Key Highlights:

- Walk-behind skid loaders are highly manoeuvrable, ideal for confined spaces in landscaping and urban projects.

- These machines are versatile, capable of using various attachments for tasks like digging, grading, and material transport.

- Operators can quickly learn to use walk-behind skid loaders, which reduces training time and boosts productivity.

- They are cost-effective, making them accessible for small businesses and short-term projects due to lower rental or purchase costs.

- Recent advancements allow walk-behind skid loaders to handle more powerful attachments, increasing their utility in construction.

- In landscaping, they efficiently move materials while being turf-friendly, minimising damage to surfaces.

- For excavation, their compact size allows for precise digging in tight spaces where larger machines are impractical.

- Walk-behind skid loaders enhance material handling efficiency, reducing manual labour and accelerating project timelines.

- Safety practises include pre-operation checks, wearing appropriate safety gear, and ensuring proper training for operators.

- Regular maintenance is crucial for safety and performance, involving checks on hydraulic systems and safety devices.

- Contractors must evaluate project duration, budget, maintenance responsibilities, and flexibility when deciding to rent or purchase skid loaders.

Introduction

Walk-behind skid loaders have become essential tools in the construction and landscaping sectors, providing exceptional maneuverability and versatility for tasks in confined spaces. By adhering to best practices for their operation, users can fully harness the capabilities of these compact machines, thereby enhancing efficiency and productivity across a range of projects. As the demand for these agile loaders continues to rise, operators must consider how to maximize their effectiveness while ensuring safety and cost-efficiency.

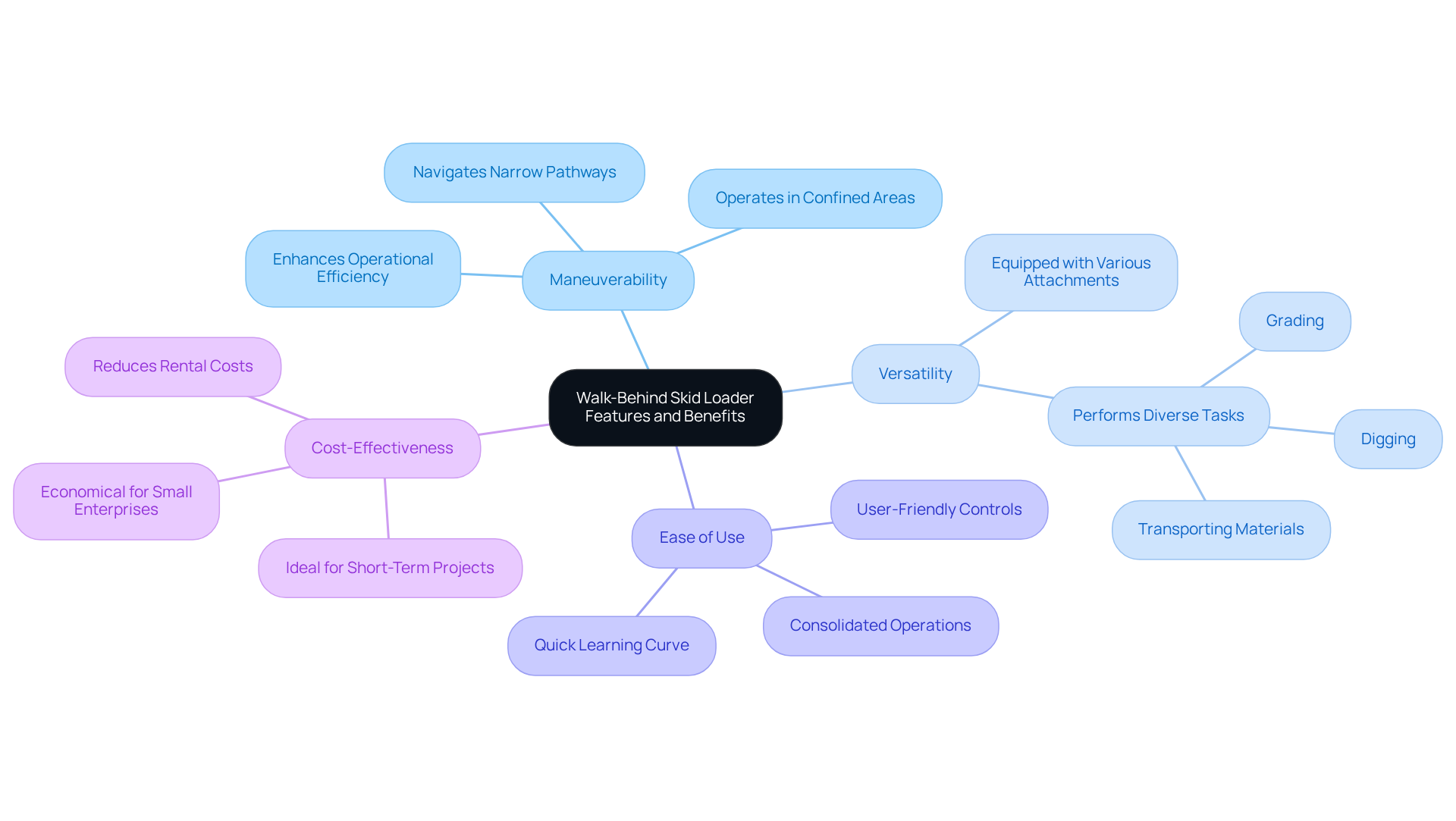

Understand Walk-Behind Skid Loader Features and Benefits

Walk behind skid loaders are versatile tools designed for various tasks in confined areas. Their key features include:

- Maneuverability: The small footprint of these loaders allows them to navigate narrow pathways and confined areas, making them ideal for landscaping, residential construction, and urban projects. Their ability to operate a walk behind skid loader through tight gates and work in crowded sites enhances operational efficiency.

- Versatility: A walk behind skid loader can be equipped with a range of attachments, enabling it to perform diverse tasks such as digging, grading, and transporting materials. This adaptability makes them invaluable across various job sites, especially when using a walk behind skid loader, from small backyards to larger construction areas. As noted by Badger Equipment, "Badger Equipment’s mini machines can manage a variety of capacities to meet different project requirements."

- Ease of Use: Operators can quickly learn to operate a walk behind skid loader, which significantly reduces training time and enhances productivity. Their user-friendly controls allow for consolidated operations, enabling tasks to be executed efficiently.

- Cost-Effectiveness: Typically, these machines are more economical to rent or buy compared to larger equipment, making them attainable for small enterprises and contractors. This cost-effectiveness is especially advantageous for short-term projects, where renting can supply necessary tools without the financial obligation of buying.

Recent advancements in walk behind skid loader machines have further enhanced their performance, enabling them to accommodate more power-hungry attachments like trenchers. As the construction segment continues to grow, expected to be the fastest-growing segment during the forecast period from 2022 to 2030, the demand for these nimble machines is anticipated to rise. This demand is driven by their ability to improve operational efficiency and productivity in various sectors. Real-world examples highlight the effectiveness of the walk behind skid loader in navigating tight spaces and performing tasks that larger machinery cannot, solidifying its role as an essential tool in modern construction and landscaping.

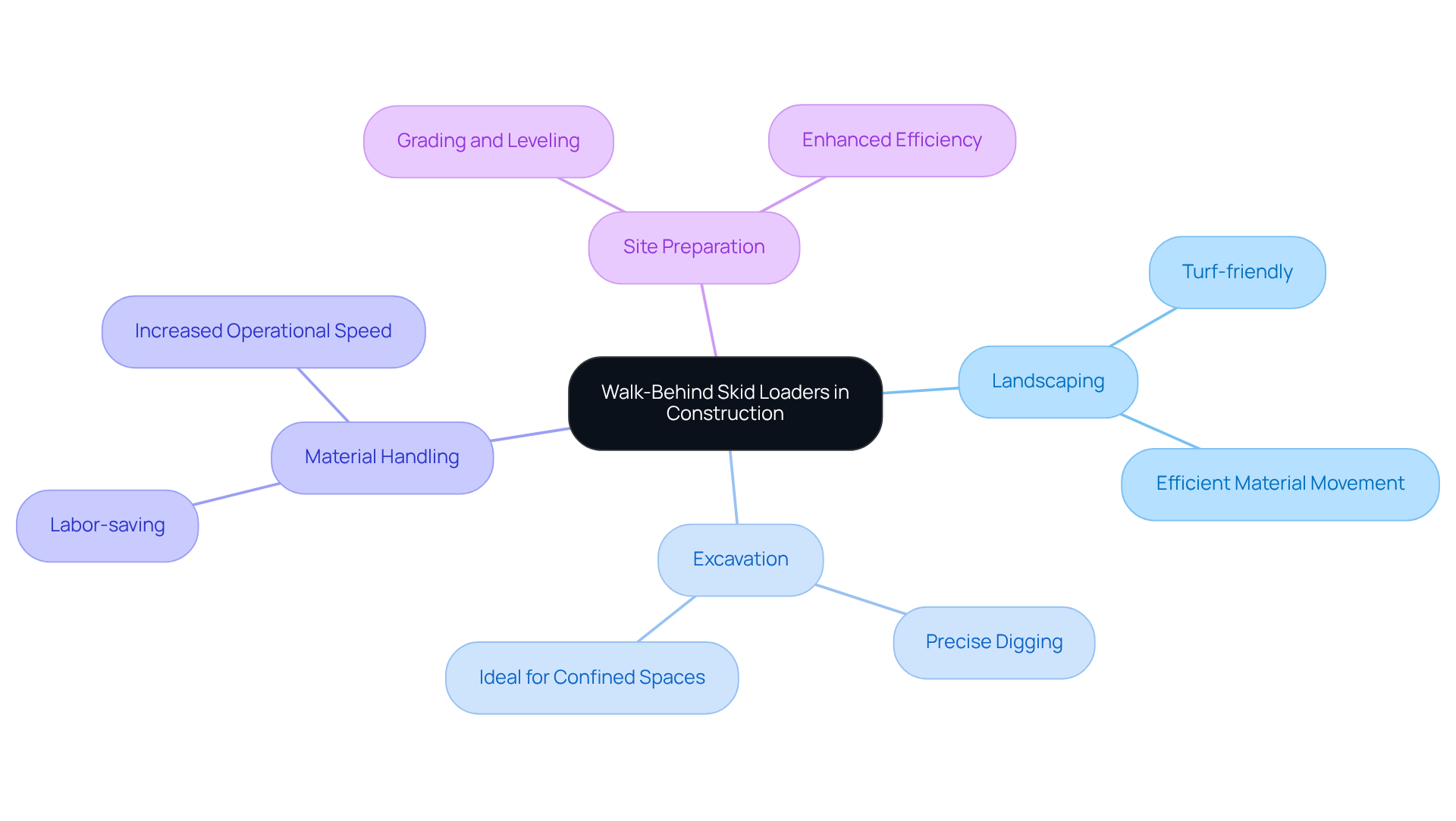

Implement Walk-Behind Skid Loaders in Diverse Construction Tasks

Walk behind skid loader machines are essential assets in various construction tasks, offering both efficiency and versatility. Their compact design makes them particularly effective in several key areas:

- Landscaping: These machines excel at moving soil, mulch, and other materials, facilitating the creation of visually appealing landscapes with minimal effort. Compared to wheeled counterparts, they are more turf-friendly, reducing damage to grass and delicate surfaces.

- Excavation: Their small footprint allows for precise digging in confined spaces, making them ideal for small excavation projects where larger equipment would be impractical.

- Material handling: The use of walk behind skid loaders improves the transportation of heavy materials across job sites, significantly reducing manual labor and increasing operational speed. A mini compact loader can save a contractor approximately 1.5 crew members, underscoring their labor-saving capabilities.

- Site Preparation: They are proficient at grading and leveling surfaces, ensuring that sites are adequately prepared for subsequent construction activities. The new Stellar NXT30 stands out as a powerful option for material and equipment handling, reflecting current trends in the industry.

Incorporating a walk behind skid loader into these tasks streamlines operations and reduces labor expenses, ultimately enhancing overall efficiency. As contractors increasingly recognize the advantages of these machines, they are becoming indispensable tools for maximizing productivity in landscaping and excavation projects. The improved operator experience with the walk behind skid loader further highlights its usability and efficiency, solidifying its status as a preferred choice in the industry.

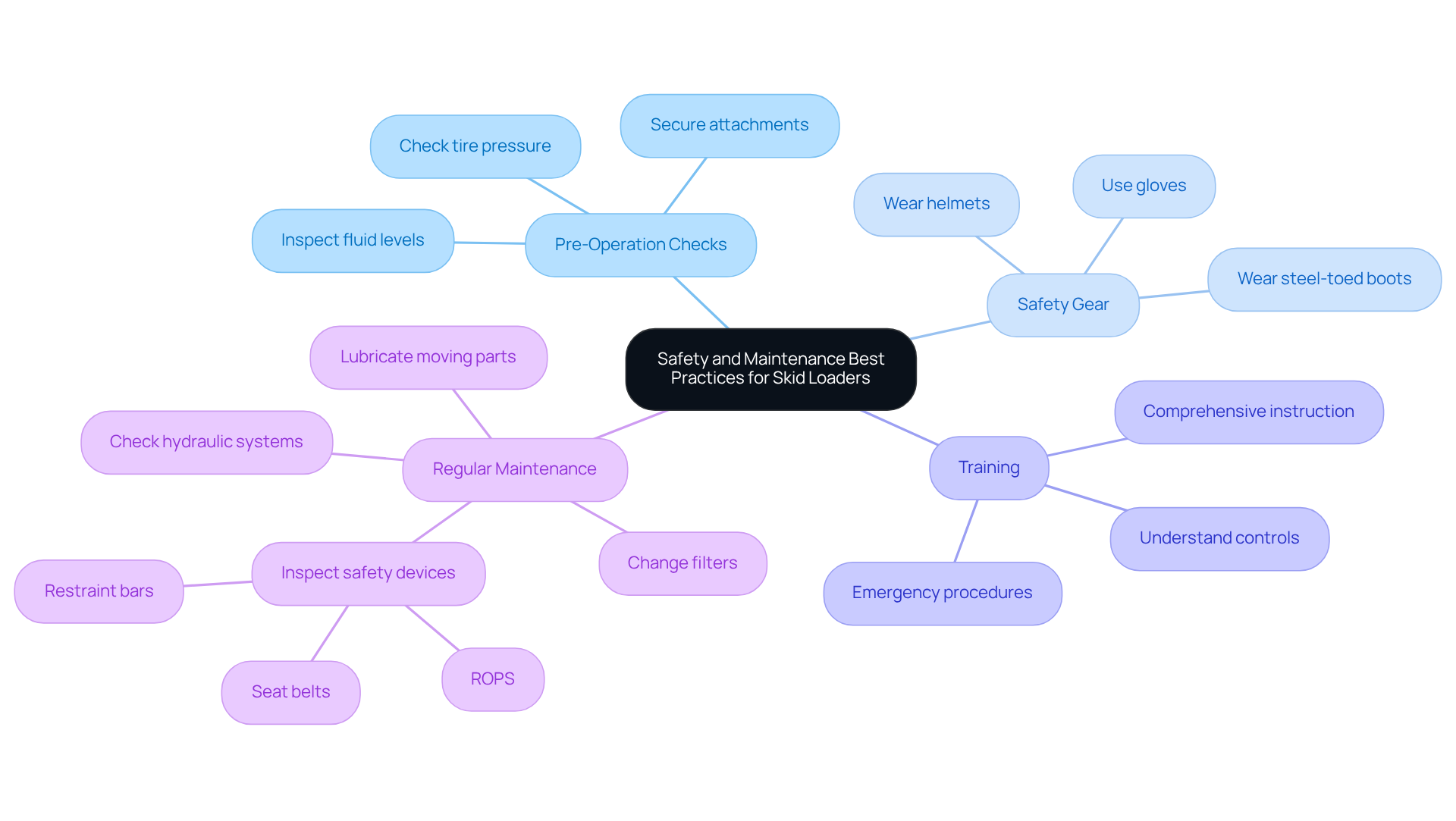

Adhere to Safety and Maintenance Best Practices for Skid Loaders

To ensure the safe and efficient operation of a walk behind skid loader, it is essential to adhere to best practices.

Pre-Operation Checks: Conduct thorough inspections before use, focusing on fluid levels, tire pressure, and the security of attachments. Routine pre-operation inspections are crucial, as they can prevent accidents caused by machinery failure, which accounted for 48 fatal agricultural injuries recorded in Florida from 2015 to 2019.

Safety Gear: Operators must wear appropriate safety gear, including helmets, gloves, and steel-toed boots, to minimize injury risks. As workplace safety specialist Jason Hessom notes, "Skid steer incidents are serious because this machinery is heavy with powerful arms." The use of safety gear is vital, as numerous accidents can lead to serious injuries or fatalities.

Proper training is essential to ensure that all operators receive comprehensive instruction in the safe operation of equipment such as the walk behind skid loader, including a clear understanding of controls and emergency procedures. With 86% of documented injuries being occupational, training programs should incorporate real-life accident scenarios to emphasize the importance of safety.

Regular Maintenance: Adhere to a strict maintenance schedule that includes checking hydraulic systems, changing filters, and lubricating moving parts. Regular upkeep not only prevents failures but also prolongs the machinery's lifespan, ensuring dependable performance on the job site. For instance, it is essential to regularly inspect and maintain safety devices like seat belts, restraint bars, side screens, interlocked controls, and the rollover protection structure (ROPS) to safeguard operators and bystanders alike.

Implementing these practices enhances safety and reliability, ultimately contributing to a more efficient work environment.

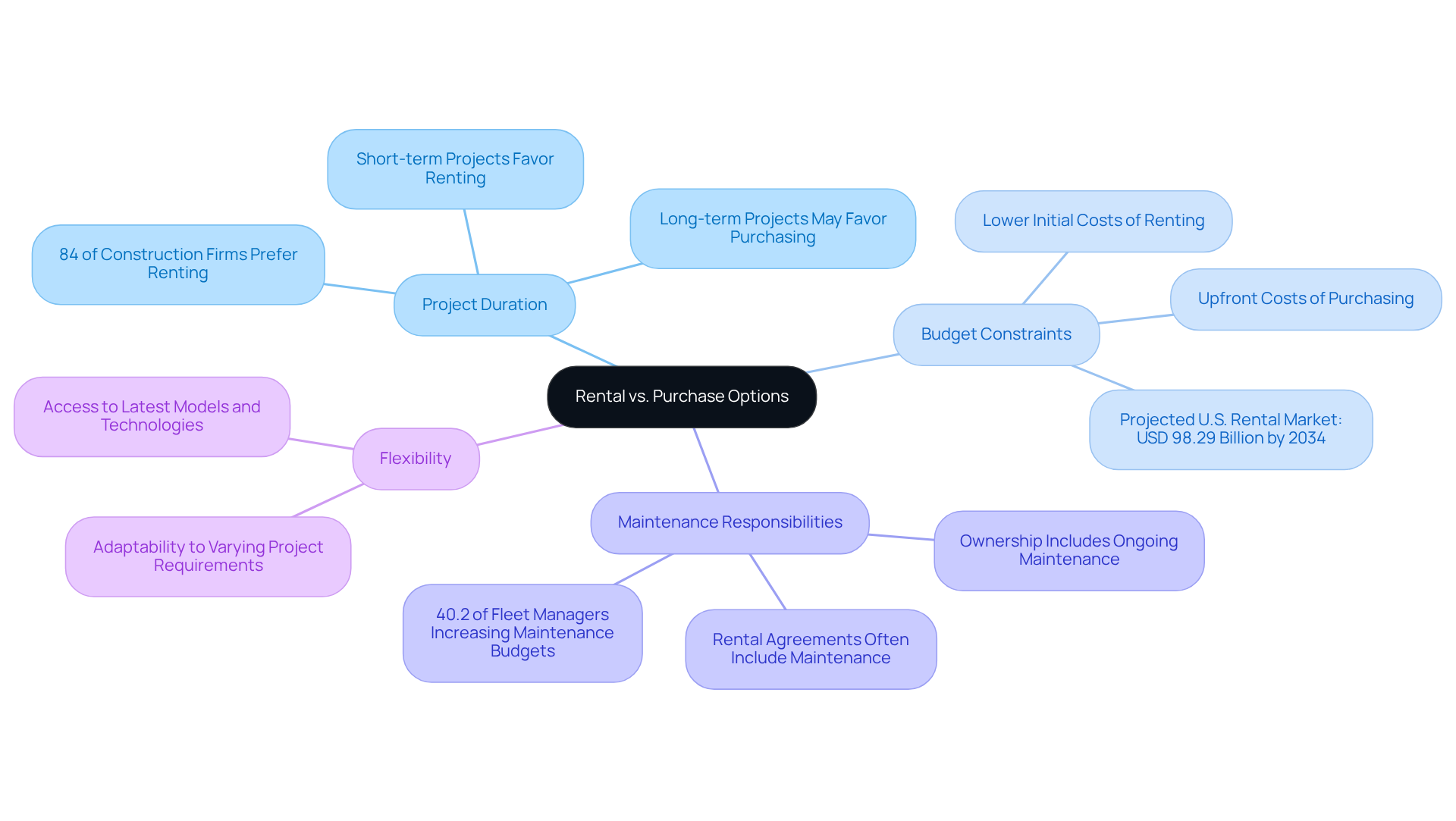

Evaluate Rental vs. Purchase Options for Cost-Effective Solutions

When deciding whether to rent or purchase a walk-behind skid loader, several key factors warrant careful evaluation:

-

Project Duration: For short-term projects, renting is often more cost-effective, while purchasing may be beneficial for long-term use. Notably, statistics indicate that 84% of construction firms in the U.S. prefer leasing tools, reflecting a trend towards adaptability in project management.

-

Budget Constraints: It is essential to assess your budget to determine if the upfront cost of purchasing is manageable compared to the lower initial expenses associated with renting. Renting can significantly reduce overhead costs related to maintenance and storage, making it a financially sound choice for many contractors. The U.S. construction machinery rental market is projected to reach USD 98.29 billion by 2034, underscoring the growing preference for renting.

-

Maintenance Responsibilities: Ownership comes with ongoing maintenance responsibilities, whereas rental agreements typically include maintenance services. This arrangement can alleviate the burden on contractors, allowing them to focus on task execution rather than machinery upkeep. Significantly, 40.2% of surveyed fleet managers are increasing maintenance budgets to extend the lifespan of their assets, highlighting the financial implications of ownership.

-

Flexibility: Renting offers access to the latest models and technologies without the long-term commitment of ownership. This flexibility is particularly advantageous for contractors who need to adapt to varying project requirements and ensure they are utilizing the most effective tools available.

By thoroughly evaluating these factors, contractors can make informed decisions that optimize their asset investments and enhance overall project efficiency. Additionally, consulting with financial advisors can provide valuable insights into budgeting for equipment rental, ensuring that contractors make the most cost-effective choices.

Conclusion

Maximizing efficiency with walk-behind skid loaders requires a thorough understanding of their unique features and benefits, which are tailored for various construction and landscaping tasks. These compact machines are not only maneuverable and versatile but also cost-effective, making them essential tools for contractors looking to enhance productivity on job sites. By integrating these loaders into diverse applications, operators can streamline processes and achieve superior results.

The article emphasizes key arguments, including the significance of safety and maintenance best practices to ensure the reliable operation of skid loaders. Proper training, pre-operation checks, and adherence to safety protocols are crucial for minimizing risks associated with these powerful machines. Furthermore, evaluating the choice between renting and purchasing a skid loader can significantly impact project budgets and operational flexibility, aligning with the needs of contractors across various project durations.

Ultimately, adopting best practices for using walk-behind skid loaders not only improves operational efficiency but also contributes to a safer work environment. As the construction industry evolves, the demand for these versatile machines will continue to grow. It is essential for contractors to stay informed and make strategic decisions regarding equipment use, ensuring they remain competitive and effective in their projects.

Frequently Asked Questions

What are the main features of walk-behind skid loaders?

The main features of walk-behind skid loaders include maneuverability for navigating narrow pathways, versatility with various attachments for different tasks, ease of use for quick operator training, and cost-effectiveness compared to larger equipment.

How does maneuverability benefit walk-behind skid loaders?

Maneuverability allows walk-behind skid loaders to operate in tight spaces, such as narrow pathways and crowded job sites, enhancing operational efficiency in landscaping, residential construction, and urban projects.

What types of tasks can walk-behind skid loaders perform?

Walk-behind skid loaders can perform a variety of tasks, including digging, grading, and transporting materials, thanks to their ability to be equipped with different attachments.

Why are walk-behind skid loaders considered cost-effective?

Walk-behind skid loaders are generally more economical to rent or purchase than larger machinery, making them accessible for small businesses and contractors, especially for short-term projects.

What recent advancements have been made in walk-behind skid loaders?

Recent advancements have improved the performance of walk-behind skid loaders, allowing them to accommodate more power-hungry attachments, such as trenchers, enhancing their utility in various applications.

What is the anticipated demand for walk-behind skid loaders in the future?

The demand for walk-behind skid loaders is expected to rise, particularly in the construction segment, which is projected to be the fastest-growing sector from 2022 to 2030, driven by their ability to improve operational efficiency and productivity.

How do walk-behind skid loaders compare to larger machinery in terms of effectiveness?

Walk-behind skid loaders are particularly effective in navigating tight spaces and performing tasks that larger machinery cannot, solidifying their role as essential tools in modern construction and landscaping.

List of Sources

- Understand Walk-Behind Skid Loader Features and Benefits

- Stand Behind Skid Steer | Pros and Cons Unveiled (https://badgerequipllc.com/pros-and-cons-of-a-stand-behind-skid-steer)

- Stand on Mini Skid Steer Loader Market's Growth Drivers and Key Trends (https://voltequip.com/news/stand-on-mini-skid-steer-loader-markets-growth-drivers-and-key-trends)

- The Immense Benefits Of Walk Behind Skid Steers (https://spartanequipment.com/blog/the-immense-benefits-of-walk-behind-skid-steers?srsltid=AfmBOoplaFxYyYEg5IAQsIxEHGKGBBsOk0VbwaPliGvNUxsxUo2EbILm)

- Why Use Mini Skid Steers: 5 Powerful Benefits for Your Project Success - Rentalex (https://rentalex.com/why-use-mini-skid-steers-5-powerful-benefits-for-your-project-success)

- Implement Walk-Behind Skid Loaders in Diverse Construction Tasks

- Stand Behind Skid Steer | Pros and Cons Unveiled (https://badgerequipllc.com/pros-and-cons-of-a-stand-behind-skid-steer)

- Why The Mini Skid Steer Belongs on a Landscaping JobSite (https://greenindustrypros.com/design-installation/compact-equipment/article/21563372/why-the-mini-skid-steer-belongs-on-a-landscaping-jobsite)

- Why Use Mini Skid Steers: 5 Powerful Benefits for Your Project Success - Rentalex (https://rentalex.com/why-use-mini-skid-steers-5-powerful-benefits-for-your-project-success)

- The Immense Benefits Of Walk Behind Skid Steers (https://spartanequipment.com/blog/the-immense-benefits-of-walk-behind-skid-steers?srsltid=AfmBOoqIZJ4PDYzafTfcMYwgWzTQp0_0Lyo4OkGuOKNkLgpAE5exEDmk)

- Adhere to Safety and Maintenance Best Practices for Skid Loaders

- Safety is Important When Operating Skid Steer Loaders (https://nahb.org/blog/2025/01/skid-steer-loader-safety)

- Tips | Essential Skid Steer Safety (https://traceyroad.com/skid-steer-safety-3-essential-tips-for-operators)

- (PDF) Injuries and Fatalities Related to Skid Steers: 2015–2020 (https://researchgate.net/publication/362478830_Injuries_and_Fatalities_Related_to_Skid_Steers_2015-2020)

- Skid Steer Accidents - [2023 Facts, Statistics & Safety Tips] (https://safetyvideos.com/skid-steer-accidents?srsltid=AfmBOorPbjii0uCwDlwumcfwWL-6x4emj-5wrPX_GWUiYFPBdZdm8bNA)

- Skid Steer Safety Stats & Fact - CoAction Specialty (https://coactionspecialty.safetynow.com/skid-steer-safety-stats-fact?print=print)

- Evaluate Rental vs. Purchase Options for Cost-Effective Solutions

- 7 Must-Know Statistics About Equipment Rentals (https://gocodes.com/construction/equipment-rentals-statistics)

- Construction Equipment Rental Set to Reach $166.07 Billion by 2035 at 4.74% CAGR (https://openpr.com/news/4304565/construction-equipment-rental-set-to-reach-166-07-billion)

- Construction Equipment Rental Market Statistics 2025-2034 (https://statifacts.com/outlook/us-construction-equipment-rental-market)

- 3 Factors to Consider When Renting Construction Equipment (https://westbranchrental.com/3-factors-to-consider-when-renting-construction-equipment)

- Construction Equipment Rental Market Outlook, Insights, and Forecast 2026-2033 (https://skyquestt.com/report/construction-equipment-rental-market)