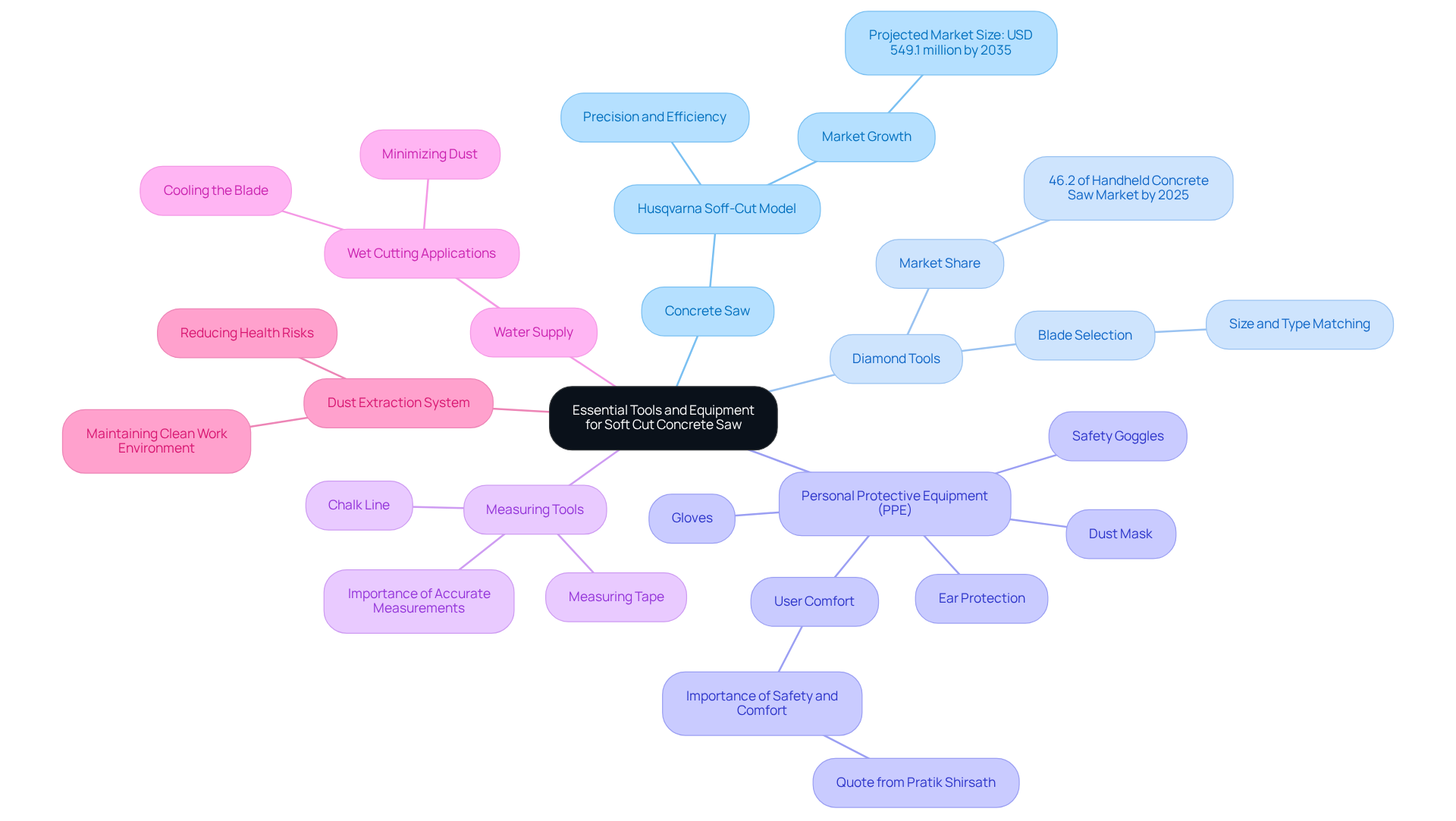

Key Highlights:

- A reliable soft cut concrete saw, like the Husqvarna Soff-Cut, is essential for precision and efficiency in early entry sawing.

- Selecting the right diamond tool based on concrete thickness is crucial; the diamond blades segment is projected to capture 46.2% of the handheld concrete saw market by 2025.

- Personal Protective Equipment (PPE) such as goggles, gloves, and masks is vital for user safety.

- Accurate cutting requires measuring tools like a tape measure and chalk line to mark cutting lines.

- A water supply is necessary for wet cutting, reducing dust and cooling the blade.

- A dust extraction system is recommended to maintain a clean work environment and reduce health risks.

- Preparing the worksite involves clearing debris, marking cutting lines, checking for underground utilities, and inspecting equipment.

- Operating the saw requires starting it correctly, adjusting RPM based on material, and maintaining proper alignment with cutting lines.

- Regular maintenance includes cleaning the saw, inspecting for wear, lubricating moving parts, and proper storage.

- Daily inspections of the saw are essential for ensuring safety and performance.

Introduction

Mastering the art of using a soft cut concrete saw is essential for enhancing the quality and efficiency of concrete cutting projects. As the global market for handheld concrete saws is projected to grow significantly, understanding the necessary tools and techniques becomes increasingly important. However, many operators encounter challenges in achieving precision and safety during the cutting process. To ensure success and avoid common pitfalls when using this powerful tool, it is crucial to follow key steps that promote effective operation.

Gather Essential Tools and Equipment

To effectively operate a soft cut concrete saw, several essential tools and equipment are necessary:

-

A reliable soft cut concrete saw, such as the Husqvarna Soff-Cut model, is crucial for early entry sawing, ensuring precision and efficiency. The global handheld concrete saw market is projected to reach USD 549.1 million by 2035, underscoring the importance of investing in quality equipment.

-

Diamond Tools: Choose the appropriate diamond tool tailored to your cutting needs. Blades vary in size and type, so select one that matches the thickness of the concrete being cut. The diamond blades segment is expected to capture a 46.2% share in the handheld concrete saw market by 2025, emphasizing their role in achieving optimal performance.

-

Personal Protective Equipment (PPE): Safety is paramount; equip yourself with safety goggles, gloves, ear protection, and a dust mask to protect against debris and noise. As industry expert Pratik Shirsath notes, "Safety and comfort for the users has also been taken care of and is of utmost importance."

-

Measuring Tools: Accurate cutting begins with precise measurements. Use a measuring tape and chalk line to clearly mark your cutting lines.

-

Water Supply (if applicable): For wet cutting applications, ensure a water source is available to minimize dust and cool the blade, enhancing performance.

-

Dust Extraction System: Implementing a dust extractor is advisable to maintain a clean and safe work environment, reducing health risks associated with dust exposure.

Having these tools ready will not only simplify your cutting process but also significantly enhance safety on the job site.

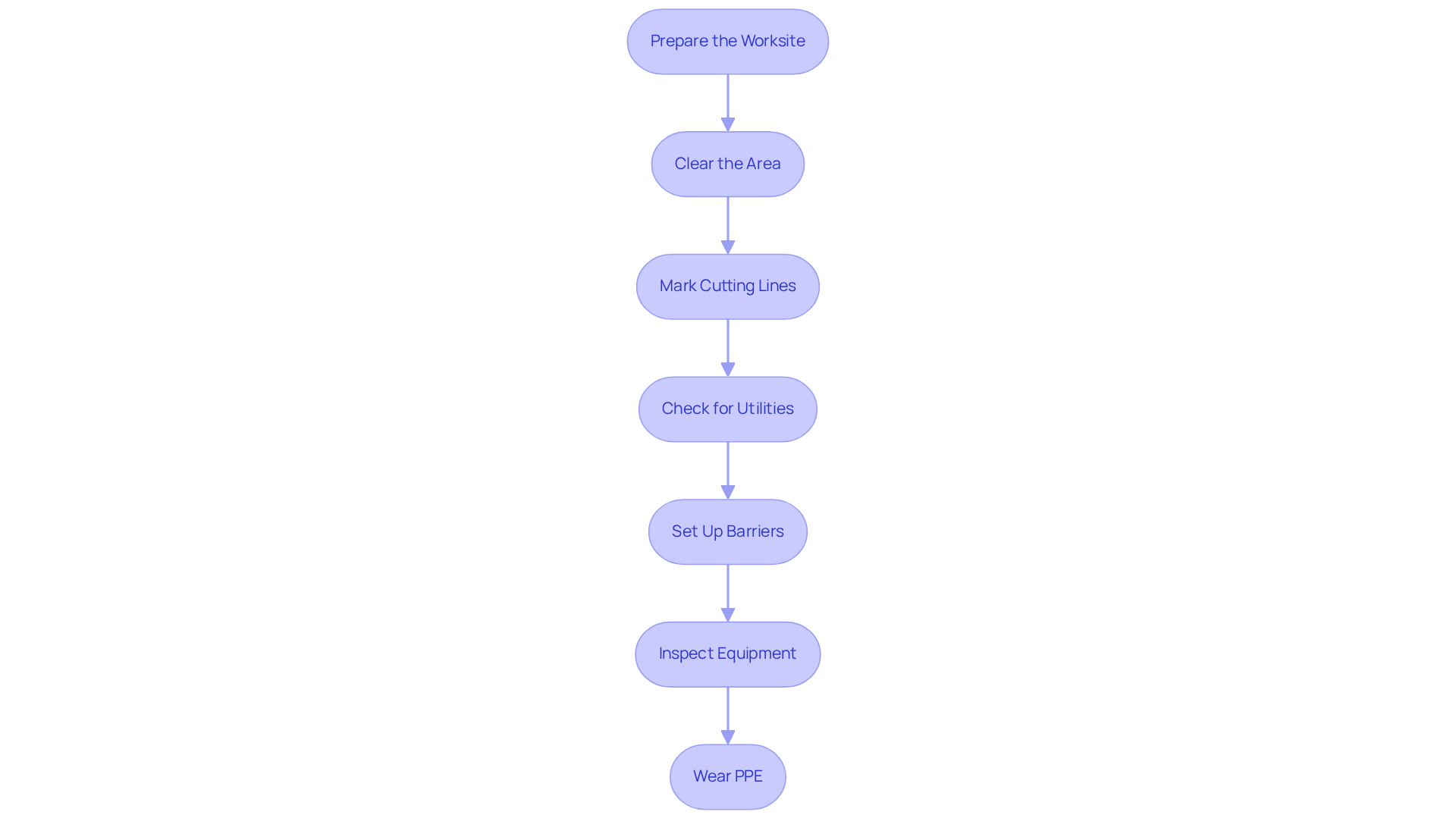

Prepare the Worksite and Ensure Safety

Before you begin cutting, it’s essential to prepare your worksite properly. Start by clearing the area: remove any obstacles, debris, or materials from the work zone to create a safe working environment. Next, mark your cutting lines using a chalk line; this ensures precision and helps avoid mistakes. It’s also crucial to check for utilities - use a utility locator to confirm there are no underground pipes or electrical lines in the excavation area.

If necessary, set up barriers or warning signs to keep unauthorized personnel away from the worksite. Before starting, inspect your saw and other equipment for any signs of wear or damage, ensuring that all safety guards are in place. Finally, don your personal protective equipment (PPE) to safeguard against potential hazards.

By taking these precautions, you will foster a safer and more efficient work environment.

Operate the Soft Cut Concrete Saw

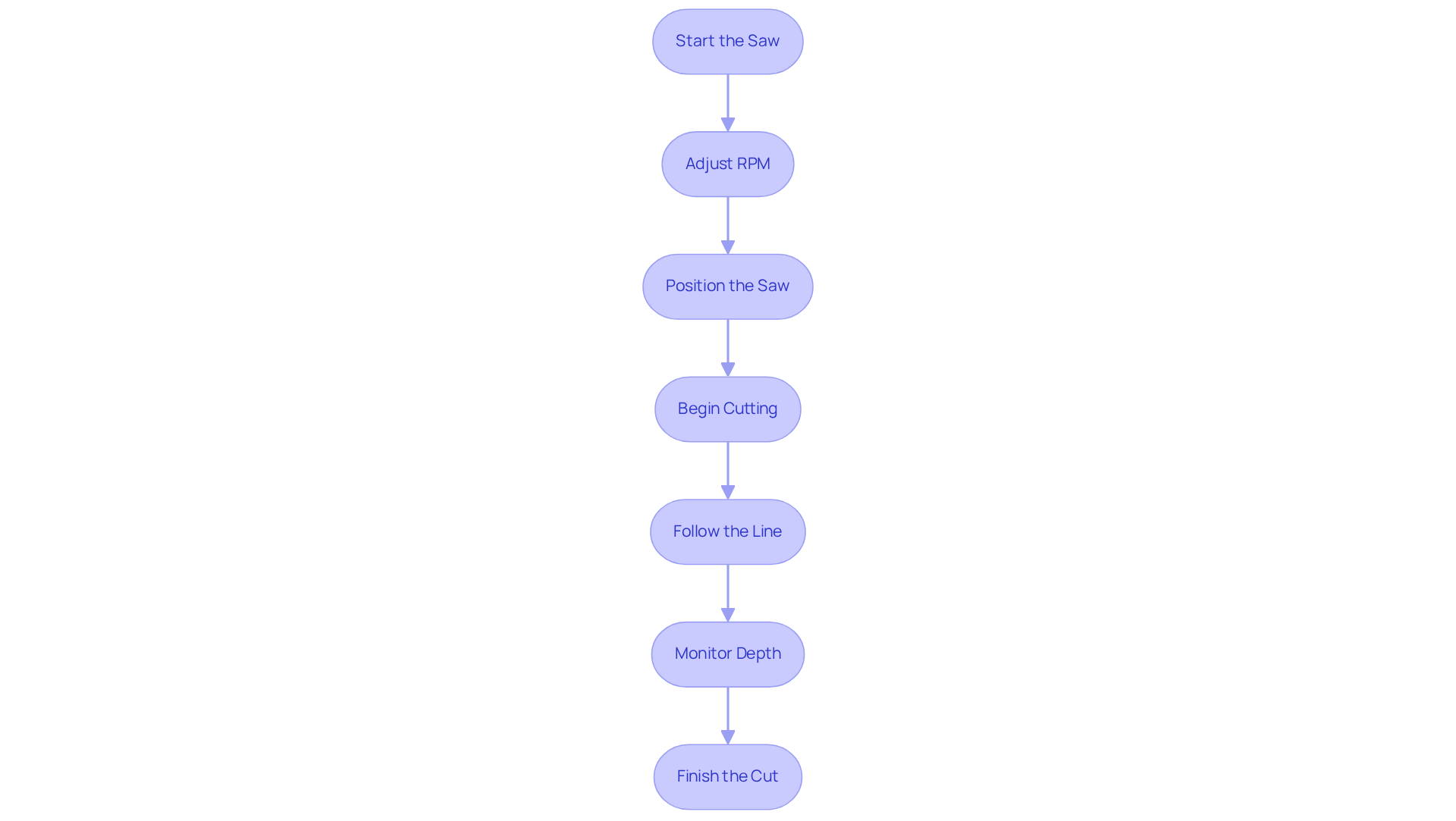

To operate your soft cut concrete saw effectively, follow these essential steps:

- Start the Saw: Ensure the cutting tool is correctly installed and aligned. Start the saw according to the manufacturer's instructions.

- Adjust RPM: Set the saw to the appropriate RPM based on the material being cut. For softer concrete, a lower RPM is often adequate, as it helps preserve tool life and efficiency in the process. Exceeding the maximum RPM can cause the blade to overheat, warp, or break, leading to unsafe working conditions.

- Position the Saw: Align the saw with the marked slicing line. Ensure the skid plate is flat against the concrete surface for stability and optimal cutting performance.

- Begin Cutting: Start the cut slowly, allowing the tool to penetrate the concrete without forcing it. A consistent pace is essential to prevent overheating the cutting tool, which can result in premature wear or damage. For instance, concrete with 3% steel can reduce bit life by about 90%, so adjusting your RPM accordingly is vital.

- Follow the Line: Keep the saw aligned with the chalk line, applying gentle pressure to guide it along the cut. Avoid sudden movements that could lead to uneven edges, which can compromise the quality of the work.

- Monitor Depth: Regularly check the depth of the cut to ensure it meets project specifications, typically between 25% to 33% of the slab thickness. This attention to detail is vital for structural integrity. Utilizing a tool at a considerably lower RPM than suggested can decrease cutting efficiency and may lead to inconsistent results.

- Finish the Cut: Once the cut is done, turn off the saw and allow the tool to come to a complete stop before lifting it from the concrete.

By following these steps, you will achieve clean, precise segments while maximizing efficiency and reducing expenses related to tool wear and project delays with your soft cut concrete saw. Additionally, consider the cost per cut when choosing cutting tools; for example, a $30 tool that lasts 100 cuts costs $0.30 per cut, while a premium option may provide better long-term value.

Perform Maintenance and Cleanup

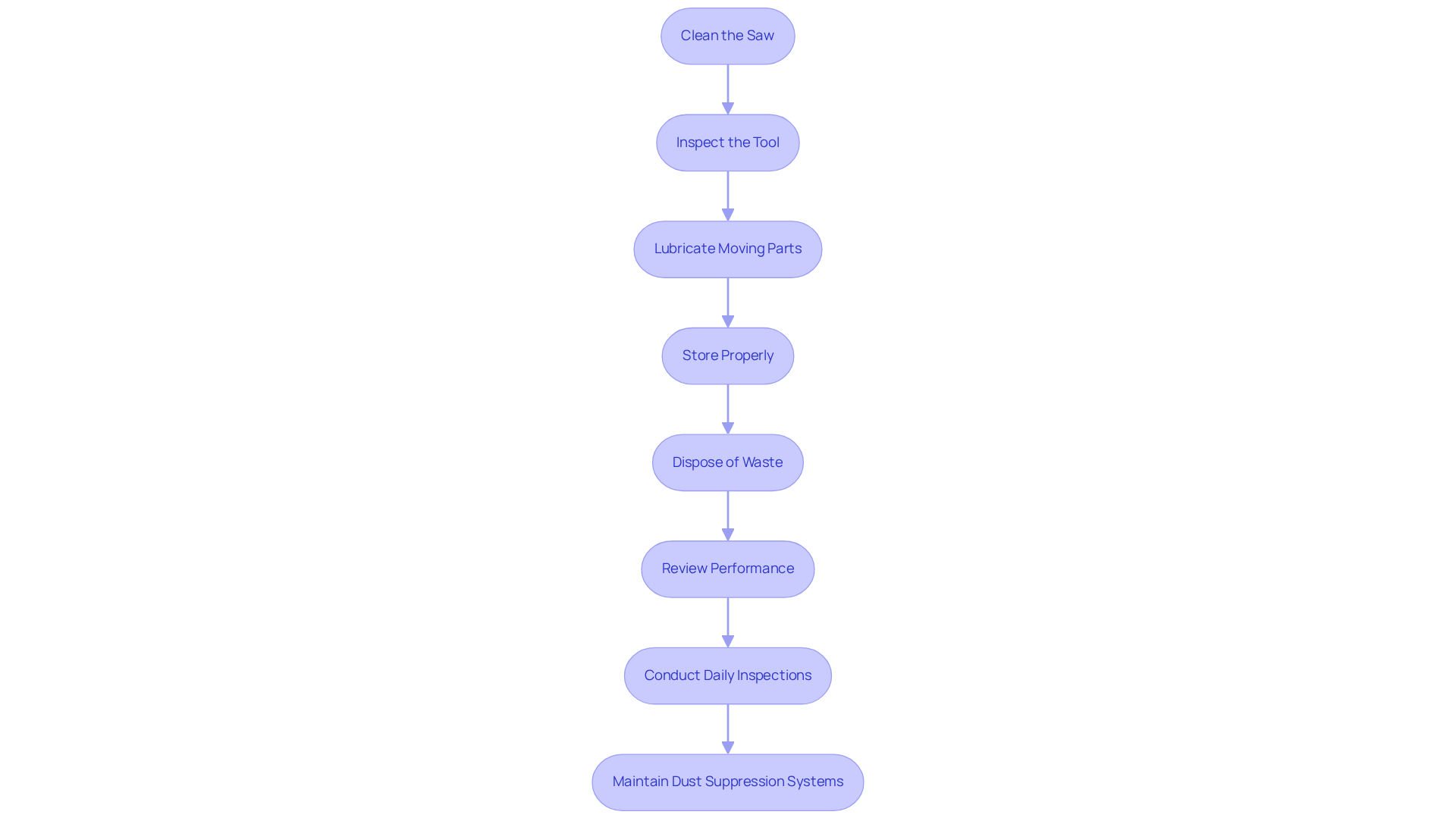

To ensure optimal performance and longevity of your soft cut concrete saw, follow these essential maintenance and cleanup steps:

- Clean the Saw: Use a soft brush or compressed air to remove concrete dust and debris, focusing on areas around the cutting edge and motor. This prevents accumulation that can negatively impact performance.

- Inspect the Tool: Regularly examine the diamond cutting tool for signs of wear or damage. A damaged edge will not resonate when tapped and should be replaced to maintain cutting efficiency. Typically, a diamond blade used for concrete lasts between 25 to 75 hours, making inspections crucial.

- Lubricate Moving Parts: Apply lubricant to moving components according to the manufacturer's recommendations. This practice helps prevent rust and ensures smooth operation, contributing to the saw's reliability.

- Store Properly: Keep the saw in a dry, secure location to protect it from environmental factors and potential damage that could compromise functionality.

- Dispose of Waste: Collect and dispose of any concrete slurry or debris in accordance with local regulations. Proper waste management is vital for maintaining a clean and safe worksite.

- Review Performance: After each use, assess the cutting process and note any adjustments needed for future projects to enhance efficiency and effectiveness.

- Conduct Daily Inspections: Operators should perform daily pre-use inspections of saws to ensure safety and performance. Key checkpoints include checking the saw frame for loose bolts and ensuring guards are secure.

- Maintain Dust Suppression Systems: Ensure that dust suppression systems are well-maintained to comply with OSHA silica dust regulations, which is essential for a safe work environment.

By diligently following these maintenance and cleanup procedures, you will extend the lifespan of your equipment and foster a safe, organized work environment.

Conclusion

Mastering the soft cut concrete saw necessitates a thorough understanding of the tools, techniques, and safety measures involved. By adhering to the outlined steps, one can achieve precision and efficiency in cutting concrete, ensuring successful and safe project completion.

Key aspects of operating a soft cut concrete saw include:

- Gathering the appropriate equipment

- Preparing the worksite

- Following operational guidelines

- Maintaining the saw for longevity

Essential tools such as diamond blades, personal protective equipment, and accurate measuring devices are critical to the cutting process. Furthermore, meticulous preparation of the worksite and diligent maintenance practices significantly enhance both safety and the quality of the finished work.

Ultimately, investing time in learning and applying these techniques not only improves cutting performance but also promotes a safer work environment. Embracing these best practices leads to superior results in concrete cutting projects while minimizing risks and costs associated with equipment wear and tear. Prioritize safety and efficiency by implementing these guidelines, ensuring that each cut is executed with confidence and precision.

Frequently Asked Questions

What is the primary tool needed for operating a soft cut concrete saw?

A reliable soft cut concrete saw, such as the Husqvarna Soff-Cut model, is crucial for early entry sawing, ensuring precision and efficiency.

Why is it important to invest in quality equipment for concrete sawing?

The global handheld concrete saw market is projected to reach USD 549.1 million by 2035, underscoring the importance of investing in quality equipment for effective performance.

What type of blades should be used with a concrete saw?

Choose diamond tools that are tailored to your cutting needs, as blades vary in size and type. Select one that matches the thickness of the concrete being cut.

What is the significance of diamond blades in the concrete saw market?

The diamond blades segment is expected to capture a 46.2% share in the handheld concrete saw market by 2025, emphasizing their role in achieving optimal performance.

What personal protective equipment (PPE) is recommended for concrete sawing?

It is recommended to use safety goggles, gloves, ear protection, and a dust mask to protect against debris and noise.

How can accurate cutting be ensured when using a concrete saw?

Accurate cutting begins with precise measurements, so it is advised to use a measuring tape and chalk line to clearly mark your cutting lines.

Is a water supply necessary when using a concrete saw?

For wet cutting applications, a water source is necessary to minimize dust and cool the blade, enhancing performance.

What is the purpose of a dust extraction system in concrete sawing?

Implementing a dust extractor is advisable to maintain a clean and safe work environment, reducing health risks associated with dust exposure.

List of Sources

- Gather Essential Tools and Equipment

- Concrete Saw Market Size, Share, Analysis & Forecast By 2032 (https://alliedmarketresearch.com/concrete-saw-market-A73411)

- Handheld Concrete Saws Market Size, Report 2032 (https://gminsights.com/industry-analysis/handheld-concrete-saws-market)

- Handheld Concrete Saws Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/handheld-concrete-saws-market)

- Cut off Concrete Saw Market Analysis 2026, Market Size, Share, Growth, CAGR, Forecast, Trends, Revenue, Industry Experts, Consultation, Online/Offline Surveys, Syndicate Reports (https://cognitivemarketresearch.com/cut-off-concrete-saw-market-report)

- Concrete Cutting Market Size, Share, Forecast | Growth [2034] (https://fortunebusinessinsights.com/concrete-cutting-market-104740)

- Prepare the Worksite and Ensure Safety

- Construction Injury & Safety Statistics: Causes, Rates and Trends (https://pelco.com/blog/construction-injury-statistics)

- Commonly Used Statistics | Occupational Safety and Health Administration (https://osha.gov/data/commonstats)

- Construction Industry Records High Fatality Numbers Once Again: 10 Steps You Can Take to Address Workplace Dangers (https://fisherphillips.com/en/news-insights/construction-industry-records-high-fatality-numbers-once-again.html)

- Construction Safety, By the Numbers | NASP (https://naspweb.com/blog/construction-safety-by-the-numbers)

- Fatal falls in the construction industry in 2023 (https://bls.gov/opub/ted/2025/fatal-falls-in-the-construction-industry-in-2023.htm)

- Operate the Soft Cut Concrete Saw

- Diamond Blade RPM Chart - Delta Diamond Products (https://deltadiamond.com/pages/diamond-blade-rpm-chart?srsltid=AfmBOoopP-ggAXTMa0ba4ePJtRKQyAWiyeUu-c98ama5h16fJrqrBQEJ)

- Top-Notch Concrete Sawing Performance (https://forconstructionpros.com/equipment/worksite/article/10286727/topnotch-concrete-sawing-performance)

- The Ultimate Guide to Diamond Blade Operating Speed (RPM) for Safe, Efficient Cutting (https://vortexdiamond.com/blogs/news/diamond-blade-operating-speed?srsltid=AfmBOoqMKTWQILwQsmvDNldvLXKQEFDZ3P7TNe7kjSK88bqZpXkDrkKB)

- Perform Maintenance and Cleanup

- How Long Do Diamond Blades Last Cutting Concrete? (https://diamondkingtools.com/blog/how-long-do-diamond-blades-last-cutting-concrete)

- Concrete Saw Maintenance (https://greenindustrypros.com/design-installation/hardscaping/article/10636319/concrete-saw-maintenance)

- Maintenance and Safety Tips for Concrete Saws (https://tomahawk-power.com/blogs/articles/maintenance-and-safety-tips-for-concrete-saws?srsltid=AfmBOops1pTRYbPN2ouHltraPMufQZXZ8UWQ_VhYM8NmEcUyIU67AWFS)

- Maintaining Concrete and Masonry Saws (https://blog.whitecap.com/2025/03/21/maintaining-concrete-and-masonry-saws)

- Diamond Blade Lifespan: A Cutting Edge Discussion (https://heypapipromotions.com/blogs/diamond-blade-lifespan-a-cutting-edge-discussion?context=category-Blogs)