Introduction

In the competitive landscape of construction and project management, the choice between renting and owning equipment can significantly impact both safety and financial outcomes. As contractors increasingly turn to machinery rentals, understanding the nuances of safety protocols, rental agreements, and lifecycle management becomes essential.

From ensuring compliance with safety standards to mastering the financial benefits of rentals, these insights empower professionals to make informed decisions that enhance operational efficiency and protect their workforce.

Exploring best practices and effective management strategies not only fosters a culture of safety but also optimizes resource allocation, paving the way for successful project execution.

Prioritizing Safety in Machinery Tool Rental

When participating in machinery tool and rental, it is essential to emphasize security by thoroughly examining the precautionary guidelines provided by the rental company. Ensuring that all tools comply with established standards for protection, particularly those set by regulatory bodies like OSHA, is essential for maintaining a secure work environment. A comprehensive inspection of the apparatus prior to use is crucial; operators should check for any visible defects to mitigate risks.

Furthermore, implementing robust training for all operators is vital. This training should prepare them not only to use the tools correctly but also to recognize and address potential hazards effectively. The utilization of personal protective gear (PPE)—including helmets, gloves, and goggles—plays a crucial role in improving protection on the job site.

As emphasized in recent reports, two-thirds of surveyed workers had never encountered specialized tools like the Wall Walker hanging scaffold, highlighting the necessity for proper training and awareness in the field. Veronica James, in her article on protective harnesses, emphasizes that 'proper equipment and training are critical to preventing injuries.' Furthermore, the initial report on the most commonly referenced OSHA standards in FY 2022 identified Fall Protection and Hazard Communication as key areas where compliance and training may require improvement.

By adhering to these safety protocols, construction managers can significantly reduce the likelihood of accidents and injuries, fostering a culture of safety that protects both workers and the integrity of the endeavor.

Understanding Rental Equipment Categories and Terms

In the machinery tool and rental sector, understanding the classification of leased devices is essential for efficient project management. Rental tools are generally categorized into key areas such as earthmoving, lifting, and compaction within the machinery tool and rental sector. Familiarity with specific leasing terms can greatly enhance your ability to navigate agreements and optimize resource allocation.

For instance, 'rate' refers to the cost associated with machinery tool and rental, while 'daily,' 'weekly,' and 'monthly rental periods' determine how long you can utilize the tools. Moreover, comprehending terms like 'damage waiver' is crucial, as it safeguards you from bearing expenses for possible damages, and 'maintenance agreements' outline the upkeep responsibilities, ensuring smooth operations throughout your endeavor. As Josh Nickell, Vice President of the American Rental Association’s equipment segment, notes,

These multi-year problems dampened the optimism that would otherwise be there.

This underscores the importance of being well-informed in today's volatile market, especially considering the impacts of the Russia-Ukraine War and COVID-19 on the Equipment Rental industry. Furthermore, with the Professional Account costing $959 USD per month, managers must carefully assess their financial obligations when entering leasing agreements. By mastering these terms, you can negotiate more favorable leasing conditions and select the right machinery tool and rental options tailored to your project's specific needs.

The significance of understanding leasing conditions is further illustrated by Herc Holdings, which reported a total revenue of $2.1 billion USD, highlighting the competitive position of major players in the machinery tool and rental sector. As the Equipment Leasing Market continues to evolve, with both long-term and short-term leases holding the largest market shares in 2024, being informed is more important than ever.

Financial Benefits of Renting Equipment Over Ownership

Renting machinery tool and rental provides considerable financial advantages over outright purchases, especially for contractors managing tight budgets. By choosing to lease, contractors can avoid the substantial upfront costs related to purchasing equipment. Furthermore, leasing expenses are typically tax-deductible, enhancing cash flow management and overall financial optimization.

Christopher Doyle, co-founder and CEO of Bills, highlights the importance of this flexibility, stating,

Recognizing the cash flow hurdles that contractors face when purchasing materials, we launched Bills to make traditional Wall Street working capital accessible to business owners in the construction industry.

This perspective emphasizes the critical role that machinery tool and rental services play in adapting to financial fluctuations and changing requirements. Furthermore, machinery tool and rental provide access to the latest technology and specialized tools, making it an ideal option for short-term endeavors without the long-term commitment of ownership.

The on-demand delivery and pickup of rented equipment ensure availability when needed, further reducing idle time and enhancing operational efficiency. When evaluating your project needs, consider the total costs of ownership, including maintenance and repair obligations, which can often be more burdensome than anticipated. Ownership involves not just the purchase cost but also recurring expenses associated with maintenance, as emphasized by the case study on repairs, where leasing companies usually manage scheduled upkeep.

Investigating the financial advantages of equipment leasing versus ownership can lead to more informed and strategic decisions that maximize efficiency and profitability.

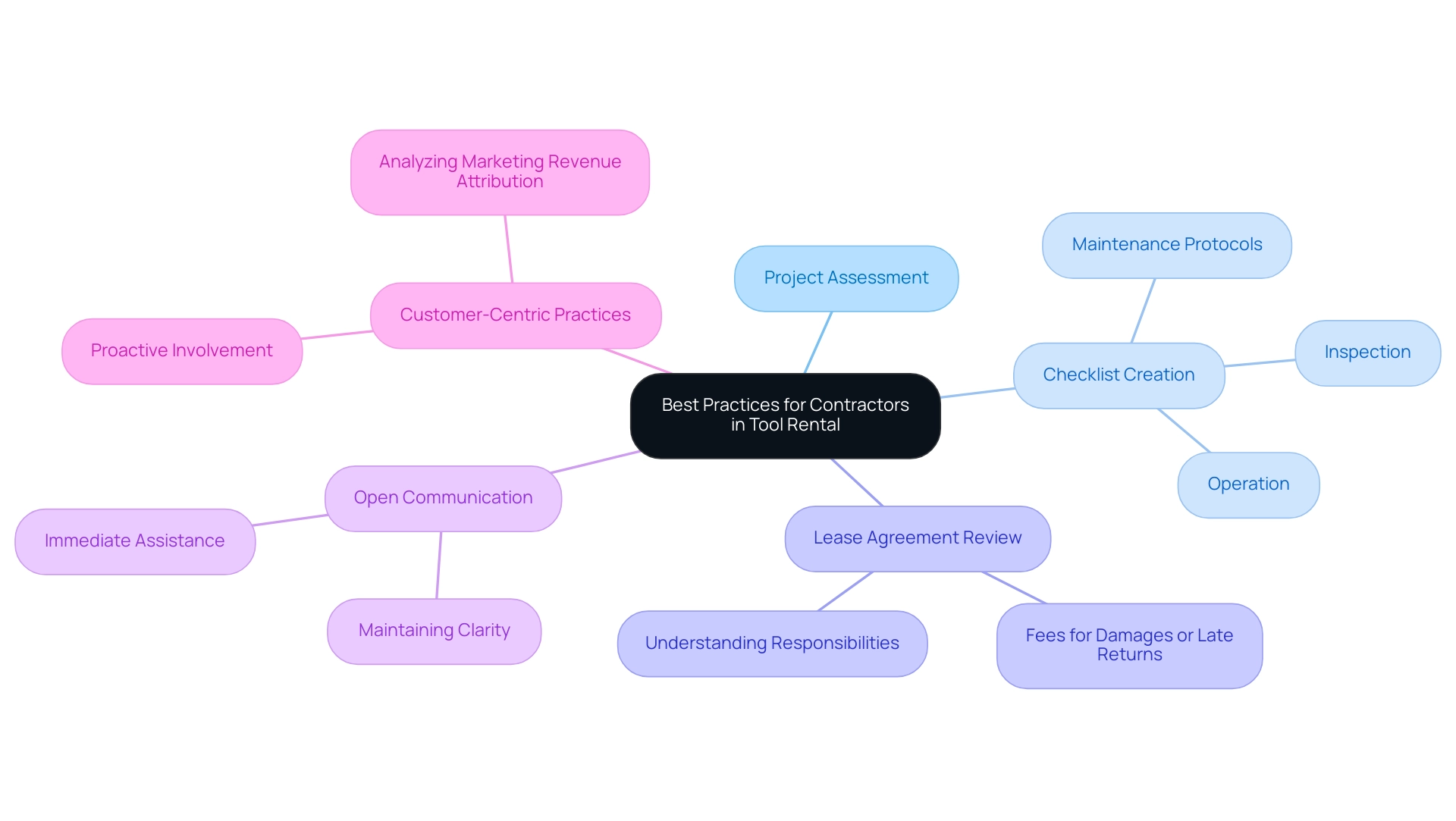

Best Practices for Contractors in Tool Rental

To facilitate a seamless tool borrowing experience, it is crucial to begin with a thorough assessment of your project requirements, ensuring that the selected tools align with specific tasks. A well-crafted checklist should encompass key aspects such as:

- Inspection

- Operation

- Maintenance protocols

This checklist serves as a comprehensive guide throughout the leasing period. It is essential to meticulously review the lease agreement to fully understand your responsibilities, including any fees that may arise for damages or late returns.

Maintaining open lines of communication with the provider is vital; this fosters clarity and allows for immediate assistance when needed. As emphasized by EquipmentWatch, 'In fact, most survey respondents reported leasing equipment in the past year,' underscoring the growing dependence on leasing services within the industry. Moreover, returning tools promptly and in excellent condition not only enhances your reputation with the leasing company but also cultivates a positive, long-term relationship.

The significance of efficient communication and customer-focused practices is additionally highlighted in Gartner's forecast that by 2025, 75% of organizations will discard NPS to assess customer service success, stressing the necessity for proactive involvement in transactions. Additionally, analyzing marketing revenue attribution can provide insights into which strategies yield the best outcomes, ensuring that your approach is not only efficient but also cost-effective. Mastering these best practices is essential for optimizing both efficiency and cost-effectiveness in the construction industry.

Managing Equipment Lifecycle for Optimal Rental Use

Efficient lifecycle management of machinery tools and rental services is crucial in improving results and optimizing leasing investments. This process begins with thorough planning, which includes assessing anticipated usage and selecting tools that align with project timelines. Significantly, the US machinery tool and rental market expanded from $46.2 billion in 2020 to $47.8 billion in 2021, representing a rise of $1.6 billion and emphasizing the increasing dependence on machinery tool and rental solutions within the industry.

Regular maintenance checks during the leasing period of machinery tool and rental are crucial; these practices not only ensure that equipment remains in optimal condition but also help to avert unexpected costs. Furthermore, utilizing lifecycle management software and ERP systems is essential for tracking and managing machinery tool and rental assets throughout their lifecycle. As Faith Kubicki aptly states,

It’s common advice that past performance is not always indicative of future success, but data doesn’t lie.

Additionally, monitoring re-rental data can indicate demand for specific machinery tools and rentals, guiding decisions on fleet management. After the completion of the task, it’s essential to evaluate the machinery tool and rental experience, analyzing which machinery tools performed effectively and which may require adjustments for future rentals. This proactive approach to lifecycle management allows contractors to refine their strategies, ensuring they are well-equipped to enhance project efficiency and address evolving needs.

Conclusion

Making informed decisions in the realm of machinery rentals is crucial for enhancing both safety and financial outcomes in construction and project management. Prioritizing safety through proper training, compliance with regulations, and thorough equipment inspections can significantly reduce the risk of accidents on the job site. By fostering a culture of safety, contractors can protect their workforce while ensuring project integrity.

Understanding the nuances of rental agreements and equipment categories empowers professionals to optimize resource allocation and navigate the complexities of the rental market effectively. Familiarity with key terms and financial implications of renting versus owning equipment allows contractors to make strategic choices that align with their project needs and budgets.

Adopting best practices in tool rental, including:

- Clear communication with rental providers

- Meticulous management of equipment lifecycles

further enhances operational efficiency. By evaluating rental experiences and adapting strategies accordingly, contractors can refine their approaches, ensuring they remain competitive in an evolving landscape.

In conclusion, embracing these insights not only equips construction professionals with the tools necessary for successful project execution but also positions them to tackle the challenges of the industry head-on. By prioritizing safety, understanding rental dynamics, and implementing effective management strategies, contractors can pave the way for sustained growth and success.

Frequently Asked Questions

What safety measures should be taken when renting machinery tools?

It is essential to thoroughly examine the precautionary guidelines provided by the rental company, ensure compliance with safety standards set by regulatory bodies like OSHA, and conduct a comprehensive inspection of the tools before use.

Why is operator training important in machinery tool rental?

Robust training prepares operators to use tools correctly and to recognize and address potential hazards effectively, which is vital for maintaining safety on the job site.

What personal protective equipment (PPE) is recommended for use with rented machinery tools?

Recommended PPE includes helmets, gloves, and goggles, which play a crucial role in improving protection on the job site.

What did recent reports reveal about workers' familiarity with specialized tools?

Two-thirds of surveyed workers had never encountered specialized tools like the Wall Walker hanging scaffold, highlighting the need for proper training and awareness in the field.

What OSHA standards are particularly important for compliance in machinery tool rental?

The most commonly referenced OSHA standards include Fall Protection and Hazard Communication, which may require improvement in compliance and training.

How can construction managers foster a culture of safety?

By adhering to safety protocols, construction managers can significantly reduce the likelihood of accidents and injuries, thereby protecting both workers and the integrity of the project.

What are the key categories of rental tools in the machinery tool and rental sector?

Rental tools are generally categorized into earthmoving, lifting, and compaction.

What do leasing terms like 'rate' and 'damage waiver' refer to in machinery tool rental?

The 'rate' refers to the cost associated with renting machinery, while a 'damage waiver' protects the renter from bearing expenses for possible damages.

Why is it important to understand leasing conditions in the current market?

Being well-informed about leasing conditions is crucial due to the impacts of events like the Russia-Ukraine War and COVID-19 on the Equipment Rental industry, which can affect financial obligations and resource allocation.

How can knowledge of leasing terms benefit project managers?

Mastering leasing terms allows project managers to negotiate more favorable leasing conditions and select the right machinery rental options tailored to their specific project needs.