Key Highlights:

- A 100 kW generator can power approximately 60-80 average-sized homes and supports multiple devices like lighting, tools, and HVAC units.

- In construction, it is essential for operating lighting systems, heavy equipment, and temporary office trailers, especially in remote areas.

- The generator consumes about 22-24 litres of diesel fuel per hour at maximum capacity, impacting operational costs.

- Optimal performance is achieved by operating the generator at 70-80% capacity to enhance fuel efficiency and minimise wear.

- Power shedding strategies can optimise load management, ensuring critical equipment receives necessary energy while reducing unnecessary consumption.

- Safety protocols include stable placement, ventilation to prevent carbon monoxide buildup, and comprehensive operator training on safe handling practises.

- Implementing lockout/tagout (LOTO) procedures during maintenance is crucial to prevent accidental startup and ensure safety.

- Regular safety drills and ongoing training on safety guidelines are vital for minimising risks associated with generator operation.

Introduction

A 100 kW generator serves as a vital asset on construction sites, delivering dependable power for essential tools and equipment. Its capacity not only accommodates multiple devices at once but also facilitates continuous operations in remote areas where access to the grid is limited. As construction demands shift, project managers must consider how to maximize the generator's potential while ensuring safety and efficiency. By examining strategic applications, load management techniques, and safety protocols related to 100 kW generators, we can uncover key insights that optimize performance and reduce risks on site.

Understand the Power Capacity of a 100 kW Generator

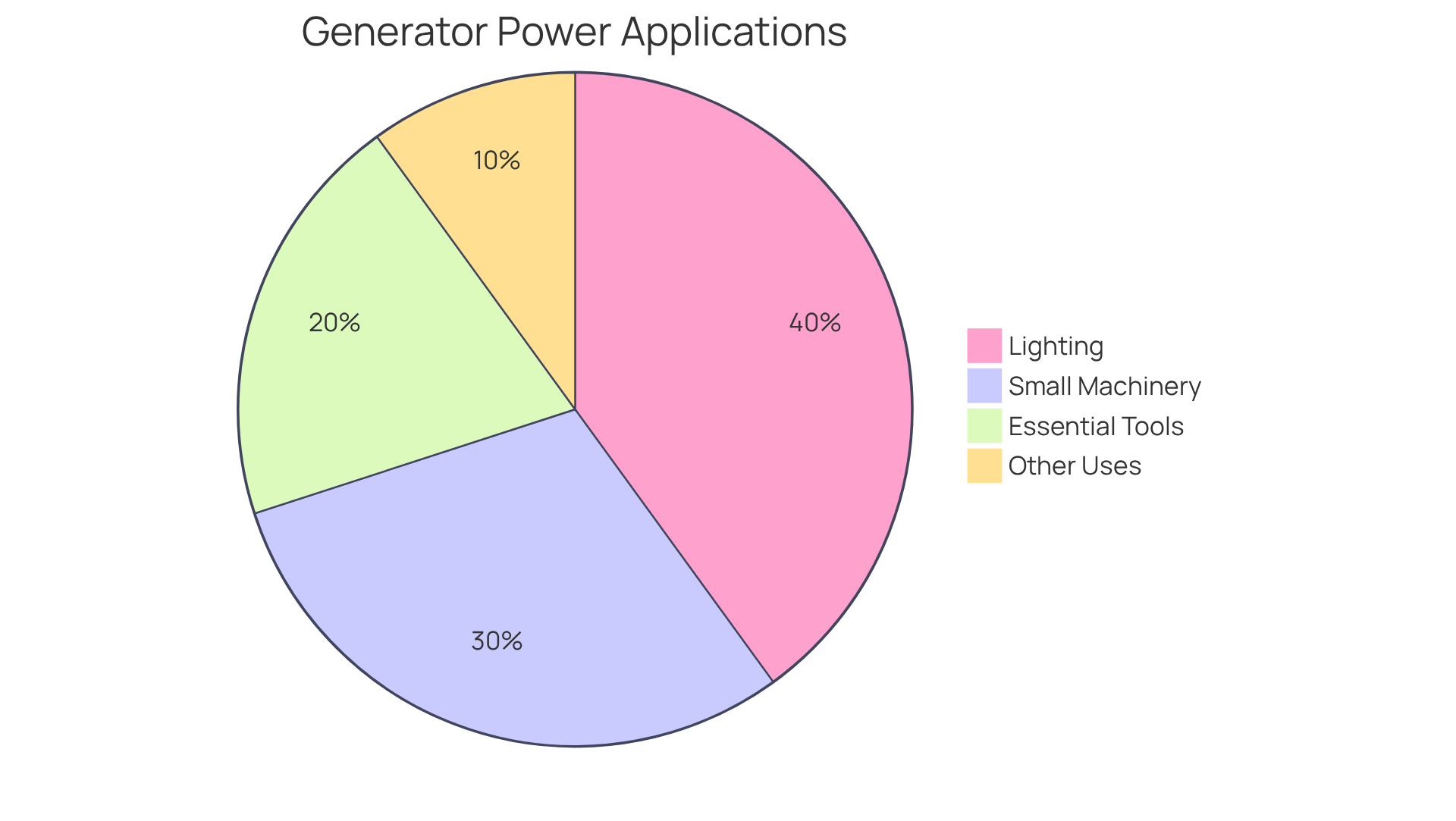

A 100 kW generator supplies adequate energy for various building applications, such as lighting, small machinery, and essential tools. It can generally support demands equivalent to approximately 60-80 average-sized residences, depending on the specific equipment used. This capacity allows multiple devices to operate simultaneously, such as electric tools, lighting systems, and HVAC units, which are often crucial on construction sites. Properly assessing your site's power requirements is essential to ensure that the generator can handle peak loads, minimizing the risk of downtime or equipment failure.

Identify Key Applications for 100 kW Generators in Construction

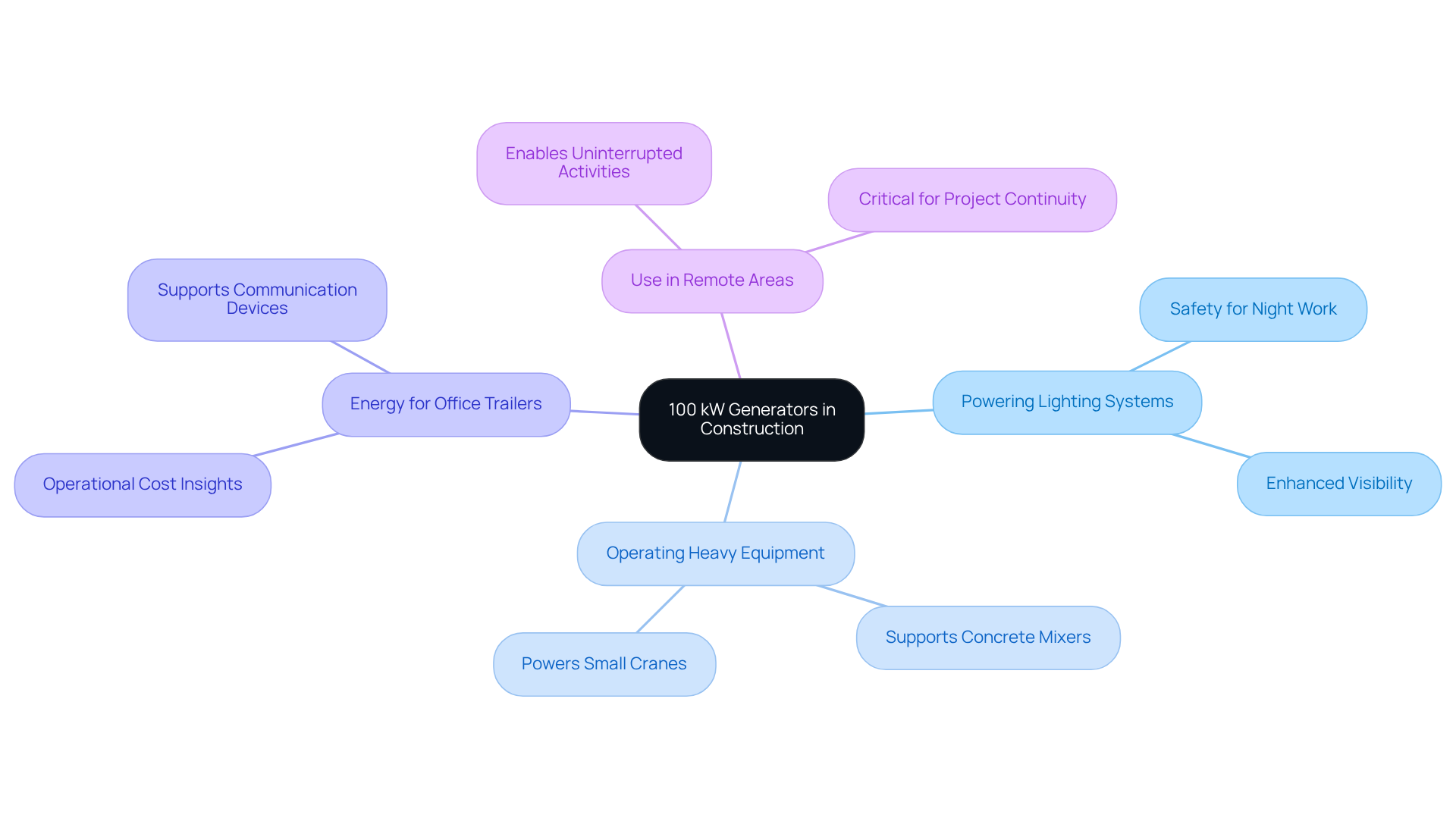

The 100 kW generator is a vital tool on construction sites, offering versatility across a range of applications. They excel at powering lighting systems, which are crucial for night work, allowing projects to proceed safely and efficiently after dark. Additionally, these machines can operate heavy equipment, such as concrete mixers and small cranes, which are essential for maintaining productivity. They also provide energy to temporary office trailers, supporting critical operations like computers and communication devices.

In remote areas where access to the electrical grid is limited, a 100 kW generator becomes indispensable, enabling uninterrupted construction activities. Their reliability ensures that both large-scale and smaller projects can maintain momentum, regardless of external energy availability. Research indicates that a 100 kVA machine can sustain essential services during outages, significantly reducing downtime and making them a crucial investment for project managers aiming to boost efficiency and productivity. As industry leaders emphasize, "On construction sites, reliable power is essential for operating heavy machinery and tools."

Moreover, a 100 kVA power source consumes approximately 22-24 liters of diesel fuel per hour at maximum capacity, providing project managers with valuable insights into operational costs. Key features, such as an auto start option and an emergency stop button, enhance the practicality and safety of these devices on-site.

Optimize Load Management and Sizing for Efficiency

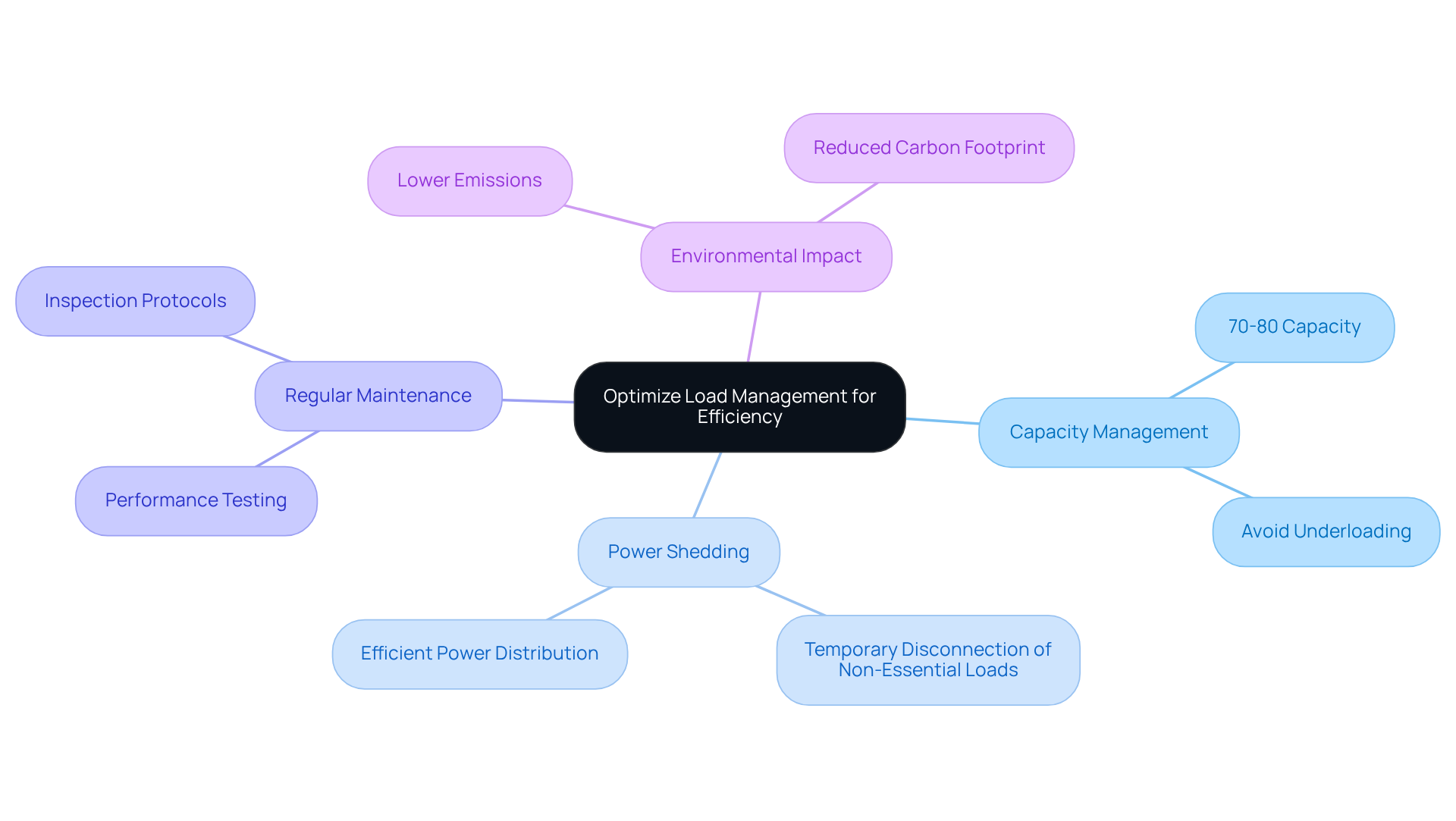

To enhance the efficiency of a 100 kW generator, effective management strategies for its usage are essential. This involves determining the total wattage of all devices powered simultaneously and ensuring the machine operates at 70-80% of its capacity. Research indicates that a 100 kW generator operating within this ideal capacity range achieves the best balance between energy output and fuel consumption, thereby improving fuel efficiency and minimizing wear and tear on the generator.

Methods such as power shedding, which temporarily disconnects non-essential demands during peak usage, can further optimize performance. For instance, Bechtel Corporation employs power shedding systems to effectively distribute energy to critical equipment while curbing unnecessary consumption. Regular performance testing and maintenance inspections are also recommended to ensure the machine operates at its peak efficiency.

Moreover, maintaining operation within the optimal load range can lead to lower emissions and a reduced carbon footprint, contributing to environmental sustainability. It is crucial to avoid running machines below 30-40% of their rated capacity, as this can lead to increased fuel consumption and a shortened lifespan. By implementing these strategies, construction sites can significantly enhance power source efficiency in 2026.

Implement Safety Protocols for Generator Operation

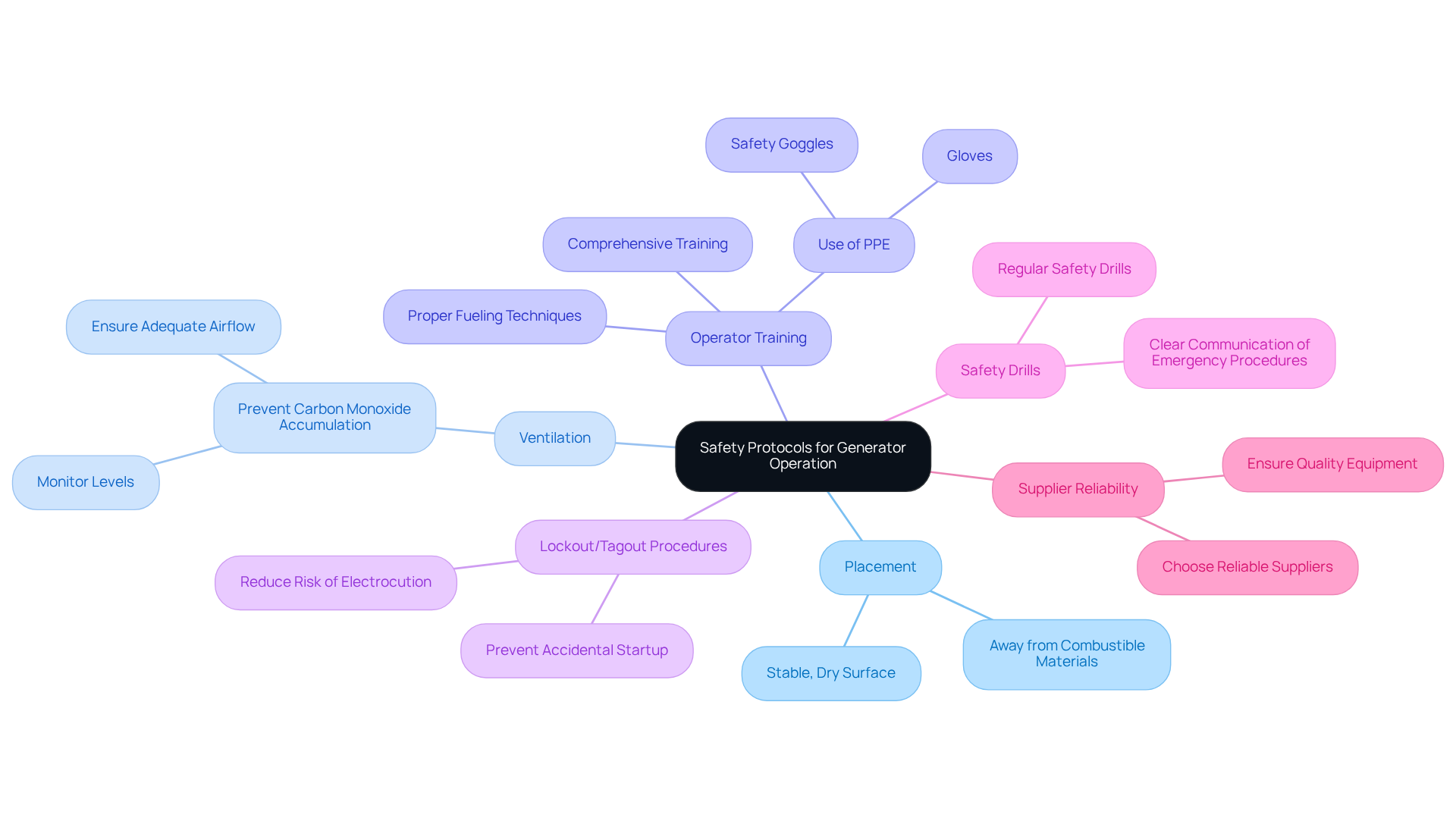

Safety is paramount when operating a 100 kw generator on construction sites. Essential protocols include:

- Placing the device on a stable, dry surface, away from combustible materials.

- Ensuring adequate ventilation to prevent carbon monoxide accumulation, which can be deadly in high concentrations. In fact, carbon monoxide poisoning can turn fatal in just a few minutes at elevated levels.

- Operators must receive comprehensive training in safe handling practices, including proper fueling techniques and the use of personal protective equipment (PPE) such as gloves and safety goggles.

As Emily Newton, Editor-in-Chief, emphasizes, "Following these steps to ensure safety of the equipment is critical to avoiding electrical, combustion, and air quality hazards."

Implementing a lockout/tagout (LOTO) procedure during maintenance is crucial to prevent accidental startup, significantly reducing the risk of electrocution or equipment damage. Regular safety drills and clear communication of emergency procedures are vital, ensuring that all personnel are prepared for potential hazards. Furthermore, ongoing training sessions should focus on the latest safety guidelines and protocols, reinforcing the importance of a safety culture on-site. By prioritizing these measures, construction teams can enhance safety and efficiency while minimizing risks associated with power source operation.

Additionally, it is essential to choose reliable suppliers and ensure proper placement of the 100 kw generator to mitigate risks. Improper grounding and failure to implement LOTO procedures can lead to severe consequences.

Conclusion

Maximizing efficiency on construction sites relies on the strategic deployment of a 100 kW generator, a robust unit capable of powering a diverse range of essential tools and machinery. By grasping its capacity and applications, construction managers can ensure that projects proceed seamlessly, even in remote areas where access to the grid is limited. The generator’s capability to support multiple devices simultaneously not only boosts productivity but also reduces the risks associated with power outages.

Key insights from this article underscore the versatility of the 100 kW generator in supplying power for:

- Lighting

- Heavy machinery

- Temporary office setups

Effective load management and proper sizing are vital for optimizing fuel consumption and minimizing wear, while adhering to safety protocols protects against potential hazards. By employing strategies such as power shedding and maintaining operations within the ideal capacity range, construction teams can significantly enhance efficiency and sustainability.

Ultimately, the significance of a reliable power source in the construction industry cannot be overstated. Prioritizing safety, efficiency, and optimal load management not only improves project outcomes but also cultivates a culture of responsibility on-site. As the demand for construction continues to rise, harnessing the capabilities of a 100 kW generator will remain crucial for achieving operational excellence and ensuring the safety of all personnel involved.

Frequently Asked Questions

What is the power capacity of a 100 kW generator?

A 100 kW generator can supply adequate energy for various applications, including lighting, small machinery, and essential tools.

How many residences can a 100 kW generator support?

A 100 kW generator can generally support demands equivalent to approximately 60-80 average-sized residences, depending on the specific equipment used.

What types of devices can operate simultaneously on a 100 kW generator?

Multiple devices such as electric tools, lighting systems, and HVAC units can operate simultaneously on a 100 kW generator.

Why is it important to assess power requirements for a generator?

Properly assessing your site's power requirements is essential to ensure that the generator can handle peak loads, minimizing the risk of downtime or equipment failure.

List of Sources

- Identify Key Applications for 100 kW Generators in Construction

- What are the Uses for a 100kw Diesel Generator? (https://americasgenerators.com/what-are-the-uses-for-a-100kw-diesel-generator)

- What Can I Power with a 100kVA Diesel Generator? (https://totalgenerators.com/what-can-i-power-with-a-100kva-diesel-generator)

- Top Uses for 100kVA Generators: Everything You Need To Know (https://hampshiregenerators.co.uk/top-uses-for-100kva-generators-powering-your-needs-efficiently)

- Optimize Load Management and Sizing for Efficiency

- Energy Efficiency in Generating Sets | Dagartech (https://dagartech.com/en/news/energy-efficiency-generator-sets)

- Load Variability and Diesel Generator Performance (https://electricaltrader.com/blogs/news/load-variability-and-diesel-generator-performance?srsltid=AfmBOoo1ynFp2BlAmBavpaOFCazoY1K3uBndJU8Cs3nX2tW0uwF3iKHC)

- Load Shedding Strategies To Optimize Industrial Generator Power (https://turnkey-industries.com/load-shedding-a-strategic-approach-to-maximize-your-industrial-power-system)

- How does fuel consumption vary with diesel generator load capacity? - Jlmech (https://whjlmech.com/knowledge/how-does-fuel-consumption-vary-with-diesel-generator-load-capacity)

- TOP 25 ENERGY EFFICIENCY QUOTES | A-Z Quotes (https://azquotes.com/quotes/topics/energy-efficiency.html)

- Implement Safety Protocols for Generator Operation

- 3 Reasons Industrial Generator Safety Can’t Be an Afterthought (https://ishn.com/articles/114704-3-reasons-industrial-generator-safety-cant-be-an-afterthought)

- Electrical Hazards in Construction - Machinery Stats and Facts (https://coactionspecialty.safetynow.com/electrical-hazards-in-construction-machinery-stats-and-facts?print=pdf)

- What Safety Precautions Should You Take with a Generator? (https://apexglobalsolutionsme.com/what-safety-precautions-should-you-take-with-a-generator)

- ESFI Releases Updated Workplace Safety Statistics - Electrical Safety Foundation International (https://esfi.org/news/esfi-releases-updated-workplace-safety-statistics-3)