Key Highlights:

- Forklift jibs enhance lifting capabilities, allowing forklifts to manage hard-to-reach loads.

- Key components of jibs include the boom, hook, and securing mechanisms, which ensure safe operation.

- Operators must understand the load capacity and operational limits of their jib attachments.

- Recent advancements include integrated sensors for overload protection and IoT-based load tracking.

- Fixed jibs are suited for repetitive tasks, while telescopic jibs offer flexibility for varying load sizes.

- Real-world applications demonstrate jibs' effectiveness in reducing costs and improving operations.

- Safety protocols include pre-use inspections, proper training, and adherence to OSHA guidelines.

- Neglecting safety measures can lead to significant accidents and injuries, with an average recovery time of 13 days.

- Regular inspection and maintenance of jibs are crucial for functionality and safety, with daily and monthly checks recommended.

- Maintaining detailed logs of inspections helps track performance and accountability.

Introduction

Forklift jibs are vital tools that significantly enhance the lifting capabilities of forklifts, enabling operators to manage challenging loads that traditional methods often struggle with. By examining the various types of jibs, their associated safety protocols, and best practices for maintenance, operators can fully leverage these attachments while ensuring a secure working environment.

As lifting operations become increasingly complex, operators must navigate the delicate balance between efficiency and safety when utilizing forklift jibs. This exploration not only highlights the importance of proper equipment use but also underscores the need for adherence to safety standards.

Understand Forklift Jib Attachments

Forklift jib are specialized devices that significantly enhance the lifting capabilities of forklifts, enabling them to manage loads that are otherwise difficult to access or lift due to height or reach limitations. These additions include essential components such as the boom, hook, and securing mechanisms, all of which play a crucial role in ensuring safe operation. Operators must become familiar with the specific jib accessory in use, including its load capacity and operational limits, to guarantee safe and effective lifting practices.

Recent advancements in jib technology have introduced features like integrated sensors for overload protection and IoT-based load tracking, which enhance operational intelligence and safety. Typically, the load capacity of hoist jib devices in the industry ranges up to 2,000 kg at a 1m reach and 1,000 kg at a 3m reach, depending on the design and configuration. For example:

- Fixed jibs are ideal for repetitive tasks

- Telescopic jibs provide flexibility for varying load sizes, allowing operators to adjust the arm length as needed

Real-world examples illustrate the effectiveness of forklift jib in improving lifting capabilities. In a manufacturing setting, a forklift jib was utilized to position heavy machinery components without the need for a crane, demonstrating how these tools can enhance operations and reduce costs. Safety specialists emphasize the importance of understanding jib connections, noting that detailed training programs encompass equipment familiarization, load calculations, and emergency procedures. Proper training and adherence to load capacity guidelines are essential for preventing accidents and ensuring safe operations. By applying best practices and staying informed about the latest technological innovations, operators can maximize the benefits of using forklift jib tools while maintaining a safe working environment.

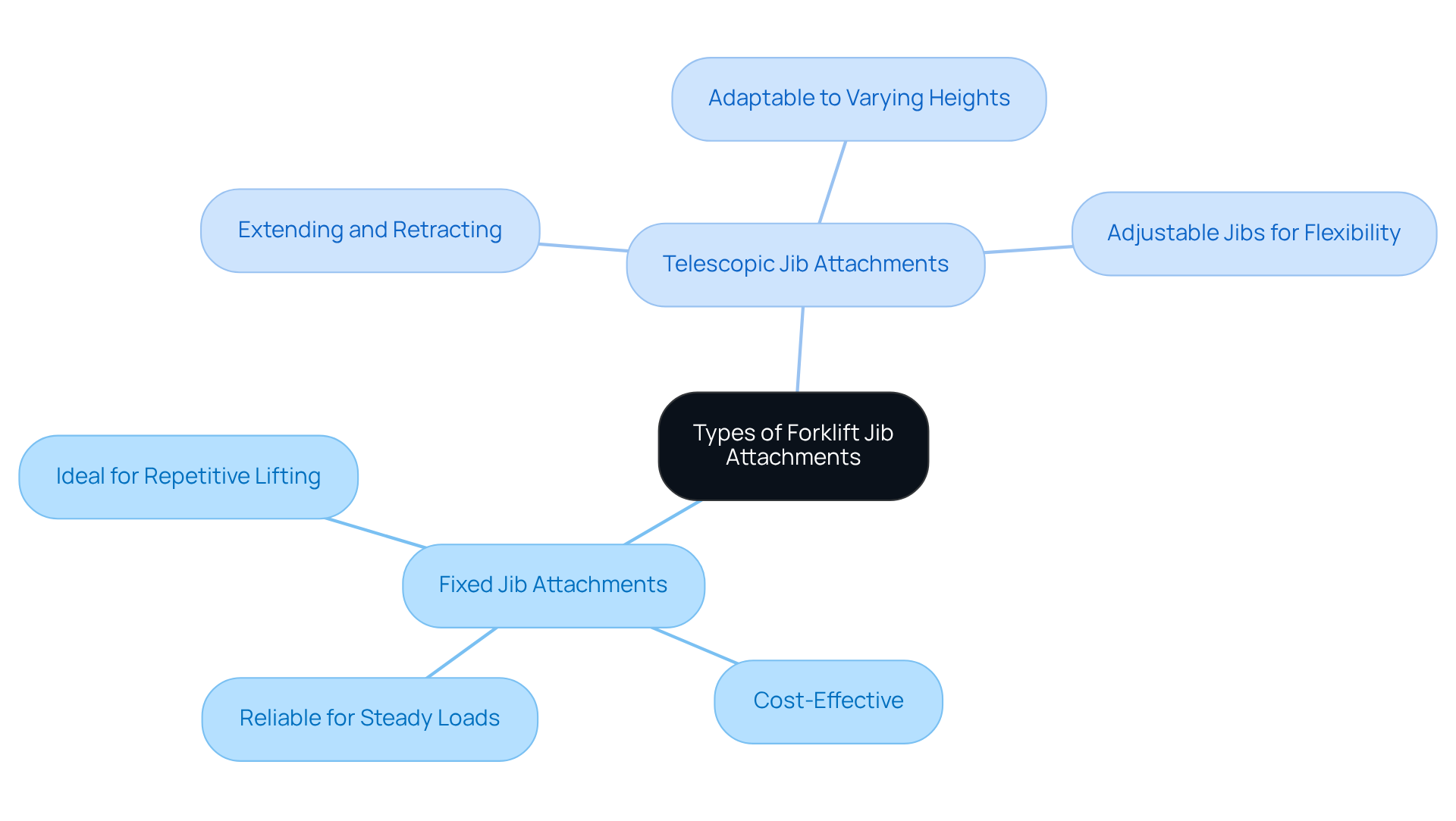

Explore Types of Forklift Jib Attachments

Forklift jib attachments are primarily categorized into fixed and telescopic types, with each type catering to specific operational requirements. Fixed booms are ideal for repetitive lifting tasks where the length remains constant, making them particularly effective for steady loads in environments such as warehouses and manufacturing facilities. Their reliability and cost-effectiveness render them a favored choice for tasks that necessitate minimal adjustments.

On the other hand, telescopic booms offer the advantage of extending and retracting, allowing operators to adapt to varying lifting heights and distances. This adaptability is essential in construction projects where load requirements frequently change. Additionally, adjustable jibs enhance this flexibility by enabling operators to modify the boom angle, accommodating different load sizes and shapes, which is vital for optimizing workflow and ensuring safety on job sites.

Recent projects have underscored the advantages of using adjustable forklift jib accessories, especially in dynamic settings where efficiency is paramount. Construction professionals emphasize the importance of selecting the right forklift jib accessory based on specific project needs, noting that the correct forklift jib choice can significantly impact productivity and safety. As industry trends evolve, the demand for adjustable and telescopic arms continues to rise, reflecting a shift towards more flexible material handling solutions that enhance operational efficiency and reduce manual handling risks. Furthermore, the global lift arm market is projected to reach approximately USD 1.37 billion in 2024, with North America anticipated to account for USD 370 million, underscoring the growing importance of these tools in the sector. As industry expert Darko Darko states, 'Selecting the appropriate jib accessory is vital for enhancing efficiency and ensuring safety on the job site.

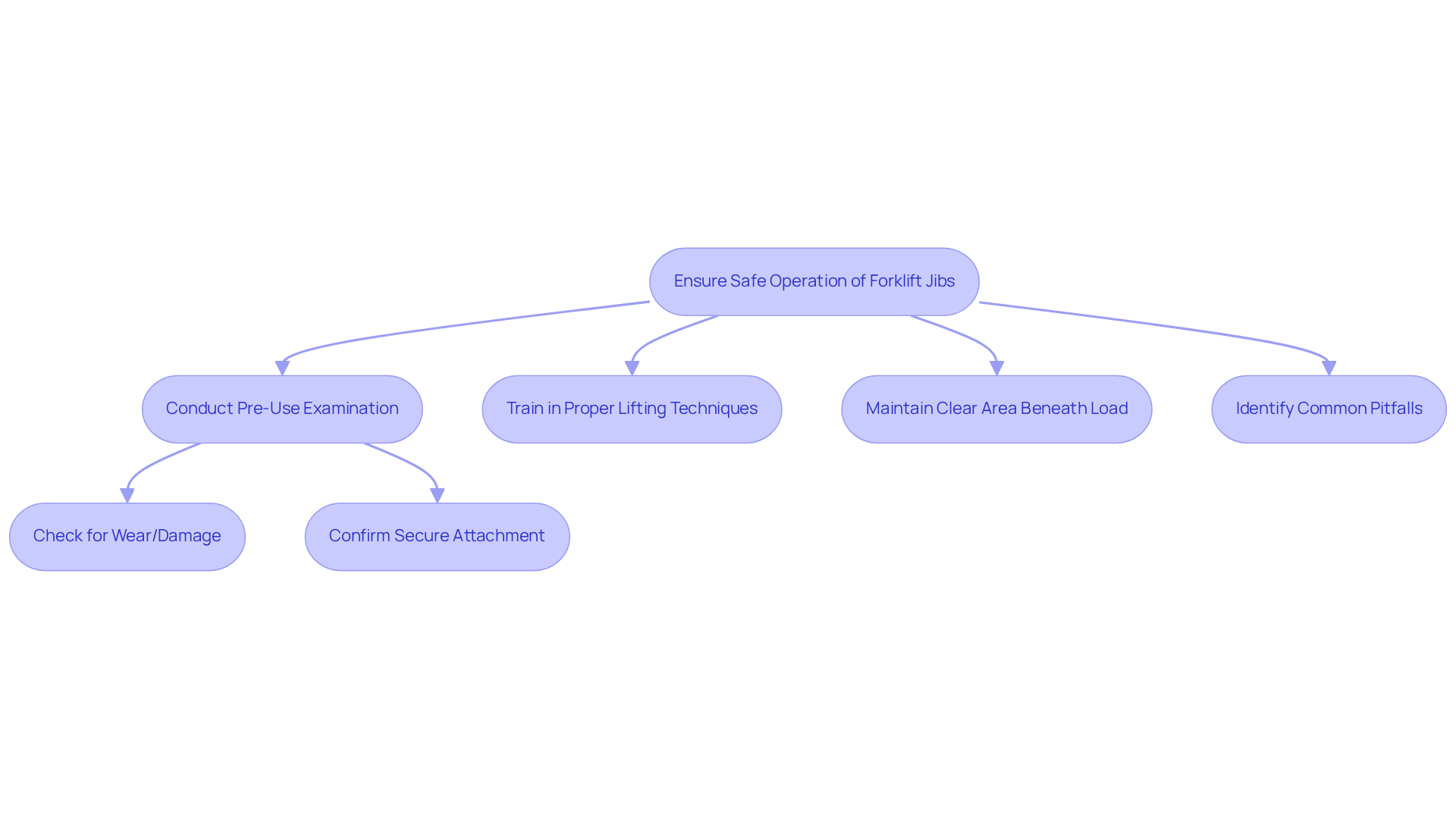

Implement Safety Protocols for Forklift Jibs

To ensure the secure operation of the forklift jib, operators must adhere to essential precautionary guidelines. A thorough pre-use examination of the jib attachment is critical; this includes checking for signs of wear or damage and confirming that the jib is securely fastened to the lift's forks, with all pins and chains properly positioned. According to OSHA, 70% of lifting vehicle incidents could have been prevented with better precautionary measures, underscoring the necessity of these inspections.

Training in proper lifting techniques is equally important, focusing on maintaining a low center of gravity and avoiding sudden movements. Additionally, keeping the area beneath the lifted load clear of personnel and obstacles is vital to prevent accidents. Regular training on protective measures and strict adherence to OSHA guidelines significantly enhance workplace safety.

As noted by an OSHA representative, "Implementing these precautionary measures can prevent many accidents," highlighting the shared responsibility for safety in lifting operations. Furthermore, neglecting precautionary measures can lead to serious consequences, with employees typically taking an average of 13 days to recover from lifting vehicle injuries.

By identifying common pitfalls, such as obstructed visibility and improper load balancing, operators can further reduce risks and foster a safer working environment.

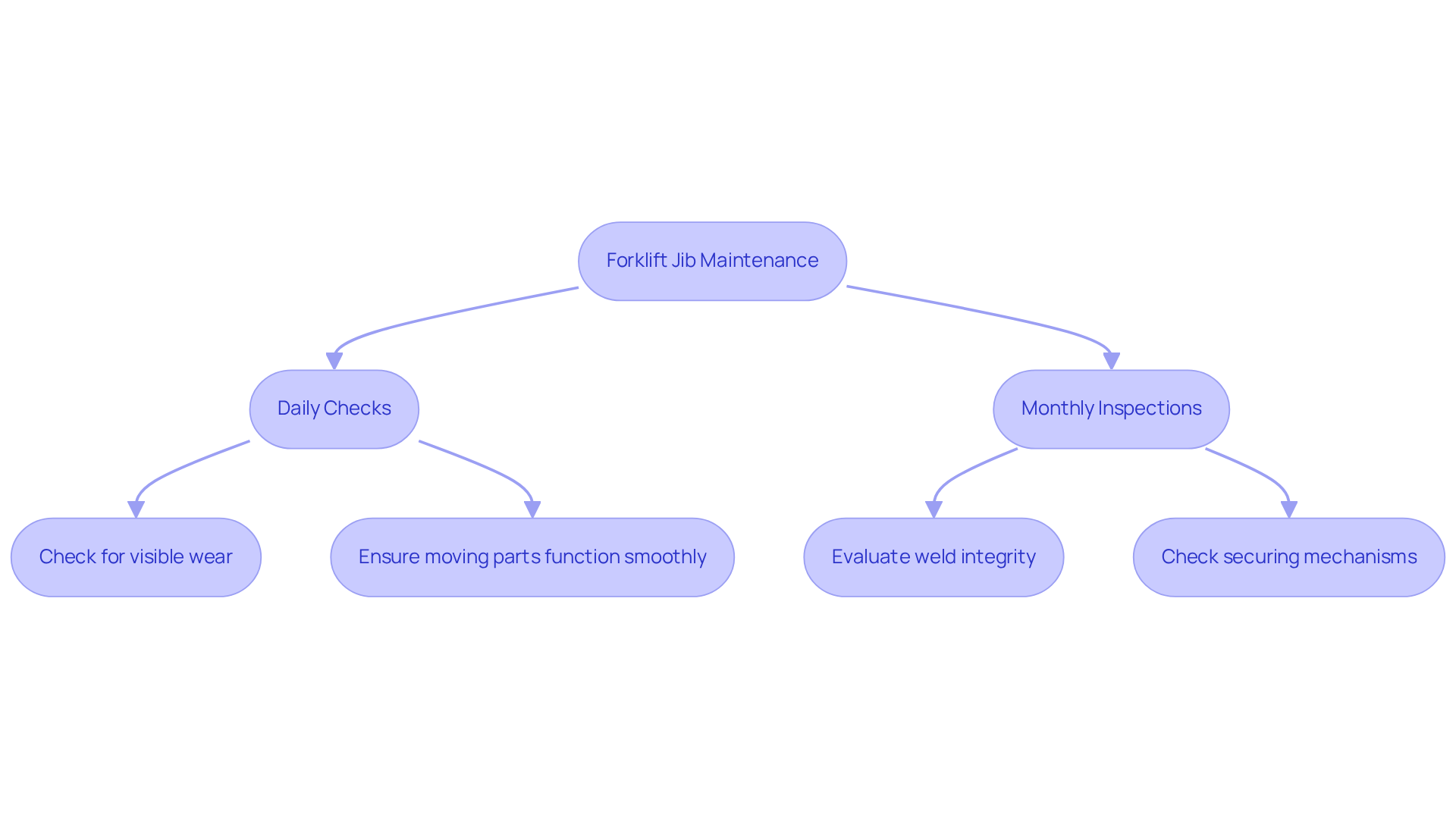

Maintain and Inspect Forklift Jibs Regularly

To maintain forklift jib functionality, operators must implement a rigorous inspection and maintenance schedule. Daily checks should prioritize identifying visible signs of wear, such as cracks or deformation, and ensuring that all moving parts function smoothly. Monthly inspections should be more thorough, evaluating the integrity of welds and securing mechanisms. Industry experts emphasize the importance of regular inspections; in fact, 42% of facilities attribute equipment failure to insufficient maintenance practices.

Maintaining a detailed log of inspections and repairs is essential for accountability and tracking performance over time. Following manufacturer guidelines and safety standards not only extends the lifespan of the forklift jib but also significantly enhances operational safety, thereby reducing the risk of costly downtime and accidents. Unplanned downtime can cost manufacturers up to $50 billion annually, highlighting the financial necessity of diligent maintenance practices.

Conclusion

Forklift jibs are a crucial advancement in material handling, significantly enhancing the lifting capabilities of forklifts while ensuring safety and efficiency across various operational contexts. Understanding the different types of jib attachments, including fixed and telescopic options, is essential for selecting the right tool for specific tasks. By prioritizing safety protocols and rigorous maintenance practices, operators can maximize the benefits of these attachments and minimize risks associated with lifting operations.

Key insights emphasize the importance of proper training, regular inspections, and adherence to safety guidelines to prevent accidents and equipment failures. The integration of advanced technologies, such as overload sensors, highlights the evolving nature of forklift jib attachments, making them indispensable in modern workplaces. As industry demands continue to grow, the focus on selecting appropriate jib types and maintaining them diligently will play a critical role in enhancing productivity and ensuring safe operations.

Ultimately, fostering a culture of safety and responsibility around forklift jib usage not only protects employees but also contributes to operational efficiency and cost savings. By embracing best practices in training, maintenance, and safety protocols, organizations can fully harness the potential of forklift jib attachments, paving the way for a safer and more productive work environment.

Frequently Asked Questions

What is a forklift jib attachment?

A forklift jib attachment is a specialized device that enhances the lifting capabilities of forklifts, allowing them to manage loads that are difficult to access or lift due to height or reach limitations.

What are the main components of a forklift jib?

The main components of a forklift jib include the boom, hook, and securing mechanisms, all of which are crucial for ensuring safe operation.

Why is it important for operators to understand the specific jib accessory in use?

It is important for operators to understand the specific jib accessory in use to know its load capacity and operational limits, which ensures safe and effective lifting practices.

What advancements have been made in jib technology?

Recent advancements in jib technology include features like integrated sensors for overload protection and IoT-based load tracking, which enhance operational intelligence and safety.

What is the typical load capacity of hoist jib devices?

The typical load capacity of hoist jib devices ranges up to 2,000 kg at a 1m reach and 1,000 kg at a 3m reach, depending on the design and configuration.

What are the different types of forklift jibs and their uses?

Fixed jibs are ideal for repetitive tasks, while telescopic jibs provide flexibility for varying load sizes, allowing operators to adjust the arm length as needed.

Can you provide an example of how forklift jibs improve operations?

In a manufacturing setting, a forklift jib was used to position heavy machinery components without the need for a crane, demonstrating how these tools can enhance operations and reduce costs.

What do safety specialists emphasize regarding forklift jib usage?

Safety specialists emphasize the importance of understanding jib connections and recommend detailed training programs that cover equipment familiarization, load calculations, and emergency procedures.

How can operators maximize the benefits of using forklift jib tools?

Operators can maximize the benefits of using forklift jib tools by applying best practices, staying informed about the latest technological innovations, and adhering to load capacity guidelines to maintain a safe working environment.

List of Sources

- Understand Forklift Jib Attachments

- Forklift Jib Attachments – Material Handling Solutions (https://materialhandlingequipment.com.au/forklift-jib-attachments?srsltid=AfmBOoqSxGLweZNGrkwW6-_s_uyLS2_wuQvNJe1c6_PeXVA7vcPYD7L0)

- (https://adaptalift.com.au/articles/essential-guide-to-forklift-jib-attachments)

- Forklift Jib Boom Market Size, Projections, Insights & Strategy 2026-2033 (https://linkedin.com/pulse/forklift-jib-boom-market-size-projections-insights-strategy-kbgcc)

- Safer Forklift Jib Operations | Best Safety Practices (https://mandarinimportsexports.com.au/blog/best-practices-for-safer-forklift-jib-operations-comprehensive-safety-guidelines-and-procedures)

- Explore Types of Forklift Jib Attachments

- Forklift Jibs Market Research Report 2033 (https://dataintelo.com/report/forklift-jibs-market)

- CREATING A SAFER, SMARTER WORKPLACE: THE STRATEGIC ROLE OF JIB CRANES IN MATERIAL HANDLING (https://liftingequipmentstore.com/blogs/blog/creating-a-safer-smarter-workplace-the-strategic-role-of-jib-cranes-in-material-handling)

- Boost Safety with Forklift Jibs (https://wollongongforklift.com.au/blog/how-forklift-jibs-increase-workplace-efficiency-and-safety)

- Forklift Attachments: The Key to a Safer and More Efficient Warehouse (https://readyrack.net.au/blogs/news/forklift-attachments-the-key-to-a-safer-and-more-efficient-warehouse?srsltid=AfmBOoriPqtAUHqaN_V8TOs5CBEkhPbCExZekCncZ1bebU_2jjikSXIp)

- Implement Safety Protocols for Forklift Jibs

- Forklift Safety and Statistics - Hit Not (https://hitnot.com/forklift-safety-and-statistics)

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- 5 Common Forklift Accidents and How to Prevent Them - OSHA.com (https://osha.com/blog/5-most-common-forklift-accidents-and-how-to-prevent-them)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- Maintain and Inspect Forklift Jibs Regularly

- 10 Compelling Statistics About Manufacturing Maintenance (https://worktrek.com/blog/manufacturing-maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Key Facts and Statistics on Equipment Maintenance (https://gocodes.com/maintenance-management/equipment-maintenance-statistics)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)