Key Highlights:

- Forklift chargers convert AC from the power grid into DC to recharge forklift batteries.

- Different battery types, such as lead-acid and lithium-ion, require specific chargers with varying recharge times.

- Safety practises include ensuring charger compatibility, preventing overheating, and following manufacturer guidelines.

- Types of forklift chargers include traditional power supply units, opportunity devices, quick power sources, and intelligent power sources.

- Regular maintenance and proper ventilation are crucial to prevent hazards during charging.

- Using personal protective equipment (PPE) is essential when handling batteries and chargers to ensure safety.

Introduction

Understanding the complexities of forklift chargers is crucial for enhancing the efficiency and safety of material handling operations. These devices play a vital role in ensuring a consistent power supply for forklifts, and having a solid grasp of their types, functions, and best practices can lead to notable operational improvements.

With various charger types available and important safety considerations to keep in mind, operators must be equipped to make informed choices tailored to their specific needs.

Explore the Basics of Forklift Chargers

Forklift chargers play a vital role in restoring energy to forklift power sources, ensuring these machines operate efficiently. For operators and maintenance personnel, understanding their function is essential.

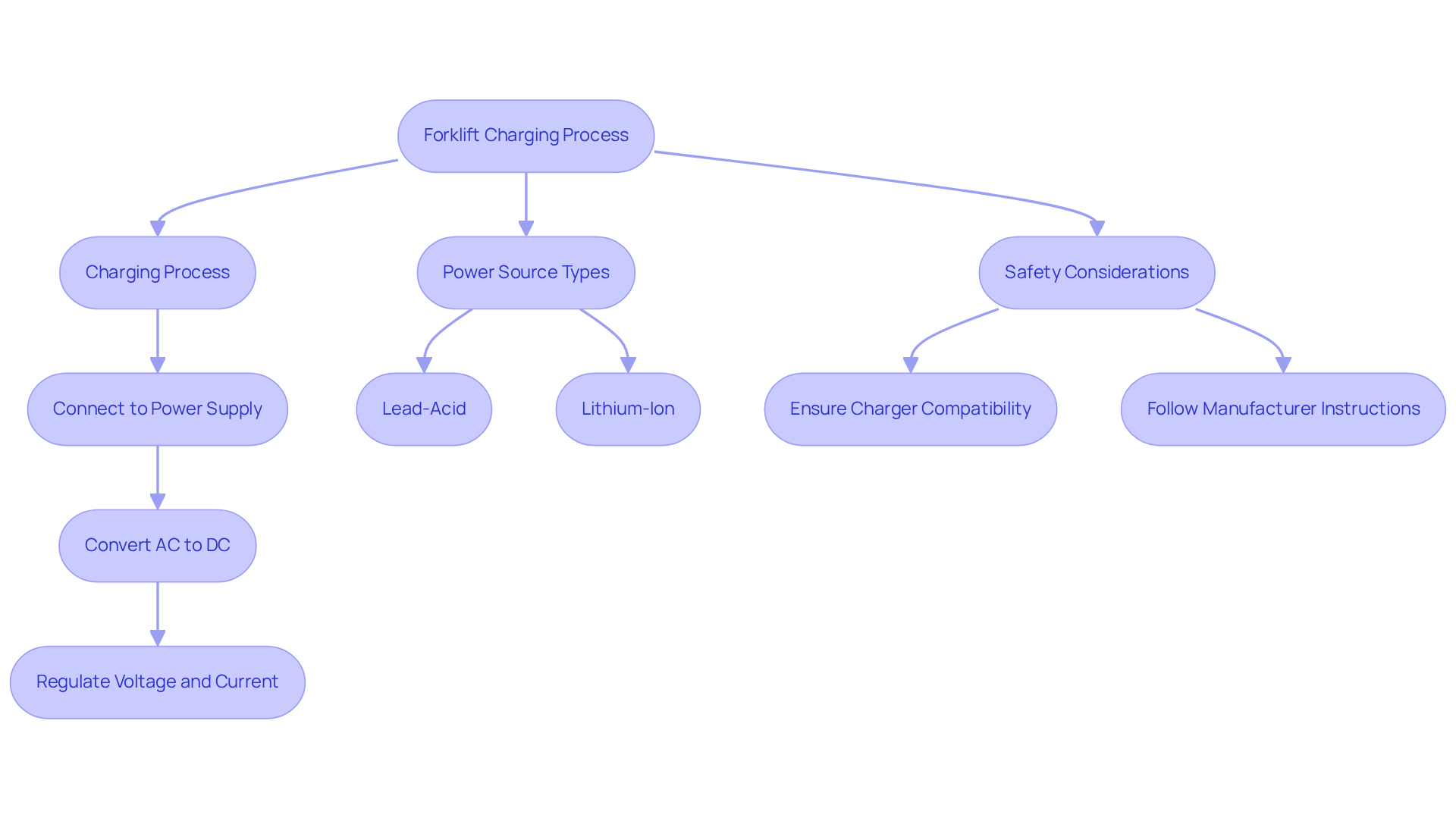

- Charging Process: When a forklift connects to a power supply, the device converts alternating current (AC) from the power grid into direct current (DC), which powers the energy storage unit. This process involves several components, including transformers and rectifiers, that regulate voltage and current to prevent overcharging.

- Power Source Types: Different types of cells, such as lead-acid and lithium-ion, require specific chargers. Lead-acid batteries typically need longer recharging durations, while lithium-ion cells can be replenished more quickly and efficiently.

- Safety Considerations: Adhering to proper charging practices is crucial to avoid hazards like overheating or damage to the power source. Always ensure that the forklift charger is compatible with the energy cell type and follow manufacturer instructions for safe usage.

Identify Different Types of Forklift Chargers

Forklift chargers are available in several types, each designed to meet specific operational needs:

-

Traditional Power Supply Units: These units are primarily intended for lead-acid batteries and require a lengthy replenishment period of approximately 8-10 hours. They are best suited for single-shift operations, where forklifts are charged overnight, ensuring readiness for the following day. While this method is straightforward for power sources, it may necessitate multiple units for continuous operations, potentially leading to increased risks and higher costs due to replacements.

-

Opportunity Devices: These chargers enable short charging sessions during breaks or downtime, making them particularly beneficial for multi-shift operations. They can recharge batteries quickly, often within 1-2 hours, thereby maximizing equipment uptime and productivity. It is crucial to ensure that devices like the forklift charger comply with international safety standards such as UL, CE, and IEC to maintain safe operation.

-

Quick Power Sources: Designed for rapid replenishment, quick power sources can restore energy in as little as 30 minutes. This feature is vital for operations that require continuous forklift usage, significantly reducing downtime and enhancing operational efficiency. High-efficiency devices, such as those from ROYPOW, achieve over 92% efficiency, minimizing energy waste and operational costs.

-

Intelligent Power Sources: These advanced chargers utilize sophisticated technology to continuously monitor energy health and adjust power parameters in real-time. This functionality helps prevent overcharging, optimizes the charging process, and ultimately extends battery life, making them a prudent investment for modern fleets. Additionally, using power adapters from the same brand ensures better compatibility and support, which is essential for maintaining warranty claims and addressing issues.

Understanding the differences between these power supply types is crucial for selecting the right forklift charger that aligns with operational requirements and enhances overall efficiency. Evaluating factors such as daily energy consumption, charging time, and potential fleet expansion will further assist in making informed decisions.

Implement Best Practices for Forklift Charger Usage

To ensure the safe and efficient operation of forklift chargers, it is essential to adhere to the following best practices:

-

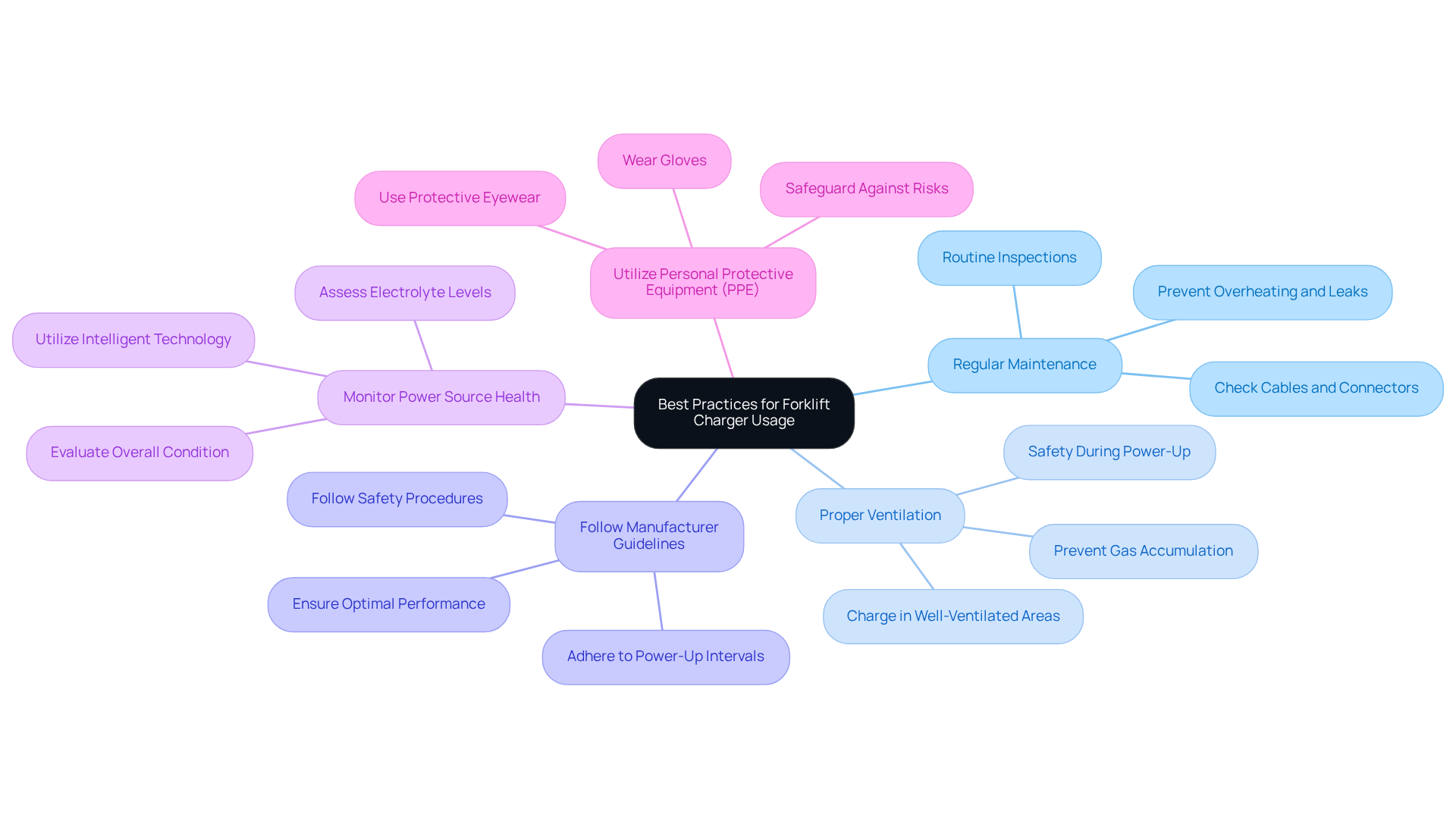

Regular Maintenance: Conduct routine inspections of chargers to identify any wear and tear. Ensure that cables and connectors are intact to mitigate electrical hazards. Regular maintenance enhances safety by preventing issues such as leaks, overheating, and explosions.

-

Proper Ventilation: Always charge cells in well-ventilated areas to prevent the accumulation of harmful gases, particularly with lead-acid types. Safety experts emphasize that sufficient ventilation is vital during the power-up process to reduce hazards linked to gas accumulation. As specialists note, 'Adequate ventilation is crucial to guarantee security during battery recharging.'

-

Follow Manufacturer Guidelines: Strictly adhere to the manufacturer's instructions regarding power-up intervals, procedures, and precautionary measures. This ensures optimal performance and safety during operation. Electric forklift chargers are essential as they convert alternating current (AC) from the power grid into direct current (DC) for charging, highlighting the importance of adhering to these guidelines.

-

Monitor Power Source Health: Regularly assess electrolyte levels (for lead-acid types) and the overall condition of the power source. Consistent upkeep can significantly prolong the lifespan of the power source and improve performance. Advanced power sources with intelligent technology adjust the charging rate according to the cell’s status, enhancing security and efficiency.

-

Utilize Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves and protective eyewear, when handling batteries and power supplies to safeguard against potential risks.

Implementing these practices not only enhances security but also reduces incident rates associated with improper charger usage, fostering a safer working environment. Statistics indicate that neglecting these practices can lead to increased safety incidents, underscoring the importance of following these guidelines.

Conclusion

Understanding the fundamentals of forklift chargers is essential for anyone involved in the operation and maintenance of these vital machines. Mastering how these chargers function, the various types available, and the best practices for their usage not only enhances operational efficiency but also ensures workplace safety.

Key insights from this article emphasize the importance of selecting the appropriate charger based on battery type and operational needs. From traditional power supply units to advanced intelligent power sources, each charger type presents unique advantages tailored to different operational demands. Furthermore, adhering to best practices - such as regular maintenance, ensuring proper ventilation, and following manufacturer guidelines - can significantly reduce safety risks and extend the lifespan of both chargers and batteries.

In conclusion, prioritizing knowledge and safety regarding forklift chargers is imperative in today’s fast-paced industrial environments. By implementing the insights and practices outlined, operators can optimize performance while minimizing hazards. Embracing these principles not only leads to more efficient operations but also fosters a culture of safety and responsibility within the workplace.

Frequently Asked Questions

What is the purpose of forklift chargers?

Forklift chargers are essential for restoring energy to forklift power sources, ensuring that these machines operate efficiently.

How does the charging process for forklifts work?

When a forklift connects to a power supply, the charger converts alternating current (AC) from the power grid into direct current (DC), which powers the energy storage unit. This process involves components like transformers and rectifiers that regulate voltage and current to prevent overcharging.

What types of power sources do forklift chargers support?

Forklift chargers support different types of cells, including lead-acid and lithium-ion batteries. Each type requires specific chargers due to their differing recharging needs.

How do lead-acid and lithium-ion battery charging times differ?

Lead-acid batteries typically require longer recharging durations, while lithium-ion cells can be replenished more quickly and efficiently.

What safety considerations should be taken into account when using forklift chargers?

It is crucial to adhere to proper charging practices to avoid hazards such as overheating or damage to the power source. Always ensure compatibility between the forklift charger and the energy cell type, and follow manufacturer instructions for safe usage.

List of Sources

- Explore the Basics of Forklift Chargers

- Forklift Chargers 2026-2033 Analysis: Trends, Competitor Dynamics, and Growth Opportunities (https://archivemarketresearch.com/reports/forklift-chargers-477634)

- Forklift Battery Performance Metrics: A Detailed Analysis (https://greencubes.com/blog/in-depth-analysis-the-performance-metrics-of-forklift-batteries)

- Forklift Battery Charger Basics (https://totalwarehouse.com/blogs/forklift-battery-charger-basics)

- How Long Does It Take to Charge a Forklift Battery? A Practical Guide for Operations Managers | Leoch Lithium America (https://leochlithium.us/how-long-does-it-take-to-charge-a-forklift-battery-a-practical-guide-for-operations-managers)

- Identify Different Types of Forklift Chargers

- Everything You Need to Know About Forklift Battery Chargers (https://fluxpower.com/blog/everything-you-need-to-know-about-forklift-battery-chargers)

- Forklift Battery Charger: How to Choose the Best Charger for Your Fleet (https://roypow.com/blog/forklift-battery-charger-how-to-choose-the-best-charger-for-your-fleet)

- Forklift Chargers Market Export Stats, Import Stats & Trends 2033 (https://linkedin.com/pulse/forklift-chargers-market-export-stats-import-trends-2033-amere)

- Forklift Batteries: Conventional Vs. Fast Vs. Opportunity Charging (https://total-ind.com/blog/forklift-battery-charging-fast-opportunity-conventional?srsltid=AfmBOor0GCnXha756_3QV207SGmUfqeyyUKSSwBlb_ELpXEg35_MiZPJ)

- Implement Best Practices for Forklift Charger Usage

- Electric Forklift Chargers: What You Need to Know (https://liftpartswarehouse.com/article-a/electric-forklift-chargers?srsltid=AfmBOooRkDU0gQ8bnbGshCvCFpsXJYgv-Azn0p-rj2bVKKc-X4GKSDDs)

- The Importance of Battery Maintenance - Remis Power Systems Inc. (https://remispowersystems.com/2023/12/the-importance-of-battery-maintenance)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Top 10 Tips for Forklift Battery Maintenance You Should Know? (https://gdtitanspower.com/blog/top-tips-for-forklift-battery-maintenance)