Introduction

Embarking on a drywall project can seem daunting, especially for those tackling it for the first time. However, with the right tools and a clear plan, achieving a professional finish is entirely within reach. This guide delves into the essential tools needed for a successful installation, provides a step-by-step approach to renting equipment, and outlines the preparation and installation processes. By understanding each phase—from selecting the right tools to applying the finishing touches—any DIY enthusiast can navigate the complexities of drywall installation with confidence and skill.

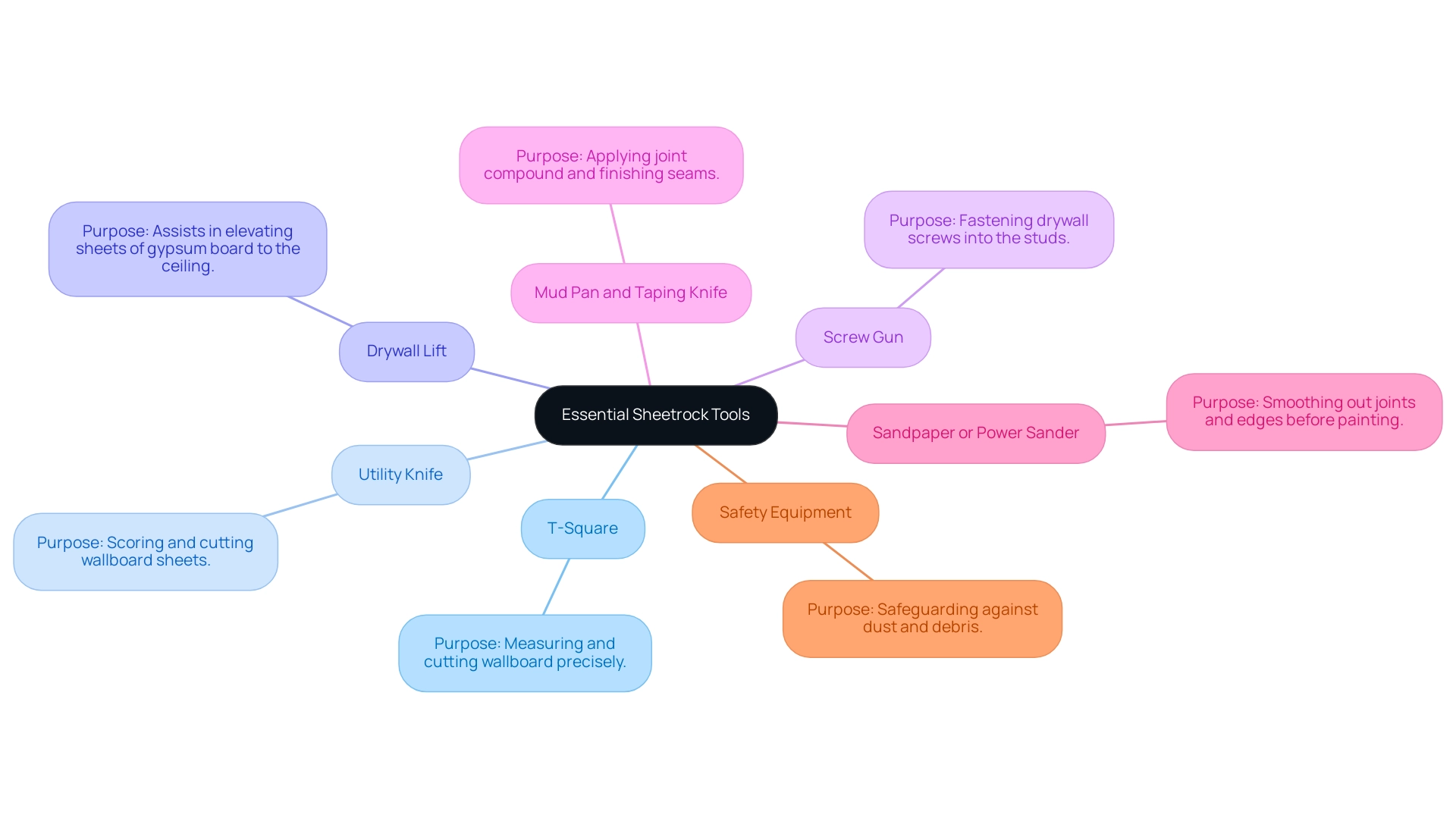

Essential Sheetrock Tools for Your DIY Project

Before starting your wallboard project, get to know the necessary equipment you will require. The following list includes key tools commonly used for sheetrock installation:

- T-Square: An essential tool for measuring and cutting wallboard precisely.

- Utility Knife: Essential for scoring and cutting wallboard sheets.

- Drywall Lift: A device that assists in elevating sheets of gypsum board to the ceiling, facilitating a simpler and safer installation process.

- Screw Gun: Used for fastening drywall screws into the studs.

- Mud Pan and Taping Knife: Necessary for applying joint compound and finishing seams.

- Sandpaper or Power Sander: For smoothing out joints and edges before painting.

- Safety Equipment: Comprising goggles and masks, to safeguard against dust and debris.

By confirming you possess these items, you will prepare yourself for a smoother and more efficient DIY endeavor.

Step-by-Step Guide to Renting Sheetrock Tools

Renting the right sheetrock equipment can be a seamless process if you adhere to the following steps:

- Identify Your Needs: Begin by evaluating the specific resources necessary for your drywall project. Comprehending the fundamental resources needed will direct your decisions efficiently.

- Research Rental Companies: Seek out local equipment rental companies or home improvement stores that offer sheetrock tool rental services. A thorough examination of their online reviews will guide you in selecting a reputable provider.

- Compare Prices: Engage with multiple rental companies to evaluate their pricing and rental terms. Inquire about any additional fees, such as deposits or delivery charges, to ensure complete transparency in your budgeting.

- Check Equipment Availability: Confirm that the resources you require are accessible during your desired rental period. Given seasonal demand, reserving equipment in advance can prevent last-minute challenges.

- Inspect Equipment Before Renting: Upon arrival to pick up your equipment, conduct a thorough inspection for any signs of damage or wear. Ensuring that the equipment is in optimal condition will help you avoid complications during your project.

- Understand Rental Terms: Carefully read the rental agreement before finalizing your transaction. Pay close attention to rental duration, late fees, and return policies to avoid unexpected charges.

- Utilize Estimating Apps: Consider using customized estimating apps created by service professionals with Homewyse Lists. These instruments can help you in planning your budget, making sure that you consider all essential costs, including equipment rentals and debris disposal.

- Return Equipment Promptly: After finishing your assignment, return the equipment on time to avoid any extra charges. Cleaning the tools before returning them will assist in preserving a good relationship with the rental company.

By adhering to these steps, you can promote a seamless experience in sheetrock tool rental, ensuring that you have the appropriate tools available for your task. Additionally, it's important to keep in mind that wallboard debris disposal can incur costs ranging from $268 to $305, emphasizing the need for careful budgeting and planning. Utilizing resources like Homewyse's free hiring guide can provide valuable insights into hiring local professionals wisely and understanding fair pricing for your tasks.

The guide also highlights the importance of selecting quality craftsmanship, which aligns with the experiences shared in the case study on hiring local professionals.

Preparing for Your Sheetrock Installation

Effective preparation is essential for achieving a successful installation, especially for construction project managers tasked with meeting project scope and deliverables. Here are the actions to ensure your workspace is ready:

- Clear the Area: Begin by removing all furniture and obstacles from the installation site. This creates a clean and safe workspace, minimizing distractions and hazards.

- Check Wall Studs: Utilize a stud finder to accurately locate and mark the positions of wall studs. This phase is essential for securing the wallboard correctly, ensuring structural integrity.

- Measure and Cut Wall Panels: Carefully measure the wall dimensions and use a utility knife along with a T-square to cut the wall sheets to the required size. Don’t forget to factor in electrical outlets and light switches to avoid any complications during installation.

- Gather Materials: Before starting, confirm you have all necessary materials at hand, including screws, joint compound, tape, and sandpaper. Having everything ready will streamline the installation process.

- Safety Precautions: Prioritize safety by wearing protective gear such as goggles and a dust mask. This will protect you from dust and debris during the installation.

These preparation actions are not just about getting ready; they play a vital role in the overall success of your drywall task, especially with the right sheetrock tool rental. According to Hadco Safety Solutions, documenting issues through photos during preparations can provide clarity for future reference, enhancing tracking. Furthermore, with over 97% of structures in the U.S. requiring gypsum board, it is essential for any construction manager to understand and effectively execute these preparation steps, which may include sheetrock tool rental.

This aligns with the insights from the recent article '8 Best Practices for Tracking Deliverables in Construction', which emphasizes the manager's critical role in completing construction activities to meet scope. By recognizing the competitive dynamics surrounding gypsum board and incorporating these preparation measures, project managers can ensure their projects are well-positioned for success.

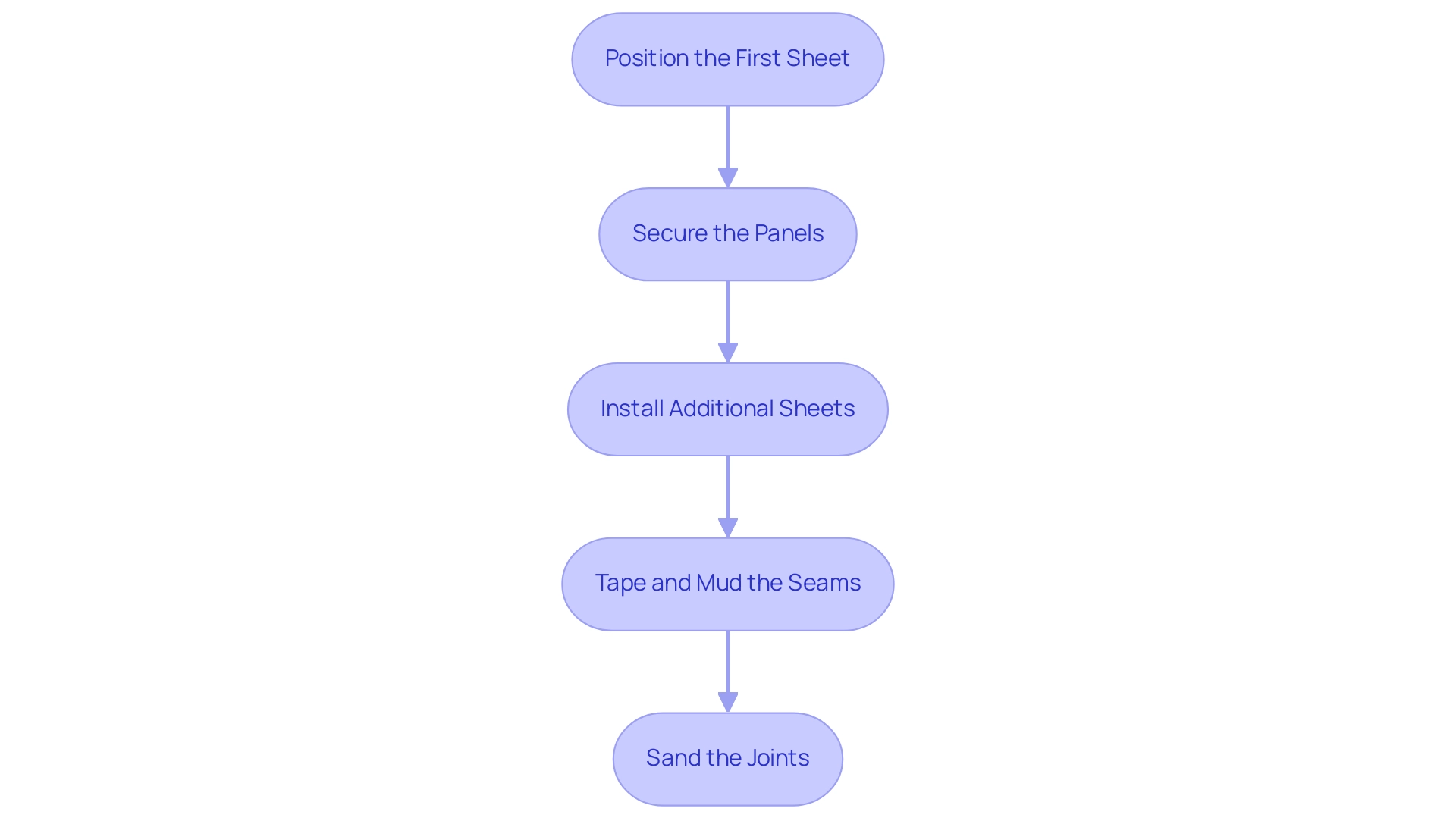

Installing Sheetrock: A Step-by-Step Process

To achieve a professional-looking wallboard installation, follow this comprehensive step-by-step guide:

- Position the First Sheet: Begin at a corner of the wall, lifting the first panel into position. Ensure it aligns perfectly with both the top and side edges for a clean start when utilizing the sheetrock tool rental.

- Secure the Panels: Utilize a screw gun to fasten the panels to the wall studs. It's recommended to place screws approximately every 16 inches along the edges and every 24 inches within the field of the sheet when using a sheetrock tool rental. This spacing helps prevent sagging and ensures a sturdy installation.

- Install Additional Sheets: Proceed to install extra panels, staggering the edges between rows. This technique not only enhances structural integrity but also minimizes the risk of cracks. Be prepared to use a sheetrock tool rental to cut sheets to fit around electrical outlets and corners as needed.

- Tape and Mud the Seams: After all sheets are secured, apply joint tape over the seams. Utilize a taping knife to apply joint compound over the tape, feathering the edges for a smooth transition between sheet materials.

- Sand the Joints: Once the joint compound has fully dried, lightly sand the seams to create a smooth surface, making it ready for painting.

A crew of two drywallers typically requires about three days to install, mud, and sand walls and ceilings in a 1000 sq ft house. This timeline can serve as a benchmark for planning your endeavor. As noted by real estate agent Cameo Bennett,

The quality of drywall installation can significantly impact the overall appeal of a property.

This emphasizes the significance of maintaining high standards in your work.

Furthermore, managers can benefit from resources like BiggerPockets, which provides networking opportunities and access to real estate professionals. Furthermore, having instant access to live construction costs can aid in better estimating budgets and managing project expenses. By following these guidelines and steering clear of typical mistakes, you can guarantee a successful wallboard installation that meets professional standards with the right sheetrock tool rental.

Finishing Touches: Painting and Decorating Your Drywall

After your wall panels have been installed, it’s crucial to adhere to these finishing procedures for optimal preparation prior to painting:

-

Clean the Surface: Begin by thoroughly wiping down the wallboard to eliminate any dust or debris left from the sanding process. This crucial step ensures that the surface is ready for further treatments.

-

Prime the Walls: Apply a quality primer to the wallboard. This not only promotes even paint coverage but also enhances adhesion, resulting in a more durable finish. A well-primed surface can significantly improve the longevity of your paint job.

-

Choose Your Paint: Selecting the right paint is vital. Opt for high-quality, eco-friendly options made from natural, renewable materials that offer a diverse palette. As David Kranker of VanDerKolk Painting emphasizes,

Just know that VanDerKolk Painting always uses premium paint for our customer’s projects!

This commitment to quality is essential for achieving a professional look. Additionally, with the Drywall Texture Paint market anticipated to grow consistently from 2024 to 2031, investing in quality materials is more relevant than ever.

-

Paint the Walls: For larger areas, utilize a roller for efficiency, while a brush is best for corners and edges. It’s advisable to apply at least two coats of paint to ensure a vibrant and uniform finish. Remember, only exterior paint should be used on garage doors, with oil-based and acrylic latex paints being the best options for durability in those applications.

-

Decorate: After the paint has dried, enhance your space with decorative elements such as wall art, shelves, or other features to add character and style. Moreover, advancements in smart paint technology, including mobile apps for color visualization and self-cleaning paints, can aid in making informed decisions and maintaining the appearance of your painted surfaces.

By diligently completing these finishing steps, you will effectively transform your newly installed drywall into a beautifully finished wall, ready to impress.

Conclusion

Achieving a professional drywall installation is a multifaceted process that begins with gathering the right tools. Understanding the essential equipment—such as a drywall T-square, utility knife, and screw gun—sets the foundation for a smoother project. Additionally, renting the necessary tools can be efficiently managed by:

- Identifying needs

- Researching rental options

- Thoroughly inspecting tools before use

Preparation plays a critical role in the overall success of drywall installation. Clearing the workspace, checking wall studs, and ensuring all materials are at hand can prevent delays and complications. The step-by-step installation process, from positioning the first sheet to applying joint compound, requires attention to detail and adherence to best practices, which ultimately enhances the structural integrity and aesthetic appeal of the finished product.

Finishing touches, including cleaning the surface, priming, and selecting high-quality paint, are essential for achieving a polished look. By following these guidelines, any DIY enthusiast can navigate the complexities of drywall installation with confidence. Taking the time to prepare and execute each phase effectively not only results in a beautiful finish but also fosters a sense of accomplishment and skill development in the realm of home improvement.

Frequently Asked Questions

What tools are necessary for a wallboard project?

Essential tools for sheetrock installation include a T-square, utility knife, drywall lift, screw gun, mud pan and taping knife, sandpaper or power sander, and safety equipment such as goggles and masks.

How can I rent the right sheetrock equipment?

To rent sheetrock equipment, identify your needs, research local rental companies, compare prices, check equipment availability, inspect equipment before renting, understand rental terms, utilize estimating apps, and return equipment promptly after use.

What preparation steps should I take before installing wallboard?

Preparation steps include clearing the area, checking wall studs with a stud finder, measuring and cutting wall panels, gathering necessary materials, and prioritizing safety by wearing protective gear.

What is the process for a professional-looking wallboard installation?

The installation process involves positioning the first sheet, securing the panels with a screw gun, installing additional sheets while staggering edges, taping and mudding the seams, and sanding the joints for a smooth surface.

What finishing procedures should I follow after installing wall panels?

After installation, clean the surface, prime the walls, choose quality paint, apply at least two coats of paint, and decorate the space to enhance its appearance.