Key Highlights:

- A two-man auger is powered by a 63 cc engine, designed for efficient drilling across various terrains with a spiral drill bit.

- Effective operation requires collaboration between two operators: one managing the throttle and the other stabilising the machine.

- Choosing the right auger size (6 to 18 inches in diameter) and understanding soil type are crucial for optimal drilling performance.

- Robust drills are recommended for rocky or heavy clay soils to prevent damage and ensure efficiency.

- Regular maintenance, including lubrication and inspection of components, is essential for prolonging the auger's lifespan and performance.

- Wearing appropriate personal protective equipment (PPE) and following safety protocols significantly reduces the risk of accidents.

- Operators should maintain clear communication and cease work if obstacles like stones or roots are encountered.

- Consulting rental companies can provide valuable insights into selecting the right auger for specific project needs.

- Proper training and adherence to safety guidelines are critical for preventing injuries during operation.

Introduction

Mastering the two-man auger can greatly improve the efficiency and precision of various drilling projects, such as installing fence posts and planting trees. This article explores essential practices that not only ensure optimal performance but also prioritize the safety and longevity of the equipment.

With a multitude of options and techniques available, operators may find it challenging to navigate the complexities of selecting the right auger and implementing effective operational strategies. By understanding these key practices, users can enhance their drilling experience and achieve better results.

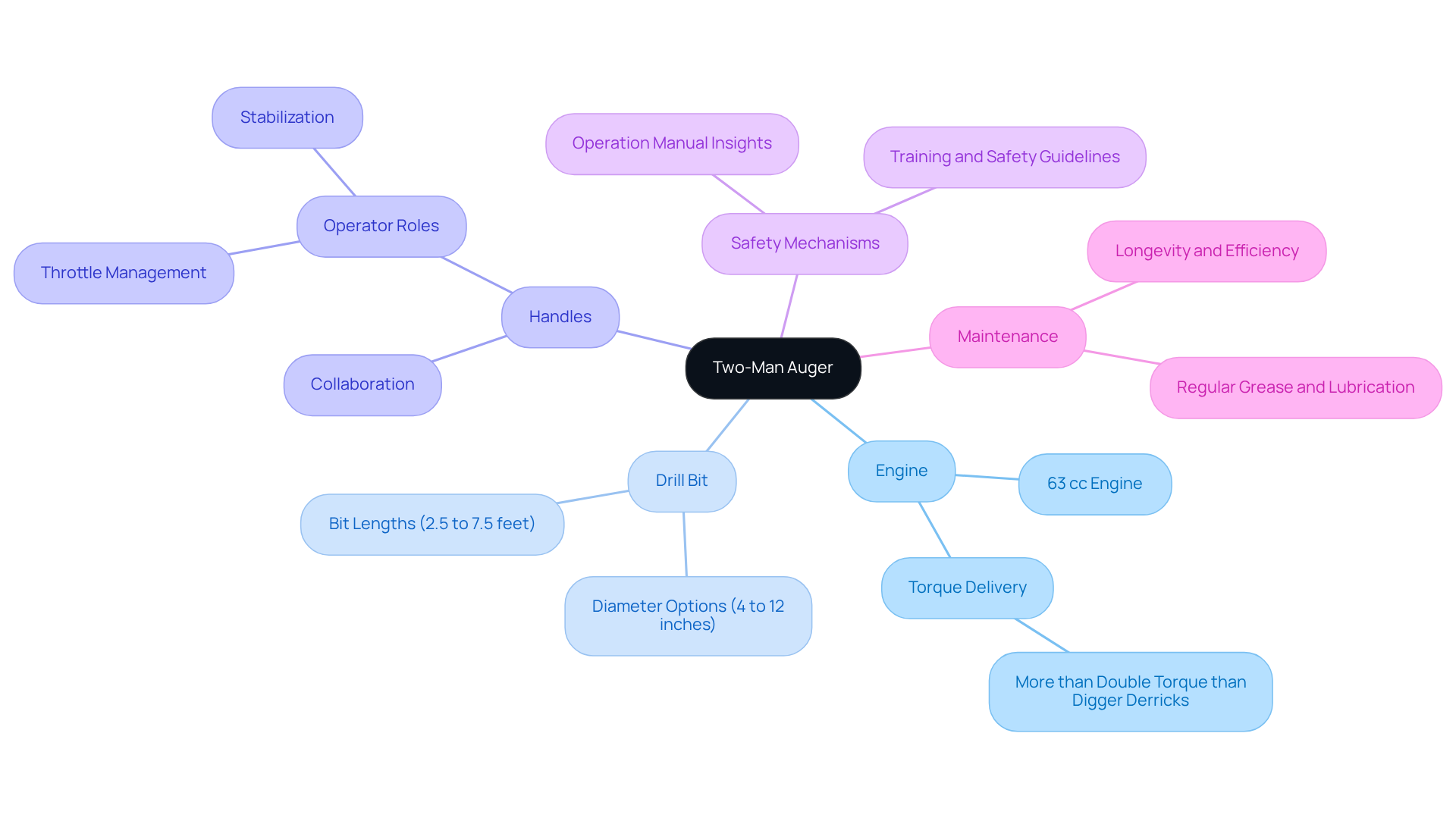

Understand the Two-Man Auger: Components and Operation

A two-person drill serves as a powerful tool designed for efficiently boring holes across various terrains. Key components include a 63 cc engine, drill bit, handles, and safety mechanisms. The engine drives the spiral bit, which is specifically engineered to penetrate the ground effectively. Understanding how these elements interact is crucial for optimal performance, as screw conveyors deliver over twice the torque compared to digger derricks, allowing for increased downward force.

The effective operation of this device relies on the collaboration of both operators. Typically, one person manages the throttle while the other stabilizes the machine, ensuring balance and precision. This teamwork is essential for achieving straight, vertical holes, which are particularly important for tasks such as fence post installation and tree planting. Familiarizing oneself with the device's operation manual can provide valuable insights into its mechanics and safety protocols, thereby enhancing both efficiency and safety during use.

A case study highlighting the operational efficiency of the two man auger revealed significant time savings and improved precision in various projects. By selecting the appropriate auger size and understanding the power requirements for the task, operators can boost productivity while minimizing the risk of malfunction. Proper training and adherence to safety guidelines further contribute to a successful digging experience. As noted by industry specialists, "Whether you are drilling, setting poles and electrical utilities, or simply gardening, it is advisable to be equipped with quality earth drilling tools." Regular maintenance, including the application of grease and lubricants, is also vital for ensuring the longevity and efficiency of the equipment.

Select the Right Two-Man Auger for Your Project Needs

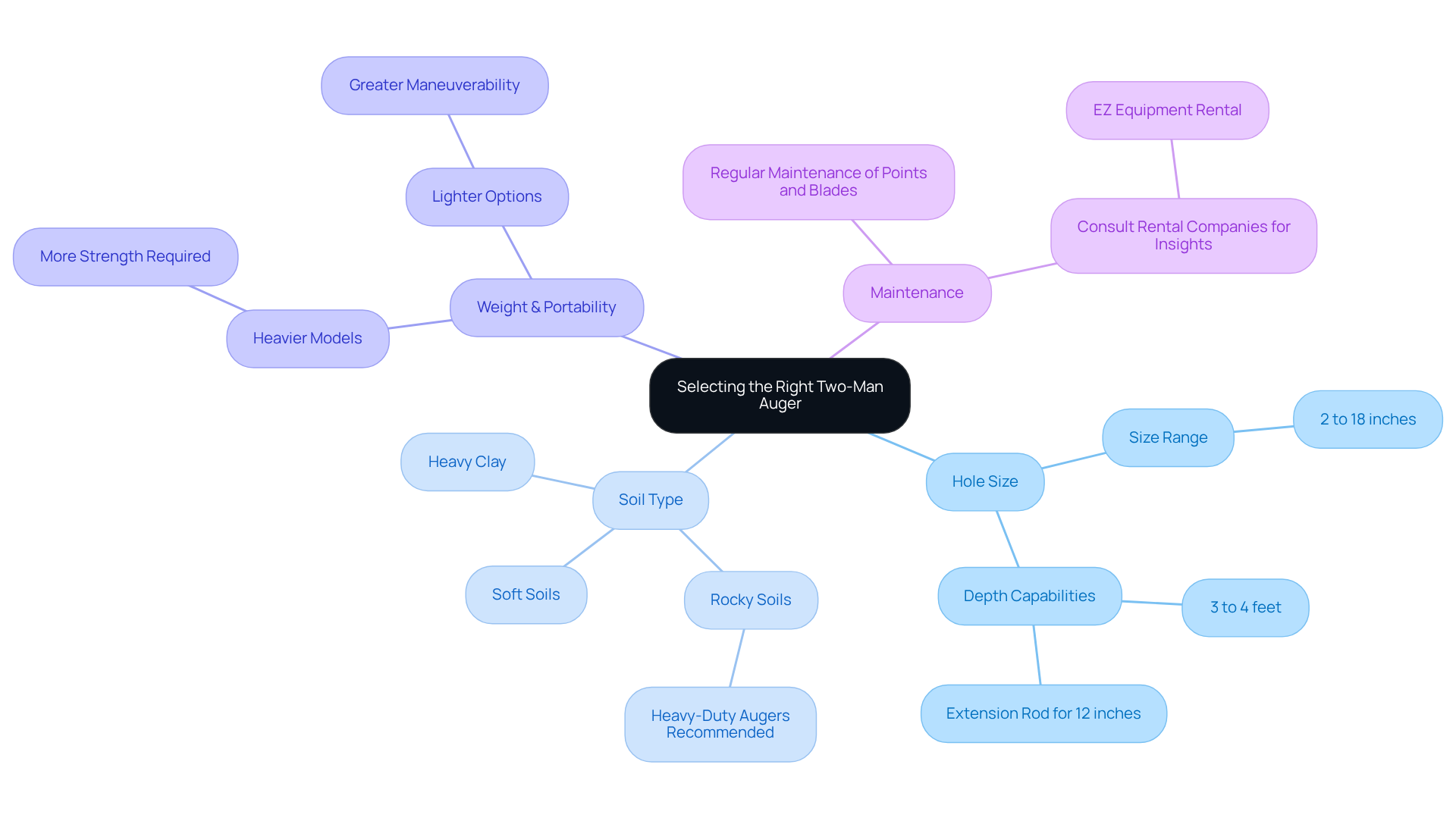

When selecting a two man auger, several key factors must be considered to ensure optimal performance for your project. First, identify the size of the holes required, as drilling tools typically range from 6 inches to 18 inches in diameter. Most drilling tools can reach depths of 3 to 4 feet, and for larger projects, particularly those involving challenging soil conditions, a more powerful device is essential for efficient excavation.

Soil type significantly influences drill selection. Standard drills perform well in soft soils but may encounter difficulties in rocky or heavy clay environments. In these cases, it is advisable to choose robust drilling tools designed to withstand abrasive conditions. As noted by Little Beaver, "for drilling in rocky soils, always suggest robust tools to avoid damage." Additionally, consider the weight and portability of the drill; heavier models may require more strength to operate effectively, while lighter options provide greater maneuverability.

Regular maintenance of points and blades is crucial for optimal performance, as neglecting this can impact drilling efficiency. Consulting with rental companies like EZ Equipment Rental can offer valuable insights into the best drilling tool for your specific project needs. Their expertise ensures you select the right tool, enhancing both efficiency and effectiveness in your digging tasks. For example, a case study on selecting the correct drill size for soil type demonstrated that choosing the appropriate drill significantly improved project outcomes.

Implement Safe and Efficient Operating Techniques

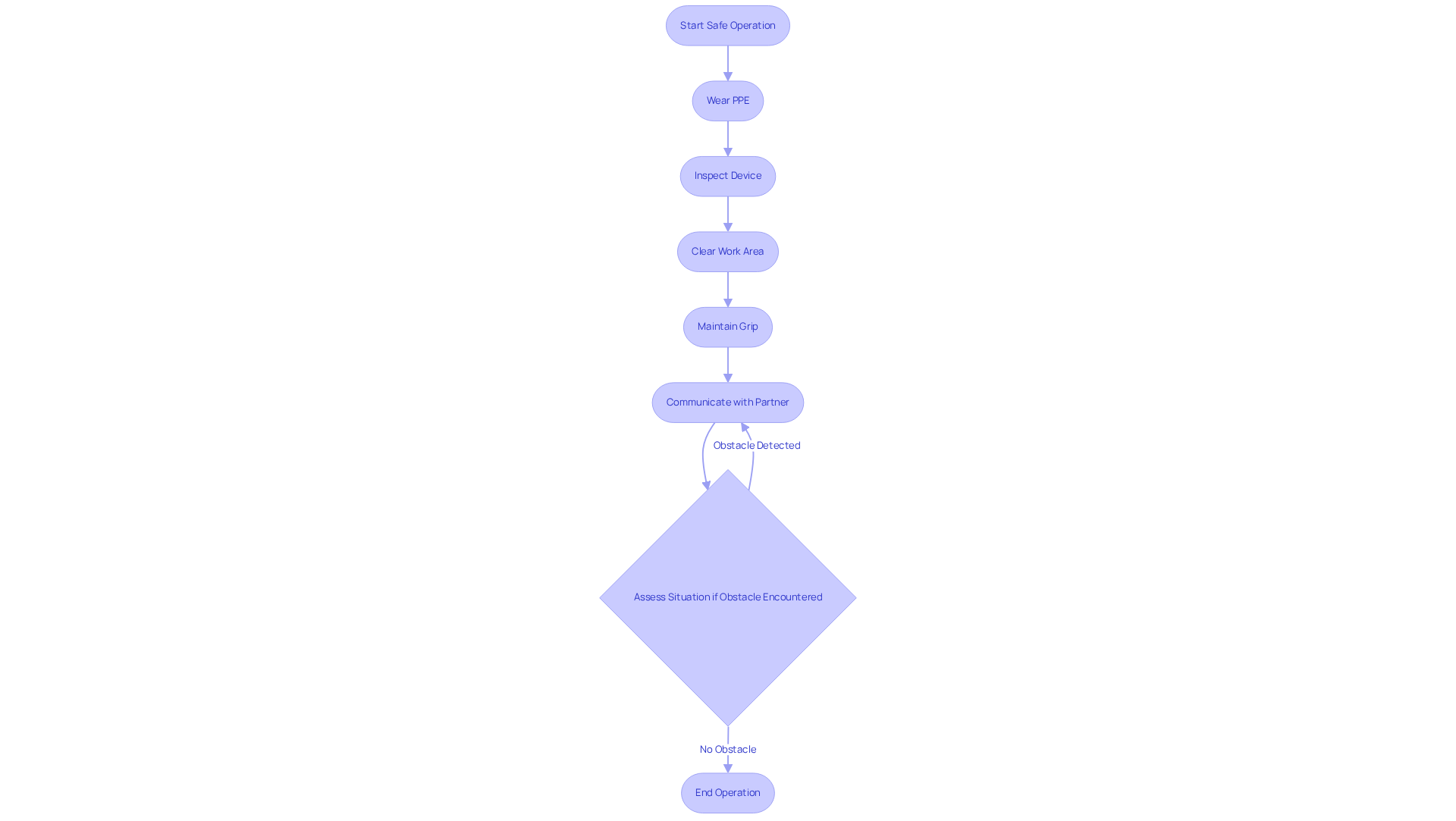

To ensure the safe operation of a two-person drill, it is crucial to wear appropriate personal protective equipment (PPE), including:

- Gloves

- Safety glasses

- Hearing protection

Before use, conduct a thorough inspection of the device for any signs of wear or damage, and ensure the work area is free of obstacles to prevent accidents.

While digging, maintain a firm grip on the handles and position your body correctly to effectively absorb any kickback. Clear communication with your partner is essential for coordinating movements, especially when starting and stopping the engine. If the drill encounters a stone or root, cease work immediately to assess the situation, thereby preventing potential injuries or damage to the machinery.

Research indicates that the use of proper PPE and adherence to safety protocols significantly reduces the risk of accidents during the operation of a two-man auger. For instance, injuries associated with the two-man auger can be minimized through effective training and awareness of safety measures, highlighting the importance of a proactive approach to protection in construction environments. According to NIOSH, children under 16 years are prohibited from operating hazardous equipment, emphasizing the necessity of following safety regulations. Furthermore, the case study on 'Education and Awareness in Auger Operation' underscores the importance of educating all operators about safe procedures, reinforcing the critical role of training in accident prevention.

Maintain Your Two-Man Auger for Optimal Performance

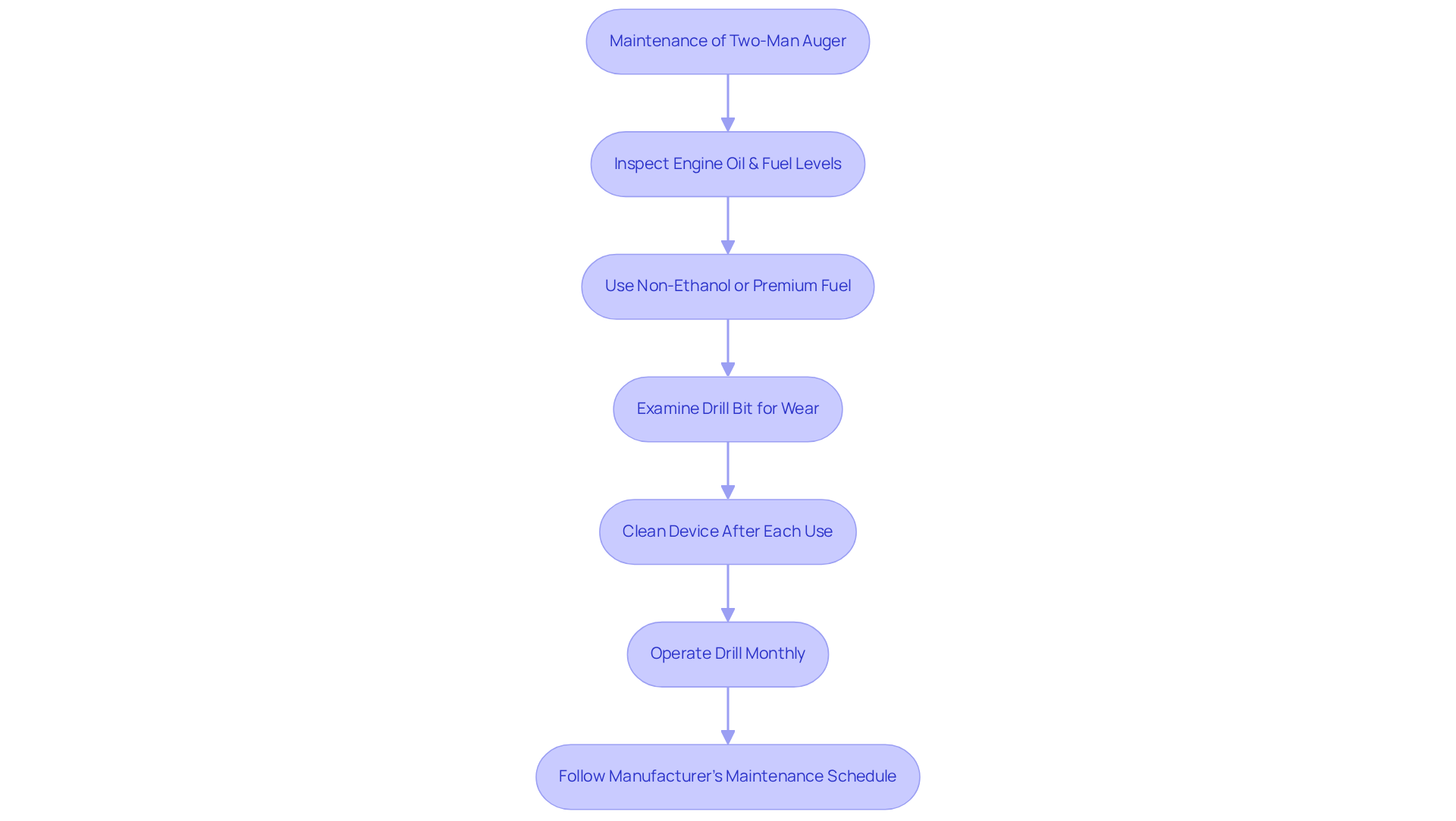

To keep your two man auger in optimal condition, it is crucial to routinely inspect the engine oil and fuel levels, changing them as necessary. Using non-ethanol or premium fuel for gasoline engines is recommended to ensure better performance. Additionally, examine the drill bit for wear, ensuring it remains sharp and free of debris. Thorough cleaning of the device after each use prevents dirt buildup, significantly extending its lifespan. Operating the drill at least once a month is also essential for maintaining its functionality.

Adhering to the manufacturer's maintenance schedule is vital for comprehensive checks, including the inspection of the spark plug and air filter. Proper lubrication of moving components is necessary to reduce friction and wear, further prolonging the drill's lifespan. Keeping a thorough service log allows you to monitor service intervals, ensuring your tools remain dependable for upcoming projects. According to Michael Jennett, Equipment Team Advisor at Federated Co-operatives Ltd, 'A properly maintained two man auger will perform for up to two additional seasons, depending on the amount of product processed through it.' Regular maintenance practices not only enhance performance but also contribute to the longevity of your equipment.

Conclusion

Mastering the two-man auger requires a solid understanding of its components, the selection of appropriate equipment, the implementation of safe operating techniques, and a commitment to regular maintenance. By concentrating on these essential practices, operators can enhance both the efficiency of their projects and the safety and longevity of their tools. The collaboration among operators, the careful choice of auger tailored to project requirements, and strict adherence to safety protocols are crucial for achieving successful outcomes.

This article has highlighted key insights, including:

- The importance of teamwork in operating the auger

- The necessity of selecting the right size and type of auger for specific soil conditions

- The critical role of personal protective equipment

Regular maintenance routines, such as thorough inspections and proper lubrication, further improve the performance and durability of the equipment, ensuring it meets the demands of various projects.

In conclusion, adopting these best practices for using a two-man auger can significantly influence project success. By prioritizing safety and efficiency, operators can achieve superior results while fostering a culture of responsibility and preparedness in their work environments. Investing time in learning and applying these techniques will lead to smoother operations and ultimately contribute to the overall success of any digging project.

Frequently Asked Questions

What is a two-man auger and what is its primary purpose?

A two-man auger is a powerful tool designed for efficiently boring holes across various terrains, commonly used for tasks such as fence post installation and tree planting.

What are the key components of a two-man auger?

The key components include a 63 cc engine, a drill bit, handles, and safety mechanisms.

How does the engine of the two-man auger function?

The engine drives the spiral bit, which is engineered to penetrate the ground effectively, allowing for efficient hole boring.

Why is collaboration between operators important when using a two-man auger?

Collaboration is crucial as one operator manages the throttle while the other stabilizes the machine, ensuring balance and precision for achieving straight, vertical holes.

How can operators enhance their efficiency and safety while using a two-man auger?

Familiarizing oneself with the device's operation manual can provide insights into its mechanics and safety protocols, enhancing both efficiency and safety during use.

What benefits were observed in the case study regarding the two-man auger?

The case study highlighted significant time savings and improved precision in various projects when using the two-man auger.

How can operators boost productivity while using a two-man auger?

By selecting the appropriate auger size and understanding the power requirements for the task, operators can boost productivity while minimizing the risk of malfunction.

What role does proper training play in the use of a two-man auger?

Proper training and adherence to safety guidelines contribute to a successful digging experience and help ensure safe operation.

What maintenance practices are essential for a two-man auger?

Regular maintenance, including the application of grease and lubricants, is vital for ensuring the longevity and efficiency of the equipment.

List of Sources

- Understand the Two-Man Auger: Components and Operation

- All You Need to Know on Earth Auger Drills - The Best Tool for Earth Drilling! (https://bunyipequipment.com.au/earth-auger-drills-the-best-tool-for-earth-drilling?srsltid=AfmBOooRgfvqysHhCLPOYPykfmT5QhislZT_ArIK8IGtflO9ci-BBx7P)

- 2 Man 63CC 2 Stroke Gas Post Hole Digger (Digger 8" 10" 12" Bit) (https://xtremepowerusa.com/products/kit288)

- Appia Acquires Two New Auger Drills and Launches New Drill Program at Gaia Target Adjacent to Taygeta and Merope, PCH REE Project, Brazil - Appia (https://appiareu.com/appia-acquires-two-new-auger-drills-and-launches-new-drill-program-at-gaia-target-adjacent-to-taygeta-and-merope-pch-ree-project-brazil)

- Mastering the Two-Man Auger: Your Guide to Effortless Earth Moving (https://oreateai.com/blog/mastering-the-twoman-auger-your-guide-to-effortless-earth-moving/70cfdd0736c4f03c0c7039fa860aba48)

- Select the Right Two-Man Auger for Your Project Needs

- 2 Man 63CC 2 Stroke Gas Post Hole Digger (Digger 8" 10" 12" Bit) (https://xtremepowerusa.com/products/kit288)

- Types of Augers and Auger Sizes: How to Choose (https://unitedrentals.com/project-uptime/equipment/types-augers-and-auger-sizes-how-choose)

- Choosing the Right Augers, Points & Blades- Little Beaver (https://littlebeaver.com/choosing-right-augers-points-blades)

- Implement Safe and Efficient Operating Techniques

- 25 Inspiring Workplace Safety Quotes for Safer Workspaces (https://yodeck.com/use-cases/workplace-safety-quotes)

- Agricultural Auger-Related Injuries and Fatalities -- Minnesota, 1992-1994 (https://cdc.gov/mmwr/preview/mmwrhtml/00038801.htm)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Safety Quotes: Motivation to Improve Work Safety Culture (https://osha.com/blog/work-safety-quotes)

- Auger Safety on the Farm Stats and Facts (https://icwgroup.safetynow.com/auger-safety-on-the-farm-stats-and-facts?print=pdf)

- Maintain Your Two-Man Auger for Optimal Performance

- Prolonging the Life of Augers: Maintenance Tips for Foundation Drilling Professionals | Tebco Augers (https://tebco.com.au/prolonging-the-life-of-augers-maintenance-tips-for-foundation-drilling-professionals)

- What is the average lifespan of Auger Wear Parts? - Blog (https://tx-industries.com/blog/what-is-the-average-lifespan-of-auger-wear-parts-664413.html)

- Auger Maintenance Essentials - Co-op Ag Equipment (https://coopagequipment.ca/auger-maintenance-essentials)

- APIE PRODUCT KNOWLEDGE—What is the life of an auger? – APIE FOUNDATION EQUIPMENT(CHINA) LIMITED (https://apiepiling.com/apie-product-knowledge-what-is-the-life-of-an-auger)

- Auger Maintenance Essentials (https://agro.crs/equip/detail/auger-maintenance-essentials)