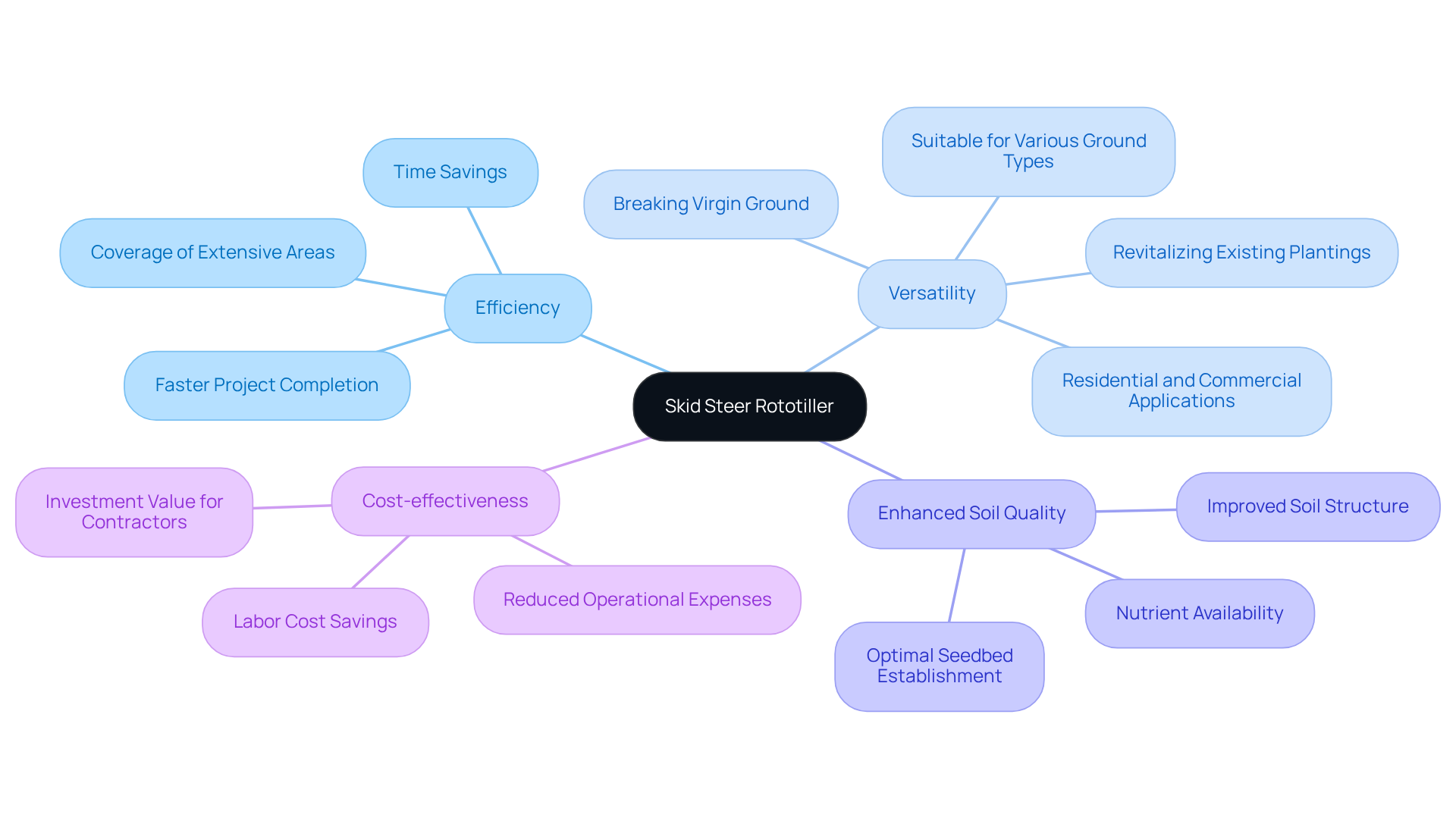

Key Highlights:

- A skid steer rototiller is crucial for breaking up and aerating soil, essential for landscaping, gardening, and agriculture.

- Benefits include efficiency in covering large areas quickly, versatility across different ground types, and enhanced soil quality for better plant growth.

- Cost-effectiveness is achieved through reduced labour costs and time savings, making it a valuable investment for contractors.

- Pre-use checks include inspecting equipment, cleaning the area, checking fluid levels, reviewing safety features, and familiarising with controls.

- Best practises for operation involve adjusting tilling depth, maintaining straight passes, monitoring speed, utilising bidirectional operation, and regularly checking performance.

- Post-operation care includes cleaning the tool, inspecting components, lubricating moving parts, proper storage, and scheduling regular maintenance to extend the equipment's lifespan.

Introduction

A skid steer rototiller is not merely an attachment; it serves as a powerful tool that significantly enhances soil preparation for landscaping and agricultural projects. By effectively breaking up and aerating the earth, it improves soil quality and fosters healthier plant growth, making it an essential asset for professionals in the field. However, the tool's effectiveness relies on a solid understanding of best practices, ranging from pre-use checks to post-operation maintenance.

What strategies can ensure optimal performance and longevity of a skid steer rototiller? Additionally, how can operators avoid common pitfalls that may compromise their results? Addressing these questions is crucial for maximizing the benefits of this equipment.

Understand the Skid Steer Rototiller: Purpose and Benefits

A compact rotary tiller is an essential attachment for breaking up and aerating soil, making it particularly effective for landscaping, gardening, and agricultural projects. Its primary role is to prepare the ground for planting by thoroughly mixing earth, compost, and organic materials. The benefits of using a skid steer rototiller include:

- Efficiency: Skid steer rototillers can cover extensive areas quickly, significantly reducing the time required for soil preparation compared to manual methods. For example, using rotary tillers can save considerable time when initiating landscaping projects, allowing for faster completion. Standard 60-inch widths efficiently process large areas, enhancing operational effectiveness.

- Versatility: These attachments perform well across various ground types and conditions, making them suitable for both residential and commercial applications. They excel in breaking virgin ground and revitalizing existing plantings, which is crucial for diverse landscaping tasks. Understanding how ground type affects tilling effectiveness is vital for optimizing performance.

- Enhanced Soil Quality: By thoroughly mixing soil and organic matter, compact machinery rototillers improve soil structure and nutrient availability, promoting healthier plant growth. This capability is essential for establishing optimal seedbeds and ensuring successful crop yields in agricultural projects.

Cost-effectiveness can be achieved by utilizing a skid steer rototiller, which can lead to significant savings in labor costs and time, making it a valuable investment for contractors and landscapers. The ability to uproot thousands of weeds in one motion further highlights the efficiency of these tools, resulting in reduced operational expenses.

Landscaping professionals have noted that with the right rototiller attachment, achieving professional-level results is attainable. Most professional-grade rotary cultivator models accommodate hydraulic flows of 15 to 30 gallons per minute, providing the necessary power for effective soil cultivation.

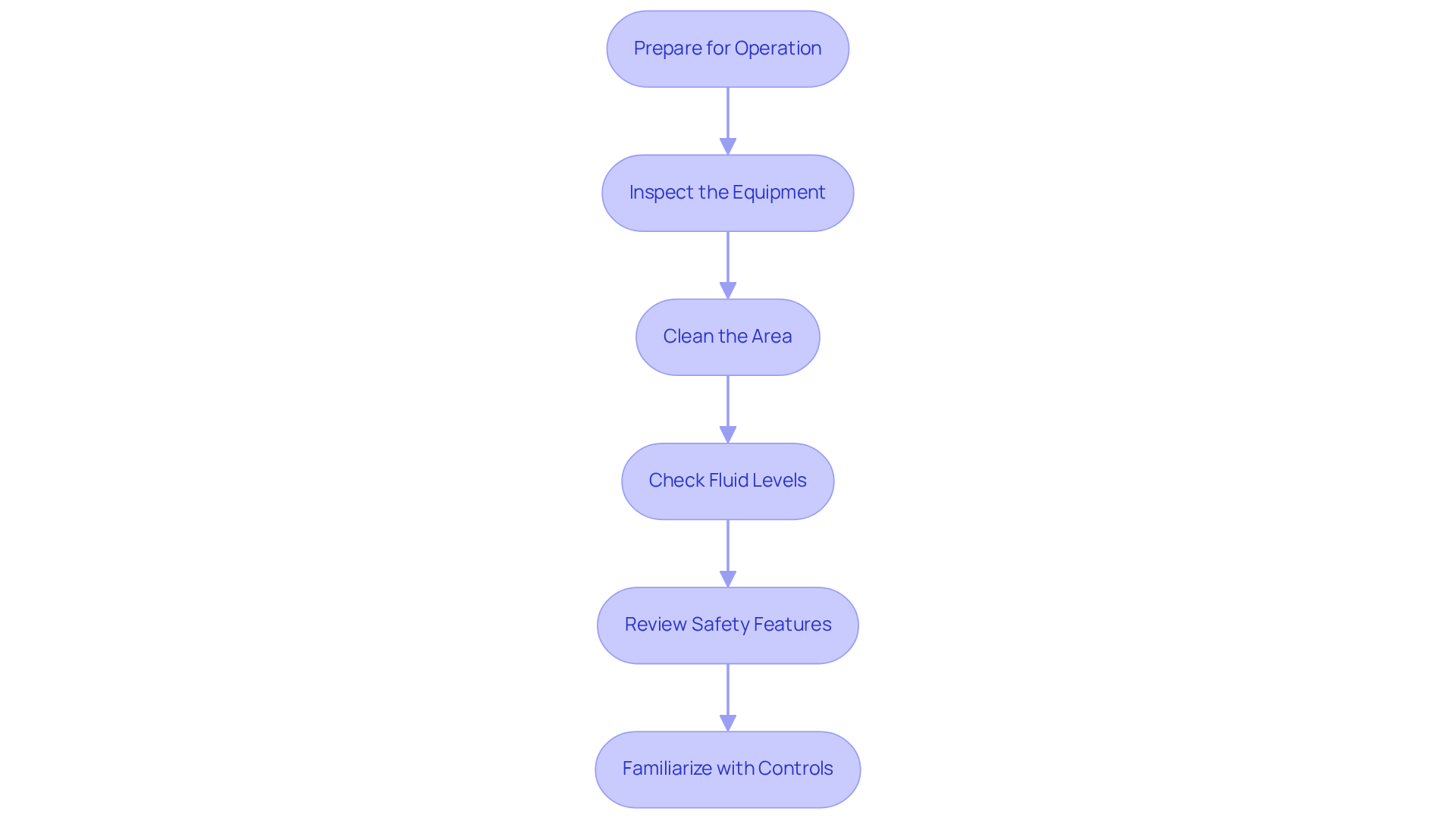

Prepare for Operation: Essential Pre-Use Checks and Setup

Before using a skid steer rototiller, it is essential to conduct thorough pre-use checks to ensure safety and optimal functionality. Key practices to follow include:

-

Inspect the Equipment: Examine the attachment for visible damage, focusing on tines, hydraulic hoses, and mounting points. Ensure all components are secure and in good condition to prevent malfunctions during operation. As Javier Bocanegra, an equipment inspector, emphasizes, "The first thing you'll want to do is complete a full 360-degree side inspection and walk around inspection complete with visual and inspection checklist."

-

Clean the Area: Clear the tilling area of rocks, roots, and debris. This not only safeguards the implement from harm but also improves its operational efficiency.

-

Check Fluid Levels: Verify that hydraulic fluid levels are adequate and inspect for any leaks in the system. Proper fluid levels are crucial for the smooth operation of the equipment.

-

Review Safety Features: Ensure that all safety devices, including roll-over protective structures (ROPS) and seat belts, are functioning correctly. These features are vital for protecting operators and preventing accidents on the job site. Neglecting these checks can lead to serious consequences, as construction accounted for 20% of all worker fatalities in the U.S. in 2023.

-

Familiarize yourself with the controls of the skid steer rototiller: Take time to understand the vehicle’s controls and the specific functions of the tiller attachment. Familiarity with the equipment enhances operational efficiency and safety.

Regular inspections and pre-use checks are not merely best practices; they are essential for maintaining compliance with safety regulations and reducing the risk of accidents. By implementing these checks, operators can significantly reduce the likelihood of unexpected breakdowns, which can lead to project delays and increased costs, thereby ensuring a safer work environment.

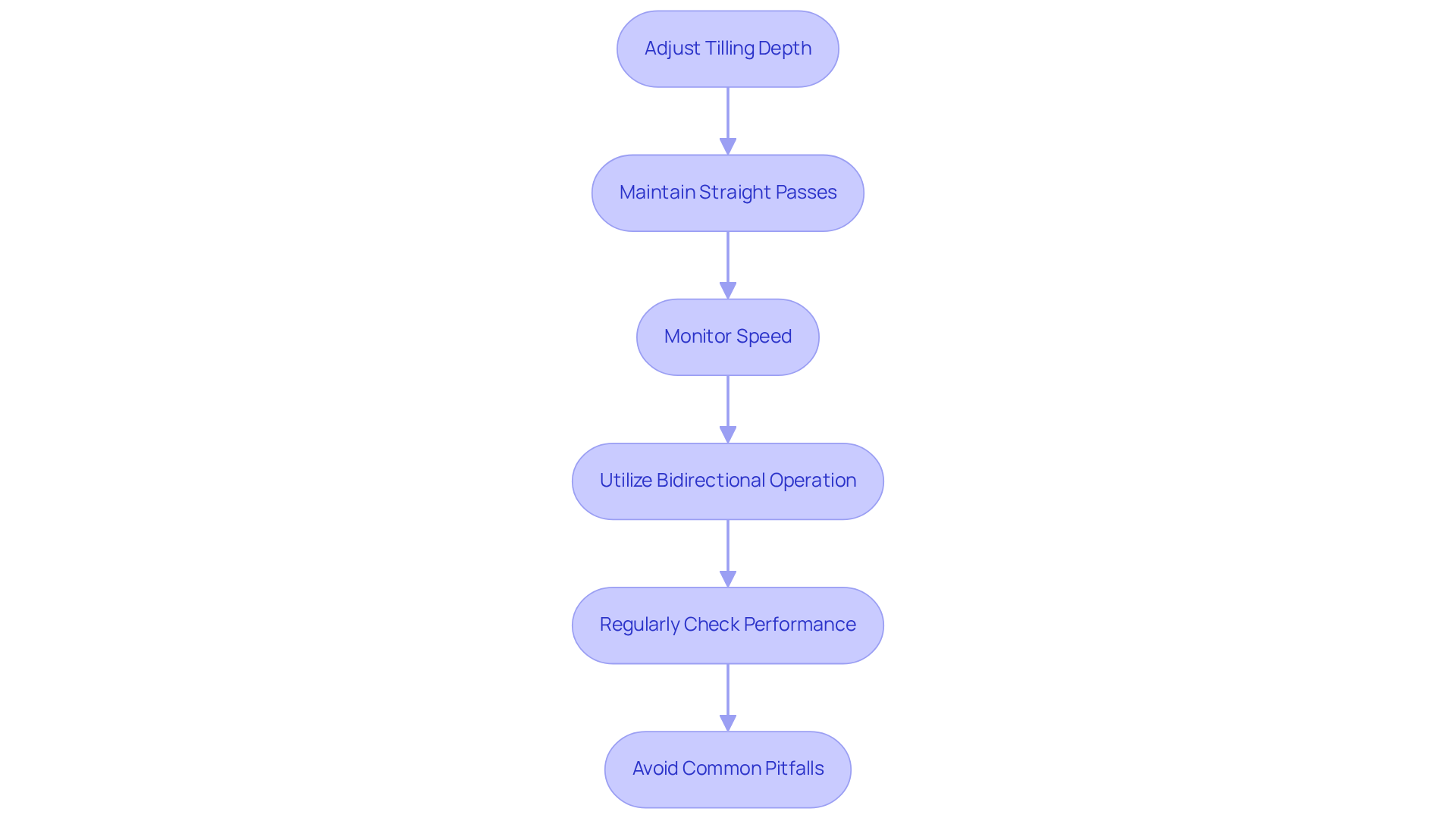

Execute Efficiently: Best Practices for Operating the Rototiller

To operate the skid steer rototiller effectively, follow these best practices:

-

Adjust Tilling Depth: Tailor the tilling depth to the specific soil conditions. Start with a shallow pass on firm ground, gradually increasing the depth to achieve optimal ground preparation. Research indicates that a final tilling depth of 4-6 inches is beneficial for most applications. A case study on the effectiveness of the skid steer rototiller attachments shows that these tools manage difficult ground conditions more effectively than traditional tillers.

-

Maintain Straight Passes: Execute tilling in straight lines, overlapping each pass slightly to ensure even ground preparation. This technique minimizes missed spots and promotes even mixing, which is crucial for effective seed bed preparation. Experienced operators note that maintaining straight passes can significantly improve the quality of ground preparation.

-

Monitor Speed: Keep a steady speed while tilling. Excessive speed can lead to uneven tilling, while moving too slowly may fail to sufficiently break up the ground, affecting overall efficiency. Remember, going too fast can cause inconsistent outcomes, while being too slow may not efficiently break apart the ground.

-

Utilize Bidirectional Operation: Leverage the device's bidirectional capabilities. Begin with forward tilling to break up the ground, then switch to reverse for a finer finish, enhancing texture and preparation quality. This method has been praised by operators for improving the overall finish of the tilled area.

-

Regularly Check Performance: Periodically pause operations to evaluate the equipment’s performance. Make necessary adjustments to optimize results, ensuring that the equipment operates at peak efficiency and effectiveness. Operators often recommend checking for wear on tines and ensuring proper hydraulic connections to maintain optimal performance.

-

Avoid Common Pitfalls: Be cautious of frequent errors, such as neglecting to adjust the tilling depth based on ground conditions or failing to monitor the tiller's performance regularly. These oversights can lead to suboptimal ground preparation and reduced efficiency.

Integrating these best practices will not only enhance the efficiency of your tilling operations but also contribute to better land health and productivity in the long term. Maintaining 30% surface residue can lead to a 70% decrease in wind erosion, emphasizing the significance of effective ground preparation.

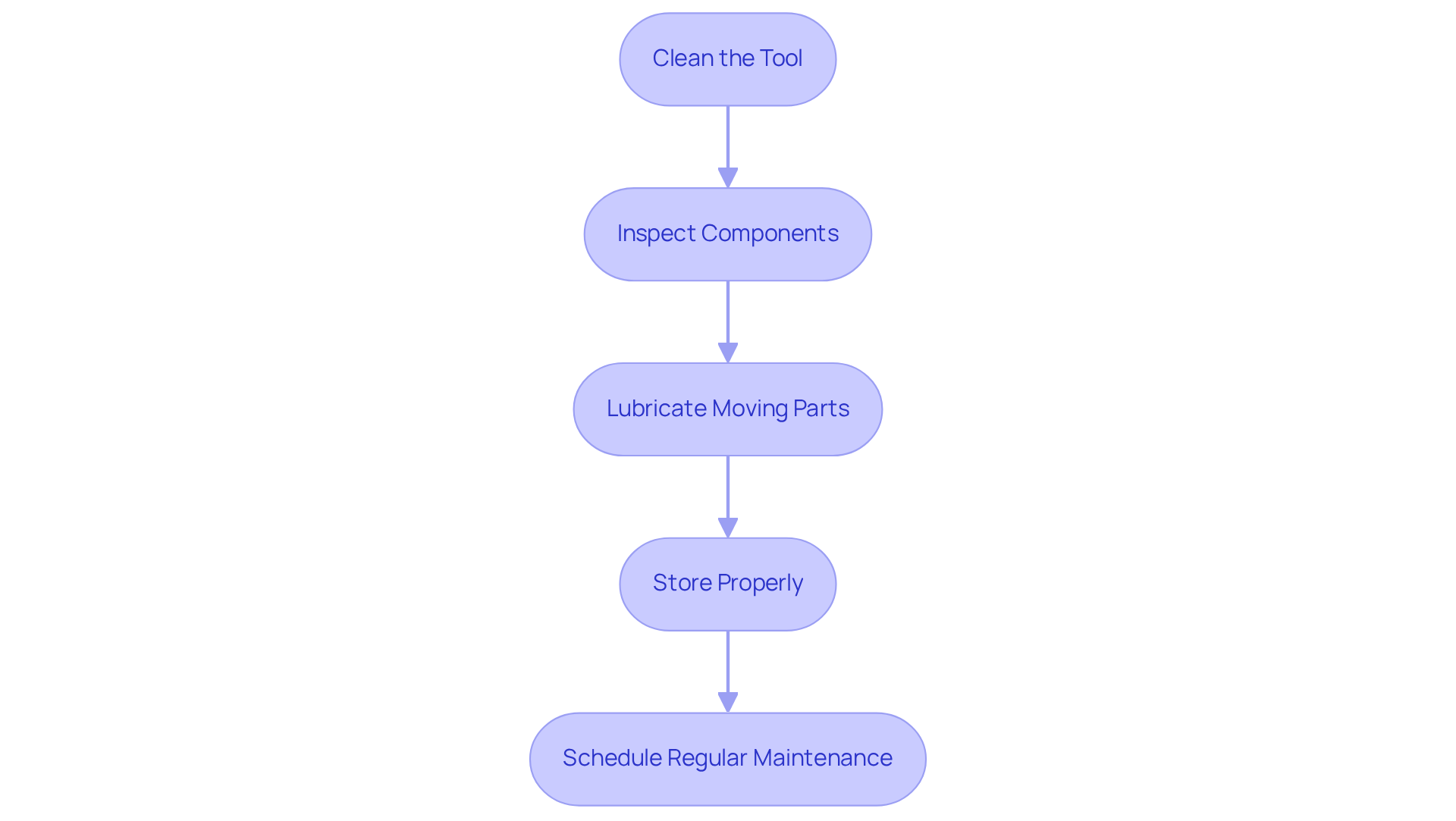

Maintain for Longevity: Post-Operation Care and Maintenance

To ensure the longevity of your skid steer rototiller, implement essential maintenance practices after each use:

- Clean the Tool: Thoroughly remove soil, plant matter, and debris from the equipment. This prevents buildup that can hinder performance and lead to corrosion, ultimately affecting the equipment's lifespan.

- Inspect Components: Regularly check the tines for wear and replace them as needed. Additionally, inspect hydraulic hoses and connections for any signs of leaks or damage to maintain optimal functionality.

- Lubricate Moving Parts: Consistently lubricate all moving parts to minimize friction and wear, ensuring smooth operation during future uses. This practice is crucial for maintaining performance and efficiency.

- Store Properly: After cleaning, keep the gardening tool in a dry, sheltered area to protect it from harsh weather conditions. Securely mount it to prevent any damage during storage, which can significantly impact its operational life.

- Schedule Regular Maintenance: Establish a routine maintenance schedule that includes thorough inspections and servicing. Regular maintenance not only keeps the tiller in top condition but also enhances its performance and longevity.

According to industry standards, compact loaders have an average operational lifespan of 6,000 to 12,000 hours with proper maintenance. As indicated by maintenance experts, "Regular servicing and ideal operating conditions can prolong the functional life of wheeled loaders beyond their average expectancy." By adhering to these practices, you can significantly extend the life of your skid steer rototiller, ensuring this rototiller remains a reliable tool for your projects.

Conclusion

Mastering the use of a skid steer rototiller requires a solid understanding of its purpose, benefits, and best practices. This essential attachment not only boosts efficiency and versatility in soil preparation but also significantly enhances soil quality, making it an invaluable tool for landscaping and agricultural projects. By employing the right techniques and maintenance practices, operators can achieve professional-level results while maximizing the lifespan of their equipment.

Key insights emphasize the importance of thorough pre-use checks, effective operating techniques, and diligent post-operation maintenance. Conducting inspections, familiarizing oneself with the equipment, and adhering to operational best practices can prevent accidents and optimize performance. Furthermore, consistent maintenance routines are crucial for extending the life of the skid steer rototiller, ensuring it remains a reliable asset for future projects.

Ultimately, embracing these practices not only enhances immediate operational success but also contributes to long-term soil health and productivity. By prioritizing safety, efficiency, and maintenance, operators can fully leverage the capabilities of skid steer rototillers, transforming their landscaping and agricultural endeavors into successful outcomes.

Frequently Asked Questions

What is the primary purpose of a skid steer rototiller?

The primary purpose of a skid steer rototiller is to break up and aerate soil, preparing the ground for planting by thoroughly mixing earth, compost, and organic materials.

What are the benefits of using a skid steer rototiller?

The benefits include efficiency in covering large areas quickly, versatility across different ground types, enhanced soil quality by improving soil structure and nutrient availability, and cost-effectiveness by reducing labor costs and time.

How does a skid steer rototiller improve efficiency in soil preparation?

Skid steer rototillers can cover extensive areas quickly, significantly reducing the time required for soil preparation compared to manual methods, which allows for faster completion of landscaping projects.

In what types of applications can skid steer rototillers be used?

Skid steer rototillers are suitable for both residential and commercial applications, excelling in breaking virgin ground and revitalizing existing plantings.

How does a skid steer rototiller enhance soil quality?

By thoroughly mixing soil and organic matter, compact machinery rototillers improve soil structure and nutrient availability, which promotes healthier plant growth and establishes optimal seedbeds for successful crop yields.

What are the cost benefits of using a skid steer rototiller?

Utilizing a skid steer rototiller can lead to significant savings in labor costs and time, making it a valuable investment for contractors and landscapers.

What capabilities do professional-grade rotary cultivator models have?

Most professional-grade rotary cultivator models accommodate hydraulic flows of 15 to 30 gallons per minute, providing the necessary power for effective soil cultivation.

List of Sources

- Understand the Skid Steer Rototiller: Purpose and Benefits

- A Quick Overview of Using a Skid Steer Rotary Tiller (https://mclarenindustries.com/us/en/news-and-resources/articles/317/a-quick-overview-of-using-a-skid-steer-rotary-tiller)

- Rototillers Trends and Opportunities for Growth (https://marketreportanalytics.com/reports/rototillers-62017)

- Understanding Skid Steer Rototillers (https://backyardprovider.com/blogs/blue-diamond/understanding-skid-steer-rototillers?srsltid=AfmBOoo0PDvaIAXW8h7h0zuSwA0m828HytXRpdOTB1ff7MSrDegLnnXE)

- Prepare for Operation: Essential Pre-Use Checks and Setup

- 34 Key Construction Safety Statistics | Procore (https://procore.com/library/construction-safety-statistics)

- Why Regular Equipment Inspections Are Important | RPM (https://rpmmachinery.com/importance-of-regular-equipment-inspections)

- How To Do a Skid Steer Pre-Operation Inspection (https://boomandbucket.com/blog/how-to-do-a-skid-steer-pre-operation-inspection?srsltid=AfmBOooZaSlqCpZy4PkR5-u-zLFj9gwl3GGkJbSrMpS20VoH8D6zJ20f)

- Optimizing Skid Steer Performance with Dozer Blade Attachments | OCNJ Daily (https://ocnjdaily.com/news/2026/feb/11/optimizing-skid-steer-performance-with-dozer-blade-attachments)

- Execute Efficiently: Best Practices for Operating the Rototiller

- Quotes and Notes from #digthectc (https://ag.ndsu.edu/greenhouse/carringtonrec/center-points/2018/quotes-and-notes-from-the-conservation-tillage-conference)

- 👷 What Is a Skid Steer Rototiller and How to Use It? (https://skidsteers.com/blog/what-is-a-skid-steer-rototiller-and-how-to-use-it?srsltid=AfmBOooXi7bBRJJQZGtiEUdn4D1hB8LWJ97iJO-TeA1XhbAKOMkuVxO0)

- The effect of tillage depth and traffic management on soil properties and root development during two growth stages of winter wheat (Triticum aestivum L.) (https://soil.copernicus.org/articles/8/391/2022)

- Best Practices for CTL and Skid Steer Operation - Lashley Kubota (https://lashleykubota.com/blog/best-practices-for-ctl-and-skid-steer-operation)

- A Quick Overview of Using a Skid Steer Rotary Tiller (https://mclarenindustries.com/us/en/news-and-resources/articles/317/a-quick-overview-of-using-a-skid-steer-rotary-tiller)

- Maintain for Longevity: Post-Operation Care and Maintenance

- The Average Life Span of Construction Equipment (https://louisianacat.com/our-company/blog/lifespan-of-heavy-equipment)

- The Average Life Span of Construction Equipment - H.O. Penn (https://hopenn.com/blog/average-life-span-of-construction-equipment)