Key Highlights:

- Project managers must understand OSHA regulations for excavations deeper than five feet, including daily inspections and safe entry/exit points.

- In 2025, there were 11 trench-related fatalities, emphasising the importance of compliance with safety regulations.

- Maintaining a distance of at least two feet between excavated materials and trench edges helps prevent collapses.

- Violations of OSHA excavation standards accounted for 9% of total penalties in 2023, highlighting the need for adherence.

- Regular educational sessions on trench safety enhance awareness and promote a culture of safety on site.

- Choosing the right trench safety equipment is crucial, with options like aluminium shields for shallow diggings and heavy-duty steel boxes for deeper sites.

- Routine maintenance and training on trench safety equipment usage significantly reduce risks and support safety compliance.

- Trench-related fatalities dropped from 39 in 2022 to 15 in 2023, indicating progress in safety enforcement and practises.

- A competent person, as defined by OSHA, must be present to identify hazards and oversee trenching operations.

- In 2023, there were 1,075 construction-related fatalities, reinforcing the need for competent personnel in trench safety.

- Regular inspections of trench safety equipment are vital for compliance and incident prevention, with systematic schedules recommended.

- Routine evaluations have led to a 70% decrease in trench-related incidents since 2022, underscoring the effectiveness of safety protocols.

Introduction

Understanding the complexities of trench safety is crucial for project managers overseeing excavation projects. Given the alarming statistics surrounding trench-related fatalities and the stringent OSHA regulations, the importance of ensuring worker safety has never been more pronounced. This article explores best practices for mastering trench safety equipment, emphasizing:

- Compliance

- The selection of appropriate protective systems

- The necessity of competent personnel

Project managers must effectively balance safety regulations with practical implementation to safeguard their teams and reduce incident rates.

Understand Trench Safety Regulations and Guidelines

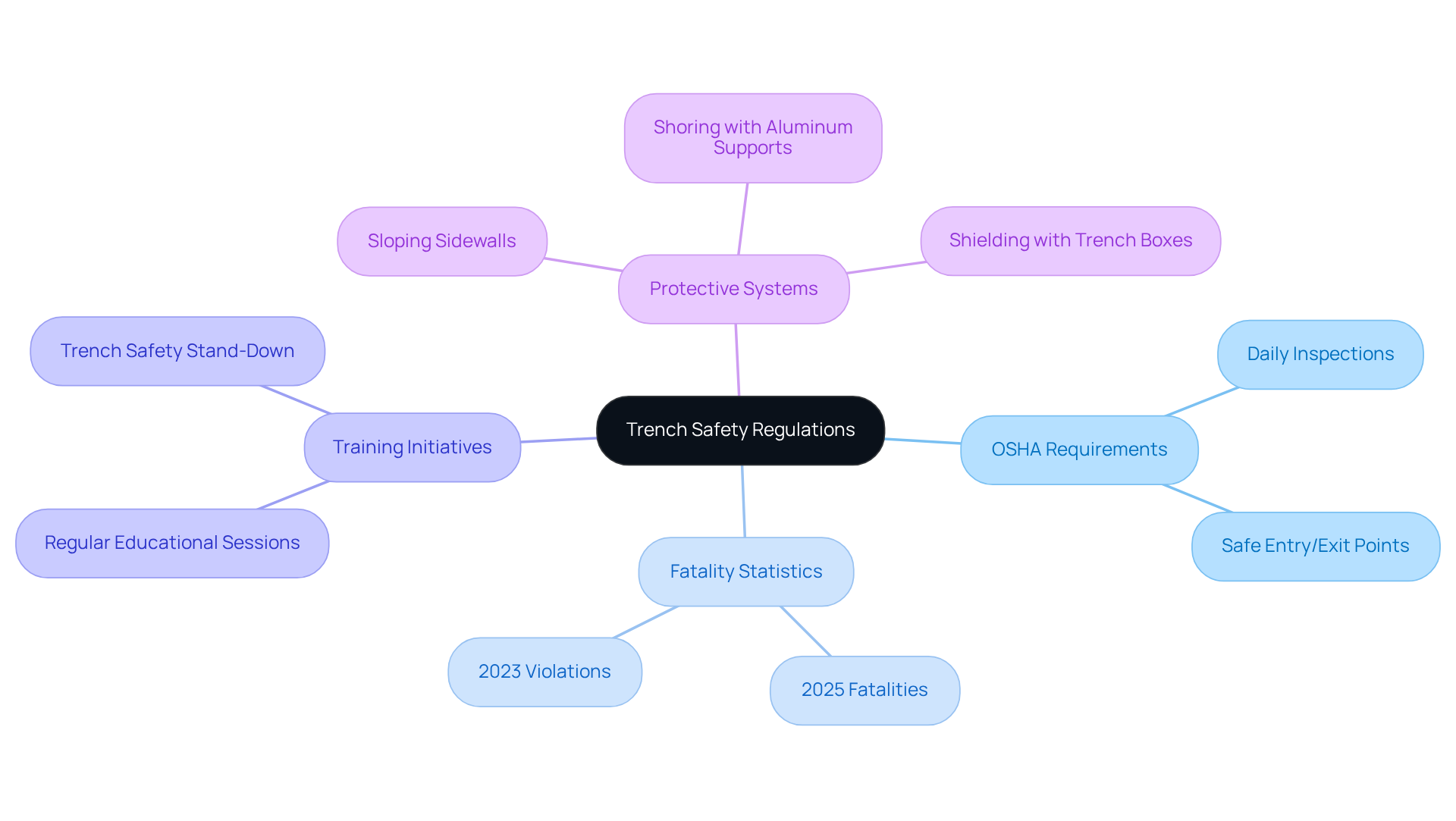

Project managers must have a comprehensive understanding of OSHA regulations concerning excavation safety, particularly the requirements for protective systems in excavations deeper than five feet. These regulations mandate daily inspections by a competent person and the establishment of safe entry and exit points. Adhering to these guidelines is essential, as it significantly reduces the risk of accidents; for instance, maintaining a distance of at least two feet between excavated materials and trench edges can help prevent collapses.

In 2025, there were 11 trench-related fatalities reported nationwide, underscoring the critical need for compliance with these regulations. Furthermore, violations of OSHA’s excavation standards represented 9% of total penalties issued in 2023, highlighting the ongoing necessity for adherence.

Regular educational sessions focused on these regulations not only enhance team awareness but also cultivate a robust culture of safety on site. Effective excavation hazard awareness initiatives demonstrate that proactive training can lead to a notable decrease in incidents, allowing workers to return home safely at the end of each day.

As project managers navigate the evolving landscape of excavation guidelines in 2026, emphasizing compliance and continuous training will be vital for safeguarding their teams. OSHA recommends protective systems such as sloping sidewalls and shoring with aluminum hydraulic supports to prevent collapses, which should be integral to any excavation protection strategy.

Select and Implement Appropriate Trench Safety Equipment

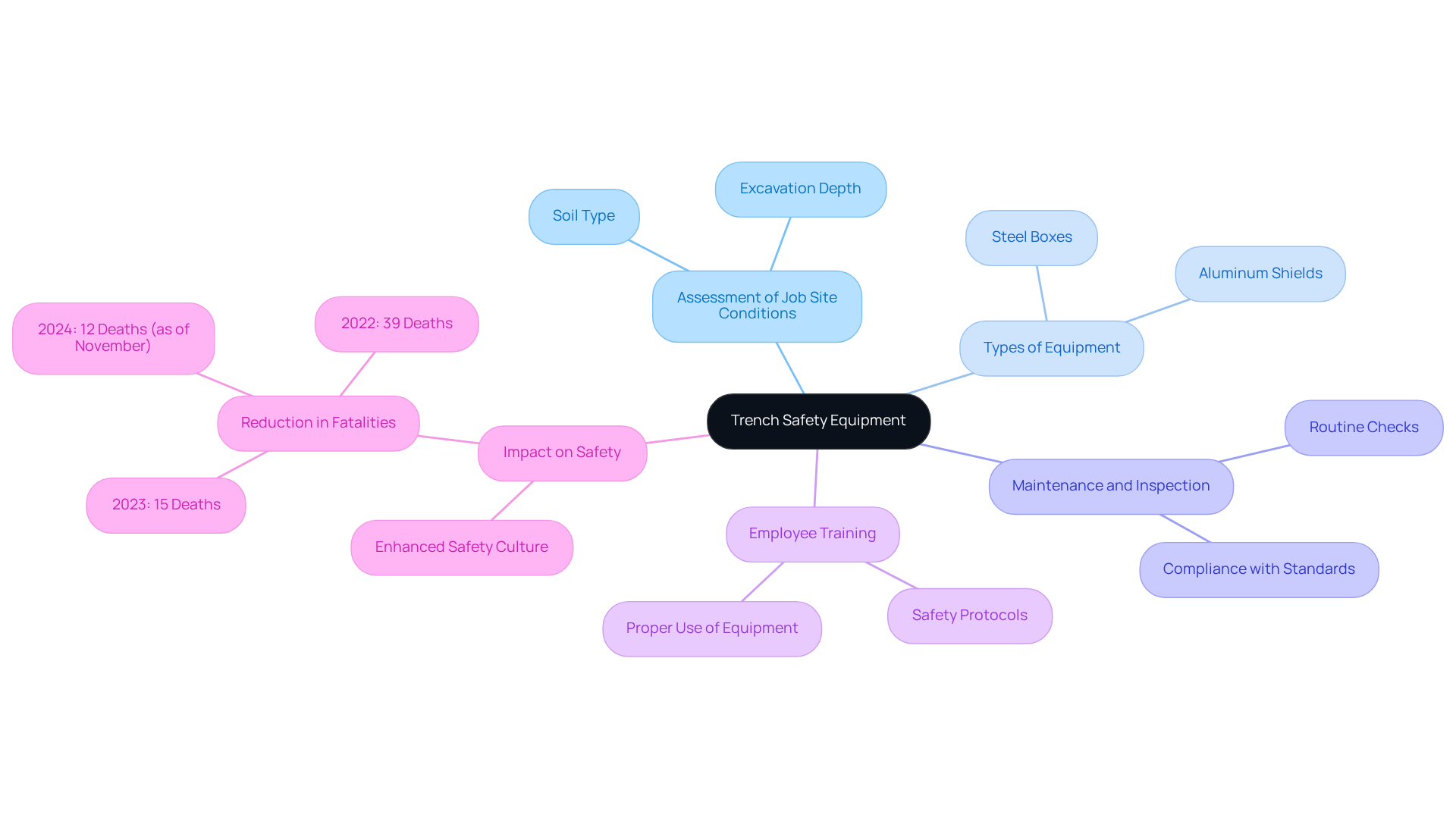

Choosing the right trench safety equipment is crucial for protecting workers against cave-ins and other digging hazards. Project managers must assess job site conditions, such as soil type and excavation depth, to determine the most effective protective systems. For instance, aluminum excavation shields offer a lightweight yet robust solution for shallow diggings, while heavy-duty steel boxes are essential for deeper sites where soil stability poses a risk.

Routine maintenance and inspection of trench safety equipment are vital to ensure reliability and compliance with safety standards. Furthermore, providing thorough training for employees on the proper use of trench safety equipment significantly enhances overall safety and adherence to regulations. This proactive approach not only reduces risks but also supports the industry's ongoing efforts to decrease trench-related fatalities. Notably, these fatalities have dropped from 39 in 2022 to 15 in 2023, with only 12 reported for 2024. As Douglas Parker, OSHA Assistant Secretary, remarked, "These numbers are promising evidence that stronger enforcement and collaboration with labor and management... is saving lives." This underscores the importance of effective protective practices and partnerships in achieving these improvements.

Ensure Competent Personnel for Trench Safety Oversight

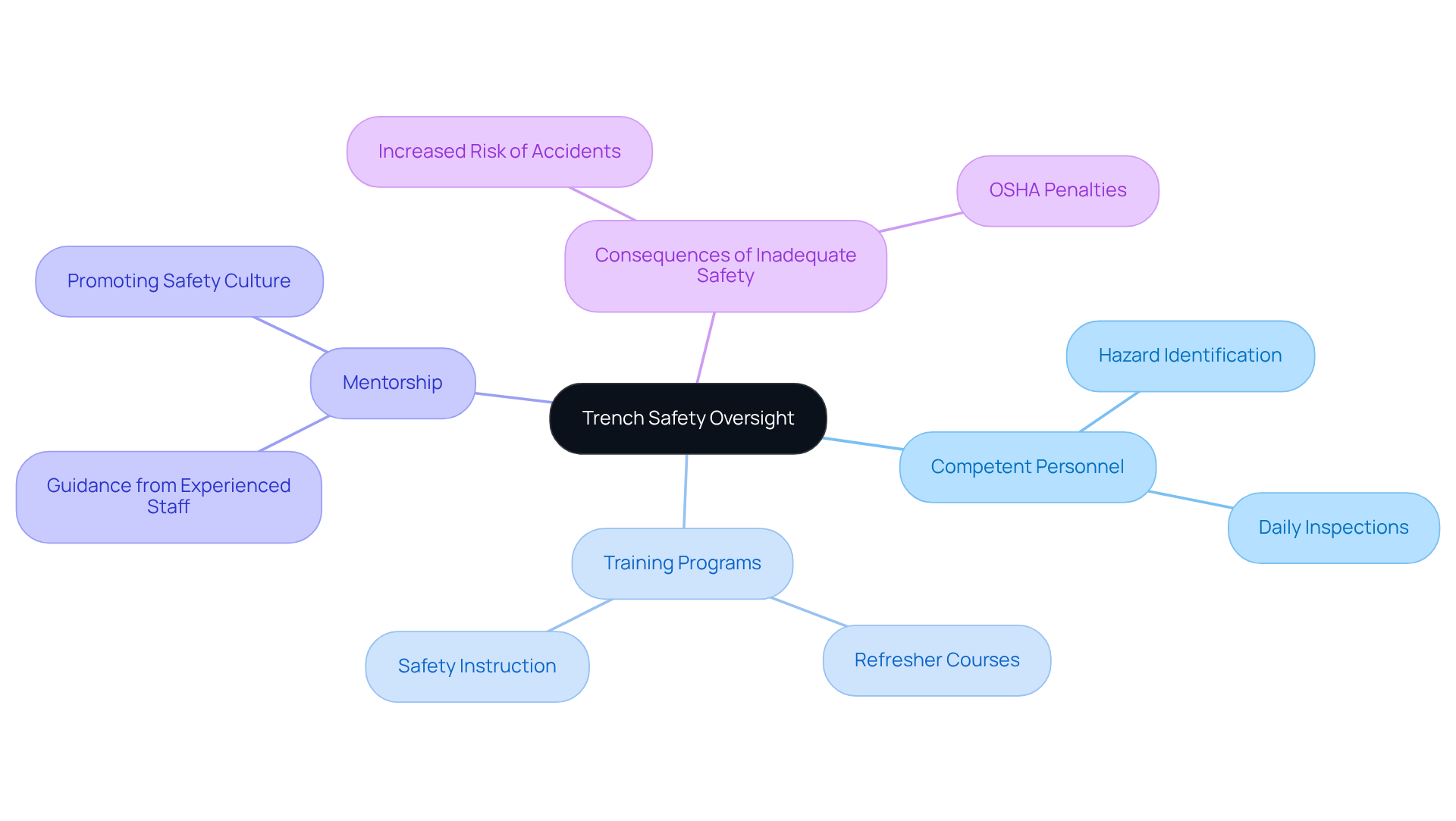

According to OSHA, a competent person is defined as someone capable of identifying existing and predictable hazards in the workplace and authorized to take corrective measures. For effective trench oversight, project managers must ensure that capable individuals are present on-site to perform daily inspections and supervise trenching operations. This involves providing thorough instruction on hazard identification, understanding soil varieties, and implementing essential precautionary measures. Regular refresher courses are crucial to uphold high standards of protection.

For instance, a project manager could establish a mentorship program where experienced staff guide newer employees in excavation practices. This initiative promotes a culture of safety and proficiency on the job site. Investing in such education not only enhances security but also aligns with OSHA's standards, ultimately reducing the risk of accidents and improving overall project outcomes.

In 2023, there were 1,075 construction-related fatalities and 173,200 nonfatal workplace injuries reported, highlighting the urgent need for competent personnel in the use of trench safety equipment. As Grace Ellis notes, "Safety instruction makes sense not only for taking care of your employees but also for protecting your bottom line." Furthermore, project managers should recognize that OSHA penalties can reach up to $161,323 per offense, making it essential to prioritize competent personnel and training programs.

Conduct Regular Inspections and Maintenance of Safety Equipment

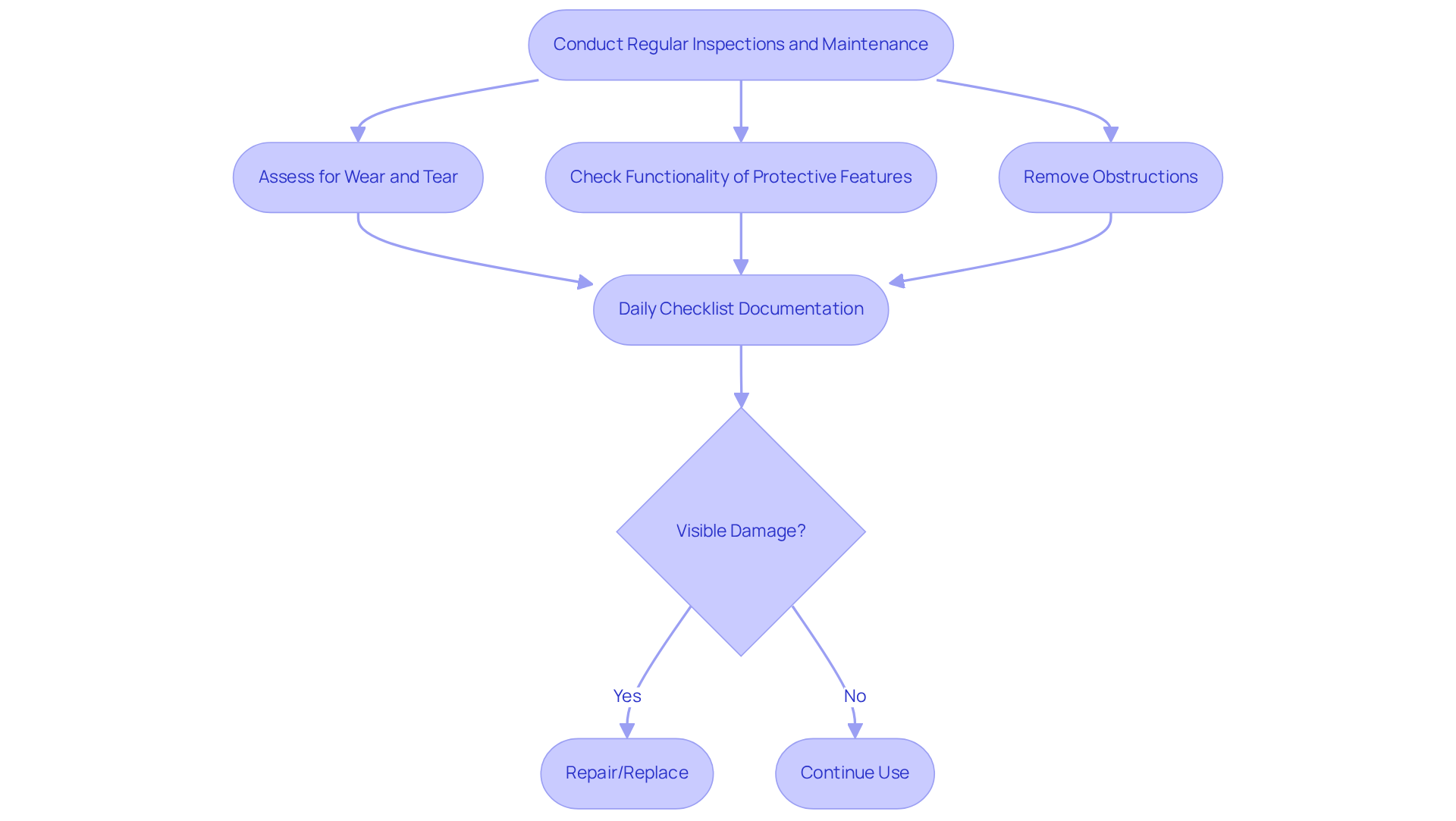

Routine evaluations and maintenance of trench safety equipment are essential for ensuring compliance with regulations and preventing incidents. Project managers should implement a systematic review schedule that includes:

- Daily assessments for wear and tear

- Functionality of protective features

- The removal of any obstructions

For instance, a daily checklist can be utilized to document the condition of trench boxes and shoring systems, ensuring that all equipment remains in optimal working order. Inspections must be conducted before each use to identify any visible damage or functional issues. Equipment showing signs of damage should be repaired or replaced immediately to mitigate risks.

Additionally, maintaining a detailed record of evaluations and repairs fosters accountability and enhances safety on the work site. Statistics indicate that routine evaluations of trench safety equipment can significantly reduce the likelihood of incidents related to trenches, underscoring the importance of these practices in creating a safe working environment. According to the Common Ground Alliance, there has been a remarkable 70% decrease in incidents since 2022, highlighting the effectiveness of targeted safety partnerships and the necessity of adhering to inspection protocols to avoid legal repercussions and protect one’s reputation.

Conclusion

Understanding and implementing trench safety practices is not merely a regulatory requirement; it is a fundamental responsibility for project managers committed to safeguarding their teams. By prioritizing compliance with OSHA regulations and fostering a culture of safety, project managers can significantly reduce the risks associated with excavation work. This dedication to trench safety can lead to a notable decrease in accidents and fatalities, ensuring that workers return home safely at the end of each day.

Key elements discussed in this article include:

- The importance of selecting appropriate trench safety equipment

- Conducting regular inspections

- Ensuring that competent personnel oversee trench operations

From understanding soil conditions to maintaining equipment and providing thorough training, each aspect plays a critical role in enhancing safety on job sites. The statistics presented, such as the reduction in trench-related fatalities, highlight the effectiveness of these practices and the positive impact of robust safety protocols.

Ultimately, the responsibility rests with project managers to champion trench safety measures and ensure that their teams are well-equipped and trained. By actively engaging in continuous education and adhering to best practices, project managers not only protect their workforce but also contribute to the broader goal of improving safety standards across the construction industry. Embracing these essential practices is crucial for fostering a safe working environment and reinforcing the significance of trench safety in every excavation project.

Frequently Asked Questions

What are the key OSHA regulations regarding trench safety?

OSHA regulations require project managers to understand the safety requirements for excavations deeper than five feet, including daily inspections by a competent person and the establishment of safe entry and exit points.

Why is it important to maintain a distance between excavated materials and trench edges?

Maintaining a distance of at least two feet between excavated materials and trench edges helps prevent collapses, significantly reducing the risk of accidents.

How many trench-related fatalities were reported in 2025?

In 2025, there were 11 trench-related fatalities reported nationwide.

What percentage of total penalties issued in 2023 were due to violations of OSHA’s excavation standards?

Violations of OSHA’s excavation standards represented 9% of total penalties issued in 2023.

How can regular educational sessions benefit excavation safety?

Regular educational sessions enhance team awareness of safety regulations and cultivate a robust culture of safety on site, leading to a notable decrease in incidents.

What protective systems does OSHA recommend for excavation safety?

OSHA recommends protective systems such as sloping sidewalls and shoring with aluminum hydraulic supports to prevent collapses in excavations.

What is the significance of continuous training for project managers in 2026?

Emphasizing compliance and continuous training will be vital for safeguarding teams as project managers navigate the evolving landscape of excavation guidelines in 2026.

List of Sources

- Understand Trench Safety Regulations and Guidelines

- Trench safety starts with you (https://blog.dol.gov/2025/06/11/trench-safety-starts-with-you)

- US Department of Labor urges safe practices during trench and excavation work | Occupational Safety and Health Administration (https://osha.gov/news/newsreleases/osha-trade-release/20250728)

- OSHA Highlights Trenching Safety as 2025 Fatalities Rise -- Occupational Health & Safety (https://ohsonline.com/articles/2025/07/29/osha-urges-trenching-safety-as-2025-fatalities-rise.aspx)

- Trenching and excavation deaths rose 160% in 2022: CPWR (https://safetyandhealthmagazine.com/articles/25402-trenching-and-excavations-deaths-rose-160-in-2022-cpwr)

- 12 Trench Collapse Deaths Reported in 2025: OSHA Concerned (https://equipmentworld.com/regulations/safety-compliance/article/15752075/12-trench-collapse-deaths-reported-in-2025-osha-concerned)

- Select and Implement Appropriate Trench Safety Equipment

- 12 Trench Collapse Deaths Reported in 2025: OSHA Concerned (https://equipmentworld.com/regulations/safety-compliance/article/15752075/12-trench-collapse-deaths-reported-in-2025-osha-concerned)

- Data Shows 70% Decline in Trench-Related Worker Fatalities | Municipal Sewer and Water (https://mswmag.com/online_exclusives/2025/03/data-shows-70-decline-in-trench-related-worker-fatalities)

- 2025 Trench Safety Stand Down - Gaines and Company Site Development (https://gainesandco.com/trench-safety-stand-down-2025)

- OSHA Reports Decrease in Construction Fatalities Tied to Trench Collapses and Falls -- Occupational Health & Safety (https://ohsonline.com/articles/2024/11/06/osha-reports-decrease-in-construction-fatalities-tied-to-trench-collapses-and-falls.aspx)

- Trench, fall fatalities down due to OSHA enforcement efforts (https://jjkeller.com/news/article/Trench-fall-fatalities-down-due-to-OSHA-enforcement-efforts_id-c5703491-92ba-4bdf-d32a-dad16ed67570?srsltid=AfmBOoqRi4Rh-qmrhQuFWphqr6rnvIWzWz7-y6_Gf1swSIwoUfHf_ko0)

- Ensure Competent Personnel for Trench Safety Oversight

- Construction Safety: 5 Statistics Everyone in the Industry Should Know (https://autodesk.com/blogs/construction/construction-safety-statistics)

- (https://oshatrainingschool.com/blog/competent-person-osha-construction-safety-training)

- OSHA standards and the ‘competent person’ (https://safetyandhealthmagazine.com/articles/21125-osha-standards-and-the-competent-person)

- 10 Construction safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/construction-safety-statistics)

- Competent Person - Overview | Occupational Safety and Health Administration (https://osha.gov/competent-person)

- Conduct Regular Inspections and Maintenance of Safety Equipment

- Data Shows 70% Decline in Trench-Related Worker Fatalities | Municipal Sewer and Water (https://mswmag.com/online_exclusives/2025/03/data-shows-70-decline-in-trench-related-worker-fatalities)

- The Importance of Trench Box Inspections: Ensuring Safety and Compliance | Northeast Shoring (https://northeastshoring.com/blog/trench-box-inspections-safety-compliance)

- OSHA's top 10 construction violations in 2024 (https://equipmentworld.com/regulations/safety-compliance/article/15707920/oshas-top-10-construction-violations-in-2024)

- 12 Trench Collapse Deaths Reported in 2025: OSHA Concerned (https://equipmentworld.com/regulations/safety-compliance/article/15752075/12-trench-collapse-deaths-reported-in-2025-osha-concerned)