Key Highlights:

- A 2-man auger is crucial for digging holes in construction and landscaping, requiring knowledge of its components like the engine and drill bit.

- Safety protocols include following manufacturer's instructions, wearing PPE, and ensuring a clear work area to prevent accidents.

- In 2023, six entanglement incidents involving augers were reported, highlighting the importance of strict adherence to safety measures.

- Essential safety tips include pre-operation checks, maintaining a safe distance from bystanders, and emergency procedures for addressing malfunctions.

- Operators should plan digging layouts and coordinate movements for efficient operation, emphasising the need for effective communication.

- Using the right drill bit, maintaining steady pressure, and regular maintenance enhance drilling efficiency.

- Effective teamwork involves establishing clear roles, using hand signals for communication, and conducting practise drills to improve coordination.

- Debriefing after operations helps teams evaluate successes and identify areas for improvement, fostering continuous enhancement of safety and efficiency.

Introduction

Mastering the use of a 2-man auger goes beyond merely digging holes; it is an essential skill that can greatly impact the success of construction and landscaping projects. Operators must understand the critical balance between safety and efficiency, as neglecting either aspect can result in costly accidents or project delays. To ensure safe operation of this powerful tool while maximizing productivity, teams can implement several effective strategies. By focusing on these key areas, operators can enhance their skills and contribute to the overall success of their projects.

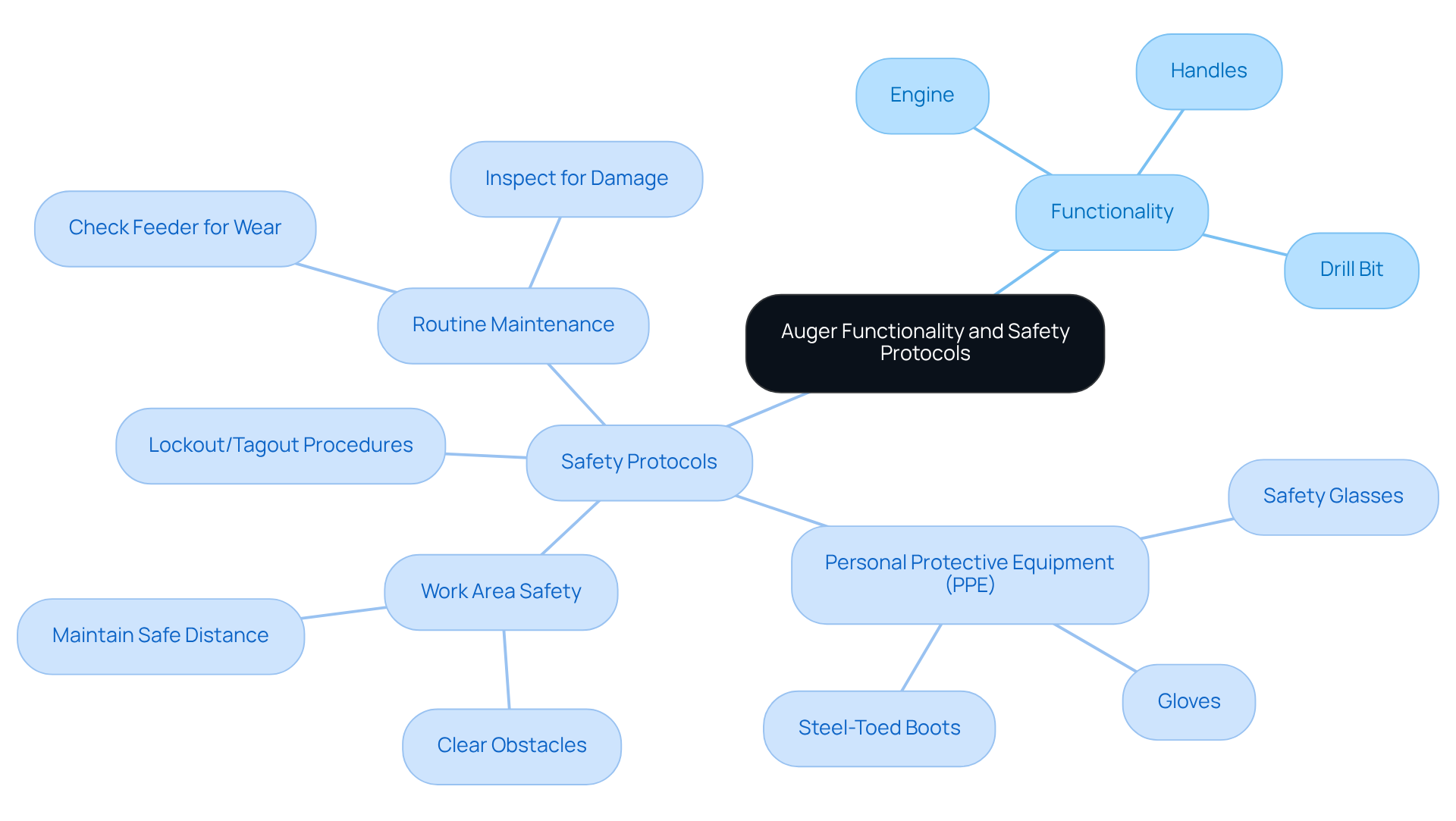

Understand Auger Functionality and Safety Protocols

A 2 man auger is an essential tool for efficiently digging holes and is commonly utilized in construction and landscaping projects. To fully understand its functionality, one must be familiar with how the 2 man auger operates, including its key components such as the engine, drill bit, and handles. Adhering to protection procedures is crucial; individuals should familiarize themselves with the manufacturer's instructions and precautionary measures. Key safety protocols include wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots.

Moreover, operators must ensure that the work area is clear of obstacles and that all bystanders maintain a safe distance during operation. Routine maintenance inspections, including checking the feeder for wear and damage, are vital to prevent malfunctions and ensure safe operation. Notably, in 2023, six incidents related to entanglement involving augers were reported, underscoring the importance of compliance with safety measures. Additionally, operators should recognize the significance of lockout/tagout procedures to avert accidents during maintenance and operation.

By prioritizing safety and operational efficiency, project managers can significantly mitigate the risk of incidents and enhance productivity on the job site. For further training on risk management protocols, the 2026 OSHA Outreach 10 Hour Virtual Training Course serves as a valuable resource.

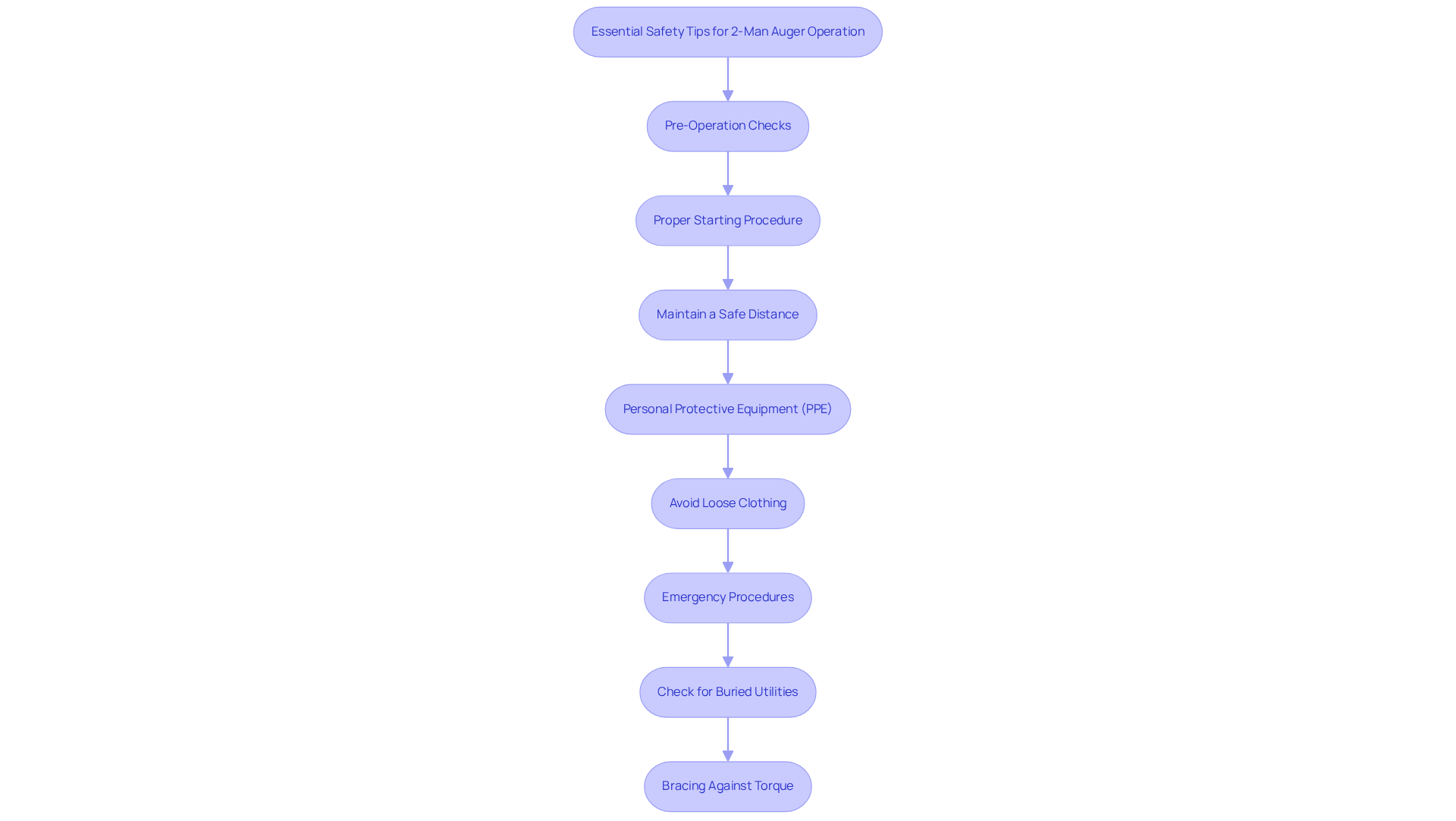

Implement Essential Safety Tips for 2-Man Auger Operation

To ensure the safe operation of a 2-man auger, operators should adhere to essential safety tips that promote a secure working environment:

- Pre-Operation Checks: Conduct a thorough inspection of the drilling tool for any signs of damage or loose components. Confirm that all safety guards are securely in place to prevent accidents.

- During the proper starting procedure for the 2-man auger, one operator must stabilize the drill while the other starts the engine, strictly following the manufacturer's instructions to ensure safe ignition.

- Maintain a Safe Distance: Keep bystanders at least 10 feet away from the drilling equipment during use to reduce the risk of injuries from flying debris or unintended contact.

- Personal Protective Equipment (PPE): Always wear suitable PPE, including gloves, safety glasses, and hearing protection, to safeguard against potential risks associated with drill usage.

- Avoid Loose Clothing: Operators should refrain from wearing loose garments that could become caught in the machinery, which is a common cause of injuries.

- Emergency Procedures: Ensure that all personnel are well-versed in emergency shut-off procedures to swiftly address any malfunctions or accidents that may occur during operation.

- Check for Buried Utilities: Always call 811 to check for buried utilities at least two days before digging to prevent accidents.

- Bracing Against Torque: For one-man augers, brace against counter-clockwise torque to maintain balance and control.

By applying these protective measures, operators can significantly reduce the risk of injuries, a primary concern in construction settings. In 2023, there were 5,283 reported fatal work injuries, with a rate of 3.5 fatalities per 100,000 full-time equivalent workers. This statistic underscores the critical need for adherence to safety protocols in equipment operation.

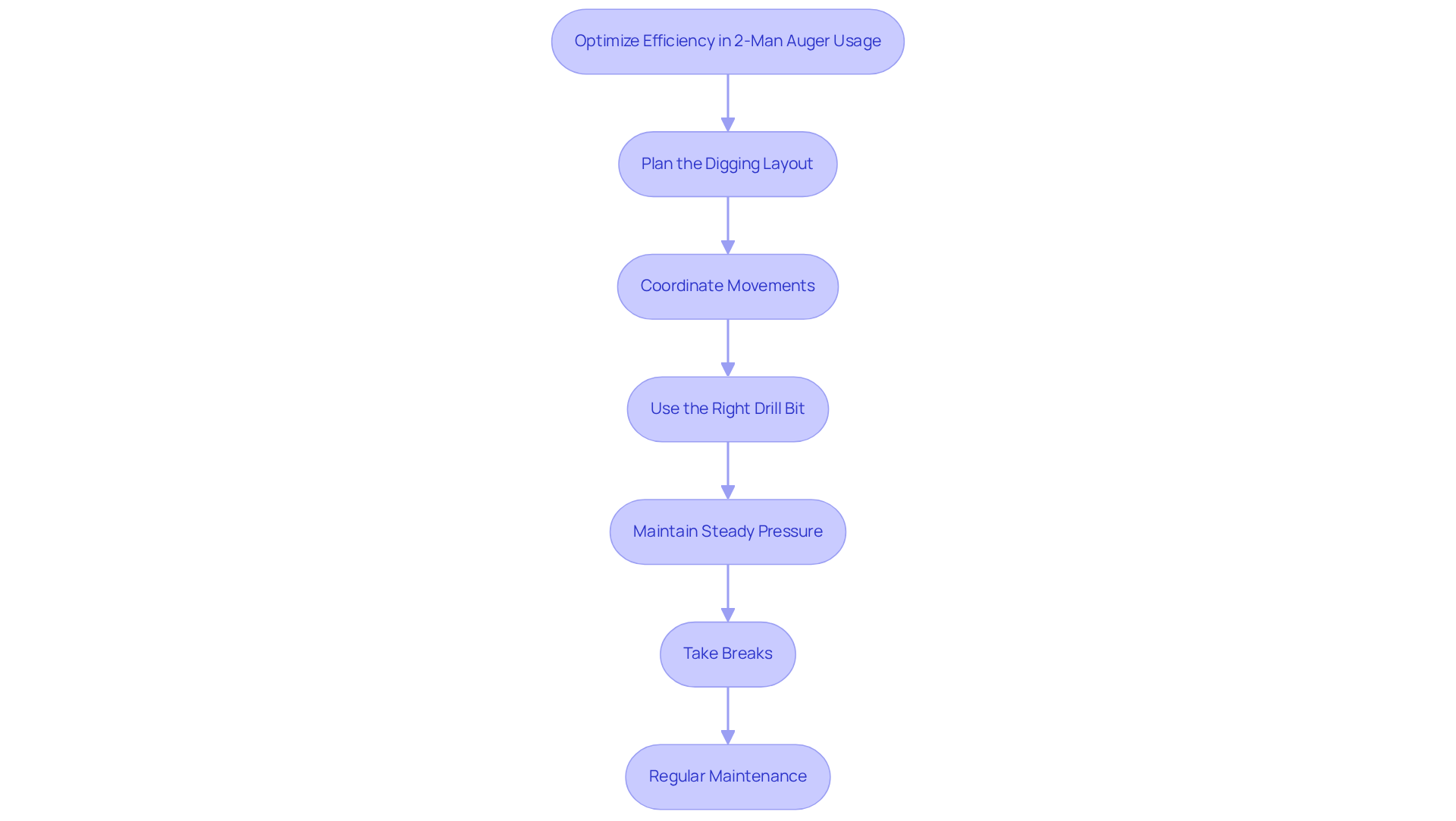

Optimize Efficiency in 2-Man Auger Usage

To optimize efficiency when using a 2-person drilling tool, consider the following strategies:

-

Plan the Digging Layout: Before starting, it’s essential to plan the layout of the holes. This minimizes movement and maximizes efficiency. As Antoine de Saint-Exupéry noted, "A goal without a plan is just a wish," highlighting the importance of thorough planning in achieving successful outcomes.

-

Coordinate Movements: Effective communication between both operators is crucial. One operator should stabilize the drill while the other controls the throttle, ensuring smooth operation.

-

Use the Right Drill Bit: Selecting the appropriate drill bit size for the task can significantly reduce resistance and enhance digging speed.

-

Maintain Steady Pressure: Consistent pressure while using the drill is vital to prevent stalling and to improve digging efficiency.

-

Take Breaks: Regular breaks are necessary to prevent fatigue, which can lead to mistakes and accidents.

-

Regular Maintenance: Keeping the drill well-maintained is essential for optimal performance. This includes sharpening the bit and lubricating moving parts.

According to a KPMG study, 71% of construction experts believe that extending project planning activities is crucial for addressing disruptions. This underscores the importance of meticulous planning in drilling tasks. Implementing these strategies not only enhances the efficiency of drilling activities with a 2 man auger but also contributes to the overall success of construction projects by ensuring that tasks are completed safely and effectively.

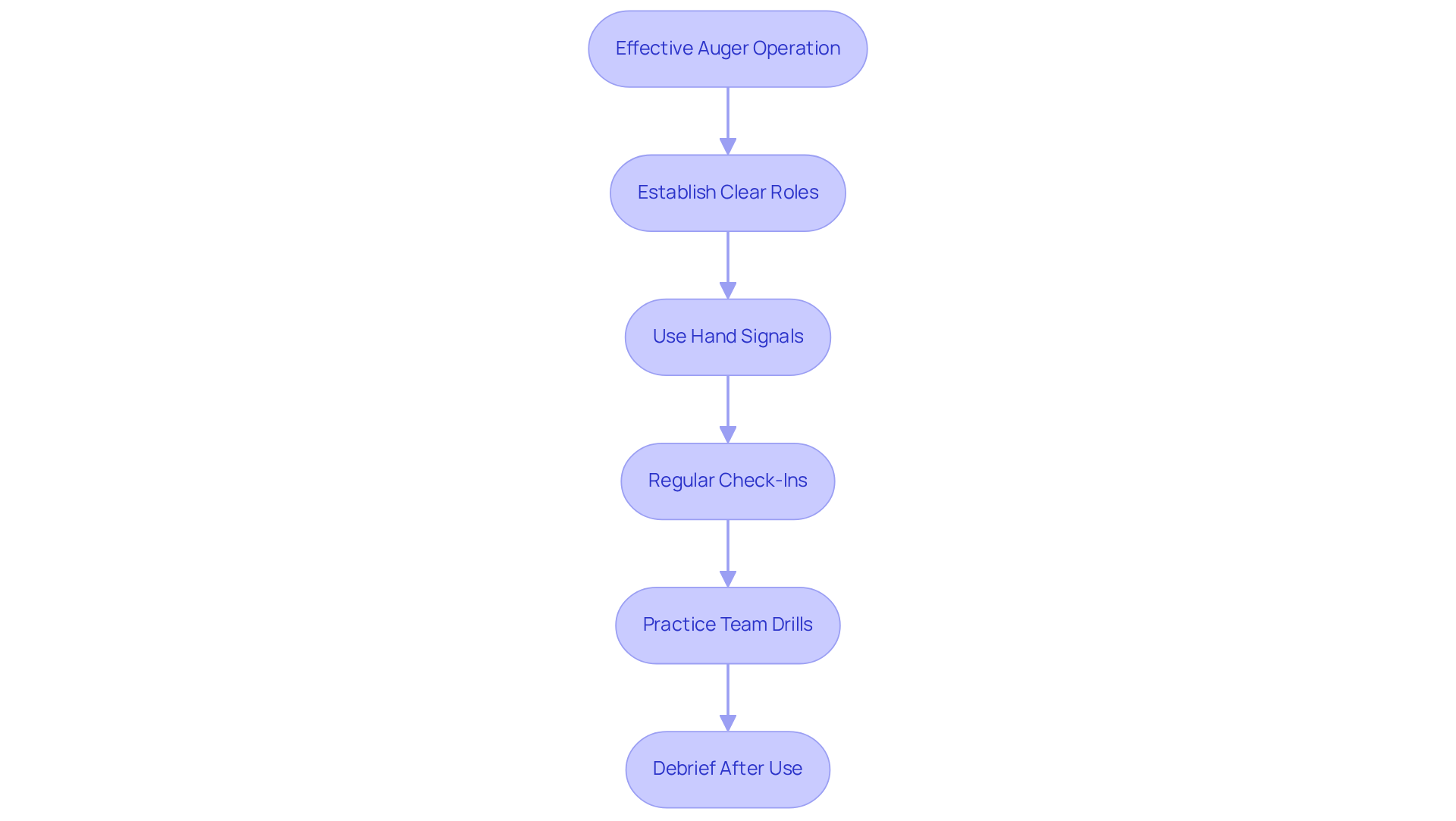

Coordinate Team Efforts for Effective Auger Operation

Effective collaboration between personnel is essential for the successful operation of a 2-man auger. Implementing the following best practices can significantly enhance both safety and efficiency:

-

Establish Clear Roles: Clearly define each worker's responsibilities before beginning work. One individual should focus on stabilizing the 2-man auger, while the other manages the throttle and direction to ensure a seamless operation.

-

Use Hand Signals: Develop a standardized set of hand signals for communication, especially in noisy environments. This practice ensures that both participants remain coordinated and can respond swiftly to any changes during operation.

-

Regular Check-Ins: Schedule periodic check-ins to discuss progress and address any challenges encountered. This fosters a collaborative environment and allows for immediate adjustments as needed.

-

Practice Team Drills: Conducting practice drills can improve coordination and build confidence in each operator's abilities. Regular training sessions reinforce roles and enhance overall teamwork.

-

Debrief After Use: After completing the task, hold a debriefing session to evaluate successes and identify areas for improvement. This reflective practice is crucial for the continuous enhancement of operational efficiency and safety.

By establishing clear roles and fostering effective communication, teams can optimize their operations with the 2-man auger, leading to successful project outcomes.

Conclusion

Mastering the operation of a 2-man auger is crucial for ensuring safety and efficiency in construction and landscaping projects. Understanding how this powerful tool functions, along with adhering to strict safety protocols, is essential. By prioritizing these elements, project managers can enhance productivity while minimizing the risk of accidents.

Key insights include:

- The necessity of conducting thorough pre-operation checks

- Maintaining clear communication between operators

- Using appropriate personal protective equipment

- Optimizing efficiency through strategic planning

- Proper drill bit selection

- Regular maintenance can lead to successful project completion

The emphasis on teamwork and defined roles further underscores the importance of collaboration in achieving operational excellence.

Given the statistics on workplace injuries and fatalities, it is evident that following safety protocols and optimizing auger usage is not merely a best practice but a necessity. By implementing these guidelines and fostering a culture of safety and efficiency, teams can navigate the complexities of auger operation effectively, ultimately contributing to the overall success of their projects.

Frequently Asked Questions

What is a 2 man auger and where is it commonly used?

A 2 man auger is a tool used for efficiently digging holes, commonly utilized in construction and landscaping projects.

What are the key components of a 2 man auger?

The key components of a 2 man auger include the engine, drill bit, and handles.

Why is it important to adhere to safety protocols when using a 2 man auger?

Adhering to safety protocols is crucial to prevent accidents and ensure safe operation, as incidents can occur if safety measures are not followed.

What personal protective equipment (PPE) should be worn when operating a 2 man auger?

Operators should wear gloves, safety glasses, and steel-toed boots as part of their personal protective equipment.

What should operators do to ensure a safe working environment when using a 2 man auger?

Operators must ensure that the work area is clear of obstacles and that all bystanders maintain a safe distance during operation.

Why are routine maintenance inspections important for a 2 man auger?

Routine maintenance inspections, such as checking the feeder for wear and damage, are vital to prevent malfunctions and ensure safe operation.

What incidents related to augers were reported in 2023?

In 2023, six incidents related to entanglement involving augers were reported, highlighting the importance of compliance with safety measures.

What are lockout/tagout procedures and why are they important?

Lockout/tagout procedures are safety measures used to prevent accidental machine startup during maintenance and operation, helping to avert accidents.

How can project managers enhance safety and productivity on job sites using a 2 man auger?

By prioritizing safety and operational efficiency, project managers can significantly mitigate the risk of incidents and enhance productivity on the job site.

Where can operators find further training on risk management protocols?

Operators can access the 2026 OSHA Outreach 10 Hour Virtual Training Course as a valuable resource for further training on risk management protocols.

List of Sources

- Understand Auger Functionality and Safety Protocols

- Auger Accidents & Fatalities: The High Cost of Lax Safety (https://arnolditkin.com/blog/work-accidents/auger-accidents-fatalities-the-high-cost-of-lax-)

- Auger Safety on the Farm Stats and Facts (https://icwgroup.safetynow.com/auger-safety-on-the-farm-stats-and-facts)

- How to Use a Gas Powered Auger (The Right Way) (https://unitedrentals.com/project-uptime/safety/common-safety-mistakes-when-using-one-man-and-two-man-augers)

- Implement Essential Safety Tips for 2-Man Auger Operation

- How to Use a Gas Powered Auger (The Right Way) (https://unitedrentals.com/project-uptime/safety/common-safety-mistakes-when-using-one-man-and-two-man-augers)

- Commonly Used Statistics | Occupational Safety and Health Administration (https://osha.gov/data/commonstats)

- Work Safety: Contact with Objects and Equipment - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/contact-with-objects-and-equipment)

- Optimize Efficiency in 2-Man Auger Usage

- 100+ Construction Industry Statistics | Autodesk (https://autodesk.com/blogs/construction/construction-industry-statistics)

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- 9 Must-Know Statistics About Construction Project Management (https://gocodes.com/construction/project-management-statistics)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- Coordinate Team Efforts for Effective Auger Operation

- How to Use a Gas Powered Auger (The Right Way) (https://unitedrentals.com/project-uptime/safety/common-safety-mistakes-when-using-one-man-and-two-man-augers)

- 100+ Construction Industry Statistics | Autodesk (https://autodesk.com/blogs/construction/construction-industry-statistics)

- 9 Must-Know Statistics About Construction Project Management (https://gocodes.com/construction/project-management-statistics)

- 95 motivational teamwork quotes - Work Life by Atlassian (https://atlassian.com/blog/inside-atlassian/good-teamwork-quotes-youll-like)