Key Highlights:

- Backhoes are categorised into light (7,000-10,000 lbs), medium (14,000-18,000 lbs), and heavy (over 20,000 lbs) based on weight, serving different construction purposes.

- Light excavators are ideal for small projects due to their manoeuvrability, while medium excavators balance power and portability for versatile applications.

- Heavy backhoes are designed for large-scale tasks, offering the necessary power for demanding operations such as foundation digging.

- Accurate backhoe weight measurement can be achieved using commercial scales, manufacturer specifications, load cells, and hydraulic scales.

- Load data is crucial for resource distribution, safety considerations, cost estimation, and timeline management in project planning.

- Common weight measurement issues include calibration errors, environmental factors, mechanical issues, and data recording errors, which can be addressed to maintain accuracy.

Introduction

Understanding backhoe weights is essential for effective project management in construction and landscaping. Backhoes are categorized into light, medium, and heavy types, each serving distinct functions that can greatly influence project efficiency and safety. The challenge for project managers lies in selecting the appropriate equipment and accurately measuring its weight to optimize performance. By making informed decisions, project managers can enhance productivity while minimizing risks. This article will explore how understanding these classifications can lead to better equipment choices and improved project outcomes.

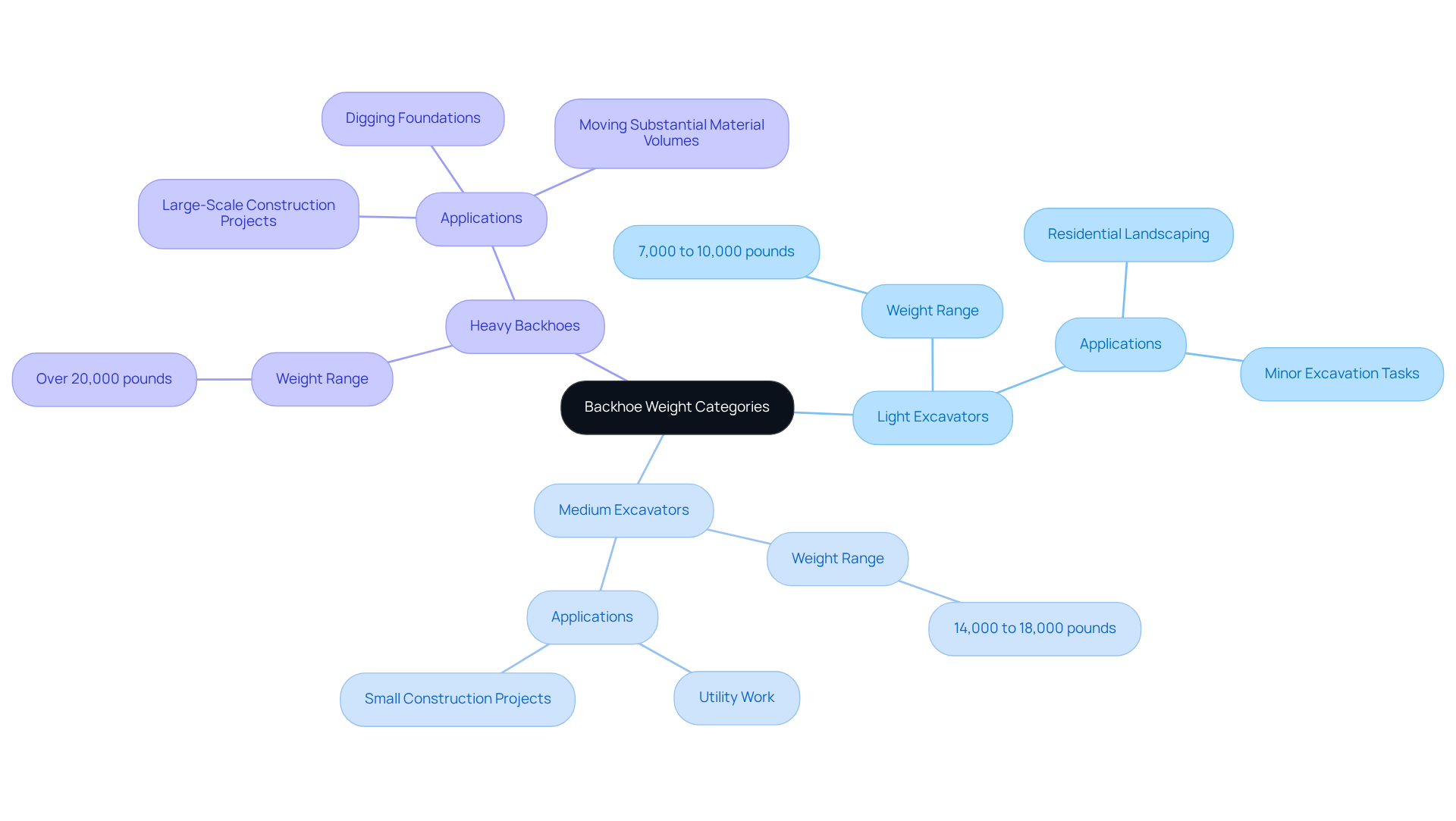

Understand Backhoe Weight Categories

Backhoes are classified based on backhoe weights into three primary categories: light, medium, and heavy. Each category serves distinct purposes in construction and landscaping. Understanding these classifications is essential for effective equipment management and selection.

-

Light Excavators: Ranging from 7,000 to 10,000 pounds, light excavators are perfect for small-scale projects, such as residential landscaping and minor excavation tasks. Their lightweight design enhances maneuverability and transport ease, making them suitable for confined spaces.

-

Medium Excavators: Weighing between 14,000 and 18,000 pounds, medium excavators offer versatility for various applications, including utility work and small construction projects. They provide a balance of power and portability, making them ideal for tasks that require both strength and mobility. As Kevin Forestell, CEO of DOZR, notes, "To simplify the process of locating the appropriate excavator model, we've arranged this spec guide by engine power, a common reference point for such machinery."

-

Heavy Backhoes: These robust machines exceed 20,000 pounds and are designed for large-scale construction projects. Heavy machinery excels in demanding tasks, such as digging foundations and moving substantial material volumes, delivering the necessary power for heavy-duty operations. Forestell adds, "Larger excavators with greater mass or horsepower can often dig deeper and are more powerful."

Recognizing backhoe weights classifications allows project managers to make informed decisions regarding equipment rental or purchase, ensuring that the selected excavator meets the specific needs of their projects. Additionally, it is important to consider that attachments can significantly impact the overall weight and performance of an excavator, further influencing machinery selection.

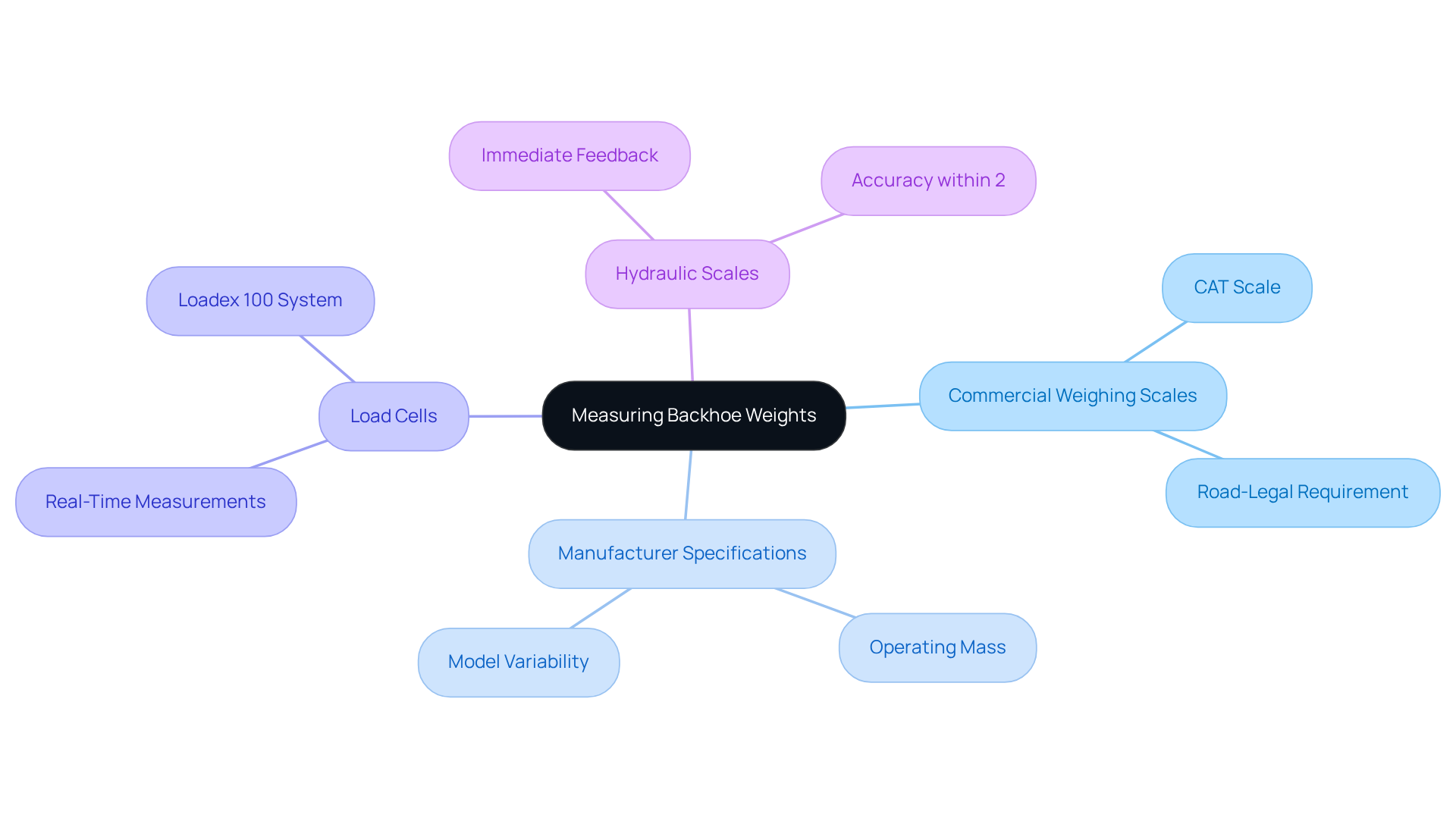

Utilize Tools for Measuring Backhoe Weights

To accurately measure backhoe weights, several tools and methods can be employed:

-

Commercial Weighing Scales: If the excavator is road-legal, driving it to a certified weighing station, such as a CAT Scale, provides a precise measurement. Heavy-duty excavators typically weigh between 20,000 and 40,000 pounds, making it crucial to adhere to load regulations.

-

Manufacturer Specifications: Consulting the excavator's manual or the manufacturer's website reveals the operating mass, usually listed for each model. For example, medium excavators weigh between 14,000 and 18,000 pounds, striking a balance between power and versatility.

-

Load Cells: These instruments can be mounted on the excavator to deliver real-time mass measurements during operation. They are particularly beneficial for monitoring loads while digging or lifting, thereby enhancing operational efficiency. The Loadex 100 system, designed specifically for excavators, enables operators to optimize truck payloads and manage load data effectively.

-

Hydraulic Scales: Some backhoes feature hydraulic scales that assess the mass of the load being lifted, providing immediate feedback to the operator. This technology ensures accuracy in weighing within 2%, which is vital for efficient management.

Incorporating these tools not only guarantees precise measurement data but also aids in enhancing project planning and execution, especially when considering backhoe weights. As Jackie Chen, a specialist in the field, states, "Precise measurement is essential for maximizing productivity and ensuring safety on construction sites." Understanding the impact of excavator attachments on mass and performance is also critical, as heavier attachments can affect the machine's stability and efficiency. By utilizing these methods, managers can significantly enhance productivity and safety on construction sites.

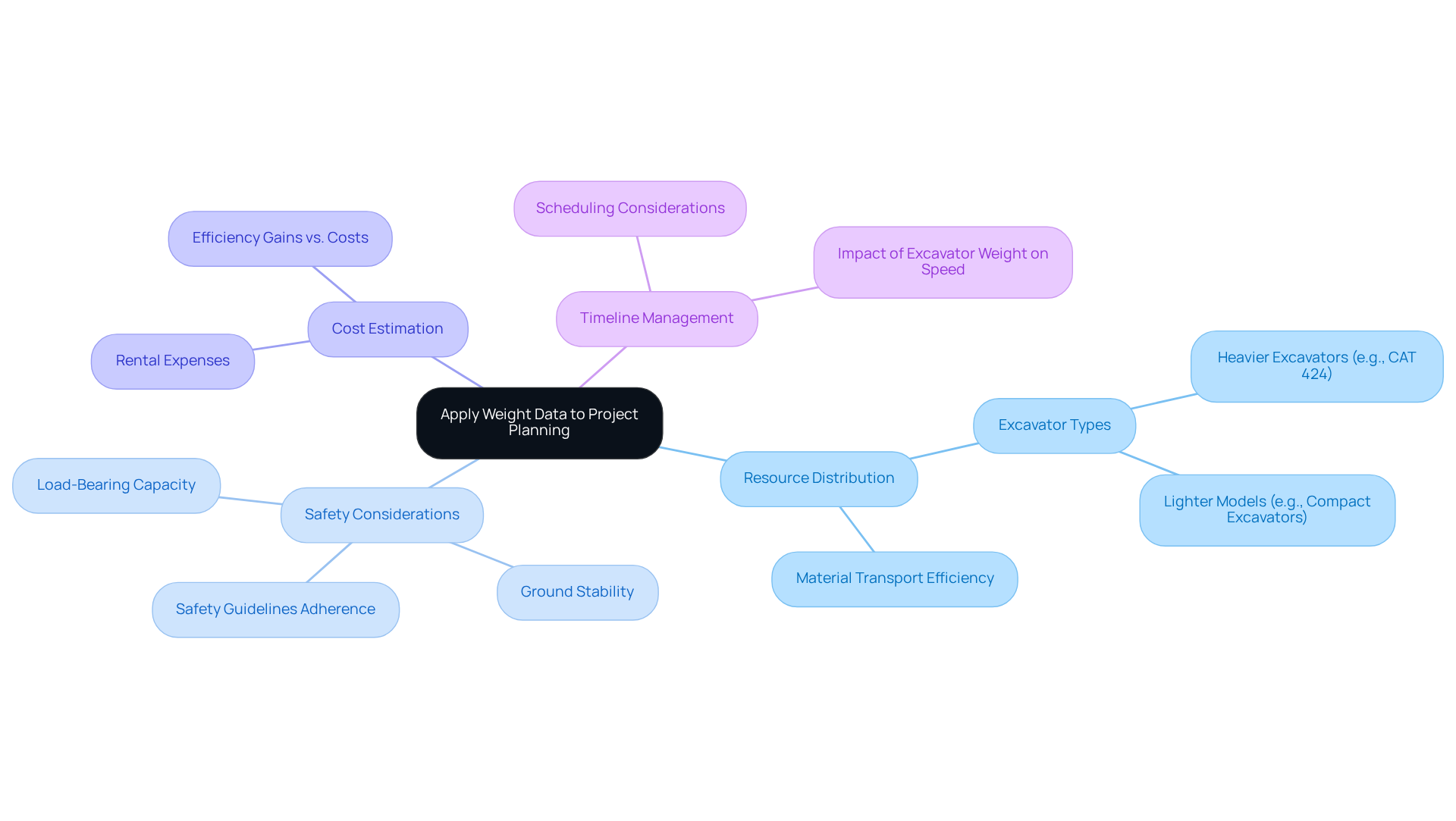

Apply Weight Data to Project Planning

Including load information for excavators in planning is crucial for enhancing efficiency and safety. Effectively applying this information can significantly impact project outcomes.

-

Resource Distribution: Examine the load data to determine the appropriate number of excavators for your project. Heavier excavators, like the CAT 424 with an operating mass of up to 8,760 kg, can transport larger amounts of materials in fewer trips, making them ideal for extensive tasks. In contrast, lighter models, such as compact excavators weighing 6,173 lbs, excel in confined spaces, enhancing maneuverability.

-

Safety Considerations: Ensuring that the excavator's mass does not exceed the load-bearing capacity of the job site is essential. This is particularly vital in areas with softer ground, where stability may be compromised. Industry statistics indicate that incidents related to exceeding load capacities have resulted in numerous accidents, underscoring the importance of adhering to safety guidelines to minimize risks and enhance operational reliability.

-

Cost Estimation: Rental expenses often correlate with the size classification of the excavator. Heavier machines typically command higher rental fees, so weighing the cost against potential efficiency gains is important. A strategic budgeting approach can lead to significant savings while meeting project requirements. As one manager noted, "Selecting the appropriate excavator according to its weight can greatly affect both expenses and workflow efficiency."

-

Timeline management indicates that backhoe weights, when heavier, can complete tasks more rapidly, significantly shortening project timelines. Integrating this factor into your scheduling allows for improved resource management and timely task delivery.

By strategically utilizing load information, project managers can enhance operational efficiency, improve safety, and achieve successful project results.

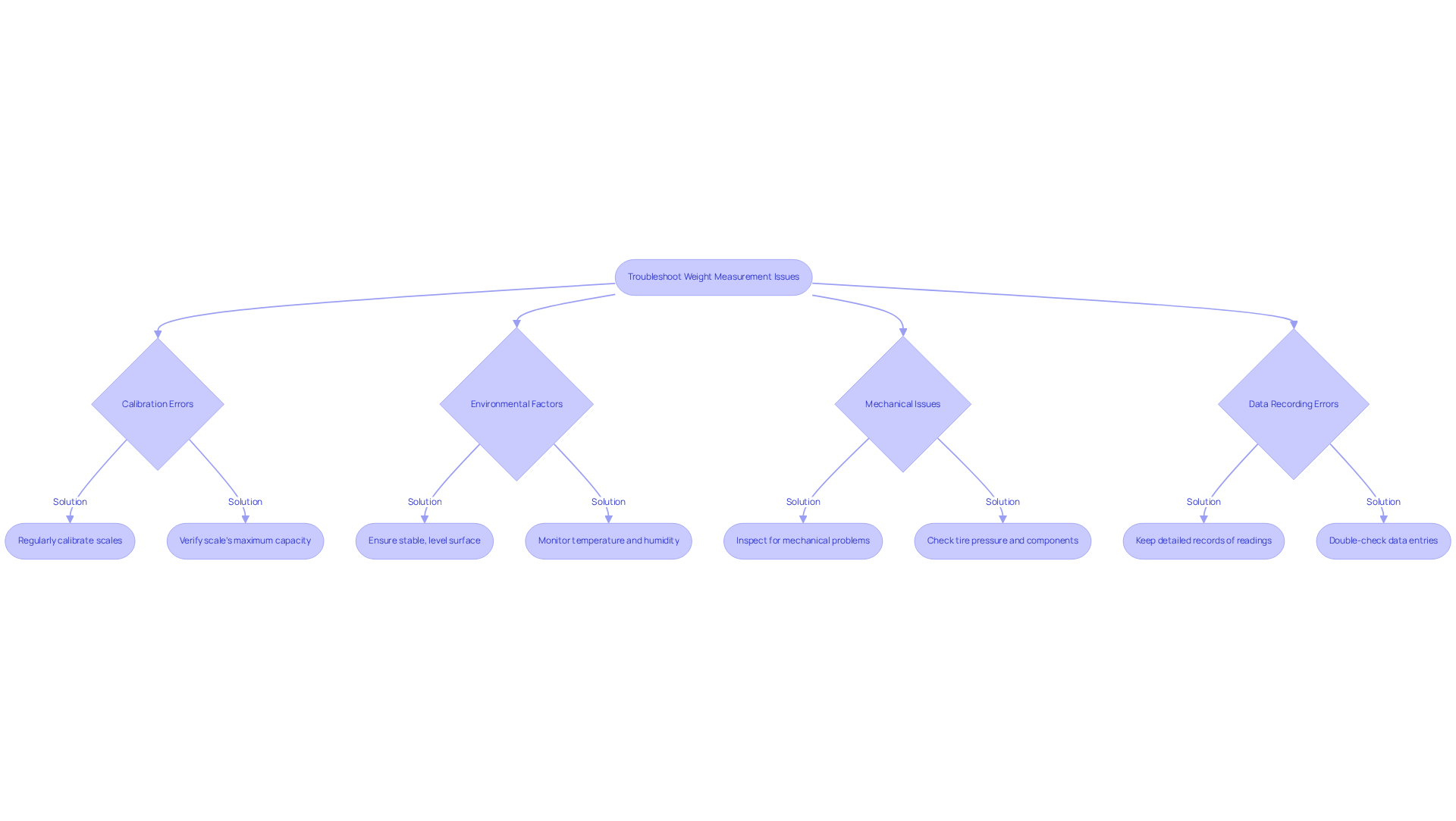

Troubleshoot Common Weight Measurement Issues

When assessing backhoe weights, several common issues can compromise accuracy. Here are essential troubleshooting tips:

-

Calibration Errors: Regular calibration of weighing scales and load cells is crucial. Inaccurate readings often stem from improper calibration, which should be checked at least once a year to maintain precision. Always verify the scale's maximum capacity before use to prevent overload errors.

-

Environmental Factors: Environmental conditions significantly affect mass assessments. Factors such as uneven ground, extreme temperatures, and humidity can lead to inaccuracies. Ensure that dimensions are taken on a stable, level surface to mitigate these effects. Be mindful that temperature and humidity changes can introduce environmental errors, impacting the accuracy of readings.

-

Mechanical Issues: Inspect the backhoe weights for any mechanical problems that could affect weight distribution. Issues like uneven tire pressure or damaged components can skew results. Mechanical degradation on scales can also result in inaccuracies, so addressing these issues before weighing is essential for precise evaluations.

-

Data Recording Errors: Precise data input is crucial for efficient task management. Keep detailed records of mass readings and ensure that information is accurately input into management software. Double-checking entries can prevent errors that may influence planning.

By proactively addressing these common issues, project managers can ensure that weight measurements remain accurate and reliable, ultimately contributing to the success of their projects.

Conclusion

In conclusion, understanding the classifications and implications of backhoe weights is essential for effective project management in construction. By mastering the weight categories - light, medium, and heavy - project managers can select the right equipment that meets the specific needs of their projects, ensuring optimal performance and efficiency.

This article has highlighted the importance of accurately measuring backhoe weights through various tools and methods. Techniques such as commercial weighing scales and hydraulic scales contribute to precise data collection, which enhances project planning. Furthermore, proper weight management plays a critical role in resource distribution, safety considerations, cost estimation, and timeline management, ultimately leading to more successful project outcomes.

Incorporating accurate backhoe weight data into project management practices not only boosts productivity but also reduces risks associated with equipment misuse. As the construction industry continues to evolve, staying informed about backhoe weight classifications and measurement techniques will empower project managers to make informed decisions that enhance both operational efficiency and safety on job sites. Embracing these best practices is vital for effectively navigating the complexities of construction projects.

Frequently Asked Questions

What are the primary weight categories for backhoes?

Backhoes are classified into three primary categories based on weight: light, medium, and heavy.

What is the weight range for light excavators?

Light excavators range from 7,000 to 10,000 pounds and are suitable for small-scale projects like residential landscaping and minor excavation tasks.

What advantages do light excavators offer?

Their lightweight design enhances maneuverability and ease of transport, making them ideal for confined spaces.

What is the weight range for medium excavators?

Medium excavators weigh between 14,000 and 18,000 pounds and are versatile for various applications, including utility work and small construction projects.

What is the benefit of using medium excavators?

They provide a balance of power and portability, making them suitable for tasks that require both strength and mobility.

What defines heavy backhoes?

Heavy backhoes exceed 20,000 pounds and are designed for large-scale construction projects, capable of handling demanding tasks.

What tasks are heavy backhoes typically used for?

They are used for tasks such as digging foundations and moving substantial volumes of material, delivering the necessary power for heavy-duty operations.

How do attachments affect backhoe performance?

Attachments can significantly impact the overall weight and performance of an excavator, influencing machinery selection for specific projects.

Why is it important to understand backhoe weight classifications?

Recognizing backhoe weight classifications helps project managers make informed decisions regarding equipment rental or purchase, ensuring the selected excavator meets the specific needs of their projects.

List of Sources

- Understand Backhoe Weight Categories

- The Ultimate Backhoe Size and Spec Guide (https://dozr.com/blog/backhoe-loader-spec-guide)

- How Much Does a Backhoe Weigh? (https://my-forklift.com/How-Much-Does-a-Backhoe-loader-Weigh-n.html)

- How Much Does a Backhoe Weigh - Updated Guide 2026 (https://jackwinsafety.com/how-much-does-a-backhoe-weigh)

- How Much Does a Backhoe Weigh? | BigRentz (https://bigrentz.com/blog/how-much-does-a-backhoe-weigh?srsltid=AfmBOopwtiTAXlps8jDZBvmD2PPHs_B-cUpVzlo0UunkXXho0EOGMjeq)

- Crown Error 404 (https://ccgit.crown.edu/how-much-does-a-backhoe-weight)

- Utilize Tools for Measuring Backhoe Weights

- Backhoe Weight: Understanding Machine Mass, Stability, and Lifting Capacity (https://everstarmachinery.com/blog/backhoe-weight-operating-weight-stability-lifting-capacity)

- Excavator Scale (https://tamtrongroup.com/en/product/excavator-scale)

- How Much Does a Backhoe Weigh - Updated Guide 2026 (https://jackwinsafety.com/how-much-does-a-backhoe-weigh)

- Weighing Systems for Excavators - RDS MME (https://rdsmme.com/blog/weighing-systems-for-excavators)

- Apply Weight Data to Project Planning

- 139 Project Management Quotes to Inspire Your Next Project (https://plaky.com/blog/project-management-quotes)

- 16 Best Project Management Quotes (https://projectmanager.com/blog/10-best-project-management-quotes)

- Backhoe Weight: Understanding Machine Mass, Stability, and Lifting Capacity (https://everstarmachinery.com/blog/backhoe-weight-operating-weight-stability-lifting-capacity)

- Boosting Backhoe Loader Productivity: Tips & Key Factors for Efficiency (https://machanx.com/blogs/boosting-backhoe-loader-productivity/detail-a60ea132-f8e1-432d-b355-927b6047506b)

- The Top 200 Project Management & Planning Quotes (https://praxie.com/top-project-management-planning-quotes)

- Troubleshoot Common Weight Measurement Issues

- Weighing Errors: Overload, Calibration & Tare (https://gram-group.com/weighing-errors)

- Can Scales Be Wrong: Factors Affecting Scales’ Accuracy (https://arlynscales.com/scale-knowledge/factors-can-affect-scales-accuracy)

- The Most Common Scale Errors – And How to Avoid Them (https://mws.ltd.uk/the-most-common-scale-errors)

- Google (https://selletonscales.com/blogs/news/maximizing-accuracy-the-best-construction-scale-calibration-methods?srsltid=AfmBOooN4Q3bk-UR5Yl535PgnJ3zJkYXBXeuUTqhbJ7xGrzSSHS904nF)

- Common Weighing Errors & Prevention | Hunter Weighing (https://hunterweighing.com.au/commonweighingerrors)