Key Highlights:

- Soil compactors compress earth and materials to enhance density and stability, preventing structural failures.

- Proper ground compaction improves load-bearing capacity and reduces issues like settling.

- Different types of soil compactors include plate compressors, jumping jacks, vibratory rollers, sheepsfoot rollers, and tandem rollers, each suited for specific applications.

- Key features of soil compactors include operating weight, drum width, compaction depth, power source, vibration frequency, and ease of operation.

- Regular maintenance practises for soil compactors include inspections, fluid level checks, cleaning, lubrication, proper storage, and following manufacturer guidelines.

- Effective maintenance can significantly improve the performance and lifespan of soil compactors, ensuring successful construction outcomes.

Introduction

Soil compactors are essential in construction, ensuring that the ground beneath structures is stable and capable of supporting heavy loads. These specialized machines not only enhance soil density but also prevent costly issues like settling and structural failures. As the construction industry evolves, understanding the various types of compactors, their key features, and effective maintenance strategies is crucial for achieving optimal results.

What challenges do operators face in selecting the right compactor? Furthermore, how can effective maintenance strategies maximize performance and longevity? By addressing these questions, we can ensure that your projects run smoothly and efficiently.

Define Soil Compactors and Their Importance in Construction

Maximize Stability with Our Compactors

Compactors are specialized machines designed to compress earth, gravel, and other materials, significantly enhancing their density and stability. This crucial process in construction reduces air pockets within the ground, thereby improving its load-bearing capacity. By ensuring proper ground compaction, you can prevent issues like settling, which often leads to structural failures, uneven surfaces, and costly repairs.

Why Choose Our Compactors?

Ground compacting machines are indispensable in construction projects, ensuring that the earth is adequately prepared to support various structures. You can trust that your foundation will be solid and stable with our reliable soil compactor. Our soil compactors not only enhance the quality of your work but also contribute to the longevity of your structures.

Take Action Today!

Don’t compromise on quality - choose our compactors for your next project. Experience the difference that reliable equipment can make. Contact us now to learn more about our rental options and how we can support your construction needs!

Explore Different Types of Soil Compactors and Their Applications

Types of Soil Compactors: Choose the Right Equipment for Your Project

When it comes to soil compactors, understanding the various types available is crucial for selecting the right equipment for your needs. Here’s a breakdown of the most common types:

-

Plate Compressors: Ideal for small to medium-sized areas such as patios and driveways, plate compressors utilize a flat plate to effectively compress earth and asphalt. Their versatility makes them a go-to choice for many contractors.

-

Jumping Jacks (Rammers): These compactors excel in cohesive materials like clay, delivering a powerful impact that compresses the ground in tight spaces. Their efficiency in challenging conditions makes them indispensable for specific projects.

-

Vibratory Rollers: Designed for larger areas, vibratory rollers can handle both granular and cohesive materials. By utilizing vibration, they significantly improve density, ensuring a solid foundation for any construction work.

-

Sheepsfoot Rollers: Tailored for dense clay and cohesive earth, sheepsfoot rollers feature protruding feet that knead the ground, making them highly effective for deep compaction. Their unique design allows for thorough soil treatment, enhancing project outcomes.

-

Tandem Rollers: Equipped with two smooth drums, tandem rollers are perfect for asphalt and granular materials. They not only compact effectively but also deliver a smooth finish, making them essential for high-quality results.

Contractors can make informed decisions that lead to successful project outcomes by understanding the specific applications of each type of soil compactor. Don’t hesitate to reach out for expert advice on selecting the right equipment for your next job!

Identify Key Features and Specifications of Soil Compactors

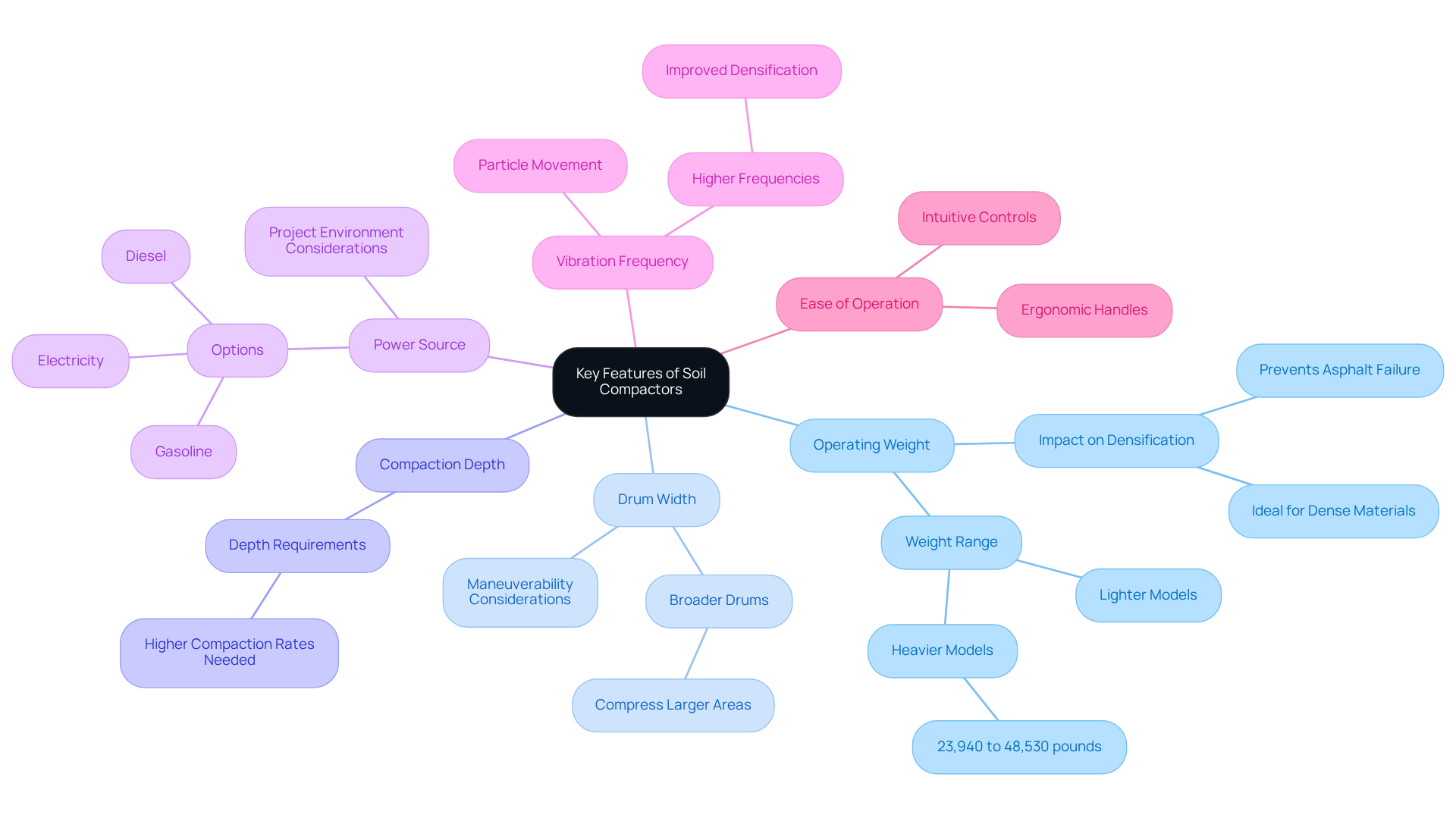

When choosing a soil compactor, it’s essential to take into account several key features and specifications to guarantee optimal performance.

-

Operating Weight: The operating weight of a ground compactor plays a significant role in its effectiveness. Heavier compactors, typically ranging from 23,940 to 48,530 pounds, exert greater force, making them ideal for dense materials. Conversely, lighter models are more suitable for granular soils, where less force is needed for adequate densification. This range of operating weight is vital, as it directly impacts the effectiveness of densification, helping to achieve the industry standard of 92% density. This standard is essential for preventing premature asphalt failure and avoiding costly repairs.

-

Drum Width: A broader drum allows for the compression of larger areas in fewer passes, enhancing efficiency. However, this can compromise maneuverability in tight spaces. Therefore, it’s essential to balance width with the specific requirements of the task at hand.

-

Compaction Depth: Different compactors achieve varying depths of density, which is crucial for the success of your project. For instance, deeper compaction often requires machines with higher compaction rates, measured in pounds per square foot or kilonewtons (kN). Understanding the necessary depth for your undertaking is key to selecting the right equipment.

-

Power Source: Power source options for soil compactors include gasoline, diesel, or electricity. The choice of power source should align with the project environment and the availability of fuel or electrical outlets, ensuring uninterrupted operation throughout the job.

-

Vibration Frequency: Higher vibration frequencies can lead to improved densification outcomes, particularly in granular materials. This feature facilitates better particle movement and density reduction, which is essential for achieving optimal compaction results.

-

Ease of Operation: Ergonomic handles and intuitive controls enhance operator comfort and efficiency, reducing fatigue and boosting productivity on the job site.

These specifications are critical in assessing the effectiveness of the soil compactor for specific types of earth and project requirements. For example, using a compactor with the appropriate operating weight can prevent premature asphalt failure and costly repairs. This underscores the importance of selecting the right equipment, particularly a soil compactor, for the task at hand. Don't compromise on quality; select the right soil compactor today!

Implement Maintenance Strategies for Soil Compactors

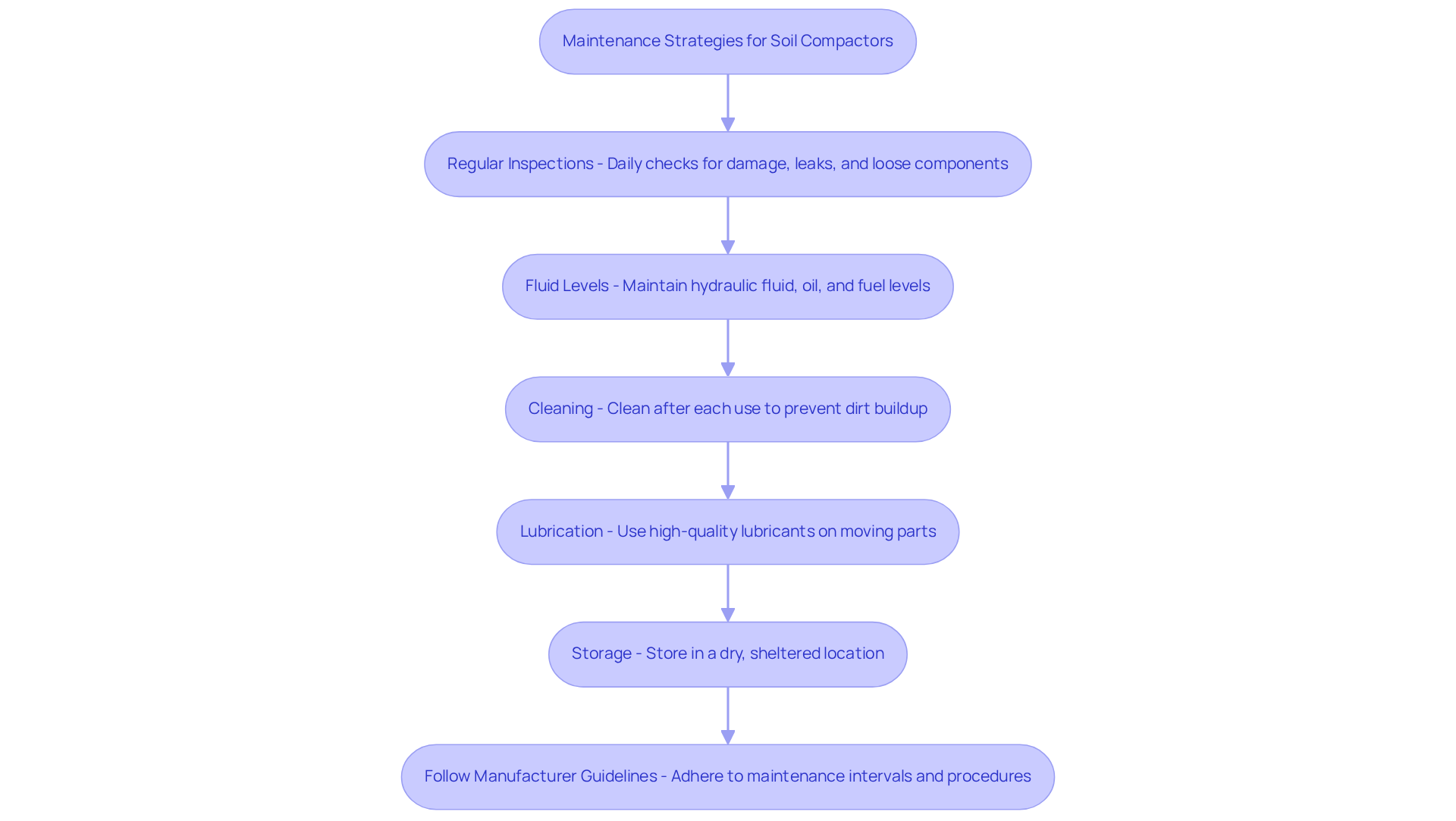

Maximize the performance and lifespan of your soil compactor by implementing effective maintenance strategies. Here are key practices to consider:

-

Regular Inspections: Conduct daily checks for visible damage, leaks, and loose components before operation. This proactive approach can significantly reduce the risk of unplanned downtime, which affects 51% of maintenance professionals as a top challenge. On average, manufacturing facilities experience about 20 unplanned downtime incidents per month, emphasizing the importance of regular inspections.

-

Fluid Levels: Regularly check and maintain hydraulic fluid, oil, and fuel levels to ensure optimal performance. Proper fluid management is essential for preventing mechanical failures and extending equipment life.

-

Cleaning: After each use, thoroughly clean the compactor, especially around moving parts, to prevent dirt buildup that can lead to wear. A clean machine operates more efficiently and reduces maintenance costs over time.

-

Lubrication: Use high-quality lubricants on moving parts to minimize friction and wear. Regular lubrication is a best practice that can enhance the longevity of the machine, as well-maintained equipment tends to perform better and last longer.

-

Storage: Place compacting machines in a dry, sheltered location to shield them from moisture and corrosion, especially during off-seasons. Appropriate storage conditions can avert deterioration and guarantee preparedness for future tasks.

-

Follow Manufacturer Guidelines: Adhere to the operation and maintenance manual for specific maintenance intervals and procedures. This ensures that all maintenance tasks are performed correctly and timely, aligning with industry standards.

As Charlie Green, Senior Research Analyst, notes, "Preventive maintenance should be part of a comprehensive maintenance strategy that includes corrective and predictive maintenance." By implementing these strategies, operators can greatly improve the reliability and efficiency of their soil compactor, making it an essential tool in construction endeavors. Regular inspections and maintenance not only improve equipment longevity but also contribute to overall project success.

Conclusion

Soil compactors are essential in construction, ensuring the ground is properly prepared to support structures, which enhances stability and longevity. Choosing the right type of compactor is crucial; it directly impacts the effectiveness of the compaction process and the overall success of your construction projects.

In this article, we explored various types of soil compactors, including:

- Plate compressors

- Jumping jacks

- Vibratory rollers

- Sheepsfoot rollers

- Tandem rollers

Each type offers distinct advantages tailored to specific project needs. Understanding their applications is vital for contractors aiming to optimize performance. Key features such as operating weight, drum width, compaction depth, and maintenance strategies were also discussed to guide effective decision-making.

Investing in the right soil compactor and adhering to maintenance best practices can significantly enhance construction outcomes. As the industry evolves, staying informed about advancements in soil compactor technology and maintenance techniques empowers contractors to uphold the highest standards of quality and safety in their projects. Prioritize the selection and care of soil compactors to establish a solid foundation for success in any construction endeavor. Take action now-ensure your projects are built on reliable equipment and expert knowledge.

Frequently Asked Questions

What are soil compactors?

Soil compactors are specialized machines designed to compress earth, gravel, and other materials, enhancing their density and stability.

Why is soil compaction important in construction?

Soil compaction is crucial because it reduces air pockets within the ground, improving its load-bearing capacity and preventing issues like settling, which can lead to structural failures and costly repairs.

How do soil compactors contribute to construction projects?

Soil compactors ensure that the earth is adequately prepared to support various structures, enhancing the quality of work and contributing to the longevity of the structures built on the compacted ground.

What benefits do your compactors offer?

Our soil compactors provide reliable performance that enhances the stability of foundations and ensures that your construction projects are built on solid ground.

How can I learn more about your soil compactor rental options?

You can contact us to learn more about our rental options and how we can support your construction needs.