Key Highlights:

- Conduct a thorough assessment of project requirements, including area size, vegetation types, and potential hazards.

- Define clear objectives for the brush clearing initiative to guide equipment and technique selection.

- Engage stakeholders early to align expectations and project goals.

- Evaluate vegetation types to determine appropriate clearing methods and equipment.

- Identify hazards such as overhead power lines and underground utilities to ensure safety.

- Select from various brush clearing equipment, including brush cutters, skid steer attachments, excavators, and bulldozers, based on project needs.

- Assess equipment performance based on manufacturer reputation, maintenance requirements, performance metrics, and warranty support.

- Implement best practises such as regular inspections, proper training, scheduled maintenance, and use of safety gear to enhance equipment operation and safety.

Introduction

Effective brush clearing is crucial for a range of projects, from construction to ecological restoration. However, many project managers face challenges in selecting the appropriate equipment and strategies. This article explores best practices that empower managers to navigate the complexities of brush clearing operations, ensuring both efficiency and safety. Key factors can significantly influence the success of a brush clearing initiative, and understanding how to leverage these factors is essential for driving successful outcomes.

Assess Project Requirements for Brush Clearing

Before embarking on any project involving brush clearing equipment, it is crucial to conduct a thorough assessment of the requirements. This includes evaluating the size of the area to be cleared, the types of vegetation present, and any potential hazards, such as overhead power lines or underground utilities. Additionally, understanding the goals of the initiative-whether for construction, landscaping, or ecological restoration-will guide the selection of appropriate equipment and techniques. For example, preparing land for construction may necessitate a more aggressive approach compared to an initiative focused on habitat restoration. Engaging with stakeholders early in the process can clarify expectations and ensure alignment on project goals.

To enhance the effectiveness of your assessments, consider the following best practices:

- Evaluate Vegetation Types: Understanding the types of vegetation present can guide the selection of appropriate clearing methods and equipment.

- Identify Hazards: Assess possible dangers, including overhead power lines and underground utilities, to ensure safety during the removal process.

- Set Clear Objectives: Clearly define the goals of the initiative to determine the most suitable method for removal.

- Engage Stakeholders: Involve stakeholders early to align expectations and objectives.

At EZ Equipment Rental, our team of knowledgeable professionals is ready to provide expert guidance and support throughout your rental experience, ensuring smooth operations and safety during your brush clearing equipment task. We offer a range of brush clearing equipment, including brush cutters, chippers, and boom lifts, tailored to meet your specific needs. As Dwight D. Eisenhower noted, 'Plans are nothing; planning is everything.' This highlights the importance of comprehensive planning in achieving successful results. By prioritizing these evaluations, managers can enhance efficiency and effectiveness in initiatives involving brush clearing equipment.

Explore Types of Brush Clearing Equipment

A diverse range of brush clearing equipment is available for brush removal, with each type tailored to specific tasks and vegetation. Key options include:

- Brush Cutters: These handheld or walk-behind machines excel at managing small to medium-sized brush, offering precision and versatility for detailed work.

- Skid Steer Attachments: With choices such as brush clearing equipment, mulchers, and grapples, skid steer loaders provide remarkable versatility for addressing larger spaces and more challenging vegetation, making them essential for small-scale endeavors with restricted access.

- Excavators: When fitted with specialized attachments, brush clearing equipment, such as excavators, can handle heavy-duty removal tasks, making them suitable for large-scale projects that require significant earthmoving capabilities. For instance, mini excavators can adapt to various tasks, enhancing their effectiveness in land preparation.

- Bulldozers: For extensive land clearing, brush clearing equipment such as bulldozers is highly effective, quickly removing large volumes of vegetation and debris, thus facilitating rapid site preparation. Their power and efficiency render them crucial in large-scale endeavors.

By understanding the advantages and drawbacks of each type of apparatus, managers can make informed choices, selecting the most appropriate tools for their specific requirements. This strategic approach not only improves project efficiency but also ensures safety throughout the removal process. Furthermore, it is essential to avoid common mistakes such as underestimating the machinery's capabilities or neglecting to evaluate the specific features of the land, which can lead to inefficiencies and increased costs.

Evaluate Equipment Performance and Reliability

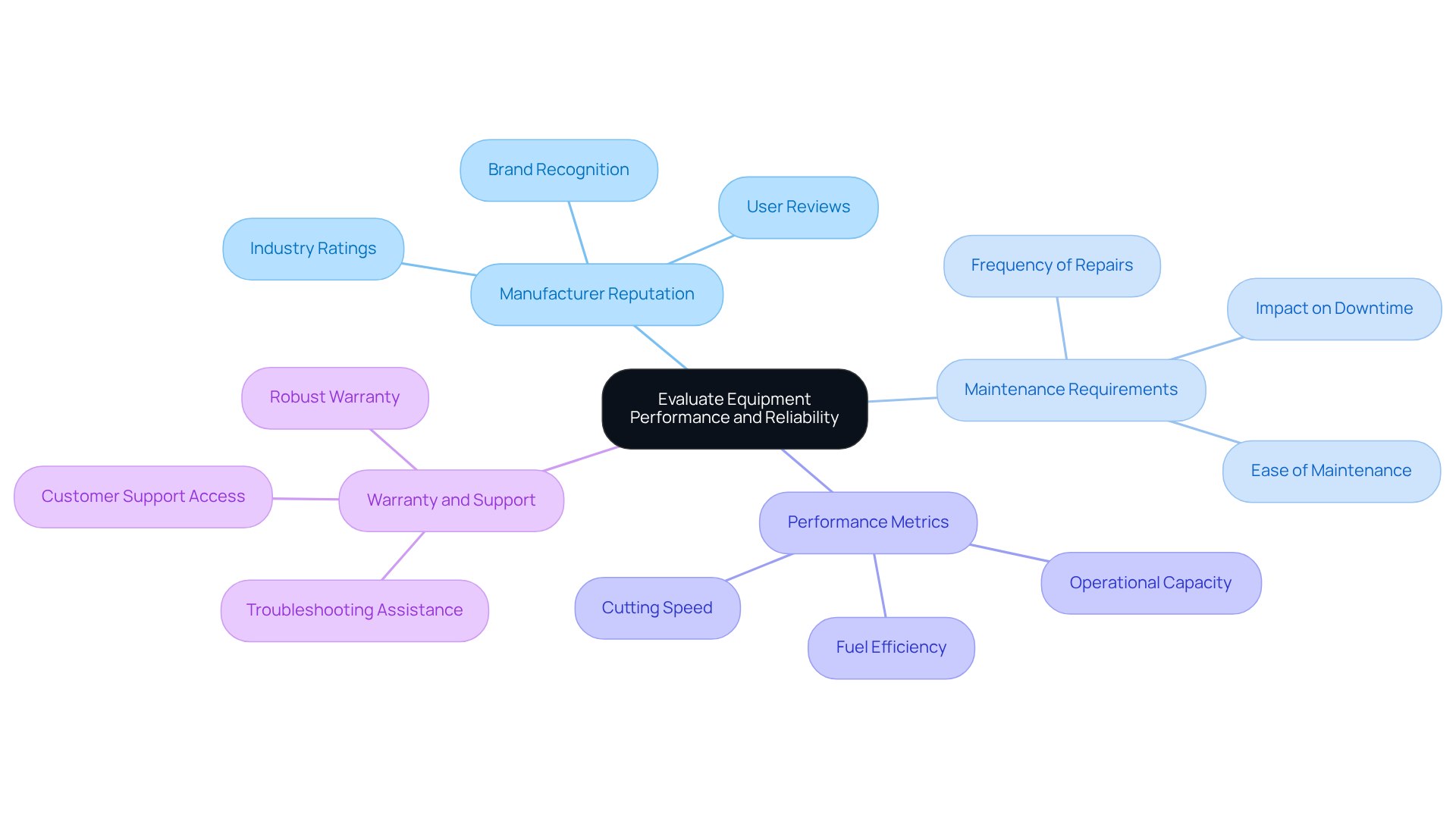

When selecting brush clearing equipment, evaluating their performance and reliability is essential. Consider the following factors:

- Manufacturer Reputation: Investigate brands recognized for producing durable and efficient equipment. User reviews and industry ratings can offer valuable insights into their reliability.

- Maintenance Requirements: Assess the ease of maintaining the machinery. Equipment that demands frequent repairs can lead to increased downtime and costs, impacting overall productivity.

- Performance Metrics: Look for specifications such as cutting speed, fuel efficiency, and operational capacity. Tools that perform well under various conditions will significantly enhance productivity.

- Warranty and Support: Ensure that the equipment comes with a robust warranty and access to customer support for troubleshooting and repairs.

By thoroughly evaluating these factors, managers can select brush clearing equipment that not only fulfills their current needs but also supports long-term success.

Implement Best Practices for Equipment Operation and Maintenance

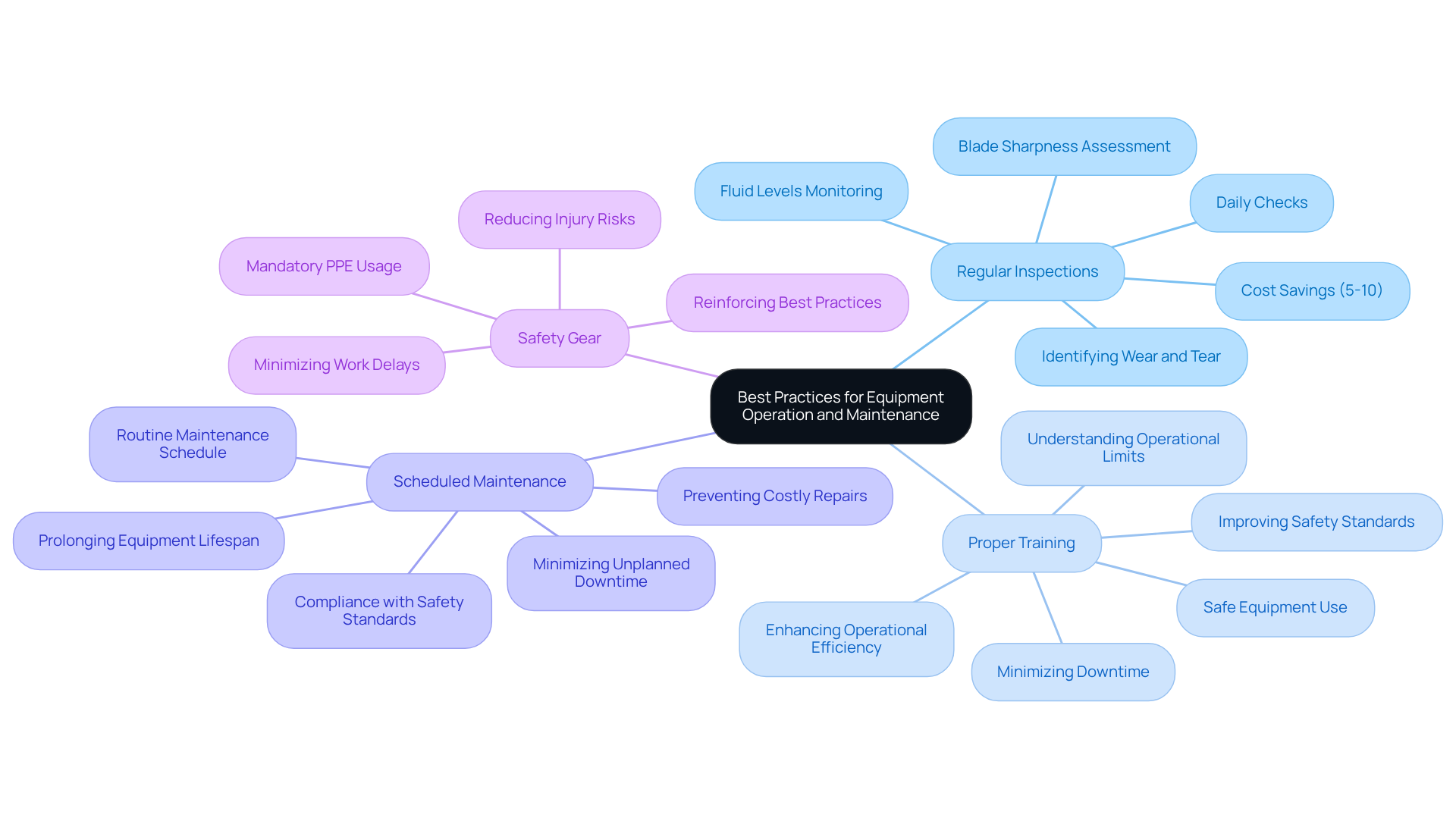

To ensure the effective operation and longevity of brush clearing equipment, project managers should implement several best practices:

-

Regular Inspections: Conduct daily checks on equipment before use, focusing on fluid levels, blade sharpness, and overall condition. Address any issues immediately to prevent breakdowns. Regular inspections help identify wear and tear, allowing for targeted replacements that extend the lifespan of machinery. Industry data indicates that regular maintenance can save 5 to 10% in material and maintenance costs.

-

Proper Training: Ensure that all operators are trained in the safe and effective use of tools. This includes understanding operational limits and security protocols. Training has been shown to reduce downtime by minimizing failures caused by misuse or mishandling, ultimately enhancing operational efficiency. A well-organized training program significantly lowers the risk of accidents and improves adherence to safety standards.

-

Scheduled Maintenance: Establish a routine maintenance schedule based on manufacturer recommendations. Regular servicing can prevent costly repairs and prolong the lifespan of machinery. A structured maintenance schedule ensures that inspections, servicing, and repairs occur at appropriate intervals, minimizing unplanned downtime and ensuring compliance with safety standards. Case studies indicate that aging machinery is a leading cause of downtime, emphasizing the need for proactive maintenance.

-

Safety Gear: Mandate the use of appropriate personal protective equipment (PPE) for all operators, including gloves, goggles, and hard hats, to minimize the risk of injury. Frequent training sessions reinforce best practices and keep employees informed on security protocols. Neglecting protective equipment can lead to higher injury rates and work delays.

By adhering to these best practices, project managers can enhance the safety and efficiency of their brush clearing equipment operations, leading to successful project outcomes. Implementing these strategies not only improves operational performance but also fosters a culture of safety and reliability within the team.

Conclusion

Effective brush clearing necessitates careful planning, appropriate equipment, and adherence to established practices. By grasping the essential components of project requirements, equipment selection, and operational strategies, project managers can significantly improve the efficiency and safety of their brush clearing efforts.

This article outlines critical steps for success, including:

- Assessing project needs

- Selecting suitable brush clearing machinery

- Implementing effective maintenance practices

Key considerations such as evaluating vegetation types, identifying hazards, and engaging stakeholders are highlighted, ensuring that projects align with their intended objectives. Moreover, the significance of regular equipment inspections, operator training, and the use of personal protective equipment is paramount, as these factors enhance operational reliability and mitigate risks.

Ultimately, the success of brush clearing projects relies on informed decision-making and proactive management. By embracing these best practices, project managers can not only meet their immediate goals but also foster a culture of safety and efficiency that benefits all stakeholders involved. Adopting these strategies will set the stage for future projects, ensuring that brush clearing operations are conducted with precision and care, leading to sustainable outcomes.

Frequently Asked Questions

Why is it important to assess project requirements before brush clearing?

Assessing project requirements is crucial to evaluate the size of the area to be cleared, the types of vegetation present, and any potential hazards, such as overhead power lines or underground utilities. This helps in selecting appropriate equipment and techniques for the project.

What factors should be evaluated during the assessment for brush clearing?

Factors to evaluate include the size of the area, types of vegetation, potential hazards (like overhead power lines and underground utilities), and the specific goals of the initiative (construction, landscaping, or ecological restoration).

How do project goals influence the brush clearing approach?

The goals of the initiative influence the approach to brush clearing; for instance, preparing land for construction may require a more aggressive clearing method compared to an initiative focused on habitat restoration.

What are some best practices for conducting assessments in brush clearing projects?

Best practices include evaluating vegetation types, identifying hazards, setting clear objectives, and engaging stakeholders early in the process to align expectations and objectives.

What types of equipment does EZ Equipment Rental offer for brush clearing?

EZ Equipment Rental offers a range of brush clearing equipment, including brush cutters, chippers, and boom lifts, tailored to meet specific project needs.

How can EZ Equipment Rental assist during the brush clearing process?

The team at EZ Equipment Rental provides expert guidance and support throughout the rental experience, ensuring smooth operations and safety during brush clearing tasks.

What is the significance of planning in brush clearing projects?

Comprehensive planning is essential for achieving successful results in brush clearing projects, as emphasized by Dwight D. Eisenhower's quote, "Plans are nothing; planning is everything."

List of Sources

- Assess Project Requirements for Brush Clearing

- 19 Timeless Project Management Quotes for Success (https://proofhub.com/articles/project-management-quotes)

- 16 Best Project Management Quotes (https://projectmanager.com/blog/10-best-project-management-quotes)

- The 62 Most Inspiring Project Management Quotes (https://inloox.com/company/blog/articles/the-62-most-inspiring-project-management-quotes)

- 50+ Project Management Quotes to Learn From (https://proprofsproject.com/blog/project-management-quotes)

- 46 Project Planning Quotes to Inspire Successful Teams | Workzone (https://workzone.com/blog/project-planning-quotes)

- Explore Types of Brush Clearing Equipment

- Best Equipment for Efficient Land and Brush Clearing (https://dozr.com/blog/best-equipment-for-efficient-land-and-brush-clearing)

- The Best Equipment To Clear Land and Brush | BigRentz (https://bigrentz.com/blog/equipment-to-clear-land?srsltid=AfmBOopjqc3gREk9t6b-dxgvefYqUk-WA4Mrd3JA4zwZOxwtAHFoEM2e)

- Land Clearing Equipment Market Size, Scope, Insights & Future Outlook 2026-2033 (https://linkedin.com/pulse/land-clearing-equipment-market-size-scope-insights-future-4xljf)

- Evaluate Equipment Performance and Reliability

- Choosing the Right Equipment for Effective Land Clearing - Connections Arbor Care LLC (https://treesvcinnj.com/blog/choosing-the-right-equipment-for-effective-land-clearing)

- Evaluating Roadside Mowing Equipment for Long-Term Use (https://energreenamerica.com/evaluating-roadside-mowing-equipment-for-long-term-use)

- Implement Best Practices for Equipment Operation and Maintenance

- Equipment Maintenance: Importance, Definition, & Examples (https://redbeam.com/blog/equipment-maintenance)

- 6 ways regular maintenance prolongs equipment life | Veritek (https://veritekglobal.com/blog/6-ways-regular-maintenance-can-help-prolong-equipment-life)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- Key Facts and Statistics on Equipment Maintenance (https://gocodes.com/maintenance-management/equipment-maintenance-statistics)

- Equipment Maintenance: The Ultimate Guide | SafetyCulture (https://safetyculture.com/topics/equipment-maintenance)