Overview

Master Machines Rental's best practices for project managers encompass:

- A thorough evaluation of equipment needs

- A meticulous review of rental agreements

- Diligent maintenance of equipment

- A seamless return process

These practices underscore the necessity of proper planning, clear communication, and ongoing maintenance to avert delays and additional costs. Notably, nearly 60% of construction projects encounter setbacks due to insufficient tools and unclear contracts, highlighting the critical importance of these best practices. By adhering to these guidelines, project managers can ensure their projects run smoothly and efficiently.

Key Highlights:

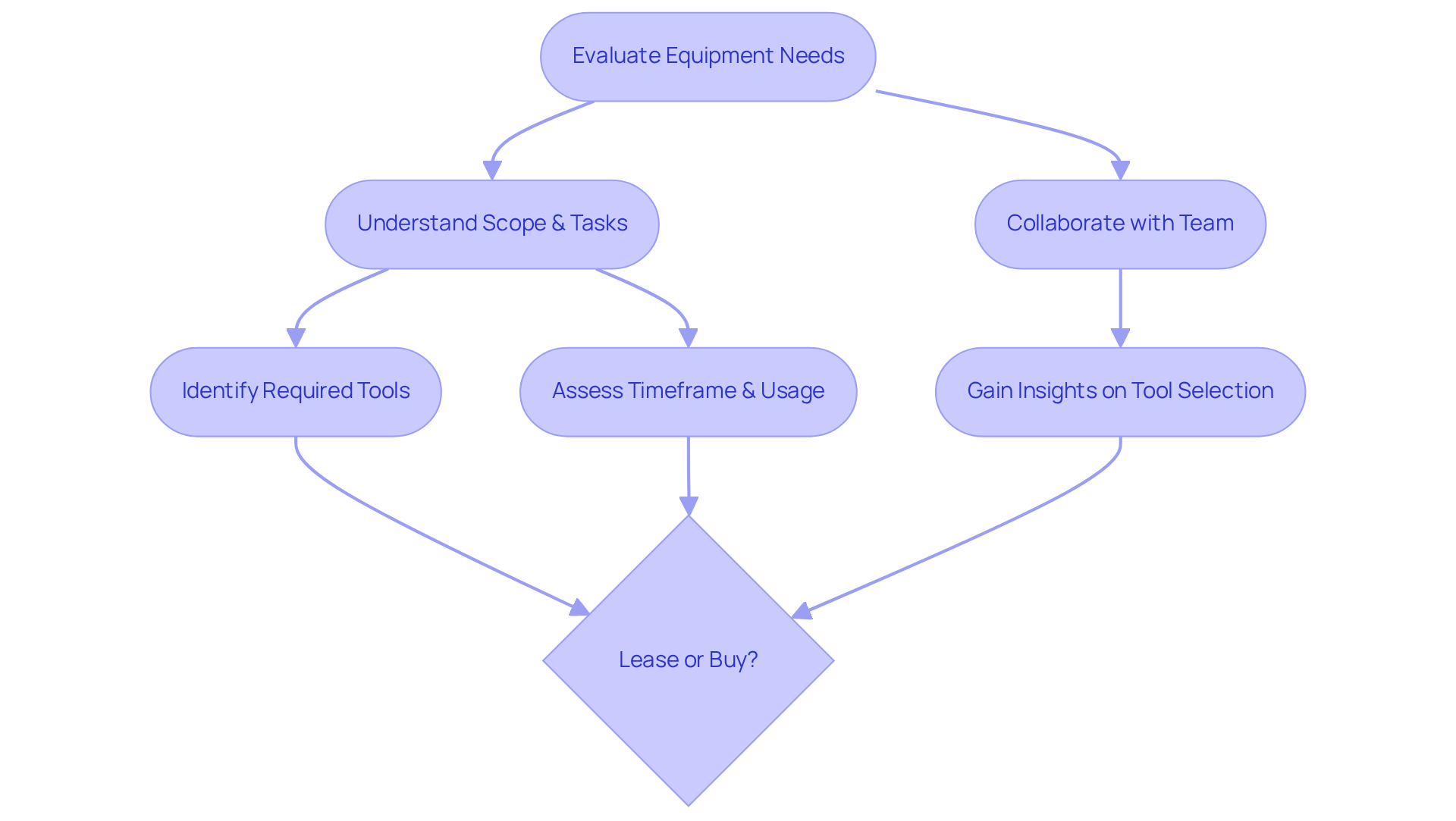

- Managers should evaluate equipment needs by understanding project scope, specific tasks, and required tools.

- Collaborating with team members can enhance tool selection for projects involving heavy lifting or concrete work.

- Assessing project timelines and tool usage frequency helps determine whether leasing or purchasing is more cost-effective.

- Thoroughly review lease agreements, focusing on duration, costs, maintenance responsibilities, and liability clauses to avoid misunderstandings.

- Nearly 60% of construction projects face delays due to insufficient tools stemming from unclear contract terms.

- Establishing a comprehensive maintenance schedule is crucial for optimal equipment functionality and to prevent costly downtime.

- Educating team members on proper tool use and maintenance can enhance safety and operational efficiency.

- A systematic return process for rental equipment helps avoid additional fees and fosters positive relationships with leasing firms.

- Documenting the condition of tools upon return protects against disputes over damages or unexpected charges.

Introduction

In the dynamic landscape of project management, the effective rental of machinery significantly impacts project timelines and budgets. Project managers face the critical task of navigating equipment needs, understanding rental agreements, and ensuring proper maintenance to avoid costly disruptions. With the construction machinery leasing market projected to soar, it is essential for managers to make informed choices amidst potential pitfalls. This article explores best practices for optimizing machine rentals, providing insights that empower project leaders to enhance efficiency and safeguard their investments.

Understand Your Equipment Needs

To enhance rental choices, managers must conduct a thorough evaluation of requirements. This necessitates a clear understanding of the scope, the specific tasks involved, and the tools required to execute those tasks effectively. For example, projects that involve heavy lifting may necessitate the use of forklifts or boom lifts, while concrete-related tasks could demand mixers and demolition hammers. Collaborating with team members and stakeholders can yield valuable insights into the most effective tool selections.

Furthermore, assessing the initiative's timeframe and the expected frequency of tool usage is crucial in determining whether leasing or buying is the more cost-effective choice. As Josh Nickell, Vice President of the American Rental Association, aptly states, "You can’t simply presume that there’s an item on your lot or wish one will return in time; you must engage in much more planning and utilize analytics to predict what your requirements will be." This strategic approach to asset management is essential for enhancing project efficiency and achieving successful outcomes.

At EZ Equipment Rental, we offer a diverse range of well-maintained forklift options tailored to meet your specific needs. Understanding the economic implications of machines rental choices is increasingly vital, especially as the U.S. construction machinery leasing market is projected to reach USD 98.29 billion by 2034. Challenges such as a shortage of skilled operators and mechanics further underscore the importance of careful planning in machines rental decisions. Our commitment to reliability and exceptional customer support ensures that project leaders have access to the right tools when they are needed.

Review Rental Agreements Thoroughly

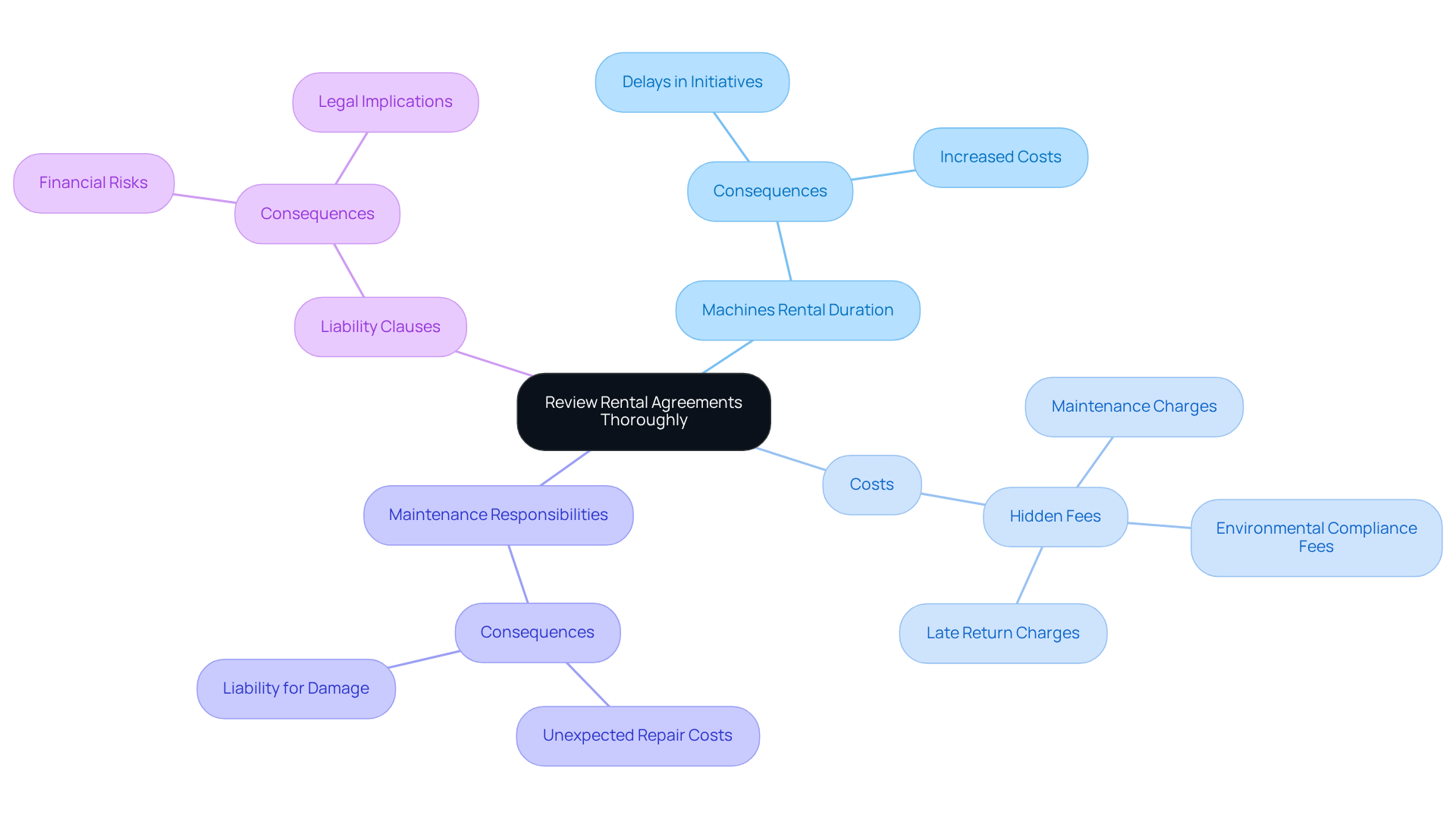

Project managers must meticulously review lease agreements before signing to avoid costly pitfalls. Key elements to scrutinize include:

- Machines rental duration

- Costs

- Maintenance responsibilities

- Liability clauses

Misunderstandings in these agreements can lead to significant delays in initiatives; nearly 60% of construction efforts experience setbacks due to insufficient tools, often stemming from unclear contract terms. Furthermore, hidden fees, such as those for maintenance or cleaning, can inflate overall costs unexpectedly. For example, some agreements may impose charges for environmental compliance or late returns, which can accumulate quickly.

It is also essential to clarify the process for reporting device issues and the expected timeline for repairs. As Steve Hansen, CEO of Equipment Leases, remarks, "A thoughtfully designed lease contract can conserve time and resources in management of tasks." By proactively understanding machines rental agreements, team leaders can mitigate risks, avoid hidden expenses, and ensure their initiatives stay within budget and on time.

Maintain Equipment During Rental

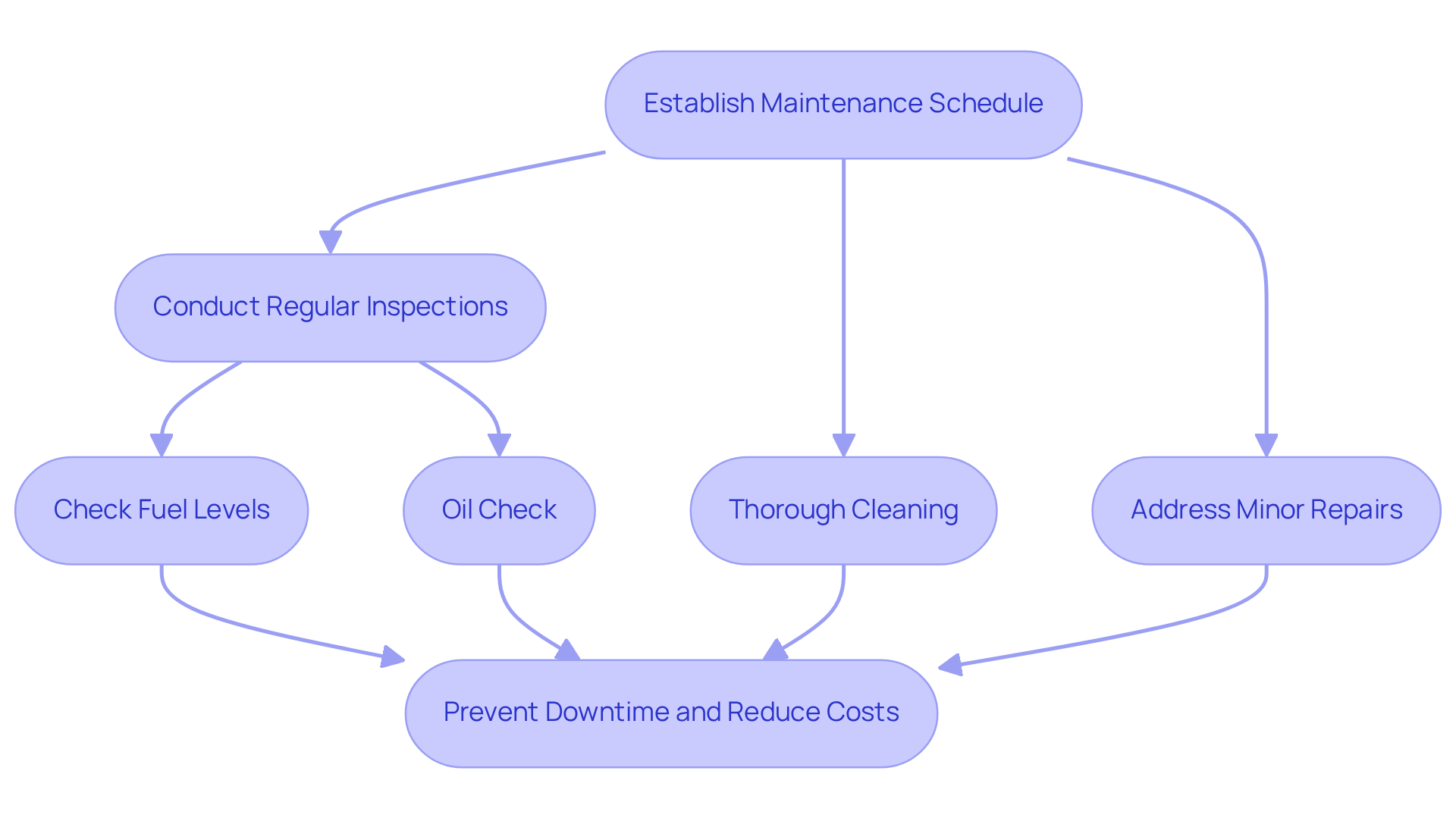

To ensure optimal functionality of machines rental, supervisors must establish a comprehensive maintenance schedule. This involves conducting regular inspections, thorough cleaning, and promptly addressing minor repairs to prevent more significant issues. For instance, routinely checking fuel levels and oil in machines rental, like generators, can substantially mitigate the risk of breakdowns. Predictive maintenance can reduce unexpected machine downtime by 50%, underscoring the necessity for project leaders to prioritize these practices.

Educating team members on the proper use and maintenance of tools is vital for enhancing both safety and operational efficiency. Notably, 52% of facility supervisors cite a lack of skills among their personnel as the primary reason for outsourcing maintenance. Furthermore, documenting all maintenance activities fosters accountability and provides valuable reference points when retrieving tools. By emphasizing these maintenance practices, supervisors can effectively minimize disruptions, ensuring that projects progress smoothly and efficiently.

Neglecting maintenance can lead to unforeseen downtime, which incurs an average cost of $260,000 per hour, highlighting the financial ramifications of proper asset care. Therefore, it is imperative for supervisors to prioritize maintenance to safeguard their investments and maintain operational integrity.

Execute a Smooth Equipment Return Process

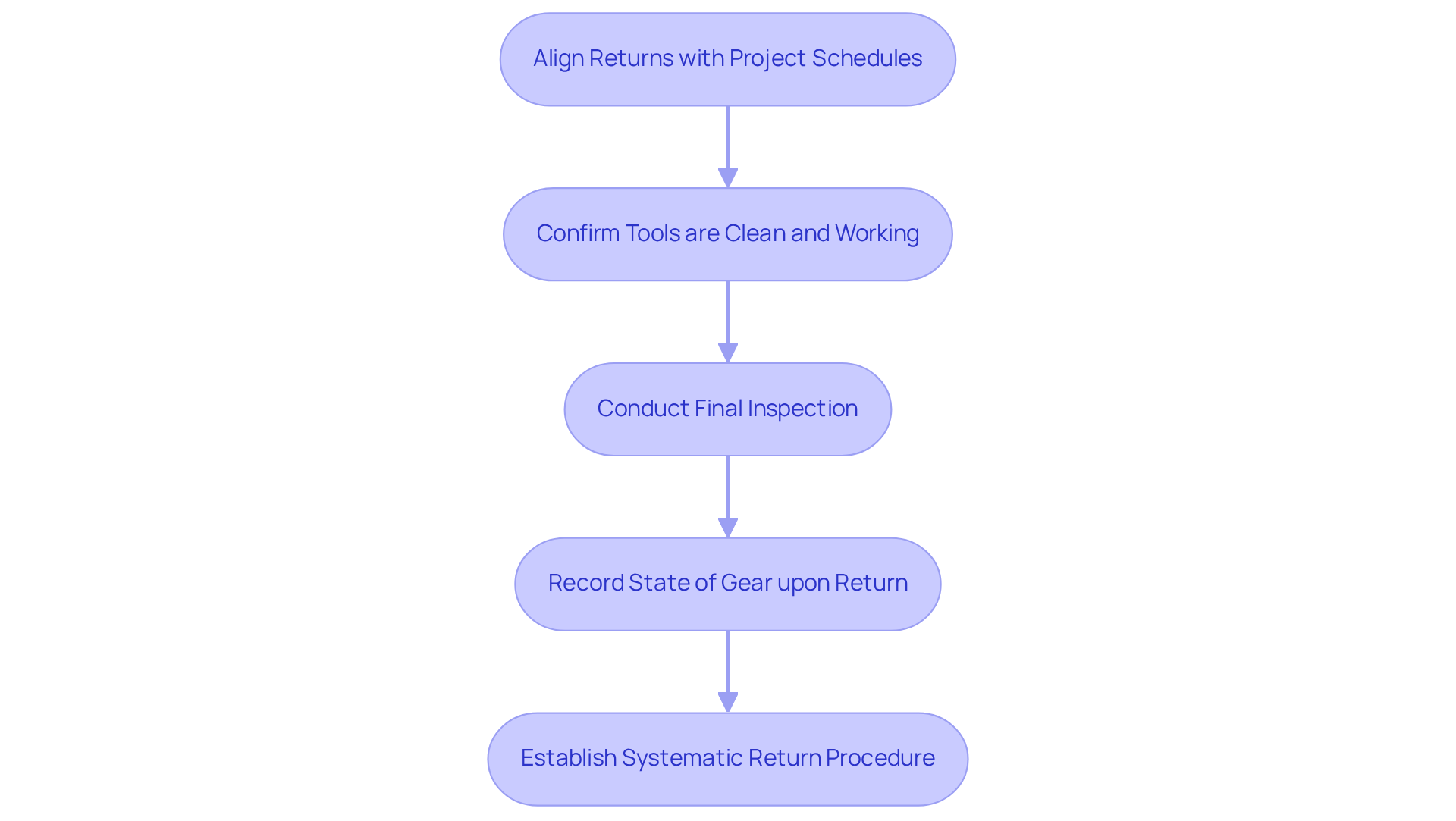

To ensure a seamless return process, managers must strategically plan the return of machines rental items well in advance. This planning involves:

- Aligning returns with project schedules.

- Confirming that all tools are meticulously cleaned and in optimal working condition.

- Conducting a final inspection to identify any issues that may need addressing prior to the return.

- Recording the state of the gear upon return to act as a safeguard against disputes over damages or unexpected charges.

According to the American Rental Association, effective management of tool returns is vital for maintaining operational efficiency and cost-effectiveness in machines rental, particularly since an hour of downtime can cost businesses an average of $260,000. By establishing a systematic return procedure, project managers can foster positive relationships with leasing firms and minimize the risk of incurring additional fees.

Common pitfalls, such as neglecting to document the condition of tools, can lead to disputes over damages or fees, highlighting the necessity of thoroughness in the return process. A case study of an ATV rental company exemplifies this; by tracking ROI and managing equipment effectively, they enhanced their overall profitability and customer satisfaction.

Conclusion

Effective management of equipment rentals is crucial for project managers aiming to enhance operational efficiency and minimize costs. By understanding equipment needs, thoroughly reviewing rental agreements, maintaining machinery during use, and executing a smooth return process, project leaders can navigate the complexities of rental management with confidence.

Key insights emphasize the importance of assessing specific project requirements to make informed rental decisions. A meticulous review of lease agreements can prevent misunderstandings that lead to delays and unexpected costs. Furthermore, establishing a robust maintenance schedule ensures optimal equipment performance and safeguards against costly downtimes. Finally, planning for the return of rented equipment fosters positive relationships with rental companies, further streamlining project execution.

Ultimately, adopting these best practices enhances project management effectiveness and contributes to the overall success of initiatives. Project managers are encouraged to prioritize these strategies, as they significantly impact timelines, budgets, and project outcomes. By taking a proactive approach to equipment rental, managers can ensure that their projects run smoothly, efficiently, and within budget, paving the way for future success.

Frequently Asked Questions

Why is it important to understand equipment needs before renting?

Understanding equipment needs is crucial to enhance rental choices by evaluating the scope of the project, specific tasks involved, and the tools required to execute those tasks effectively.

What types of equipment might be needed for different projects?

Projects involving heavy lifting may require forklifts or boom lifts, while concrete-related tasks could necessitate mixers and demolition hammers.

How can collaboration with team members improve equipment selection?

Collaborating with team members and stakeholders can provide valuable insights into the most effective tool selections for the project.

What factors should be considered when deciding between leasing or buying equipment?

Factors to consider include the initiative's timeframe, expected frequency of tool usage, and the economic implications of rental choices.

What does Josh Nickell emphasize about planning for equipment needs?

Josh Nickell emphasizes that effective planning and the use of analytics are essential for predicting equipment requirements and ensuring project efficiency.

What is the significance of the U.S. construction machinery leasing market projection?

The U.S. construction machinery leasing market is projected to reach USD 98.29 billion by 2034, highlighting the growing importance of strategic planning in equipment rental decisions.

What challenges are mentioned regarding equipment rental?

Challenges include a shortage of skilled operators and mechanics, which underscores the need for careful planning in machine rental decisions.

What services does EZ Equipment Rental offer to support project leaders?

EZ Equipment Rental offers a diverse range of well-maintained forklift options and is committed to reliability and exceptional customer support to ensure project leaders have access to the right tools when needed.