Key Highlights:

- A telehandler combines the functions of a forklift and a crane with a telescopic boom for lifting and positioning loads.

- Telehandlers have a load capacity of up to 12,000 pounds and can lift materials over 50 feet high, making them essential in construction.

- The telehandler market is expected to grow at a rate of 3.30% from 2026 to 2035, indicating increasing industry reliance on this equipment.

- Common applications include material handling, site cleanup, and elevated work, enhancing efficiency in construction projects.

- In 2024, the telehandler market was valued at USD 7.1 billion, projected to reach USD 12.3 billion by 2034.

- Rental costs for telehandlers in 2025 are estimated between $300 to $600 per day, influenced by rental duration and machine specifications.

- Telehandler attachments such as pallet forks, buckets, and jibs significantly enhance versatility and efficiency on job sites.

- Selecting the correct attachment can improve operational efficiency by up to 30% and reduce cleanup time by two full working days.

- Consistent operator training is essential for maximising the benefits of telehandler attachments while ensuring safety and compliance.

Introduction

Maximizing the efficiency of telehandler rentals is crucial for the success of construction projects. Yet, many project managers overlook best practices that can significantly enhance their utility. Telehandlers uniquely combine the functions of a forklift and crane, offering immense versatility and capability that make them indispensable on job sites.

Understanding how to effectively utilize this equipment poses a challenge. From selecting the right attachments to budgeting for rentals, these decisions can either streamline operations or lead to costly missteps. Project managers must recognize the importance of these choices to fully leverage telehandlers for optimal project outcomes.

What strategies can project managers employ? By focusing on reliable equipment and quality service, they can ensure that their projects run smoothly. Engaging with experienced rental providers can provide insights into the best practices for telehandler use, ultimately leading to enhanced efficiency and success.

Understand Telehandlers: Definition and Functionality

A telehandler, or telescopic handler, stands out as a remarkably versatile piece of equipment that combines the functionalities of both a forklift and a crane. Its standout feature is a telescopic boom that extends and retracts, allowing it to lift, move, and position heavy loads at various heights and distances. Telehandlers can be equipped with a variety of attachments, such as forks, buckets, and jibs, significantly enhancing their utility across a range of tasks.

Understanding the operational mechanics of telehandlers is crucial for managers overseeing projects. With a load capacity of up to 12,000 pounds and maximum lift heights exceeding 50 feet, this equipment plays a vital role in construction processes. This knowledge not only facilitates the effective incorporation of telehandlers but also optimizes labor utilization and boosts overall efficiency.

As the telehandler market evolves, it’s essential to stay informed about the latest advancements and trends. The market is projected to grow at a rate of 3.30% from 2026 to 2035, highlighting the increasing relevance of telehandlers in the industry. By keeping abreast of these developments, you can maximize the benefits of telehandler rental services and ensure your projects run smoothly.

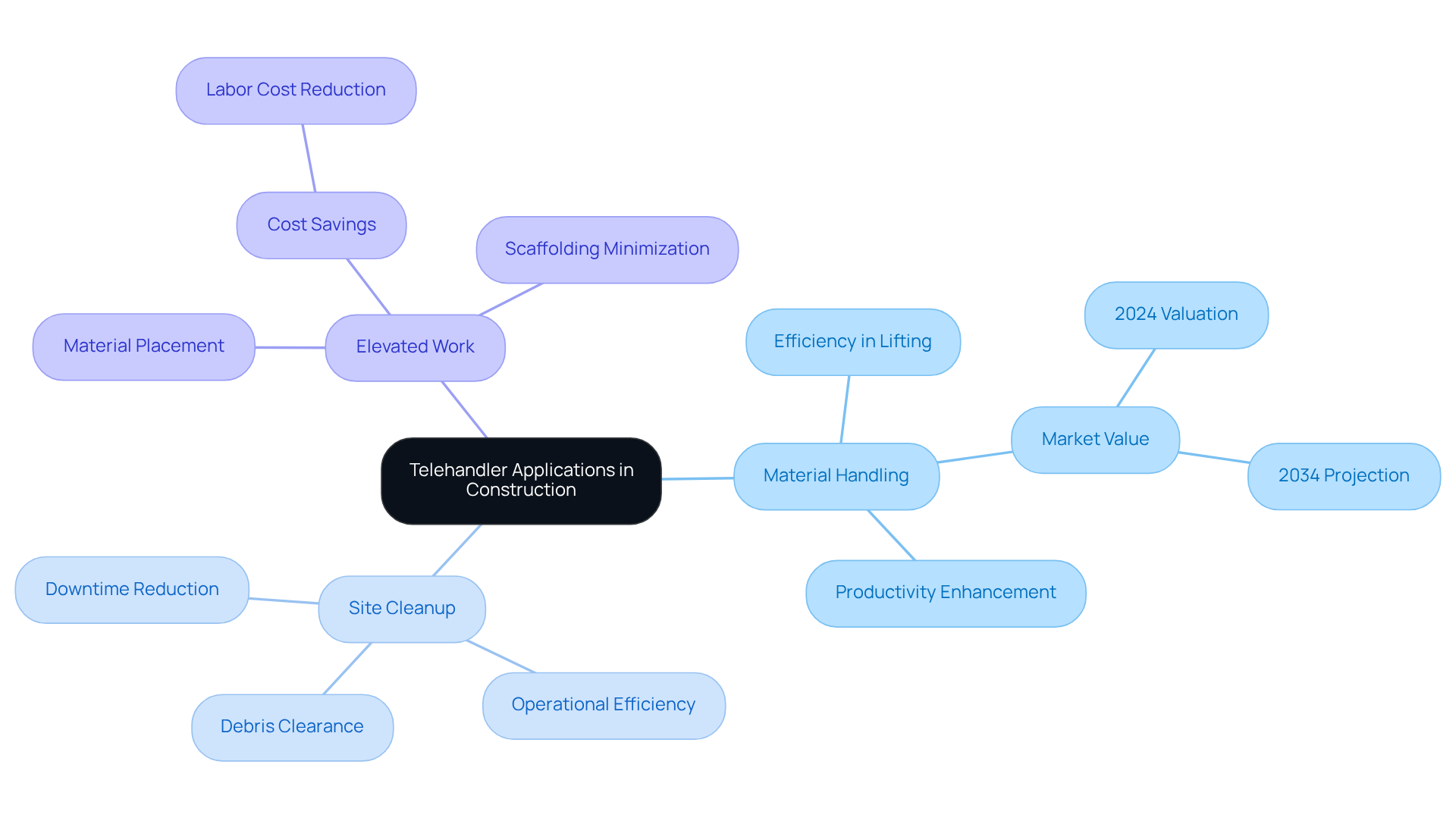

Explore Common Applications: Where Telehandlers Shine

Telehandlers are indispensable in the construction industry, excelling in tasks such as lifting and transporting goods, placing loads at height, and unloading delivery trucks. Their ability to navigate rough terrain makes them particularly suited for outdoor projects, ensuring efficiency and reliability. Here are some key applications:

- Material Handling: Telehandlers efficiently lift heavy materials like steel beams and pallets, significantly streamlining the construction process. Their capacity to handle large volumes of goods enhances productivity on job sites. In fact, the telehandler market was valued at USD 7.1 billion in 2024 and is projected to reach around USD 12.3 billion by 2034, indicating a growing reliance on these machines for material handling.

- Site Cleanup: When equipped with buckets, telehandlers can swiftly clear debris, ensuring a safe and organized work environment. This capability is crucial for maintaining operational efficiency and safety standards. Managers have observed that effective site cleanup can reduce downtime and enhance overall timelines.

- Elevated Work: With suitable attachments, these machines can position materials on rooftops or raised platforms, effectively decreasing the need for scaffolding. This not only saves time but also minimizes labor costs associated with traditional methods. A recent case analysis showed that utilizing aerial lift equipment for elevated tasks lowered labor expenses by 15% compared to traditional scaffolding techniques.

By understanding these applications, managers can leverage telehandler rental to maximize job site efficiency, leading to more successful outcomes. Integrating these machines into planning can mitigate common pitfalls, such as improper load handling and site safety concerns, ensuring a smoother workflow. Don't miss out on the opportunity to enhance your construction projects; consider telehandler rental for your next job.

Evaluate Rental Costs: Budgeting for Your Telehandler

When budgeting for telehandler rentals, project managers must consider several key factors that significantly influence costs:

- Rental Duration: Rates vary based on the length of the rental, with daily, weekly, and monthly options available. Longer rental periods typically yield better value, as costs per day decrease with extended commitments.

- Machine Specifications: The size and lifting capacity of the telehandler play a crucial role in determining rental prices. Larger models with higher lift capacities command higher rates, reflecting their advanced capabilities.

- Additional Fees: It's essential to consider extra costs such as delivery and pickup charges, insurance, and any specialized accessories needed for specific tasks. For instance, while standard forks are usually included, attachments like truss booms or material buckets often incur additional charges.

In 2025, telehandler rental prices are projected to range from $300 to $600 per day, depending on the machine's size and features. By thoroughly assessing these costs and planning ahead, managers can effectively handle their budgets while ensuring they have the necessary equipment to meet demands. Consulting with rental providers for a detailed cost breakdown can further enhance budgeting accuracy, allowing for informed decisions that align with project goals.

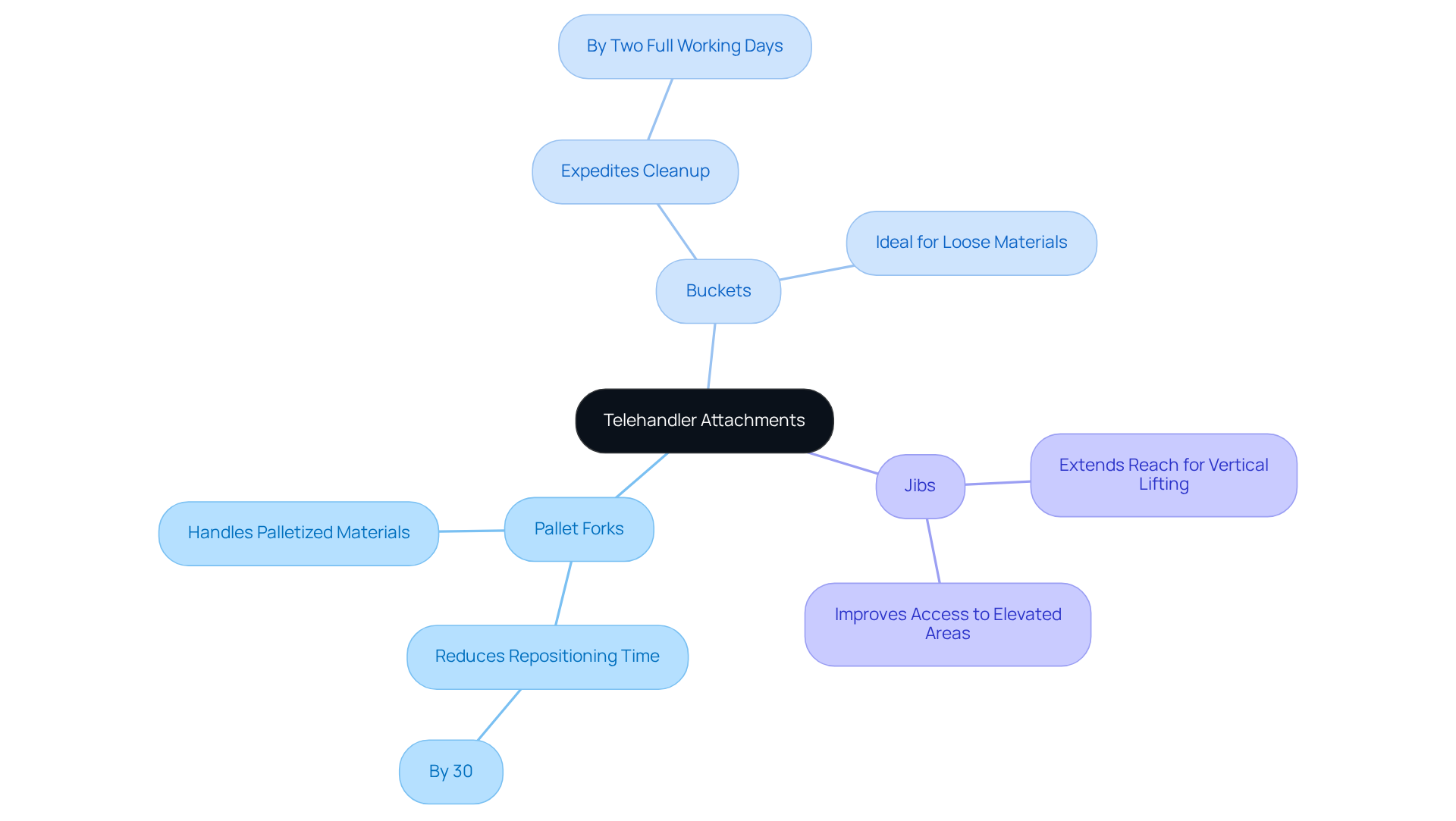

Select Appropriate Attachments: Enhance Telehandler Versatility

Telehandler rental provides access to incredibly versatile machines that can be fitted with a wide range of implements, significantly boosting their functionality on job sites. Here are some key attachments:

- Pallet Forks: Essential for lifting and transporting pallets of materials, these forks streamline the material handling process, reducing repositioning time by up to 30%.

- Buckets: Perfect for moving loose materials like gravel, sand, or debris, buckets can expedite site cleanup and loading tasks, often cutting cleanup time by as much as two full working days compared to using forks.

- Jibs: These fittings extend the reach of the telehandler, allowing for vertical lifting of heavy loads and improving access to elevated areas-crucial for tasks such as placing trusses or conducting repairs at height.

Choosing the right add-on for a telehandler rental based on the specific task can dramatically enhance project efficiency. For example, a construction firm reported a 30% decrease in handling time for resources after utilizing high-reach devices with suitable attachments. Additionally, farms using telehandlers for material handling experience a 25% improvement in operational efficiency during harvest time. Project managers should carefully evaluate their tasks and consider telehandler rental among the resources that align with project requirements. This strategic selection not only boosts productivity but also ensures safety and compliance with industry standards, including adherence to load ratings for certified jibs.

Consistent training for operators is crucial to optimize the advantages of telehandler accessories, ensuring they are well-prepared to manage various tasks safely and effectively. Furthermore, it’s vital to avoid the pitfalls of using the wrong attachment, as this can lead to unbalanced loads and safety hazards. Don't compromise on safety or efficiency-choose the right telehandler attachments today!

Conclusion

Maximizing the efficiency of telehandler rentals is crucial for project managers who want to streamline operations and boost productivity on construction sites. By grasping the unique functionalities of telehandlers, their varied applications, and the financial aspects of renting them, managers can make informed decisions that lead to successful project outcomes.

Key insights discussed throughout this article include:

- The operational mechanics of telehandlers

- Their common uses in material handling, site cleanup, and elevated work

- The significance of selecting the right attachments

- Effective budgeting for rentals

- Understanding the factors that influence costs

These insights are essential for keeping projects within financial constraints while harnessing the full potential of telehandlers.

As industries like construction and agriculture increasingly rely on telehandlers, it’s imperative for project managers to adopt best practices that leverage these versatile machines. Staying informed about market trends, investing in the right attachments, and prioritizing operator training not only enhances project efficiency but also ensures safety and compliance. Embracing these strategies will lead to more successful and streamlined operations, paving the way for future advancements in project management practices.

Take action now - invest in telehandler rentals that meet your project needs and experience the difference in efficiency and productivity. Your projects deserve the best, and with the right equipment and practices, you can achieve remarkable results.

Frequently Asked Questions

What is a telehandler?

A telehandler, or telescopic handler, is a versatile piece of equipment that combines the functionalities of both a forklift and a crane. It features a telescopic boom that extends and retracts, allowing it to lift, move, and position heavy loads at various heights and distances.

What are the main features of telehandlers?

Telehandlers can be equipped with a variety of attachments, such as forks, buckets, and jibs, which enhance their utility for different tasks. They also have a load capacity of up to 12,000 pounds and can achieve maximum lift heights exceeding 50 feet.

Why is understanding telehandlers important for project managers?

Understanding the operational mechanics of telehandlers is crucial for managers as it facilitates effective incorporation into projects, optimizes labor utilization, and boosts overall efficiency.

What is the projected growth rate of the telehandler market?

The telehandler market is projected to grow at a rate of 3.30% from 2026 to 2035, indicating its increasing relevance in the industry.

How can staying informed about telehandler advancements benefit projects?

By keeping abreast of the latest advancements and trends in telehandlers, you can maximize the benefits of telehandler rental services and ensure that your projects run smoothly.