Key Highlights:

- Forklift lift capacity is the maximum weight a lift truck can safely handle at a specified load centre and height.

- Safety is paramount; exceeding lift capacity can lead to tipping and accidents, which account for 25% of forklift-related fatalities.

- Efficiency in operations is enhanced by understanding lift capacity, allowing for the selection of appropriate equipment.

- Compliance with lift load regulations is crucial to avoid legal repercussions and penalties.

- Methods to calculate lift capacity include consulting the data plate, moment calculation, and adjustments for load centre and height.

- Factors affecting lift capacity include load centre distance, mast height, weight distribution, fork length, and environmental conditions.

- Selecting the right forklift involves evaluating weight and lift height requirements, aisle space, and consulting with experts.

Introduction

Understanding forklift lift capacity is essential for project managers who face the complexities of equipment selection and safety compliance. This knowledge not only protects against accidents but also boosts operational efficiency by ensuring the right equipment is utilized for specific tasks.

With various factors influencing lift capacity - from load center distance to environmental conditions - project managers must determine the best forklift for their needs effectively.

This article explores the key insights and calculations necessary to master forklift lift capacity, empowering managers to enhance safety and productivity on the job site.

Define Forklift Lift Capacity and Its Importance

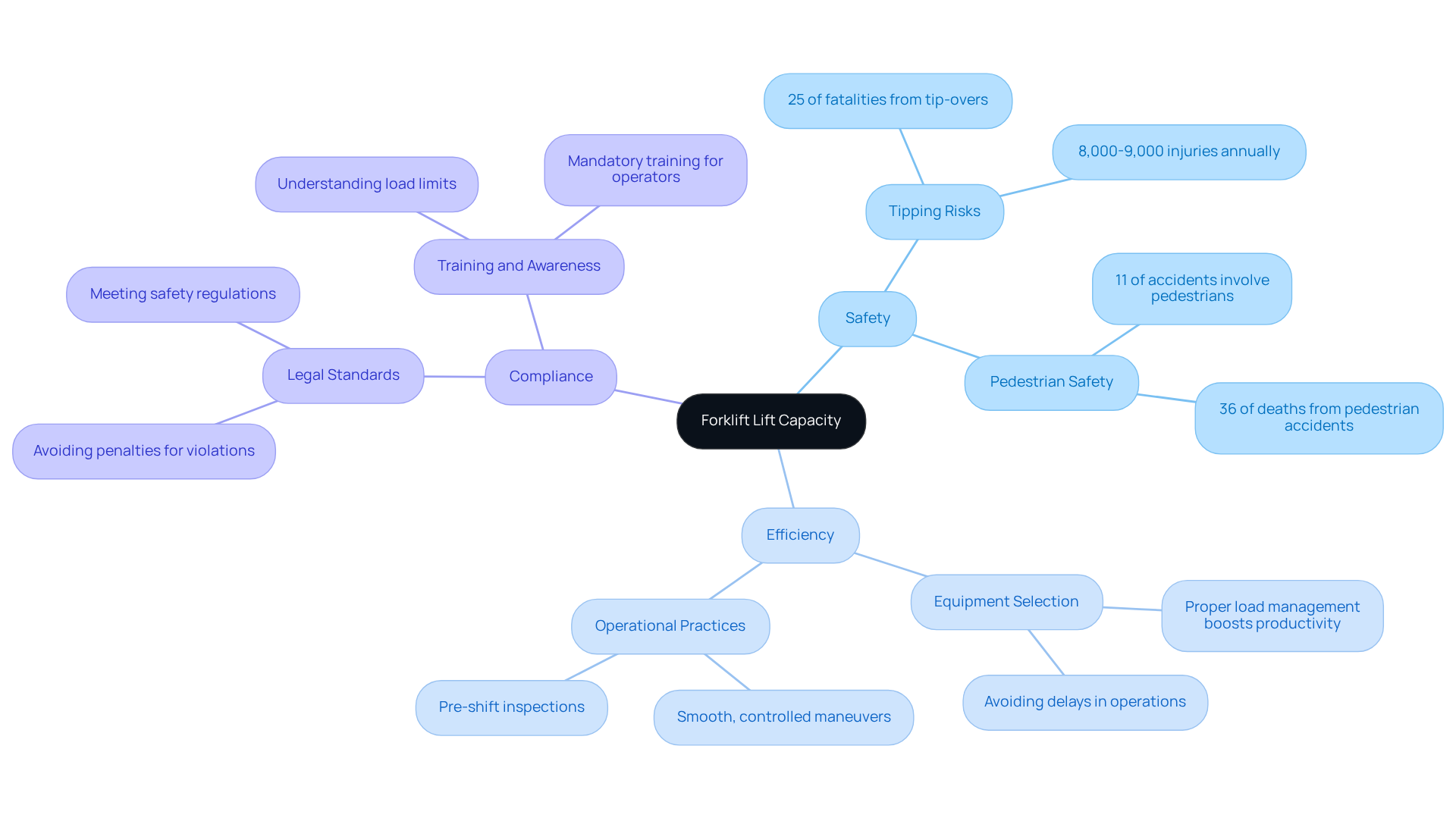

The forklift lift capacity indicates the maximum weight that a lift truck can safely manage at a specified load center and height, as detailed on the vehicle's data plate. Understanding this capacity is essential for several reasons:

- Safety: Exceeding the lift capacity can lead to tipping, equipment failure, and serious accidents, putting both operators and nearby personnel at risk. In fact, forklift tip-overs account for about 25% of all forklift-related fatalities, underscoring the critical need for adherence to load restrictions.

- Efficiency: Knowing lift capabilities enables project managers to select the appropriate equipment for specific tasks, ensuring operations run smoothly and effectively without unnecessary delays. Proper load management can significantly boost productivity on job sites.

- Compliance: Following lift load regulations is crucial for meeting safety standards and avoiding legal repercussions. As we approach 2026, compliance with these regulations remains a top priority, as violations can result in severe penalties and increased liability.

Real-world examples illustrate the importance of understanding lift potential. For instance, instances where operators exceed limits often lead to disastrous outcomes, including injuries and fatalities. Approximately 8,000 to 9,000 forklift-related injuries occur each year, resulting in days away from work, many of which stem from improper load handling.

Expert opinions emphasize that a thorough understanding of lift limits is not just a safety measure but also a fundamental aspect of effective project management. By fostering a culture of safety and compliance, project managers can significantly mitigate the risk of accidents and enhance overall operational effectiveness. Ultimately, recognizing and respecting lifting limits is vital for ensuring a safe and productive construction environment.

Calculate Forklift Lift Capacity: Methods and Formulas

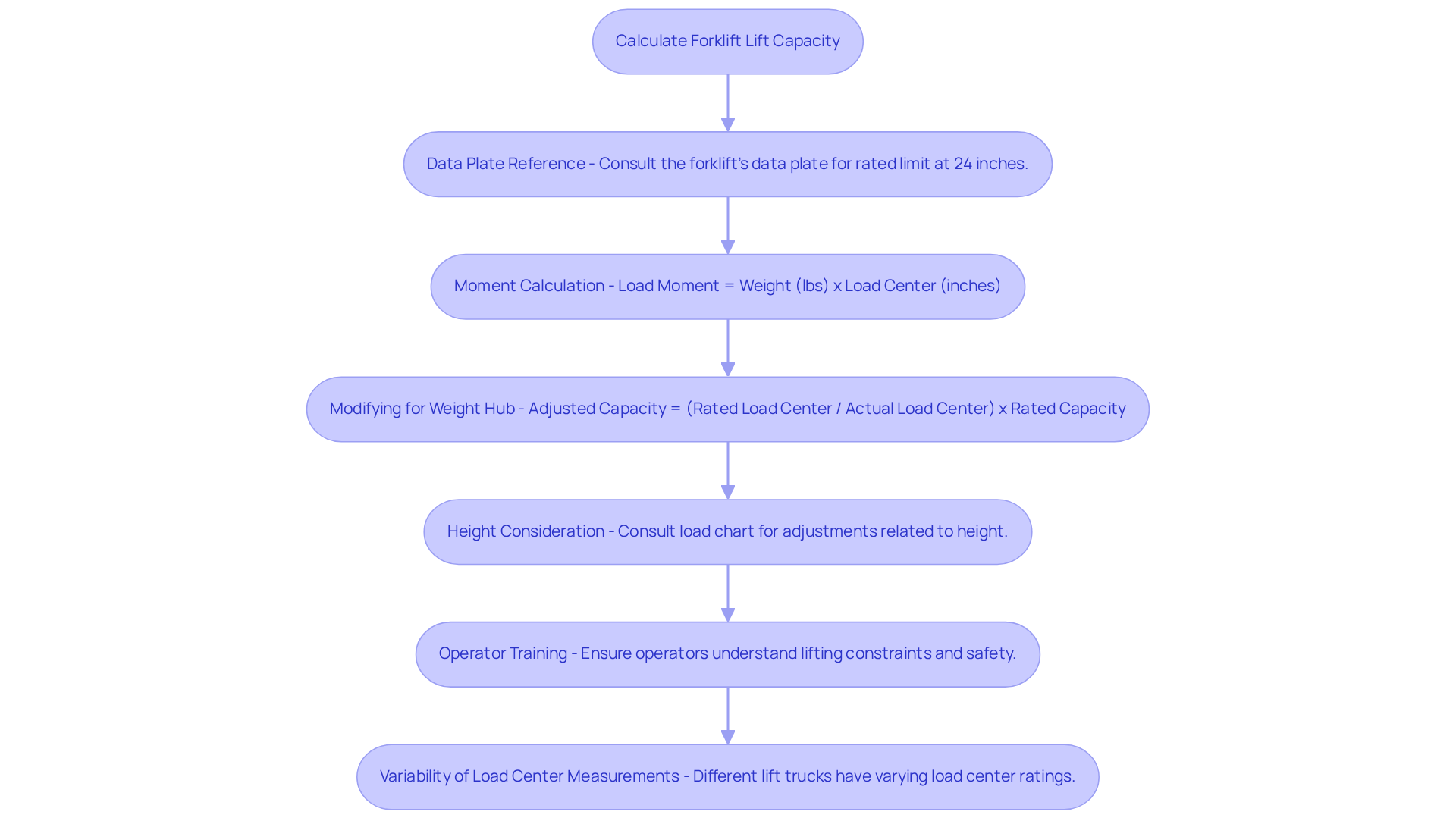

To accurately calculate forklift lift capacity, project managers should employ several methods and formulas:

-

Data Plate Reference: Start by consulting the forklift's data plate, which specifies the rated limit at a designated weight point, typically set at 24 inches. This serves as the baseline for all calculations. Always obtain the forklift lift capacity from the OEM manufacturer to ensure compliance and safety.

-

Moment Calculation: The moment is determined by multiplying the weight by the distance from the weight midpoint to the forks.

- Formula: Load Moment = Weight (lbs) x Load Center (inches)

-

Modifying for Weight Hub: If the actual weight hub exceeds the rated weight hub, the capacity must be adjusted accordingly. Use the following formula:

- Formula: Adjusted Capacity = (Rated Load Center / Actual Load Center) x Rated Capacity

For example, a forklift rated for 5,000 lbs at a 24-inch load center can lift only 3,333 lbs at a 36-inch load center, illustrating how load center adjustments impact capacity.

- Formula: Adjusted Capacity = (Rated Load Center / Actual Load Center) x Rated Capacity

-

Height Consideration: Recognize that lift ability diminishes as height increases. Always consult the load chart of the lifting vehicle for specific adjustments related to height. This is crucial, as higher lifts can significantly decrease stability and the overall forklift lift capacity.

-

Operator Training: Adequate training for operators is essential to understand the constraints of different types of lifting trucks according to their balance point. This knowledge is vital for safe operations and preventing load-related incidents, which have resulted in 62 fatalities and over 6,000 serious injury claims in Australia.

-

Variability of Load Center Measurements: Different types of lift trucks may have varying load center ratings, affecting their lifting capabilities. Understanding these distinctions is essential for selecting the appropriate vehicle for specific tasks.

By employing these methods, project managers can ensure safe operations and select the right equipment for their specific requirements, thereby minimizing the risk of load-related incidents.

Identify Factors Affecting Forklift Lift Capacity

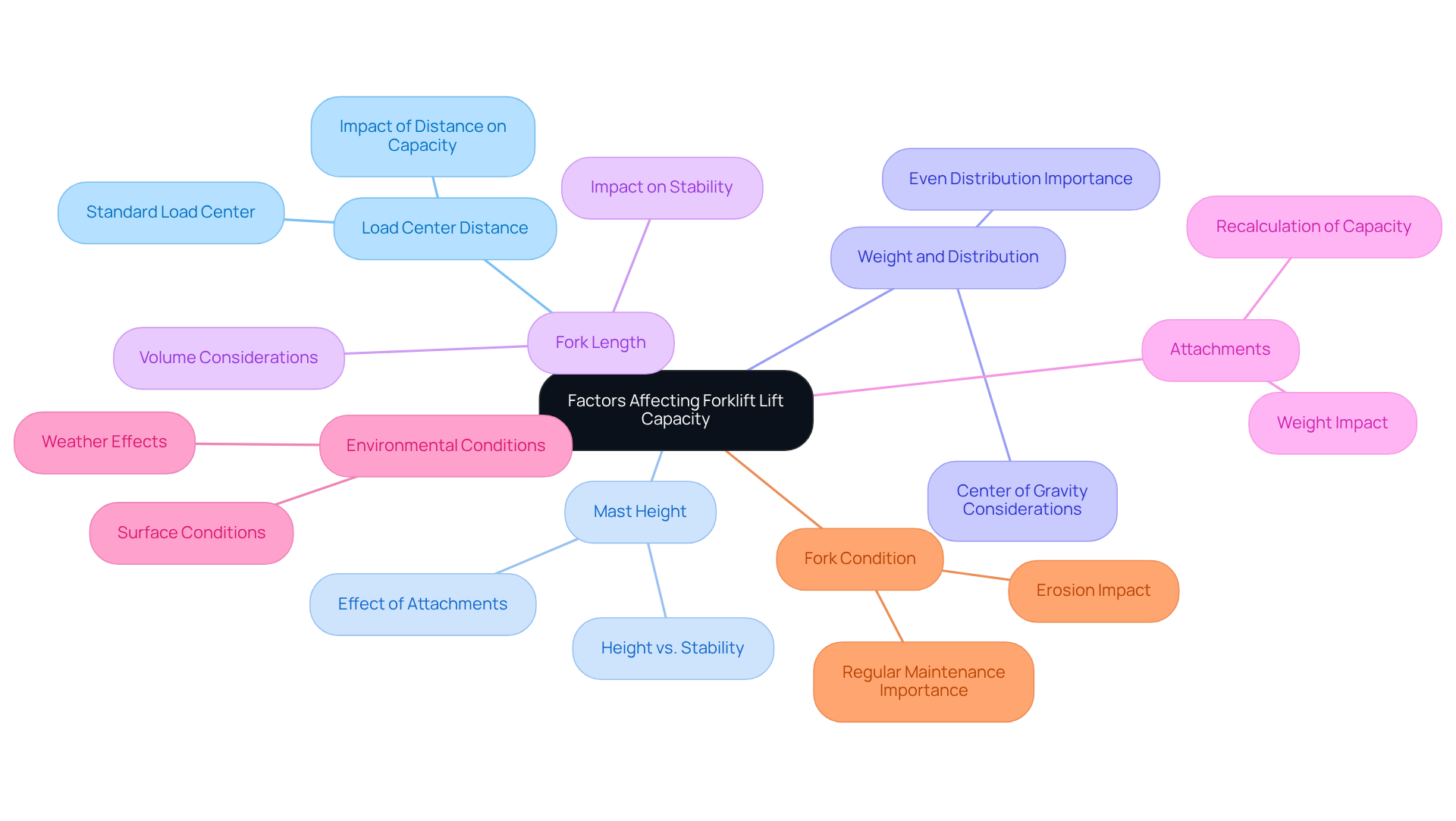

Several factors significantly influence a forklift's lift capacity:

-

Load Center Distance: This refers to the distance from the weight's center of gravity to the forks. A larger distance from the pivot point decreases the truck's ability due to heightened leverage effects. The standard load center distance for lift trucks is 24 inches; for instance, a forklift lift capacity rated at 5,000 lbs at a 24-inch load center may only handle 4,000 lbs at a 30-inch load center.

-

Mast Height: As the lift height increases, the forklift lift capacity generally diminishes due to stability issues. For example, adding a 200 lbs side-shifter attachment can decrease the forklift lift capacity from 5,000 lbs to 4,800 lbs, illustrating how attachments can influence strength.

-

Weight and Distribution: Unevenly distributed weights can shift the balance point, significantly affecting both stability and capability. The heaviest component of a shipment should be positioned nearest to the fork face to ensure stability. Improper placement can lead to tip-overs, a major cause of forklift-related accidents.

-

Fork Length: Longer tines can decrease volume as they may cause the center of mass to shift, impacting the overall stability of the vehicle.

-

The use of attachments alters the functional ability of the lifting device, necessitating recalculations of the forklift lift capacity. For instance, installing a Cascade attachment can reduce over 1,522 lbs from the weight limit, transforming a forklift lift capacity of 3,000 lbs into a forklift lift capacity of 2,700 lbs when a sideshifter is installed. This emphasizes the need for careful assessment of each load.

-

Environmental Conditions: Factors such as surface conditions, slope, and weather can affect stability and operational safety. For example, lifting trucks should not operate on uneven surfaces or slopes without proper precautions, as these conditions can increase the risk of tipping.

-

Fork Condition: Forklifts lose approximately 20% of their lifting capacity for every 10% erosion of the fork's heel thickness. Regular inspections and maintenance are crucial to ensure safety and optimal performance.

By understanding these factors, project managers can better evaluate the appropriateness of lifting equipment for specific tasks, ensuring safe operations and ultimately reducing the risk of accidents while enhancing productivity.

Select the Right Forklift Based on Lift Capacity Requirements

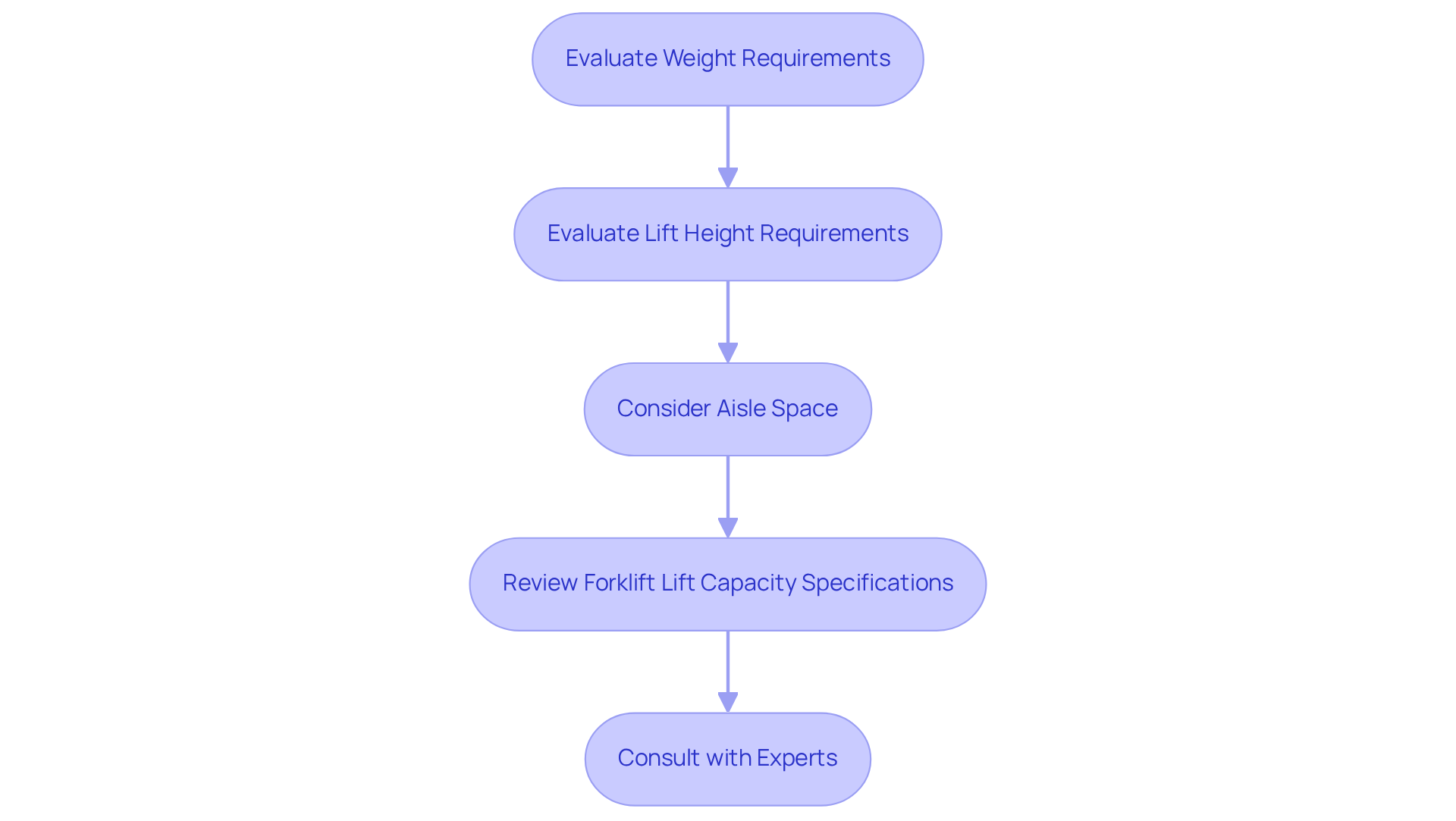

When selecting a forklift, project managers should follow essential steps to ensure optimal performance and safety:

- Evaluate Weight Requirements: Accurately ascertain the weight, dimensions, and distribution of the items to be lifted. Unevenly distributed weights can significantly decrease lifting potential, making this evaluation essential.

- Evaluate Lift Height Requirements: Determine the maximum height to which items will be raised. As lift height rises, the truck's ability may diminish, necessitating careful consideration of the vertical load center.

- Consider Aisle Space: Ensure the vehicle can maneuver effectively within the available area, taking into account the turning radius and width. This is particularly important in environments with narrow aisles or tight corners.

- Review forklift lift capacity specifications: Compare different models based on their rated loads, mast types, and any required attachments. Understanding the specifications helps in selecting a lift truck that meets the specific forklift lift capacity required for the project.

- Consult with Experts: Engage with equipment rental specialists to gain insights on the best options tailored to specific project needs. Their expertise can guide decisions on the most appropriate vehicle configurations and capacities.

By adhering to these steps, project managers can select the right forklift, ensuring safe and efficient operations on the job site while minimizing the risk of accidents related to load handling.

Conclusion

Understanding forklift lift capacity is essential for project managers aiming to ensure safety, efficiency, and compliance in their operations. By grasping the nuances of lift capacity, project managers can make informed decisions that protect their teams and optimize productivity on job sites. Recognizing the significance of adhering to load limits and selecting the right equipment can substantially impact operational success.

This article has discussed key aspects such as:

- The definition of lift capacity

- Methods for calculating it

- The various factors that influence it

Emphasis has been placed on the importance of safety, the role of operator training, and the necessity of understanding equipment specifications. Each of these elements contributes to a comprehensive approach to managing forklift operations effectively.

Ultimately, the insights provided highlight that a thorough understanding of forklift lift capacity is not merely a technical requirement but a foundational pillar of effective project management. By prioritizing safety and compliance, project managers can significantly reduce risks and enhance the overall efficiency of their operations. It is crucial to implement these best practices and continuously educate teams to foster a culture of safety that safeguards both personnel and productivity.

Frequently Asked Questions

What is forklift lift capacity?

Forklift lift capacity is the maximum weight that a lift truck can safely manage at a specified load center and height, as indicated on the vehicle's data plate.

Why is understanding lift capacity important?

Understanding lift capacity is important for safety, efficiency, and compliance. It helps prevent accidents, ensures the right equipment is used for tasks, and meets safety regulations to avoid legal repercussions.

What are the safety risks of exceeding lift capacity?

Exceeding lift capacity can lead to tipping, equipment failure, and serious accidents, which pose risks to both operators and nearby personnel. Forklift tip-overs account for about 25% of all forklift-related fatalities.

How does lift capacity impact operational efficiency?

Knowing lift capabilities allows project managers to select the appropriate equipment for specific tasks, ensuring smooth operations and preventing unnecessary delays, which can boost productivity on job sites.

What are the legal implications of not following lift load regulations?

Not adhering to lift load regulations can lead to violations of safety standards, resulting in severe penalties and increased liability for organizations.

What are the statistics related to forklift-related injuries?

Approximately 8,000 to 9,000 forklift-related injuries occur each year, many of which stem from improper load handling, resulting in days away from work.

How can project managers promote safety regarding lift capacity?

Project managers can foster a culture of safety and compliance by educating staff on lift limits and emphasizing the importance of adhering to these limits to mitigate the risk of accidents and enhance operational effectiveness.

List of Sources

- Define Forklift Lift Capacity and Its Importance

- 5 Common Forklift Accidents and How to Prevent Them - OSHA.com (https://osha.com/blog/5-most-common-forklift-accidents-and-how-to-prevent-them)

- 18 Important Forklift Statistics | BigRentz (https://bigrentz.com/blog/forklift-statistics)

- Prioritizing Safety: Preventing Forklift Accidents (https://theaustin.com/blogs/prioritizing-safety-preventing-forklift-accidents)

- Forklift Tip-Overs [Stats, Causes, Prevention, and Procedures] (https://conger.com/forklift-tip-over)

- Why Forklift Driver Training is Important for the Safety of Workers and Customers (https://safetycounselling.com/why-forklift-driver-training-is-important-for-the-safety-of-workers-and-customers)

- Calculate Forklift Lift Capacity: Methods and Formulas

- Forklift Capacity and Load Center (https://totalwarehouse.com/blogs/forklift-capacity-and-load-center)

- Forklift Capacity Ratings Insights | Abel Womack, Inc. (https://abelwomack.com/forklift-capacity-ratings-blog)

- Understanding Forklift Capacity Limits - FQT (https://forkliftqualitytraining.com/understanding-forklift-capacity-limits-a-guide-to-safe-operation)

- Forklift Load Centers: Everything You Need to Know (https://conger.com/forklift-load-center)

- How To Determine Your Forklift Capacity When Adding New Attachments (https://raymondwest.com/learn/blog/2020/jan/forklift-attachment-safety)

- Identify Factors Affecting Forklift Lift Capacity

- How High Can Your Forklift Go? (https://zonemfc.com/forklift-lifting-height)

- Forklift Weight Capacity: Everything You Need to Know (https://conger.com/forklift-weight-capacity)

- Navigating Forklift Capacity: Key Considerations for Operations (https://linde-mh.us/insights/articles/forklift-capacity)

- What Factors Affect a Forklift’s Lifting Capacity? (https://htxforklifts.com/blog/forklifts/what-factors-affect-a-forklifts-lifting-capacity)

- Select the Right Forklift Based on Lift Capacity Requirements

- Forklift Sizes: What to Know About Types, Capacities and Dimensions (https://unitedrentals.com/project-uptime/equipment/forklift-sizes-what-know-about-types-capacities-and-dimensions)

- Understanding Forklift Lifting Capacities and Data Plates (https://toyotaforklift.com/resource-library/blog/toyota-products/understanding-forklift-lifting-capacities-data-plates)

- Navigating Forklift Capacity: Key Considerations for Operations (https://linde-mh.us/insights/articles/forklift-capacity)

- Understanding Forklift Capacity Limits - FQT (https://forkliftqualitytraining.com/understanding-forklift-capacity-limits-a-guide-to-safe-operation)