Key Highlights:

- Tree shears come in various types, including fixed, rotating, grapple, and mini excavator models, each suited for specific tasks.

- Fixed tree shears are reliable for basic trimming, while rotating models offer enhanced adaptability and precision.

- Grapple cutting tools can both cut and hold plants, facilitating efficient material movement.

- Mini excavator tree cutters are designed for smaller projects, ensuring effective landscaping.

- Key features of effective tree shears include high-quality blade materials, robust hydraulic power, cutting capacity, weight compatibility, and essential safety features.

- Selecting the right shear involves assessing project scope, excavator compatibility, terrain, budget, and user experience.

- Tree shears are vital in various industries: forestry for land management, landscaping for aesthetic trimming, utility maintenance for safety, farming for crop preparation, and construction for site clearing.

- Investing in quality tree shears enhances productivity and safety in tree management tasks across diverse sectors.

Introduction

Understanding the complexities of tree shears is crucial for operators aiming to boost their efficiency in vegetation management. With a range of models available, each tailored for specific tasks, selecting the right tool can greatly influence the success of any project. But how do you sift through the extensive options to find the perfect balance of performance, safety, and cost-effectiveness? This article delves into the key features and best practices for utilizing tree shears on excavators, providing you with the insights needed to make informed choices for your cutting requirements.

Understand Tree Shear Types and Functions

Explore Our Range of Tree Shears

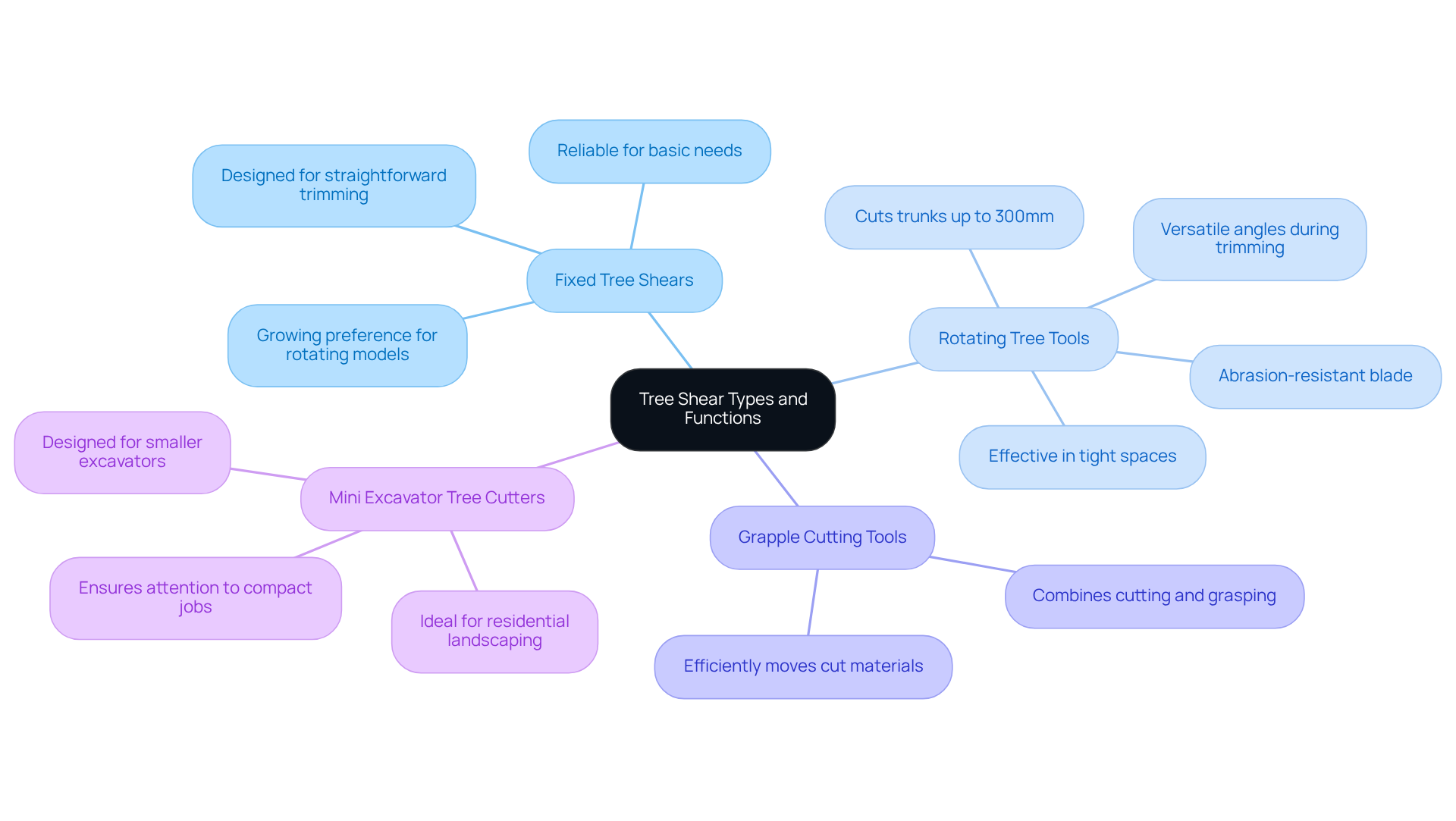

Tree shears come in various types, each tailored for specific applications. Understanding these options is crucial for selecting the right tool for your project. Let’s delve into the most common types:

-

Fixed Tree Shears: Designed for straightforward trimming tasks, these shears excel at felling trees and clearing land. They provide a steady slicing action, making them reliable for basic needs. However, as market trends indicate, there’s a growing preference for rotating models due to their enhanced adaptability and precision.

-

Rotating Tree Tools: These innovative tools offer the ability to rotate, allowing for versatile angles during trimming. Their improved maneuverability makes them particularly effective in tight spaces where precision is key. A recent case study highlighted a rotating vegetation cutter with an abrasion-resistant blade, capable of slicing through trunks up to 300mm in diameter, showcasing its efficiency in confined areas.

-

Grapple Cutting Tools: Combining cutting and grasping functions, grapple tools can slice and hold plants simultaneously. This dual capability makes them invaluable for moving cut materials efficiently.

-

Mini Excavator Tree Cutters: Specifically crafted for smaller excavators, these tools are ideal for residential landscaping and smaller-scale projects, ensuring that even compact jobs receive the attention they deserve.

By comprehending these varieties, operators can select the appropriate cutting tool based on plant dimensions, landscape characteristics, and project requirements. For instance, the plant cutter can slice trunks with a diameter of 400mm using 65 tons of hydraulic power, particularly relevant for larger stationary and rotating models.

Take Action Today

Don’t compromise on quality when it comes to your tree cutting needs. Explore our range of tree shears for excavators and discover the ideal tool for your project. Contact us now to learn more!

Identify Key Features of Effective Tree Shears

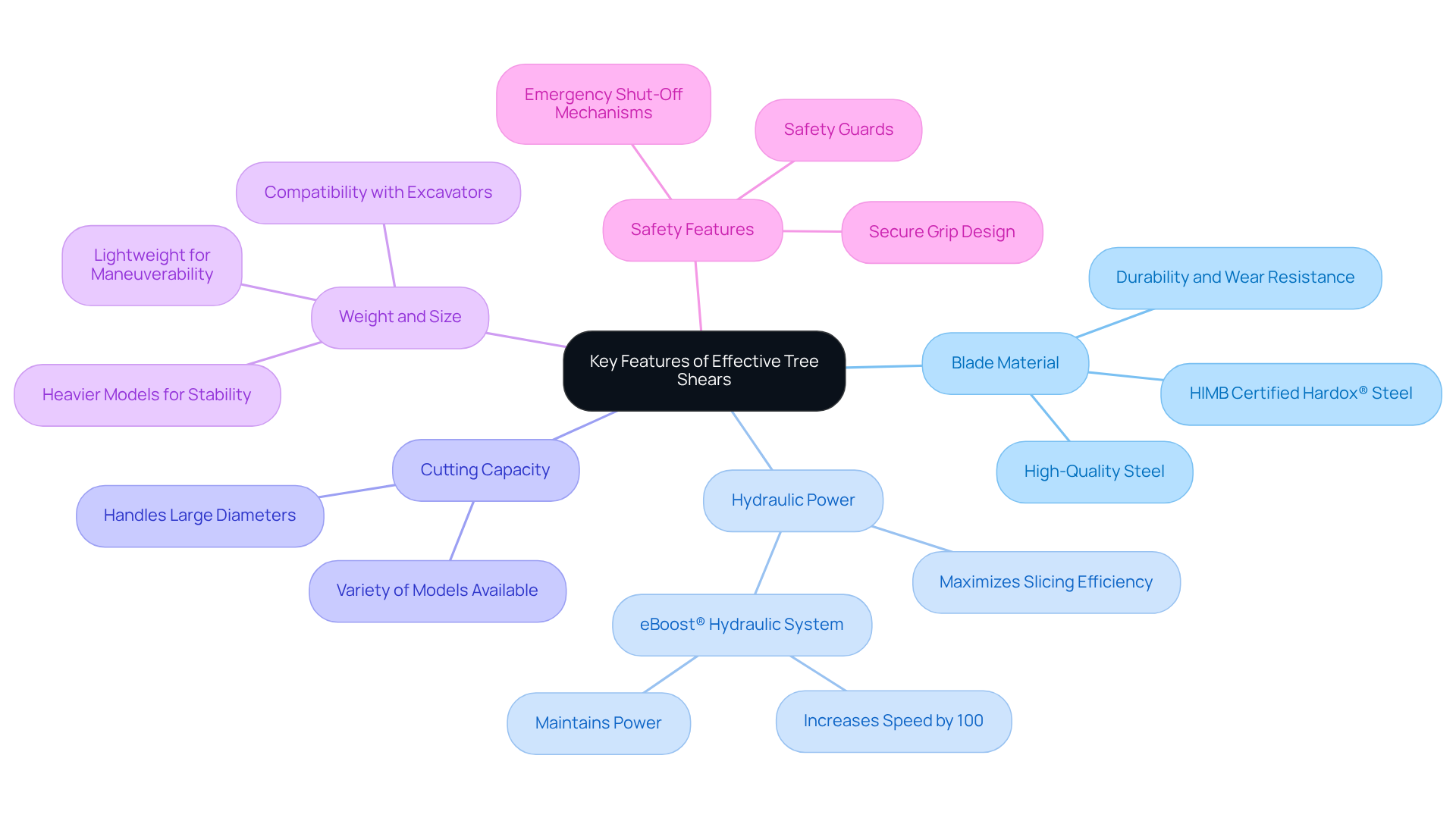

When selecting tree shears, prioritizing key features is essential for optimal performance and safety.

-

Blade Material is a critical factor; high-quality steel, especially Hardox, is celebrated for its durability and wear resistance. All JAK Tree Shears are HIMB certified and come with serially numbered Hardox® labels, confirming the use of genuine Hardox® steel. This ensures that the shear maintains its sharpness even in challenging conditions, significantly reducing the need for replacements.

-

Hydraulic Power plays a vital role in maximizing slicing efficiency. Models equipped with robust hydraulic systems can effortlessly slice through larger vegetation. Some even feature the eBoost® hydraulic system, which enhances speed by up to 100% without sacrificing power. This capability allows for greater versatility in various slicing tasks.

-

Cutting Capacity is another crucial aspect. It's important to ensure that the tool can handle the largest diameter of plants you intend to cut. Different models offer varying capacities, with some capable of managing trees up to 24 inches in diameter. Selecting the right shear that meets your specific project needs is essential.

-

Weight and Size compatibility with your excavator's specifications cannot be overlooked. A lightweight cutter facilitates easier maneuverability, while a heavier model may provide increased stability during operation, especially in challenging terrains.

-

Safety Features should never be compromised. Opt for shears that include safety guards and emergency shut-off mechanisms, which are vital for protecting users and ensuring secure operation. The design of the JAK Tree Shear also ensures that the plant remains securely gripped during operation, enhancing safety for operators.

These characteristics collectively enhance the efficiency and safety of cutting tools, making them indispensable for anyone involved in vegetation trimming and land clearing. Don't compromise on quality-choose JAK Tree Shears for your next project!

Choose the Right Tree Shear Model for Your Project

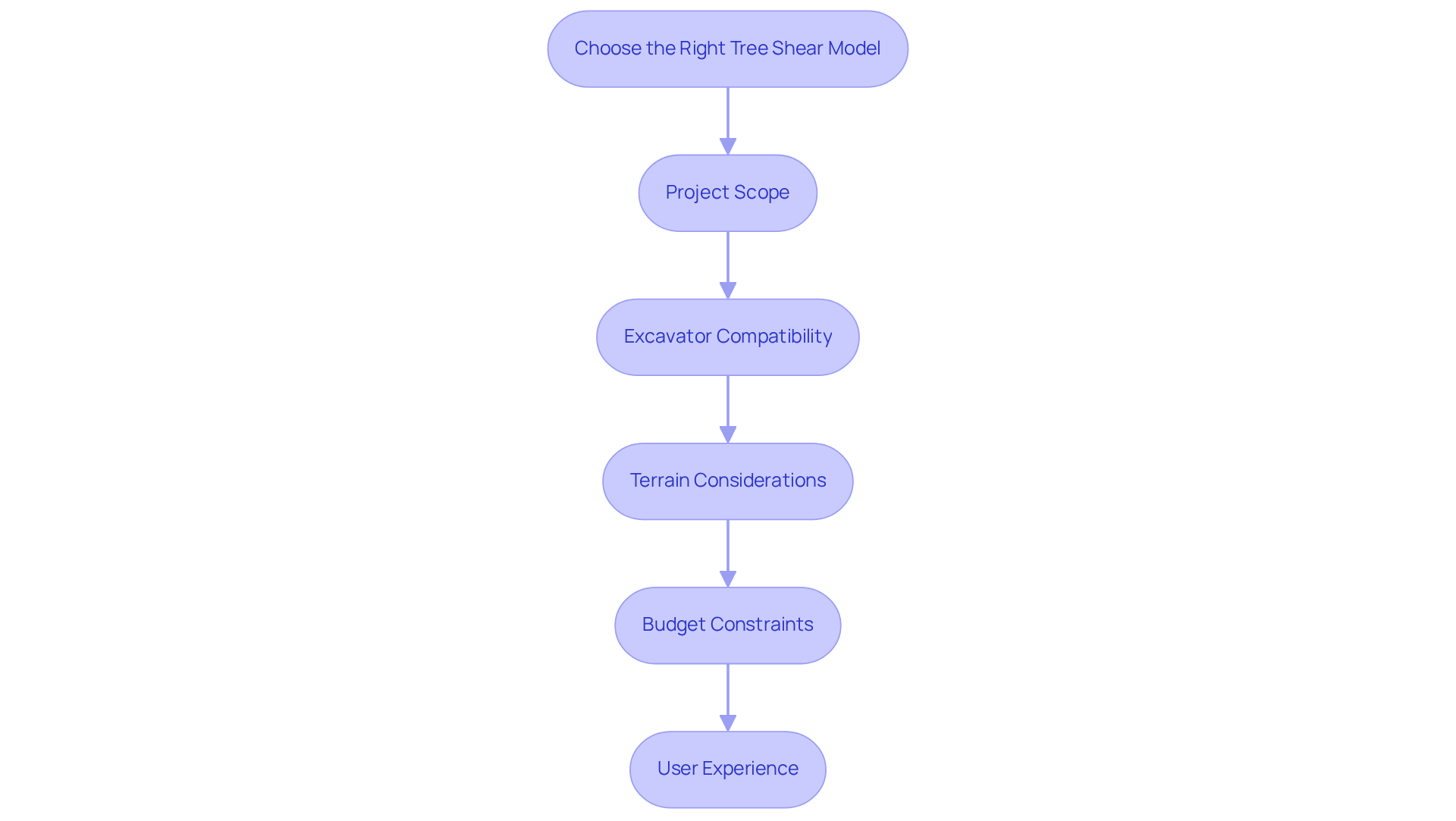

Choosing the appropriate tree shears for excavators is essential for the success of your project. Assess these key factors to make an informed decision:

- Project Scope: Understand the scale of your project. For extensive land clearing, a robust, high-capacity cutting tool is essential. Conversely, smaller projects may only require a mini cutting device.

- Excavator Compatibility: Verify that the attachment aligns with your excavator's weight class and hydraulic system. Always consult the manufacturer's specifications for recommended models.

- Terrain Considerations: Evaluate the landscape where the cutting tool will be used. In uneven or rocky terrain, a tool with a lower center of gravity can provide enhanced stability.

- Budget Constraints: Keep your budget in mind. While high-quality cutting tools may seem expensive initially, they often prove to be cost-effective over time due to their durability and efficiency.

- User Experience: If possible, seek insights from operators experienced with specific models. Their feedback can offer valuable perspectives on performance and reliability.

By carefully considering these factors, operators can confidently select tree shears for excavators as the most suitable cutting device model tailored to their project needs. Take action now and ensure your project is equipped with the right tools for success!

Explore Applications of Tree Shears in Different Industries

Tree Shears: Essential Tools for Diverse Industries

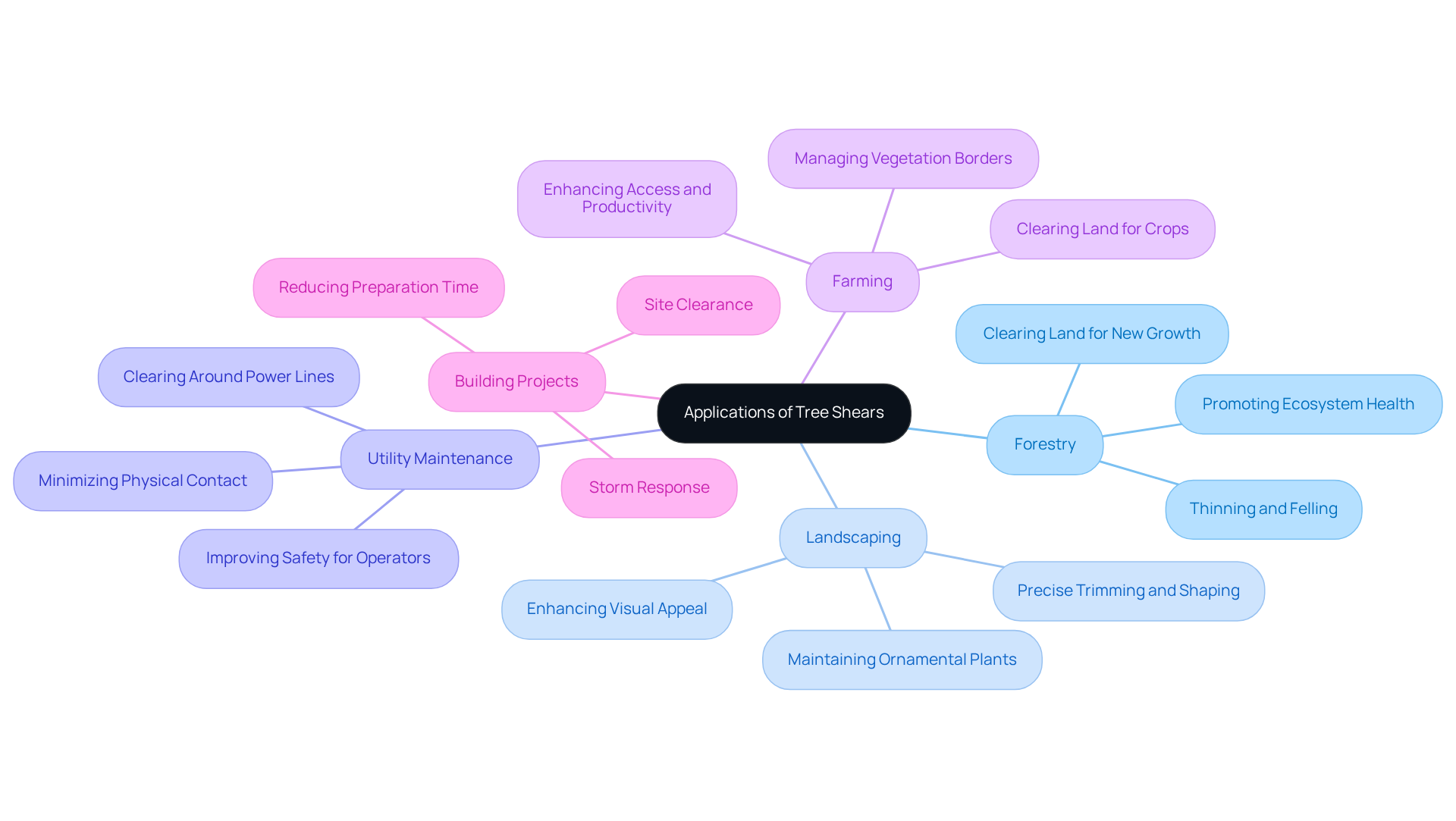

Tree shears are versatile tools that play a vital role across multiple sectors, showcasing their adaptability and effectiveness.

Forestry Applications

In forestry, branch cutters are indispensable for thinning, felling, and clearing land for new growth. They are crucial in managing forest health by efficiently removing diseased or dead plants, promoting a healthier ecosystem. This proactive approach not only enhances biodiversity but also supports sustainable forestry practices.

Landscaping Benefits

Professionals in landscaping utilize pruning tools for precise trimming and shaping of plants and shrubs, significantly enhancing the visual appeal of both residential and commercial properties. Recent landscaping trends in 2026 indicate a growing preference for pruners to establish clean lines and maintain the health of ornamental plants. This trend reflects a commitment to quality and aesthetics in outdoor spaces.

Utility Maintenance Importance

Utility firms rely on vegetation cutters to clear plant life around power lines and pipelines, ensuring safe and dependable service. Statistics show that the use of pruning tools in utility maintenance has increased, as they minimize physical contact with plants, improving safety for operators while speeding up the clearing process. As noted by Rut Manufacturing, "Safety is paramount in any industry, and tree-cutting is no exception."

Farming Efficiency

In farming environments, specialized cutting tools are essential for clearing land for crops and managing vegetation borders, enhancing access and productivity. Their ability to handle various plant sizes makes them ideal for efficient field preparation, ultimately leading to better crop yields.

Building Project Applications

During construction projects, vegetation cutters are employed to clear sites swiftly and effectively, significantly reducing the time and effort required for land preparation. Case studies highlight their effectiveness in storm response, where they facilitate the rapid removal of downed vegetation, ensuring safer working conditions. However, it’s crucial to address operator competence, as inexperienced users can compromise quality and safety.

These applications underscore the importance of tree shears for excavators as invaluable tools across diverse sectors, enhancing productivity and safety in tree management tasks. For those looking to improve their operations, investing in quality tree shears is a step towards efficiency and reliability.

Conclusion

Understanding the various types and features of tree shears for excavators is crucial for optimizing performance and ensuring safety in vegetation management. The right tool significantly enhances efficiency, empowering operators to tackle diverse projects, from land clearing to landscaping. By selecting the appropriate shear based on its functions and capabilities, users can achieve superior results while minimizing risks.

Choosing between fixed and rotating tree shears is a pivotal decision. Key features such as blade material, hydraulic power, and safety mechanisms must be considered, along with ensuring compatibility with specific excavator models. Each of these aspects plays a vital role in determining the tool's effectiveness across industries like forestry, landscaping, utility maintenance, farming, and construction.

Investing in high-quality tree shears not only boosts productivity but also fosters safer working conditions. As industries evolve, the demand for versatile and efficient cutting tools will only increase. Operators are encouraged to assess their project needs carefully, consider the outlined factors, and make informed decisions to enhance their tree management practices. Taking action now to equip projects with the right tools will pave the way for success and efficiency in vegetation management.

Frequently Asked Questions

What are the main types of tree shears available?

The main types of tree shears include Fixed Tree Shears, Rotating Tree Tools, Grapple Cutting Tools, and Mini Excavator Tree Cutters.

What are Fixed Tree Shears used for?

Fixed Tree Shears are designed for straightforward trimming tasks, excelling at felling trees and clearing land with a steady slicing action.

Why are Rotating Tree Tools preferred over Fixed Tree Shears?

Rotating Tree Tools offer enhanced adaptability and precision, allowing for versatile angles during trimming, making them particularly effective in tight spaces.

What is a notable feature of Rotating Tree Tools?

A notable feature of Rotating Tree Tools is their ability to rotate, which improves maneuverability and precision, especially in confined areas.

What are Grapple Cutting Tools capable of?

Grapple Cutting Tools can slice and hold plants simultaneously, combining cutting and grasping functions for efficient movement of cut materials.

Who are Mini Excavator Tree Cutters designed for?

Mini Excavator Tree Cutters are specifically crafted for smaller excavators, making them ideal for residential landscaping and smaller-scale projects.

How does the plant cutter perform in terms of cutting capacity?

The plant cutter can slice trunks with a diameter of 400mm using 65 tons of hydraulic power, relevant for larger stationary and rotating models.

Why is it important to understand the different types of tree shears?

Understanding the different types of tree shears is crucial for selecting the appropriate cutting tool based on plant dimensions, landscape characteristics, and project requirements.