Key Highlights:

- Concrete buckets are essential tools for transporting and dispensing cement at construction sites, especially in hard-to-reach areas.

- They reduce spillage, lower labour costs, and enhance the speed of material placement, contributing to project efficiency.

- Key features of effective concrete buckets include high-quality steel construction, tapered bottoms for precise pouring, and hydraulic chutes for better flow control.

- Best practises for using concrete buckets involve securing them properly, familiarising with controls, and maintaining a steady pace to prevent accidents.

- Regular inspections for damage and adherence to load limits are critical for safety; improper use can significantly increase incident rates on sites.

- Clear communication among team members is vital during operations to enhance safety and prevent accidents.

- Training and preparedness for emergencies, along with proper attire, are essential for safe handling of concrete buckets.

Introduction

The construction industry relies heavily on efficiency and precision, where every tool is crucial for achieving project success. Among these tools, concrete buckets for skid steers are essential equipment, specifically designed to facilitate the transportation and pouring of cement in even the most challenging environments. This article explores best practices for utilizing these powerful tools, highlighting how their effective use can significantly boost productivity while minimizing risks on construction sites.

Operators often encounter various challenges when using concrete buckets; understanding these obstacles and implementing strategies to overcome them is vital for ensuring both safety and efficiency.

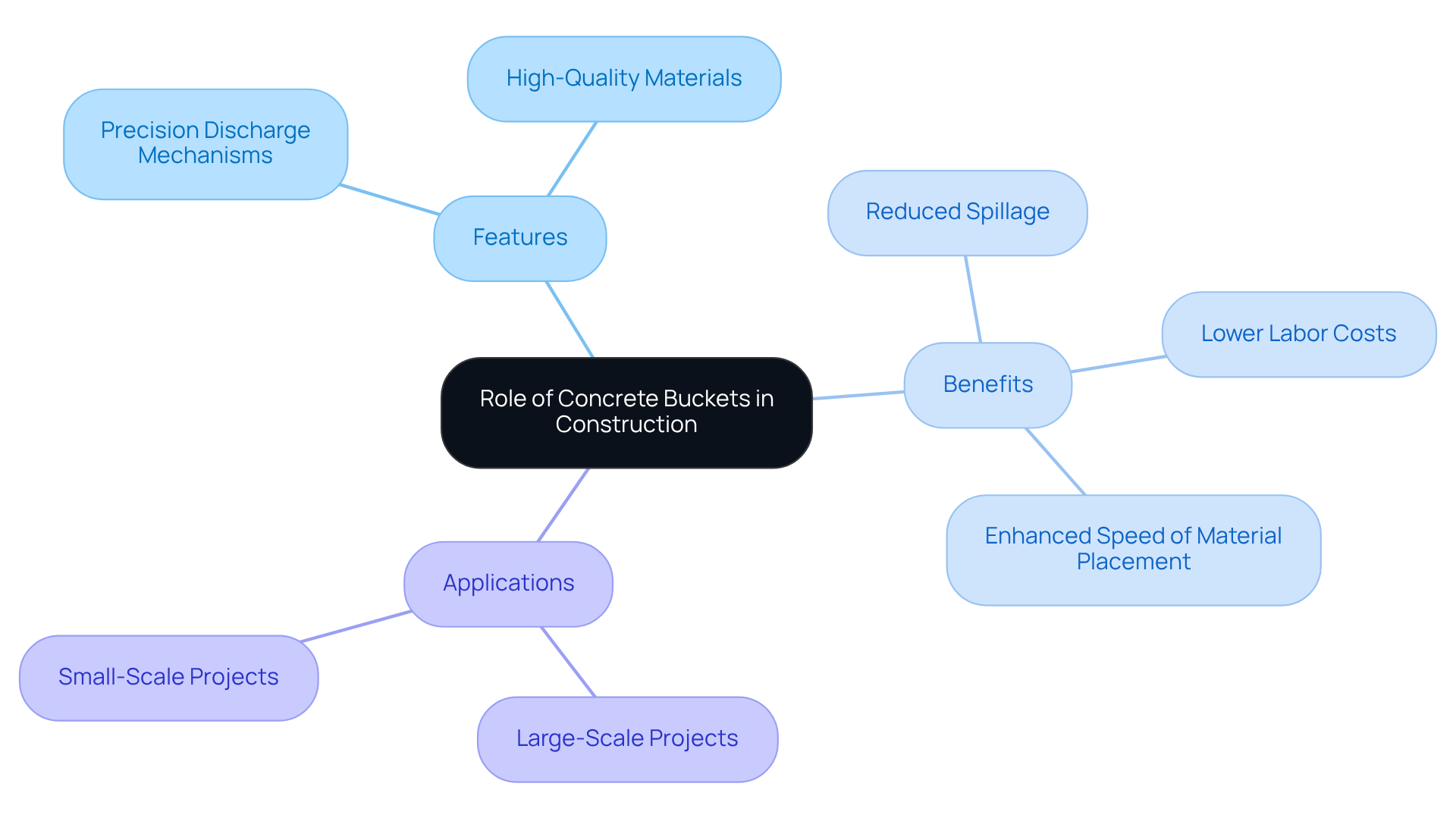

Understand the Role of Concrete Buckets in Construction

Cement containers are specialized tools designed to transport and dispense cement efficiently at construction sites. They are essential for delivering material accurately to challenging locations that conventional trucks may not reach. By utilizing robust containers, construction teams can reduce spillage, lower labor costs, and enhance the speed of material placement. In confined spaces or elevated areas, cement containers allow for precise pouring, which is vital for maintaining the structural integrity of buildings.

These containers often feature precision discharge mechanisms and high-quality materials that facilitate easy loading and controlled pouring. This makes them indispensable for both large-scale and small-scale projects. Construction professionals acknowledge the significance of these tools, frequently highlighting their contribution to improved project outcomes and safety standards. With their durable design and compatibility with various excavator models, cement containers represent a sound investment for any construction endeavor.

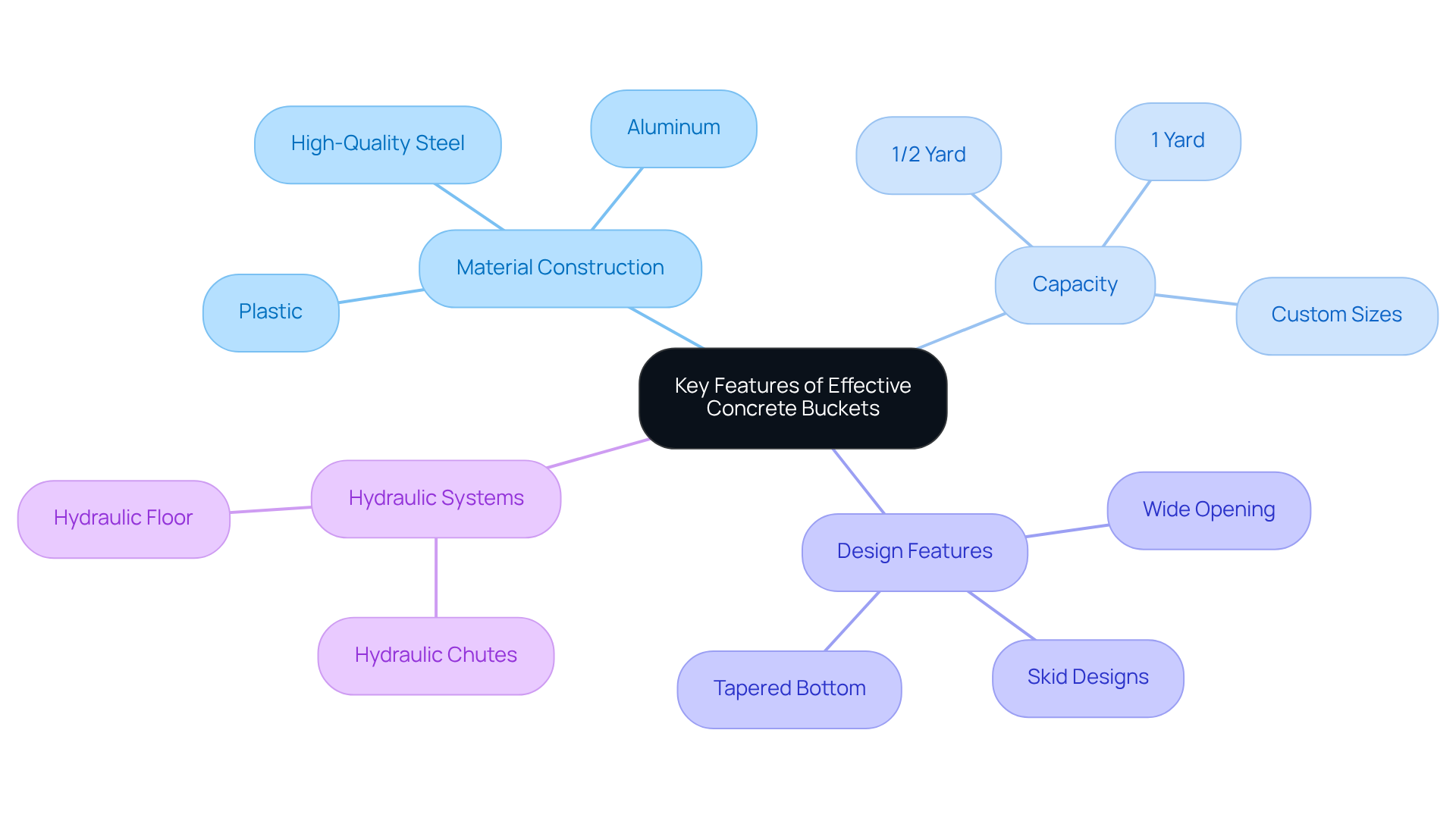

Identify Key Features of Effective Concrete Buckets

When selecting a concrete container, it is essential to consider several key features to ensure optimal performance. The material construction is paramount; high-quality steel containers offer durability and resistance to wear and tear. Additionally, the container's capacity must align with the project's scale, with common sizes ranging from 1/2 yard to 1 yard. A well-designed container will also include:

- A tapered bottom for precise pouring

- A wide opening for easy filling

Furthermore, hydraulic chutes can enhance control over the flow of cement, facilitating accurate placement. For example, a container equipped with a hydraulic floor can help regulate the discharge rate, minimizing the risk of spillage and ensuring a smooth pour.

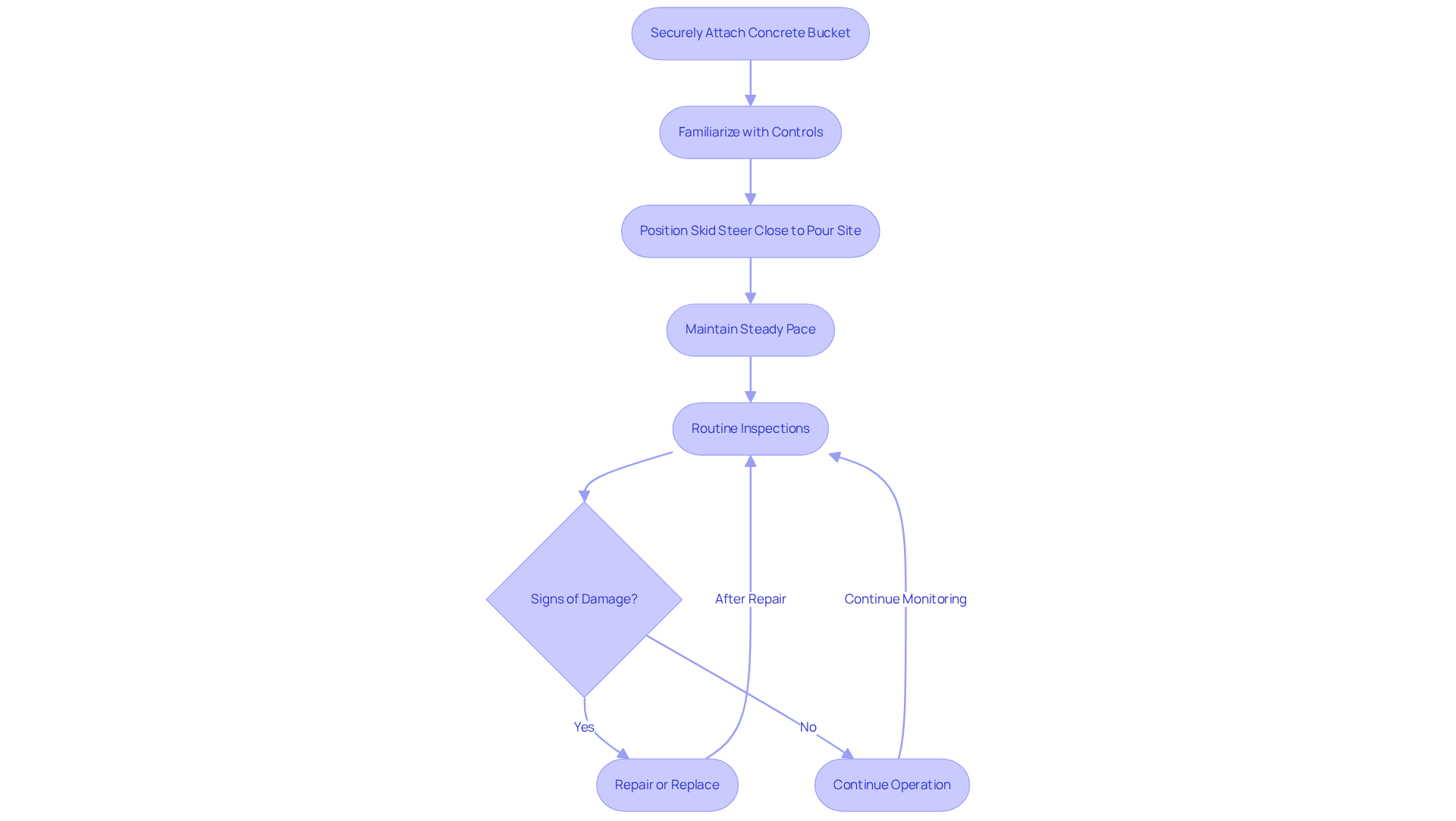

Implement Best Practices for Efficient Use of Concrete Buckets

To maximize the efficiency and safety of concrete containers, operators must adhere to several best practices. First, it is crucial to ensure that the concrete bucket for skid steer is securely attached to the skid steer before use. Familiarity with the container's controls, especially if it includes hydraulic functions, is essential for effective operation. Positioning the skid steer as close to the pour site as possible minimizes spillage and optimizes the pouring angle.

During operation, maintaining a steady pace is vital to avoid overloading the container, which can lead to instability and accidents. Routine examinations of the container for signs of deterioration or damage are essential; operators should inspect for fractures or indentations after each use to prevent costly repairs and ensure safe operation. Statistics indicate that improper use of concrete buckets significantly increases the risk of incidents on construction sites, underscoring the importance of these precautionary measures. Research shows that nearly 30% of construction site incidents are linked to equipment misuse, highlighting the necessity for appropriate training and adherence to safety protocols.

As construction expert Dan Petersen emphasizes, 'Individuals, not documents, preserve lives in protection.' Furthermore, operators should be aware of common pitfalls, such as neglecting load limits or failing to secure the container properly, which can lead to hazardous situations. By following these guidelines and utilizing a concrete bucket for skid steer that is designed for durability, operators can enhance both the efficiency and safety of their operations.

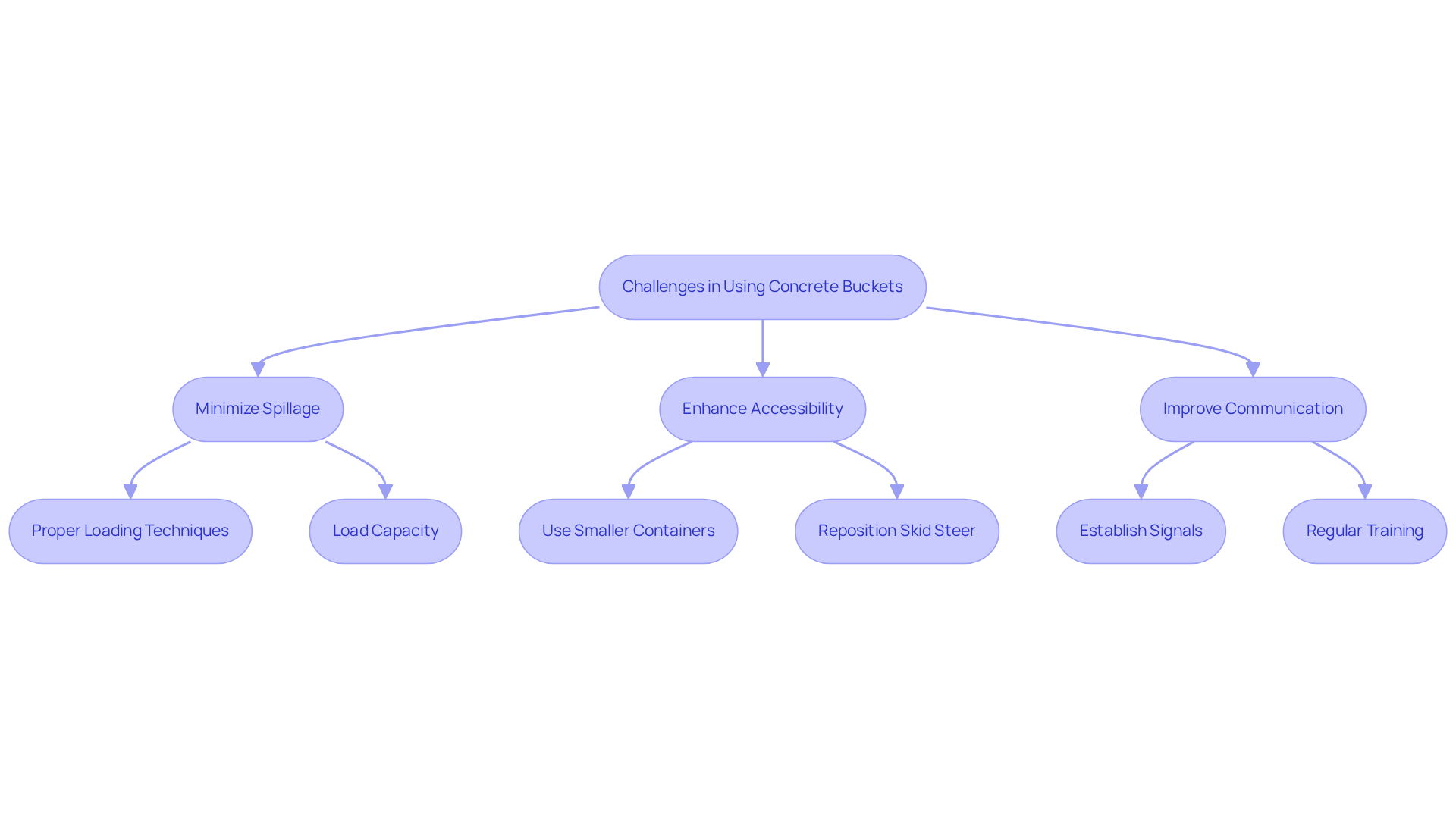

Overcome Challenges in Using Concrete Buckets

Effectively managing concrete containers requires addressing challenges such as spillage, access to tight spaces, and handling heavy loads. To minimize spillage, operators should adhere to proper loading techniques, ensuring containers are not overloaded, as this can compromise stability. Research indicates that spillage rates can be significantly reduced by maintaining a load within the container's capacity, with estimates suggesting that proper loading can decrease spillage by as much as 30%. In confined spaces, opting for smaller containers or repositioning the skid steer can enhance accessibility and control.

Clear communication among team members is vital during concrete pouring operations. Establishing distinct signals for lifting and lowering the bucket can prevent accidents and promote a coordinated effort. As trainers emphasize, "Clear communication is the foundation of security on site; if team members feel empowered to voice concerns about potential risks, we can avert accidents before they occur." Regular training sessions, including emergency drills, prepare operators for unforeseen circumstances, bolstering their ability to respond efficiently and safely. Additionally, wearing waterproof gloves and long-sleeve attire when handling wet material is crucial to prevent skin injuries. By prioritizing these practices, construction teams can enhance both safety and efficiency when using a concrete bucket for skid steer.

Conclusion

Concrete buckets are essential for improving the efficiency and safety of construction projects, especially when paired with skid steers. Their specialized design facilitates precise material delivery, making them vital tools on job sites where traditional methods may not suffice. By recognizing their importance and adhering to best practices, construction teams can enhance their operations and achieve successful project outcomes.

This article has provided key insights, covering the essential features to consider in high-quality concrete buckets and the best practices for their effective use. Highlighting the significance of proper loading techniques, routine inspections, and clear communication among team members can greatly mitigate risks and boost overall efficiency. Furthermore, being aware of challenges related to concrete buckets, such as spillage and accessibility, empowers operators to implement proactive measures that enhance safety and performance.

In summary, the effective utilization of concrete buckets is vital for attaining successful results in construction projects. By embracing the best practices discussed, construction professionals can protect their teams and streamline their operations. Investing in quality equipment and prioritizing safety measures will ultimately foster more efficient workflows and improved project outcomes. Adopting these strategies will maximize the potential of concrete buckets and elevate construction efficiency to new heights.

Frequently Asked Questions

What are concrete buckets used for in construction?

Concrete buckets are specialized tools designed to transport and dispense cement efficiently at construction sites, allowing for accurate delivery to challenging locations.

How do concrete buckets benefit construction teams?

They help reduce spillage, lower labor costs, and enhance the speed of material placement, especially in confined spaces or elevated areas.

What features do concrete buckets typically have?

Concrete buckets often feature precision discharge mechanisms and are made from high-quality materials that facilitate easy loading and controlled pouring.

Are concrete buckets suitable for both large and small construction projects?

Yes, concrete buckets are indispensable for both large-scale and small-scale projects.

Why are concrete buckets important for maintaining structural integrity?

They allow for precise pouring, which is vital for maintaining the structural integrity of buildings.

How do construction professionals view the significance of concrete buckets?

Construction professionals frequently highlight their contribution to improved project outcomes and safety standards.

Are concrete buckets compatible with different types of equipment?

Yes, they have a durable design and are compatible with various excavator models, making them versatile for construction endeavors.

List of Sources

- Understand the Role of Concrete Buckets in Construction

- Masterhitch Concrete Buckets (https://masterhitch.co.uk/blog/concrete-bucket-to-improve-efficiency)

- VLIFT Concrete Bucket: The Smarter Way to Pour Concrete on Construction Sites - VLIFT | Material Handling and Lifting Solutions (https://vliftuae.com/vlift-concrete-bucket-the-smarter-way-to-pour-concrete-on-construction-sites)

- Identify Key Features of Effective Concrete Buckets

- Best Cement Pouring Buckets | Del Zotto Products (https://delzottoproducts.com/2016/08/29/best-cement-pouring-buckets)

- Aluminum and Steel Concrete Bucket Market Size, Share, Trends & Forecast Report 2035 (https://marketresearchfuture.com/reports/aluminum-steel-concrete-bucket-market-34995)

- North America Aluminum and Steel Concrete Bucket Market, 2031 (https://persistencemarketresearch.com/market-research/north-america-aluminum-and-steel-concrete-bucket-market.asp)

- Implement Best Practices for Efficient Use of Concrete Buckets

- Improving Concrete Durability: Real World Case Study (https://linkedin.com/pulse/improving-concrete-durability-real-world-case-study-iroce)

- Masterhitch Concrete Buckets (https://masterhitch.co.uk/blog/concrete-bucket-to-improve-efficiency)

- Material Handling in Pindwara Cement Plant | PDF | Cement | Belt (Mechanical) (https://scribd.com/document/547859110/12945HA)

- 119 Construction Quotes that Hit the Nail on the Head | BigRentz (https://bigrentz.com/blog/construction-quotes?srsltid=AfmBOooaet_yjNH6sSs_rR84hdewCM4etDTxe3cHy5t1cmmjghy3NWQT)

- Top 20 Safety Quotes To Improve Your Safety Culture (https://blog.safetyculture.com/industry-trends/top-20-safety-quotes-improve-safety-culture)

- Overcome Challenges in Using Concrete Buckets

- Top 20 Safety Quotes To Improve Your Safety Culture (https://blog.safetyculture.com/industry-trends/top-20-safety-quotes-improve-safety-culture)

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- Concrete Work – The Hazards of Working with Concrete Stats and Facts (https://icwgroup.safetynow.com/concrete-work-the-hazards-of-working-with-concrete-stats-and-facts?print=pdf)

- Concrete Safety Precautions | Working With Concrete Safely (https://dcpu1.com/blog/concrete-safety)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)