Key Highlights:

- Asphalt coatings protect pavement surfaces and vary in type for specific applications.

- Coal Tar Coatings are durable and resistant to oil and UV rays but face environmental concerns due to PAHs.

- Asphalt Emulsion Coatings are eco-friendly, suitable for residential use, and projected to grow significantly in market value.

- Acrylic Coatings offer a glossy finish and UV protection but are less durable and have low VOC content.

- Quick-Dry Coatings allow for rapid application but may lack long-lasting protection, suitable for temporary tasks.

- Key specifications for asphalt sealer equipment include tank capacity, pump type, agitation system, application method, and mobility.

- Regular inspections, cleaning, monitoring fluid levels, proper storage, and replacing worn components are vital for maintaining sealcoating equipment.

- Personal Protective Equipment (PPE) is essential for worker safety during sealcoating, along with comprehensive safety training and weather monitoring.

- Proper handling of materials and regular safety meetings enhance project efficiency and reduce accident risks.

Introduction

Understanding the complexities of asphalt sealing is crucial for contractors striving for project success. With a range of sealers available, each presenting unique benefits and challenges, selecting the right option can greatly influence both durability and environmental sustainability. As the industry continues to evolve, professionals must consider how to stay informed about best practices and the knowledge necessary to navigate this intricate landscape.

Understand Types of Asphalt Sealers

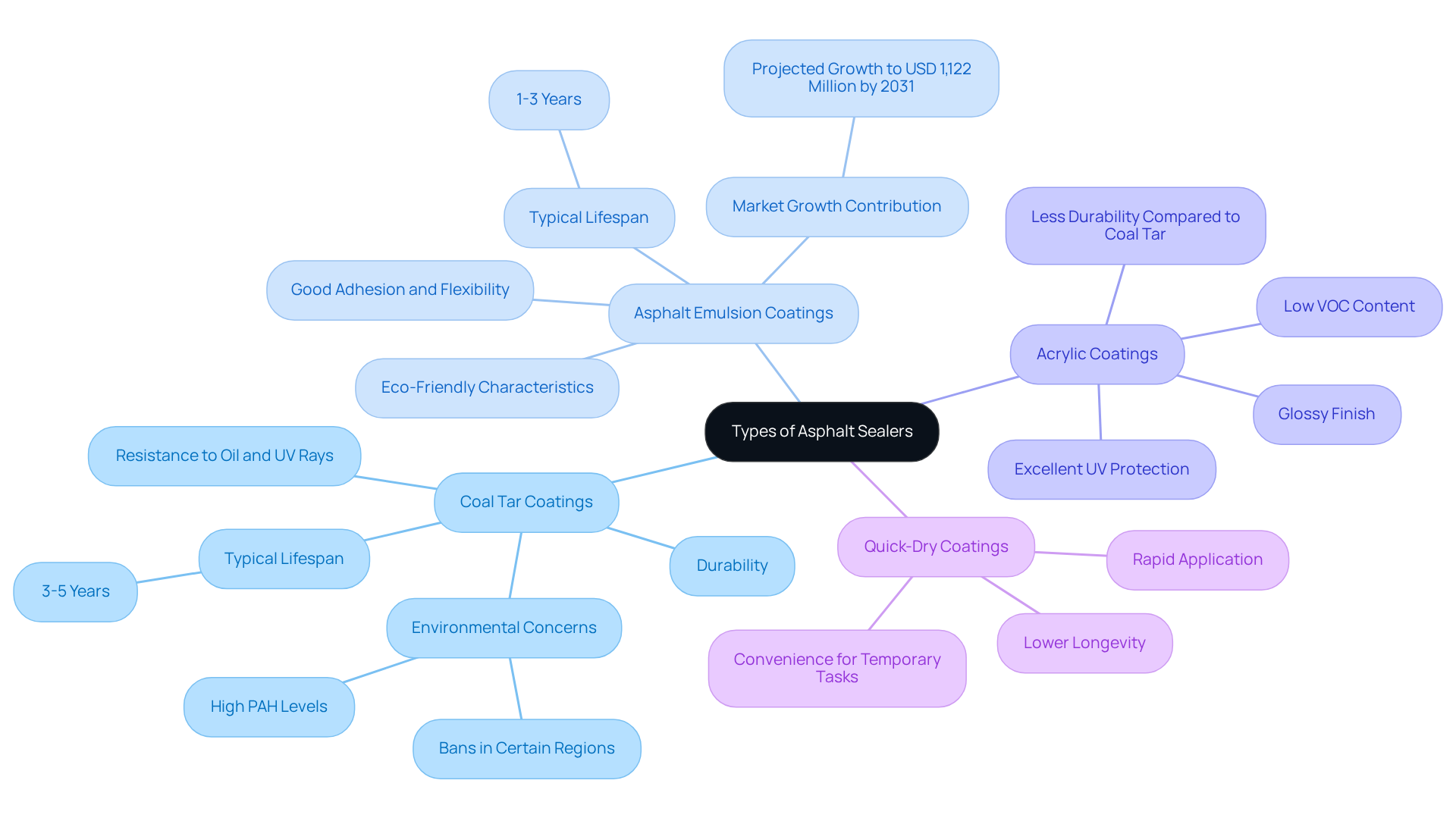

Asphalt coatings play a crucial role in protecting and extending the lifespan of pavement surfaces. They come in various types, each tailored for specific applications and conditions. The most common types include:

-

Coal Tar Coatings: Known for their remarkable durability and resistance to oil and UV rays, coal tar coatings are often used in commercial environments. They form a strong protective barrier, typically lasting 3-5 years, making them suitable for high-traffic areas. However, environmental concerns regarding high levels of polycyclic aromatic hydrocarbons (PAHs) have led to bans in certain regions, raising awareness among property owners and contractors about the need for safer alternatives.

-

Asphalt Emulsion Coatings: These water-based coatings are becoming increasingly popular due to their eco-friendly characteristics, making them ideal for residential projects. They offer good adhesion and flexibility, drying to a deep black finish that enhances curb appeal. While they may require reapplication every 1-3 years and have lower chemical resistance compared to coal tar coatings, their reduced environmental impact is appealing to property owners. The global asphalt coating market, valued at USD 852 million in 2024, is projected to grow to USD 1,122 million by 2031, with asphalt emulsion coatings significantly contributing to this expansion.

-

Acrylic Coatings: Often chosen for decorative purposes, acrylic coatings provide a glossy finish and excellent UV protection. Although they are less durable than coal tar coatings, their low volatile organic compound (VOC) content makes them a safer choice for sensitive areas.

-

Quick-Dry Coatings: Designed for rapid application, quick-dry coatings harden quickly, allowing for faster project completion. While convenient, they may not provide the same level of long-lasting protection as traditional coatings, making them best suited for temporary tasks or low-traffic zones.

Understanding these different types of asphalt coatings and asphalt sealer equipment is essential for selecting the right product based on project requirements, environmental considerations, and budget constraints. As the market evolves, the trend towards sustainable practices is driving the development of new formulations, particularly in the asphalt emulsion category, which is expected to see significant growth in the coming years. Industry leaders stress the importance of selecting the appropriate sealer to balance performance with environmental impact, reflecting the increasing focus on sustainability in construction.

Evaluate Equipment Specifications and Features

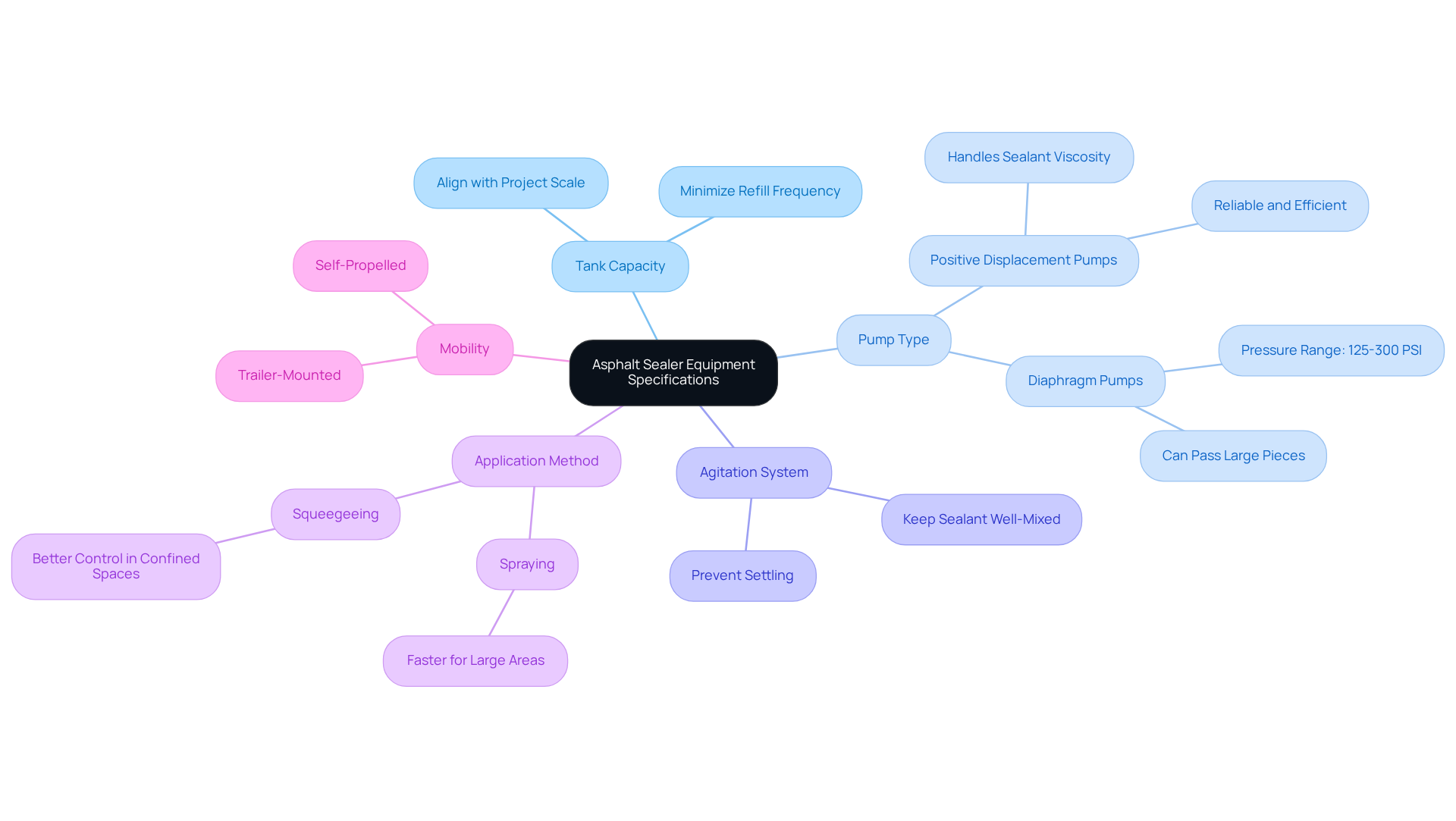

When selecting asphalt sealer equipment, it’s essential to consider several key specifications and features that can significantly impact the efficiency and quality of the project.

- Tank Capacity: Opt for a tank size that aligns with the scale of your project. Larger tanks minimize the frequency of refills, thereby enhancing operational efficiency.

- Pump Type: Select pumps capable of handling the viscosity of the sealant. Positive displacement pumps are often favored due to their reliability and efficiency.

- Agitation System: A robust agitation system is crucial for keeping the sealant well-mixed, preventing settling, and ensuring a consistent application.

- Application Method: Equipment can be tailored for either spraying or squeegeeing. Sprayers are typically faster for covering large areas, while squeegees offer better control in confined spaces.

- Mobility: Assess whether the machinery is trailer-mounted or self-propelled, as this will influence maneuverability on the job site.

By thoroughly evaluating these specifications, contractors can select asphalt sealer equipment that enhances productivity and ensures high-quality results.

Implement Maintenance Best Practices for Longevity

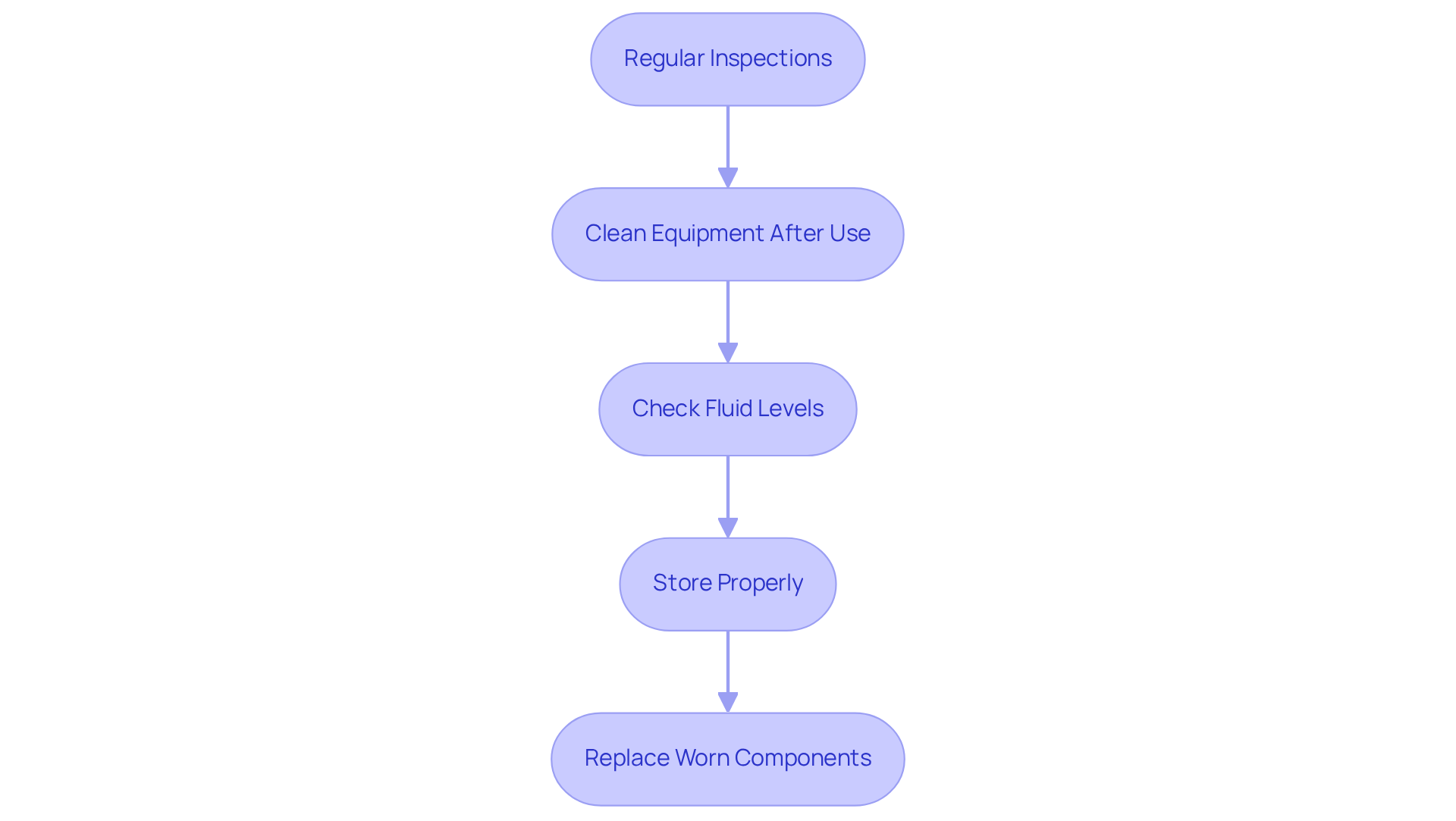

To maximize the lifespan of your sealcoating equipment, it is crucial to adhere to essential maintenance practices:

-

Regular Inspections: Conduct routine checks on hoses, pumps, and tanks to identify wear and tear before they lead to failures. Regular inspections significantly enhance the lifespan and performance of machinery. Notably, 34% of unplanned downtime is attributed to aging machinery, highlighting the necessity of these checks.

-

Clean Equipment After Use: Thoroughly clean all components after each use to prevent residue buildup, which can adversely affect performance. This practice not only maintains efficiency but also contributes to the overall quality of sealcoating applications with asphalt sealer equipment. As industry experts emphasize, "Maintenance is key to keeping businesses competitive and increasing return on investment."

-

Check Fluid Levels: Regularly monitor and maintain appropriate fluid levels in the system to ensure optimal operation. Consistent fluid checks are essential for avoiding operational problems and prolonging the lifespan of machinery. Neglecting this can lead to significant performance declines.

-

Store Properly: When not in use, keep tools in a dry, temperature-controlled environment to prevent damage from extreme weather conditions. Proper storage is vital for maintaining the integrity of the apparatus over time.

-

Replace Worn Components: Maintain a stock of necessary spare parts and substitute them as required to prevent delays during essential tasks. Proactive replacement of worn components can avert costly delays and enhance overall productivity.

Implementing these practices not only prolongs equipment lifespan but also improves the quality of sealcoating applications, ensuring tasks are accomplished efficiently and effectively.

Prioritize Training and Safety Protocols

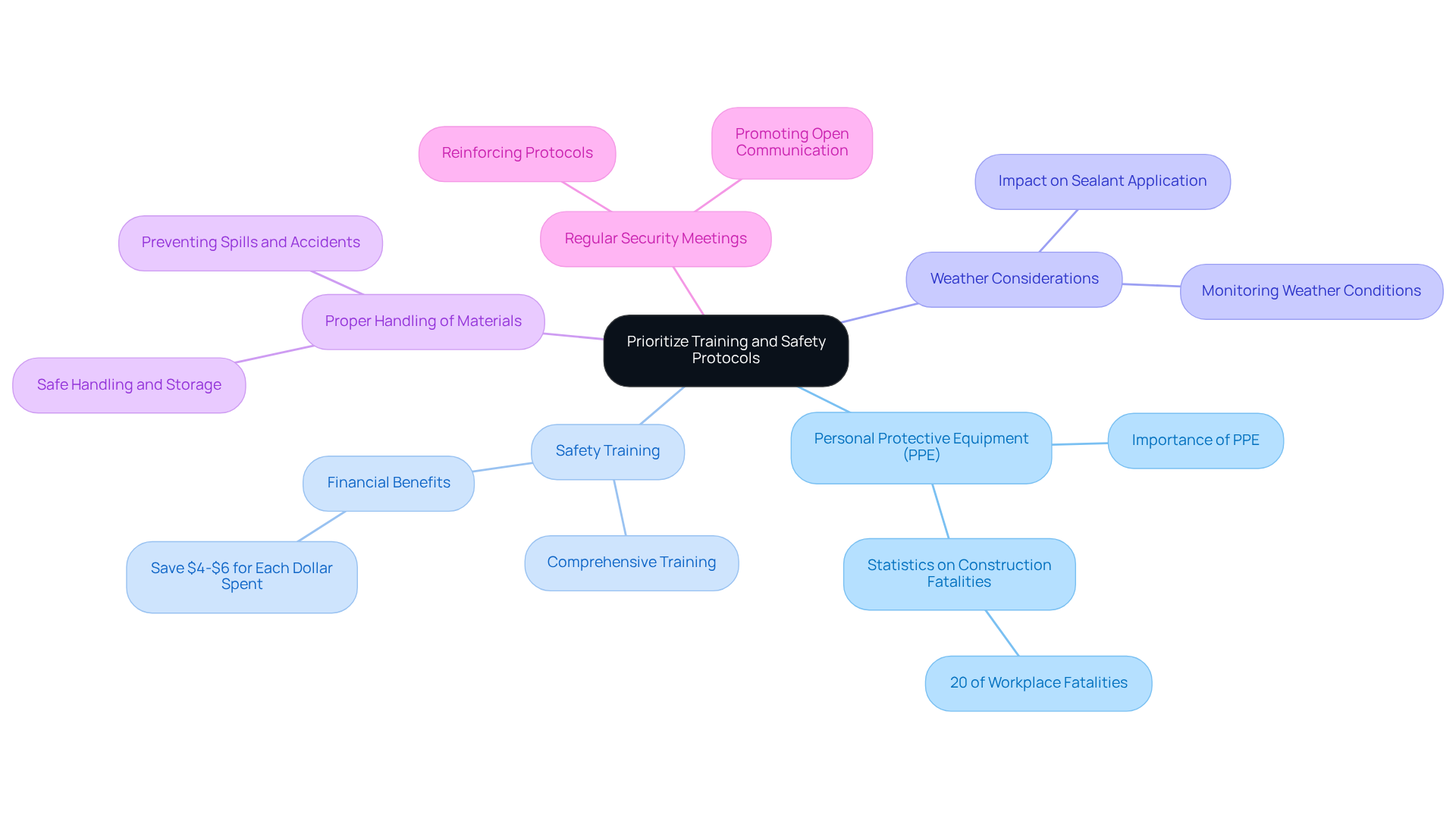

Safety is paramount in any sealcoating undertaking. Implementing effective training and security protocols significantly enhances project outcomes. Here are essential practices to consider:

-

Personal Protective Equipment (PPE): All workers must wear appropriate PPE, including gloves, goggles, and masks, to safeguard against harmful fumes and splashes. The significance of PPE cannot be overstated, as it directly affects worker well-being and health during sealcoating operations. In 2023, construction workers represented roughly 20% of all workplace fatalities in the United States, highlighting the essential need for appropriate protective measures.

-

Safety Training: Comprehensive training on equipment operation, hazard recognition, and emergency procedures is crucial for all team members. Research shows that effective training in risk prevention can lead to a reduction in accident rates, making it a vital investment for contractors. Businesses that invest in protection training can save over $4-$6 for each dollar spent, emphasizing the financial benefits of prioritizing security.

-

Weather Considerations: Workers should be trained to monitor weather conditions closely. Applying sealant in unsuitable temperatures can compromise adhesion and finish quality, leading to costly rework.

-

Proper Handling of Materials: Educating workers on the safe handling and storage of sealants is essential to prevent spills and accidents. Effective material management not only improves security but also guarantees project efficiency.

-

Regular Security Meetings: Frequent security meetings are necessary to reinforce protocols and address any concerns or incidents that may arise on the job site. These meetings promote a culture of security and encourage open communication among team members. Regular training and discussions can significantly decrease the chances of accidents, as specialists emphasize.

By prioritizing training and safety, contractors can create a safer work environment, significantly reduce the risk of accidents, and ensure the success of their projects involving asphalt sealer equipment.

Conclusion

Mastering asphalt sealer equipment is crucial for successful paving projects. Understanding the various types of asphalt sealers, evaluating the right equipment, implementing maintenance best practices, and prioritizing safety training enables contractors to achieve high-quality results while extending the lifespan of their machinery.

Selecting the appropriate asphalt sealer based on project requirements and environmental considerations is essential. This article emphasizes the specifications of asphalt sealing equipment, highlighting features such as tank capacity, pump type, and mobility, which significantly impact project efficiency. Furthermore, it outlines crucial maintenance practices that enhance equipment longevity and performance, alongside the necessity of safety protocols to protect workers and improve overall project outcomes.

In a rapidly evolving industry, embracing sustainable practices and investing in proper training can enhance productivity and contribute to a safer work environment. By integrating these best practices, contractors can navigate the complexities of asphalt sealing confidently, ensuring their projects are completed efficiently and effectively while fostering a culture of safety and responsibility.

Frequently Asked Questions

What are the main types of asphalt sealers?

The main types of asphalt sealers include coal tar coatings, asphalt emulsion coatings, acrylic coatings, and quick-dry coatings, each tailored for specific applications and conditions.

What are the characteristics of coal tar coatings?

Coal tar coatings are known for their durability and resistance to oil and UV rays, making them suitable for commercial environments and high-traffic areas. They typically last 3-5 years but have raised environmental concerns due to high levels of polycyclic aromatic hydrocarbons (PAHs), leading to bans in some regions.

What are the benefits of asphalt emulsion coatings?

Asphalt emulsion coatings are water-based and eco-friendly, making them ideal for residential projects. They offer good adhesion, flexibility, and enhance curb appeal with a deep black finish. However, they may require reapplication every 1-3 years and have lower chemical resistance compared to coal tar coatings.

What are acrylic coatings used for?

Acrylic coatings are often chosen for decorative purposes due to their glossy finish and excellent UV protection. They have a low volatile organic compound (VOC) content, making them a safer choice for sensitive areas, although they are less durable than coal tar coatings.

What are quick-dry coatings and when are they used?

Quick-dry coatings are designed for rapid application and harden quickly, allowing for faster project completion. They are best suited for temporary tasks or low-traffic zones, although they may not provide the same level of long-lasting protection as traditional coatings.

Why is it important to understand different types of asphalt coatings?

Understanding the different types of asphalt coatings is essential for selecting the right product based on project requirements, environmental considerations, and budget constraints, especially as the trend towards sustainable practices grows in the industry.

List of Sources

- Understand Types of Asphalt Sealers

- Asphalt Sealer Market Outlook 2025-2032 (https://intelmarketresearch.com/asphalt-sealer-market-9663)

- Seal Coat Market Size, Demand & Industry Growth (https://marketresearchfuture.com/reports/seal-coat-market-38047)

- The Pros and Cons of Different Asphalt Sealer Types (https://maintainitall.com/the-pros-and-cons-of-different-asphalt-sealer-types)

- Asphalt Sealer Market Size 2026 | Opportunities, Dynamics & Growth 2033 (https://linkedin.com/pulse/asphalt-sealer-market-size-2026-opportunities-dynamics-fku9f)

- Evaluate Equipment Specifications and Features

- Case Studies - Asphalt Systems Inc (https://asphaltsystemsinc.com/case-studies)

- 7 Equipment Setup Tips for Sealing Success (https://theasphaltpro.com/articles/7-equipment-setup-tips-for-sealing-success)

- Asphalt Emulsion Pump Guide | RoadResource.org (https://roadresource.org/emulsion_resources/pump_types)

- Asphalt Sealing Equipment Pump Selection (https://sealcoatingequipmentdirect.com/information/asphalt-sealing-equipment-pump-selection)

- What To Consider Before Buying a Sealcoat Tank (https://nacsupply.com/blogs/asphalt-advisor-blog/what-to-consider-before-buying-a-sealcoat-tank)

- Implement Maintenance Best Practices for Longevity

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- Maintenance Musts for Your Sealcoating Equipment - TRID (https://trid.trb.org/View/758998)

- Key Facts and Statistics on Equipment Maintenance (https://gocodes.com/maintenance-management/equipment-maintenance-statistics)

- Maintenance statistics and trends 2025 • Infraspeak Blog (https://blog.infraspeak.com/maintenance-statistics-trends-challenges)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Prioritize Training and Safety Protocols

- Construction Safety Statistics (2026) (https://blog.oshaonlinecenter.com/construction-safety-statistics)

- Construction Safety Quotes That Actually Get Read (https://armedamerican.supply/blogs/news/construction-safety-quotes?srsltid=AfmBOoqu7OQ_o7dq_YhosErtqDJ1wxxPtDnGCF5brAkkysghCNKrx_tx)

- 41 Construction Safety Statistics for 2025 (https://clarisdesignbuild.com/41-construction-safety-statistics)

- Construction Safety: 5 Statistics Everyone in the Industry Should Know (https://autodesk.com/blogs/construction/construction-safety-statistics)