Key Highlights:

- Forklifts consist of key components: mast, forks, counterweight, power source, and chassis, each vital for safe and efficient operation.

- The mast is crucial for lift height and stability, impacting safety and efficiency on construction sites.

- Forks must be selected based on their length and design to match the specific weight and transport needs.

- Counterweights stabilise loads, preventing tipping, especially on uneven terrain; regular maintenance is essential for safety.

- The power source influences operational costs and suitability; electric forklifts are ideal for indoor use, while diesel is better for outdoor tasks.

- Chassis design affects durability and stability, crucial for demanding construction environments.

- Selecting the right forklift involves assessing load capacity, terrain, lift height, manoeuvrability, and any special features needed for the project.

- Ergonomic features like adjustable seating, control placement, visibility, vibration dampening, and easy entry enhance operator comfort and productivity.

- Regular maintenance practises, including daily inspections, scheduled maintenance, lubrication, battery maintenance, and record keeping, are vital for reliability and safety.

- Implementing best practises in maintenance can significantly improve forklift performance and reduce operational risks.

Introduction

In the dynamic realm of construction, the efficiency of operations significantly relies on the capabilities of lift trucks. Understanding the intricacies of forklift design is not merely advantageous; it is crucial for maximizing safety and productivity on job sites. This article explores the essential components and best practices of forklift design, illustrating how strategic choices can enhance construction efficiency.

With a multitude of options and design considerations available, construction managers must ask: how can they select the right forklift tailored to their specific needs while prioritizing operator safety and comfort?

Understand Core Components of Forklift Design

Forklifts are essential machines made up of several key components that work together to ensure efficient operation. Understanding these components is crucial for selecting the right forklift for specific construction tasks, especially with the diverse fleet available at EZ Equipment Rental in Dallas.

-

Mast: The mast is the vertical assembly responsible for raising and lowering loads. Its design is vital for determining lift height and stability, which directly impacts construction safety. An effective forklift design can prevent accidents and enhance operational efficiency on job sites.

-

Forks: These prongs are engineered to lift and transport items. The length and forklift design of the forks significantly influence the types of weights that can be managed, making it essential to choose forks that align with the specific needs of the task at hand.

-

Counterweight: This component stabilizes the load being lifted, preventing the vehicle from tipping over. Proper counterweighting is critical for safety, particularly on uneven terrain, where stability is paramount. Regular maintenance of the counterweight is necessary to avoid operational hazards.

-

Power Source: Forklifts can be powered by electric batteries, propane, or diesel engines. The choice of power source affects operational costs and suitability for indoor or outdoor use. For instance, electric lift trucks produce zero emissions, making them ideal for indoor environments, while diesel models may be better suited for outdoor tasks. EZ Equipment Rental's fleet features both electric and rough terrain lifting machines, ensuring clients find the perfect fit for their specific needs.

-

Chassis: The chassis serves as the frame that supports all other components. A robust chassis is essential for durability and stability, especially in demanding construction environments. The performance and security of the lifting vehicle can be greatly affected by the forklift design criteria of the chassis.

Understanding these elements is vital for choosing the right lift truck for particular tasks, ensuring both safety and efficiency on the job site. As industry leaders emphasize, investing in quality forklift design and maintenance can lead to significant improvements in productivity and safety outcomes.

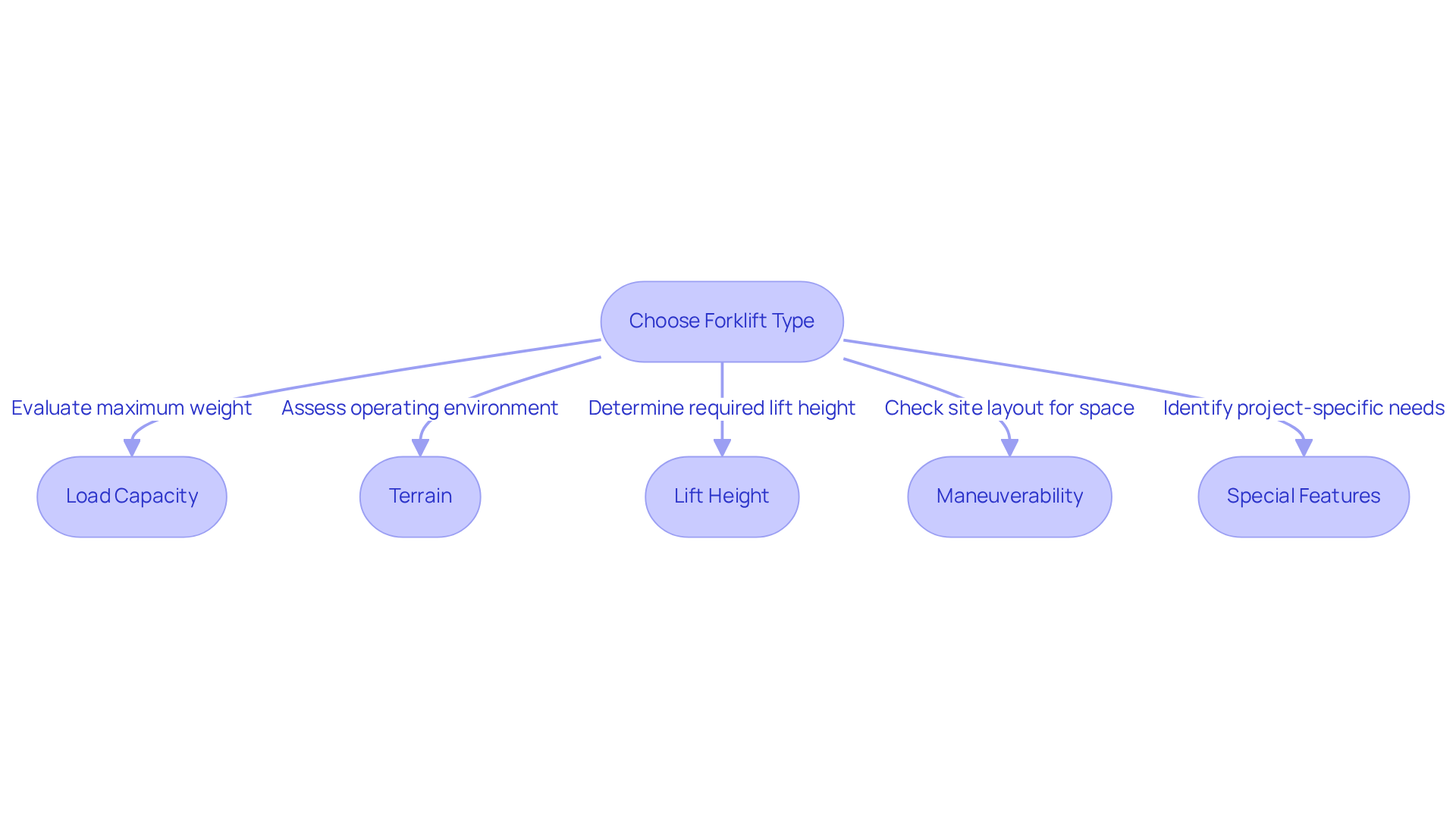

Choose the Right Forklift Type for Your Project

Choosing the right type of lift is essential for ensuring that construction tasks are executed effectively and safely. Here are some critical considerations:

-

Load Capacity: Assess the maximum weight that needs to be lifted. The rating of forklifts for specific weight capacities is an important aspect of forklift design, typically based on a 24-inch center of mass. Selecting a lifting device that can handle the required load without exceeding its specified capacity is vital, as overloading can lead to accidents and injuries.

-

Terrain: Consider the environment where the lifting device will operate. For rough terrain, a vehicle designed for such conditions, featuring larger tires and higher ground clearance, is ideal for navigating uneven surfaces. Conversely, for indoor applications, electric lift trucks are often preferred due to their reduced emissions and quieter operation, making them suitable for confined spaces.

-

Lift Height: Determine the height to which loads need to be lifted. Reach vehicles excel in high stacking scenarios, while counterbalance machines are better suited for lower heights. Understanding the necessary lift height is crucial, as it directly influences the forklift design and its operational efficiency.

-

Maneuverability: In tight spaces, a narrow aisle lifting vehicle may be required. Evaluate the layout of the job site to ensure the lifting equipment can move efficiently without risking collisions or damage to materials. Clear sight lines and designated pathways enhance safety and effectiveness in maneuvering.

-

Special Features: Some projects may necessitate specialized lifting equipment, such as telehandlers for raising materials to elevated locations or pallet jacks for transporting pallets. Assessing the specific needs of the project will aid in selecting the right equipment that boosts operational performance.

By thoroughly evaluating these factors, construction managers can select the appropriate lifting equipment that not only meets operational demands but also prioritizes safety and productivity on the job site.

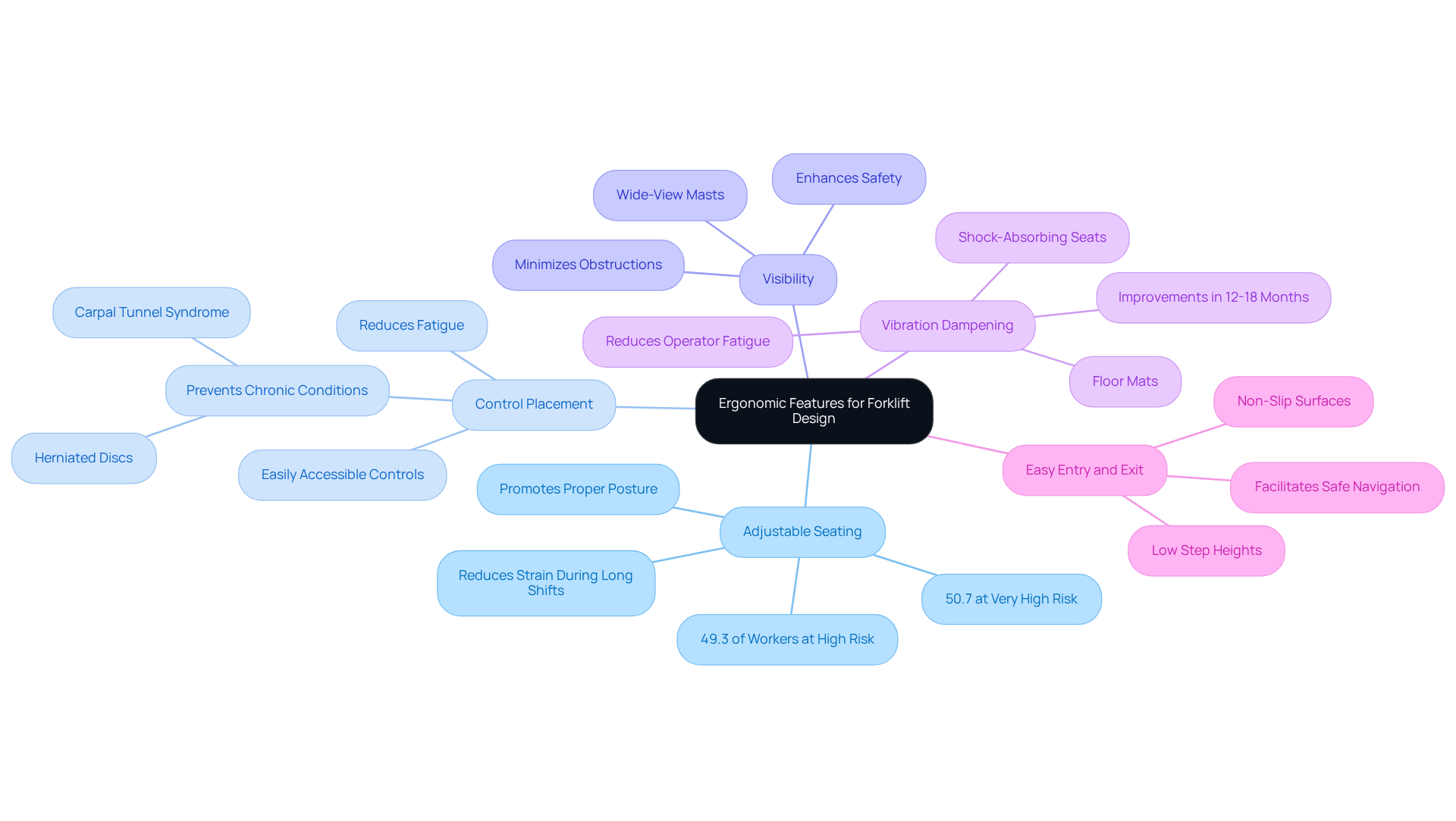

Incorporate Ergonomic Features for Enhanced Operator Efficiency

Ergonomics plays a crucial role in forklift design, significantly affecting operator comfort and productivity. By focusing on key ergonomic features, companies can create a safer and more efficient working environment.

-

Adjustable Seating is a fundamental aspect of ergonomic design. Seats must be adjustable to cater to operators of varying heights and body types, promoting proper posture and reducing strain during long shifts. Research shows that ergonomic seating can enhance productivity by minimizing discomfort. Gabriela P. Urrejola-Contreras found that 49.3% of workers faced high ergonomic risk, with 50.7% at very high risk, underscoring the necessity for well-designed seating.

-

Control Placement is another vital consideration. Controls should be easily accessible and intuitively positioned to limit unnecessary movements. This thoughtful design reduces fatigue and enables quicker responses to operational demands. Poor cab ergonomics can lead to chronic conditions like herniated discs and carpal tunnel syndrome, making proper control placement essential for operator health.

-

Visibility is paramount for safe operation. Forklifts should feature wide-view masts and minimal obstructions to enhance visibility, crucial for preventing accidents and ensuring safe maneuvering in busy environments. A clear view of the load and surroundings is not just a convenience; it’s a safety imperative.

-

Vibration Dampening features are designed to minimize operator fatigue, especially during prolonged use. Incorporating shock-absorbing seats and floor mats can significantly enhance comfort. Successful ergonomic programs often show improvements in multiple indicators within 12-18 months of implementation, highlighting the long-term benefits of investing in vibration dampening technologies.

-

Easy Entry and Exit are essential for safety and accessibility. Forklifts should have low step heights and non-slip surfaces to facilitate safe entry and exit, particularly for operators with mobility challenges. This consideration is vital for maintaining a safe working environment and ensuring all operators can navigate the equipment comfortably.

By prioritizing forklift design with ergonomic features, companies can boost operator efficiency, reduce injury risks, and enhance overall productivity on construction sites. Investing in ergonomics is not just a choice; it’s a commitment to safety and excellence.

Implement Regular Maintenance Practices for Reliability

Regular maintenance is crucial for ensuring that lift trucks operate reliably and safely. By implementing best practices, you can significantly enhance performance and reduce risks:

-

Daily Inspections: Operators must conduct daily pre-operation checks, focusing on fluid levels, brakes, and tires. This proactive approach helps identify potential issues before they escalate into serious problems. According to OSHA, a pre-use inspection must be performed before each shift to ensure safety. Neglecting this can lead to serious accidents, including tip-overs, which are a leading cause of fatalities in lift truck operations.

-

Scheduled Maintenance: Adhering to the manufacturer's recommended maintenance schedule is essential. Typically, this involves servicing every 90 days or after a specified number of operating hours to maintain optimal performance. In 2021, there were 70 fatalities related to industrial vehicles, underscoring the importance of regular upkeep to prevent such tragedies.

-

Lubrication: Regular lubrication of moving parts, including the mast, chains, and wheel bearings, is vital to prevent wear and tear, ensuring smooth operation. This practice helps avoid structural degradation or collapse of racking systems due to repeated impacts.

-

Battery Maintenance: For electric lift trucks, it’s important to charge and maintain batteries according to manufacturer guidelines. Regular checks of water levels and terminal cleanliness can prevent corrosion and extend battery life.

-

Record Keeping: Keeping detailed records of all maintenance activities-including inspections, repairs, and parts replacements-can help identify patterns and inform future maintenance decisions. This documentation is essential for adhering to regulations and can enhance overall operational effectiveness.

By implementing these maintenance practices, construction companies can improve the forklift design for better reliability, minimize downtime, and foster a safer working environment. Regular inspections and maintenance not only comply with safety regulations but also contribute to overall operational efficiency. Initiatives like the "Improving Forklift Safety" program demonstrate the effectiveness of these practices in real-world scenarios.

Conclusion

Mastering forklift design is crucial for boosting construction efficiency and safety. Understanding the core components of forklifts, selecting the right type for specific tasks, and incorporating ergonomic features are essential strategies for optimizing performance on construction sites. By prioritizing these aspects, companies can ensure their lifting equipment meets operational demands while safeguarding the well-being of operators.

Key arguments highlight the significance of understanding forklift components such as:

- the mast

- forks

- counterweight

- power source

- chassis

These elements collectively determine a forklift's effectiveness. Furthermore, choosing the right forklift type based on:

- load capacity

- terrain

- lift height

- maneuverability

- special features

is vital. Ergonomic considerations, like adjustable seating and control placement, enhance operator comfort and productivity. Regular maintenance practices are also crucial, ensuring reliability and safety, ultimately reducing the risk of accidents.

Investing in quality forklift design and maintenance transcends mere compliance; it represents a commitment to operational excellence and safety in the construction industry. By adopting these best practices, construction managers can significantly improve productivity while fostering a safer working environment. Embracing these principles leads to better outcomes on job sites, contributing to the overall success of construction projects. Don't wait - prioritize forklift design and maintenance today for a safer, more efficient tomorrow.

Frequently Asked Questions

What are the core components of forklift design?

The core components of forklift design include the mast, forks, counterweight, power source, and chassis.

What is the function of the mast in a forklift?

The mast is the vertical assembly responsible for raising and lowering loads, and its design is crucial for determining lift height and stability, impacting construction safety.

How do forks contribute to a forklift's operation?

Forks are engineered to lift and transport items, and their length and design significantly influence the types of weights that can be managed.

What role does the counterweight play in forklift safety?

The counterweight stabilizes the load being lifted, preventing the vehicle from tipping over, which is critical for safety, especially on uneven terrain.

What are the different power sources for forklifts?

Forklifts can be powered by electric batteries, propane, or diesel engines, with each power source affecting operational costs and suitability for indoor or outdoor use.

Why is the chassis important in forklift design?

The chassis serves as the frame that supports all other components, and a robust chassis is essential for durability and stability in demanding construction environments.

How can understanding forklift components improve safety and efficiency?

Understanding these elements is vital for choosing the right lift truck for specific tasks, ensuring both safety and efficiency on the job site, and investing in quality forklift design and maintenance can enhance productivity and safety outcomes.