Key Highlights:

- Telescoping boom lifts offer vertical reach up to 210 feet, crucial for accessing hard-to-reach areas in construction.

- Load capacity must be verified to ensure safety and compliance during operation.

- Stability features like stabilisers enhance safety when the lift is extended.

- Advanced control systems improve manoeuvrability, requiring operator training for effective use.

- Routine inspections and adherence to safety protocols are vital for safe operation, including emergency procedures and use of PPE.

- Rental costs for a 40-foot lift are approximately $228 per day or $1,651 per month, making rentals a cost-effective solution.

- Applications include roofing, painting, electrical systems maintenance, and signage installation, improving efficiency by up to 40% in some tasks.

- Safety protocols include pre-operation inspections, operator training, and establishing safe work zones.

- Maintenance strategies involve regular inspections, lubrication, hydraulic system checks, and adherence to manufacturer guidelines to extend equipment lifespan.

Introduction

Telescoping boom lifts have become essential in the construction industry, especially with the rapid urban development in cities like Dallas. Their unique features - ranging from impressive reach capabilities to critical safety protocols - can greatly enhance both operational efficiency and safety on job sites.

However, how can construction managers ensure they are utilizing these powerful tools to their fullest potential while minimizing risks? This article explores best practices for maximizing the effectiveness of telescoping boom lifts, providing insights that can significantly improve project outcomes and elevate safety standards.

Understand Telescoping Boom Lift Features

Telescoping aerial platforms are equipped with several key features that enhance their functionality on construction sites, particularly in the context of Dallas's ongoing urban development. These features include:

-

Vertical and Horizontal Reach: Telescoping boom lifts can extend both vertically and horizontally, allowing access to hard-to-reach areas. With capabilities reaching up to 210 feet in vertical height, understanding the maximum reach of the apparatus is crucial for effective task planning, especially for projects like window installations and facade maintenance in tall structures.

-

Load Capacity: Each model has a specified load capacity that must not be exceeded. Operators should always verify this specification to ensure safety and compliance.

-

Stability Features: Many models are equipped with stabilizers or outriggers that enhance stability when the apparatus is extended. Familiarity with these features can prevent accidents and improve operational efficiency, which is vital in the bustling construction environment of Dallas.

Modern telescoping boom lifts often incorporate advanced control systems that facilitate precise maneuvering. Operators should receive training on these systems to maximize their effectiveness.

-

Safety Protocols: Routine inspections and adherence to safety guidelines are essential when using boom platforms. Ensuring that all safety components are functional can significantly enhance safety on construction sites, particularly in a rapidly growing city. Operators should be well-versed in emergency procedures and the importance of using personal protective equipment (PPE).

-

Rental Costs: For managers considering rental options, a 40-foot telescopic lift can be rented for $228 a day or $1,651 a month, providing a cost-effective solution for accessing elevated areas without the burden of ownership. Leasing from EZ Equipment Rental ensures that you have the appropriate equipment for your needs. Additionally, comparing various models can help in selecting the best fit for specific task requirements.

By understanding these characteristics, operators can utilize the telescoping boom lift more effectively to enhance productivity and safety on the job site. As one satisfied client noted, "Renting from EZ Equipment Rental was a game-changer for our endeavor; the equipment was top-notch and the service was exceptional," underscoring the importance of choosing the right rental partner.

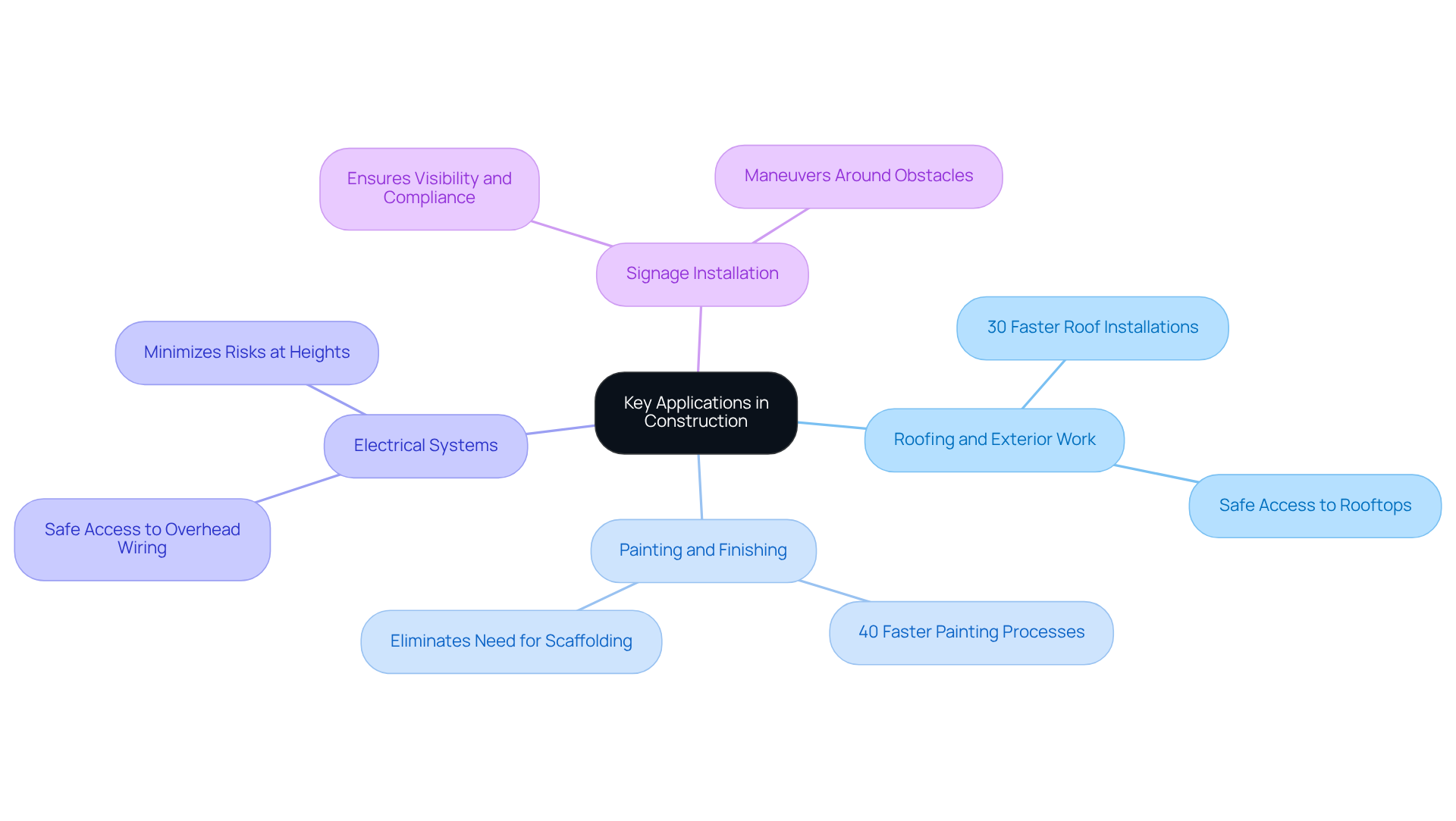

Identify Key Applications in Construction

Telescoping boom lifts are vital tools in the construction industry, providing versatility across various applications:

- Roofing and Exterior Work: Their impressive height and reach make them ideal for roofing tasks, allowing workers to safely access rooftops for installation or repairs. A recent initiative demonstrated that using telescoping platforms reduced the time required for roof installations by 30%. This efficiency is particularly relevant given the overall increase in total construction activity, which rose by 11.7% in March 2022 compared to March 2021.

- Painting and Finishing: These devices enable painters to reach high walls and ceilings without the cumbersome setup of scaffolding, significantly speeding up the painting process. Case studies show that projects utilizing telescoping platforms for painting can complete tasks up to 40% faster than conventional methods. The global market is projected to expand at a CAGR of 6.4% from 2022 to 2030, reflecting the rising demand for such equipment in the sector.

Commonly used for installing and maintaining electrical systems, telescoping boom lifts provide safe access to overhead wiring and fixtures, minimizing risks associated with working at heights. Their design allows for rapid repositioning, enhancing productivity during maintenance tasks while also improving safety on job sites. - Signage Installation: Businesses frequently employ these devices for installing or maintaining signage at elevated heights, ensuring visibility and compliance with local regulations. The ability to maneuver around obstacles without repositioning the base further streamlines the installation process.

By recognizing these applications, construction managers can effectively integrate telescoping cranes into their plans, enhancing overall efficiency and safety on job sites. Additionally, with the rental segment accounting for 93.5% of global revenue in 2021, renting aerial platforms offers a cost-effective solution for short-term projects.

Implement Safety Protocols for Operation

Safety is paramount when operating a telescoping boom lift. Implementing essential protocols can significantly enhance operational safety and efficiency:

- Pre-Operation Inspections: Conduct thorough inspections of the lift before use, checking for mechanical issues, fluid levels, and ensuring that safety features are functional. Regular inspections are mandated by federal law every 150 hours or 90 days, whichever comes first. Additionally, annual inspections should be performed no later than 13 months from the date of the last inspection to maintain compliance.

- Training and Certification: Ensure that all operators are properly trained and certified to operate the equipment. Adherence to OSHA Standard 1926.454 mandates that only trained and authorized individuals operate aerial platforms. Formal training is essential for every operator, regardless of experience, covering controls, safety features, and emergency procedures. Recertification every three years is necessary to maintain skills and knowledge.

- Use of Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including hard hats, harnesses, and non-slip footwear, to minimize the risk of injury. Falls are the leading cause of fatalities in aerial equipment operations, making proper PPE crucial in preventing such incidents.

- Establish a Safe Work Zone: Clearly mark the area around the hoist to keep unauthorized personnel at a safe distance. This practice not only prevents accidents but also allows operators to focus on their tasks without distractions.

- Weather Considerations: Avoid operating the hoist in adverse weather conditions, such as high winds or rain, which can compromise stability and security. Training should emphasize recognizing hazardous weather conditions and the importance of halting operations when necessary.

By adhering to these safety protocols when operating a telescoping boom lift, construction teams can significantly reduce the risk of accidents and injuries, fostering a culture of safety and compliance on job sites.

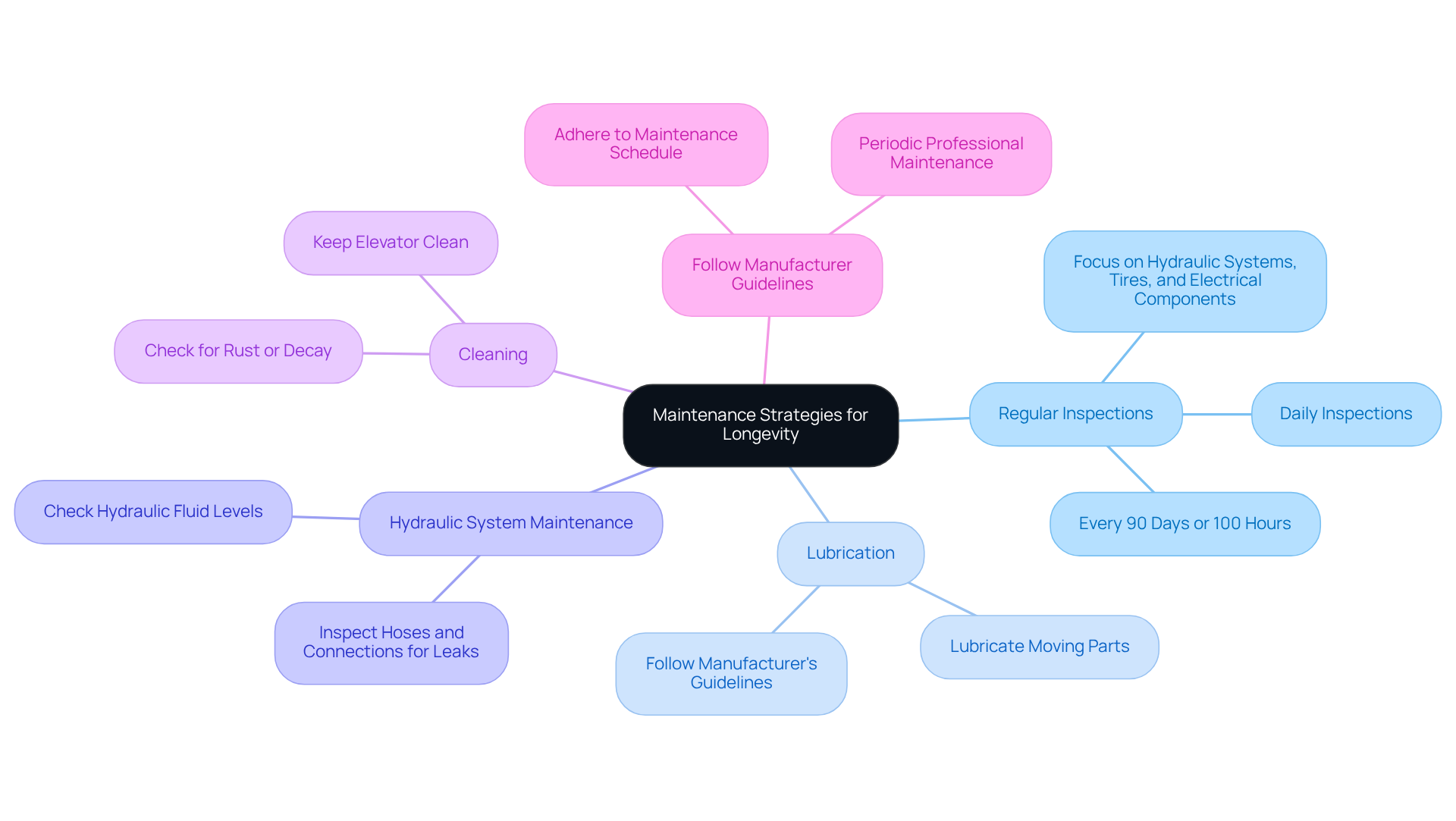

Adopt Maintenance Strategies for Longevity

To maximize the lifespan and performance of a telescoping boom lift, it is essential to implement effective maintenance strategies.

-

Regular Inspections: Conduct daily inspections to identify wear and tear, focusing on hydraulic systems, tires, and electrical components. Many operators recommend inspections every 90 days or after every 100 hours of operation to catch issues early and prevent further damage. Regular maintenance significantly reduces the likelihood of equipment failure, making these inspections crucial.

-

Lubrication: Ensure all moving parts are well-lubricated to facilitate smooth operation and minimize wear. Adhere to the manufacturer's guidelines regarding lubrication intervals and types of lubricants to maintain optimal performance.

-

Hydraulic System Maintenance: Regularly check hydraulic fluid levels and replace fluids as recommended. Examine hoses and connections for leaks or damage, as a well-maintained hydraulic system is vital for the operation of the hoist.

-

Cleaning: Keep the elevator clean to prevent corrosion and damage from debris. Consistently clean the exterior and check for indications of rust or decay, which can undermine security and efficiency.

-

Follow Manufacturer Guidelines: Adhere to the manufacturer's maintenance schedule for servicing and repairs. This practice guarantees that the elevator remains in peak condition and complies with regulatory standards. The case study titled 'Importance of Professional Maintenance for Boom Lifts' emphasizes the necessity of periodic professional maintenance, which includes full system diagnostics and inspections.

Implementing these maintenance strategies enhances the reliability and efficiency of the telescoping boom lift, significantly extending its operational lifespan. This ultimately leads to cost savings and improved safety on job sites. As TGME states, maintenance should be treated as a comprehensive system rather than isolated tasks.

Conclusion

Maximizing efficiency with telescoping boom lifts relies on a solid understanding of their unique features and the implementation of best practices tailored for the construction industry. These aerial platforms provide exceptional vertical and horizontal reach, robust load capacities, and essential stability features, all contributing to safer and more productive job sites. By prioritizing operator training and adhering to safety protocols, teams can effectively leverage these tools while minimizing risks.

Key insights from this article emphasize the importance of thorough inspections, proper use of personal protective equipment, and ongoing maintenance strategies to ensure the longevity and optimal performance of telescoping boom lifts. Their various applications, from roofing to signage installation, highlight their versatility and the significant time savings they can offer in construction projects. With a thriving rental market, utilizing these lifts presents a cost-effective and efficient solution for short-term tasks.

Ultimately, embracing these best practices enhances safety and productivity while fostering a culture of compliance and care within the construction environment. As the demand for efficient construction solutions continues to rise, the strategic use of telescoping boom lifts will play a vital role in shaping successful project outcomes. Prioritizing safety and maintenance ensures that these powerful tools remain reliable assets on any job site, paving the way for future successes in the industry.

Frequently Asked Questions

What are the key features of telescoping boom lifts?

Telescoping boom lifts have several key features, including vertical and horizontal reach, load capacity, stability features, advanced control systems, and safety protocols.

How high can telescoping boom lifts reach?

Telescoping boom lifts can extend up to 210 feet in vertical height, allowing access to hard-to-reach areas, which is particularly useful for tasks like window installations and facade maintenance.

Why is load capacity important when using a telescoping boom lift?

Each model has a specified load capacity that must not be exceeded to ensure safety and compliance during operation.

What stability features do telescoping boom lifts have?

Many models are equipped with stabilizers or outriggers that enhance stability when the lift is extended, which helps prevent accidents and improves operational efficiency.

Why is training on advanced control systems important for operators?

Modern telescoping boom lifts incorporate advanced control systems that facilitate precise maneuvering, and training on these systems maximizes their effectiveness.

What safety protocols should be followed when using boom platforms?

Routine inspections and adherence to safety guidelines are essential, including ensuring all safety components are functional and being well-versed in emergency procedures and the use of personal protective equipment (PPE).

What are the rental costs for telescoping boom lifts?

A 40-foot telescopic lift can be rented for $228 a day or $1,651 a month, providing a cost-effective solution for accessing elevated areas.

Where can one rent telescoping boom lifts?

EZ Equipment Rental offers rental options for telescoping boom lifts, ensuring that customers have the appropriate equipment for their needs.

How can comparing models help in selecting a telescoping boom lift?

Comparing various models can help in selecting the best fit for specific task requirements, enhancing productivity and safety on the job site.

List of Sources

- Understand Telescoping Boom Lift Features

- How to Choose The Right Boom Lift Height | Hastings Motor (https://hastingsmotor.com/how-to-choose-the-right-boom-lift-height)

- Boom Lifts Market Size, Share And Forecast Report, 2033 (https://imarcgroup.com/boom-lifts-market)

- Articulating vs. Telescopic Boom Lifts: What Are The Differences | BigRentz (https://bigrentz.com/blog/articulating-vs-telescoping-boom-lifts-whats-difference?srsltid=AfmBOoog-GISCaoJIKX6PP2cPizItDwP4G_2MFhYWG7D1k7dJNfuF2q1)

- Unlock New Heights with Boom Lifts (https://zonemfc.com/maximum-height-boom-lift)

- Telescopic Boom Lifts Specifications & Dimensions | Aerial Work Platforms | LECTURA Specs - 60 (https://lectura-specs.com/en/specs/aerial-work-platform/telescopic-boom-lifts/page/60)

- Identify Key Applications in Construction

- Why Boom Lifts Are Essential for Construction and Maintenance (https://bvmtransport.com/blog/how-boom-lifts-improve-productivity-on-construction-and-maintenance-sites)

- Boom Lifts Market Size, Share, Trends & Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/boom-lifts-market-report)

- Telescopic Boom Lift Market Size | Mordor Intelligence (https://mordorintelligence.com/industry-reports/telescopic-boom-lift-market)

- Boom Lifts Market Size, Share And Forecast Report, 2033 (https://imarcgroup.com/boom-lifts-market)

- Top Content on LinkedIn (https://linkedin.com/pulse/telescoping-boom-lifts-market-size-forecast-key-iud4c)

- Implement Safety Protocols for Operation

- What Is The Recommended Frequency For Aerial Lift Inspection? (https://cnclifttruck.com/blog/what-is-the-recommended-frequency-for-aerial-lift-inspection--64474)

- Aerial Lift Training: Mastering Safety 2025 (https://trainforthecrane.com/aerial-lift-training)

- Aerial Lift Pre-Operation Inspection Checklist: OSHA-Compliant Safety Guide (https://heavyvehicleinspection.com/checklist/post/aerial-lift-pre-operation-inspection-checklist-osha)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Adopt Maintenance Strategies for Longevity

- 5 Steps to Maintain a Telescopic Boom Lift - TGME (https://tgmegroup.com/5-steps-to-maintain-a-telescopic-boom-lift)

- Best Practices for Aerial Boom Lift Rentals: Ensuring Safety and Efficiency (https://blog.ezequipmentrental.com/best-practices-for-aerial-boom-lift-rentals-ensuring-safety-and-efficiency)

- Seven Statistics on Aerial Lift Equipment (https://bhhcsafetycenter.com/seven-statistics-on-aerial-lift-equipment)

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- Telescopic Boom Lift Market Size | Mordor Intelligence (https://mordorintelligence.com/industry-reports/telescopic-boom-lift-market)