important to understand the specific demands of a project before renting a welder?

Different applications may require distinct joining techniques and equipment, which impacts the choice of welder needed for the job.

What specifications should be considered when selecting a welder for aluminum welding?

Important specifications include the required amperage, AC/DC capability, and whether the welder has pulse options, as these affect the quality of the welds.

How can rental duration affect the overall cost of renting a welder?

Clearly defining the rental duration helps avoid excess costs associated with prolonged rentals, allowing for better budget optimization.

How does skill level influence the choice of welder for rental?

Less experienced users may prefer user-friendly devices, while advanced users might benefit from sophisticated models that offer greater versatility.

What budgeting considerations should be made when renting an aluminum welder?

Establish a comprehensive budget that includes the rental cost and any ancillary expenses such as accessories or protective gear.

What steps should be followed to successfully rent an aluminum welder?

Steps include researching equipment providers, comparing options, checking availability, asking questions about the welder, finalizing the rental, inspecting the equipment, and reading the operation manual.

How can one ensure they are choosing a reputable equipment provider for rental?

Research companies with a strong track record and positive customer reviews, focusing on those that specialize in welding tools.

What should be done before taking possession of the rented welder?

Conduct a thorough inspection for any damages or operational issues and document the condition to avoid liability for pre-existing damages.

Why is it important to read the operation manual of the welder?

Familiarizing yourself with the operation manual ensures safe and effective usage of the welder, which is crucial for successful welding.