Overview

Construction projects encounter substantial equipment-related challenges, including breakdowns, inadequate machinery, supply chain delays, operator errors, and adverse weather conditions. These obstacles can result in costly delays and inefficiencies, significantly impacting project timelines and budgets. To address these issues effectively, it is crucial to implement:

- Routine maintenance

- Appropriate tool selection

- Comprehensive training programs

- Contingency plans

Such proactive measures not only enhance project efficiency but also minimize downtime, ensuring smoother operations.

By prioritizing routine maintenance, construction teams can prevent unexpected equipment failures that lead to project delays. Proper tool selection is equally essential; utilizing the right machinery for specific tasks can improve productivity and reduce the risk of operator errors. Furthermore, comprehensive training programs empower operators with the knowledge and skills necessary to handle equipment safely and efficiently. These strategies collectively foster a more reliable construction environment, ultimately driving project success.

In addition, contingency planning plays a vital role in mitigating the impact of unforeseen challenges. By preparing for potential setbacks, teams can respond swiftly and effectively, maintaining momentum even in adverse conditions. The implementation of these strategies not only enhances the reliability of construction projects but also builds a culture of preparedness and resilience.

To achieve optimal results, it is imperative to adopt a holistic approach that encompasses all aspects of equipment management. By focusing on maintenance, tool selection, training, and contingency planning, construction teams can significantly improve efficiency and reduce downtime. Take action today to ensure your projects run smoothly and successfully.

Key Highlights:

- Equipment breakdowns can cause costly delays, with an average loss of $260,000 per hour due to machinery inactivity.

- Routine maintenance can reduce equipment failures by 70 to 75%, highlighting the importance of regular inspections.

- Using inadequate equipment leads to inefficiencies; investing in high-quality machinery is essential.

- Supply chain delays can stall projects, necessitating strong supplier communication and contingency plans.

- Operator errors due to inadequate training can lead to accidents; comprehensive training programmes are vital.

- Adverse weather conditions can disrupt operations, making flexible scheduling and weather contingency plans necessary.

- Implementing a routine upkeep plan, proper tool selection, and thorough operator training can significantly improve project efficiency.

- Establishing maintenance protocols and performance monitoring is crucial for the longevity and reliability of construction equipment.

Introduction

In the high-stakes world of construction, equipment-related obstacles can spell disaster for project timelines and budgets. Unexpected machinery breakdowns and operator errors present significant risks that demand proactive management. This article delves into effective strategies for identifying and overcoming these hurdles, equipping construction managers with essential tools to enhance efficiency and ensure project success.

How can one adeptly navigate the complexities of equipment management and transform potential setbacks into streamlined operations?

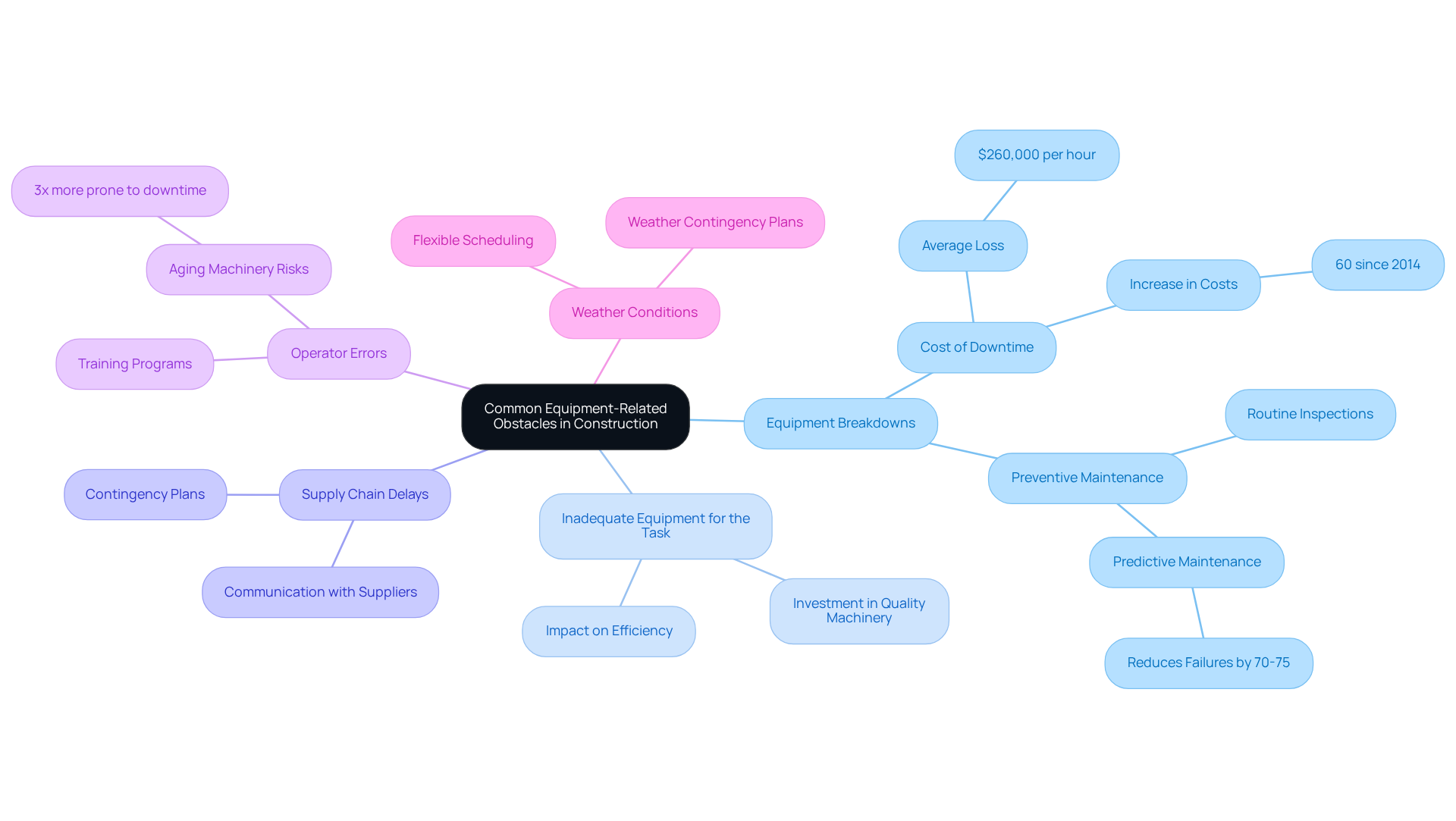

Identify Common Equipment-Related Obstacles in Construction

In construction projects, equipment-related obstacles can significantly disrupt timelines and inflate budgets. Here are some prevalent issues that demand attention:

-

Equipment Breakdowns: Mechanical failures can halt work, leading to costly delays. Sixty minutes of machinery inactivity can result in an average loss of $260,000 for companies, a number that has risen by 60% since 2014. This statistic highlights the significance of routine upkeep to lessen this risk. Establishing a predictive upkeep program can decrease failures by 70 to 75%, ensuring smoother operations. Inadequate maintenance practices are among the primary reasons for machinery failure, making regular inspections crucial.

-

Inadequate Equipment for the Task: Utilizing the wrong type or size of equipment can lead to inefficiencies and increased labor costs. Investing in high-quality machinery reduces failures and ensures parts are readily available for repairs. As Conplant advises, seeking out trusted manufacturers can further reduce the likelihood of frequent breakdowns, ultimately saving time and costs.

-

Supply Chain Delays: Delays in obtaining tools can stall project timelines. Establishing strong communication with suppliers and having contingency plans in place are essential strategies to manage these risks effectively.

-

Operator Errors: Inadequate training can result in improper handling of tools, leading to accidents or damage. Investing in comprehensive training programs for machinery operators is essential to avoid malfunctions and guarantee safety on construction sites. Significantly, aging machinery is nearly three times more prone to causing unplanned downtime than operator errors, emphasizing the necessity of keeping modern tools in good condition.

-

Weather Conditions: Adverse weather can affect equipment performance and safety, necessitating flexible scheduling and planning. Proactive strategies, such as incorporating weather contingency plans into timelines, can help sustain momentum during adverse weather.

By identifying equipment-related obstacles in construction projects early, managers can develop targeted strategies to address them effectively, ensuring success.

Implement Strategies to Mitigate Equipment Challenges

To effectively mitigate equipment-related challenges in construction, consider implementing the following strategies:

-

Routine Upkeep Plan: Establishing a regular servicing strategy for all machinery is crucial to avoid unforeseen failures. Daily checks and periodic servicing can significantly reduce unplanned downtime, which costs manufacturers an average of $260,000 per hour. A functional predictive maintenance program can lead to a reduction in breakdowns by 70 to 75%, ultimately enhancing overall efficiency.

-

Proper Tool Selection: A careful assessment of project requirements is vital to ensure the right tools are selected. Interacting with rental specialists can aid in identifying the best fit, thus enhancing productivity and minimizing expenses related to improper tool usage. For instance, loaders, which account for 38.2% of all machinery owned by construction firms, are often preferred for their versatility across various tasks.

-

Contingency Planning: Developing backup plans for resource availability and supply chain issues is essential. This may involve establishing relationships with alternative suppliers or rental options to guarantee that projects remain on schedule, even when unexpected challenges arise.

-

Training Programs: Investing in comprehensive training for operators minimizes errors and enhances safety. Regular refresher courses can keep skills sharp, significantly reducing the likelihood of operational errors, which account for 11% of unplanned downtime.

-

Weather Monitoring: Utilizing weather forecasting tools to plan work schedules around adverse conditions ensures safety and protects the integrity of tools. This proactive approach can prevent costly delays and damage to equipment.

Implementing these strategies can greatly reduce the impact of equipment-related obstacles in construction projects, leading to improved efficiency and overall project success.

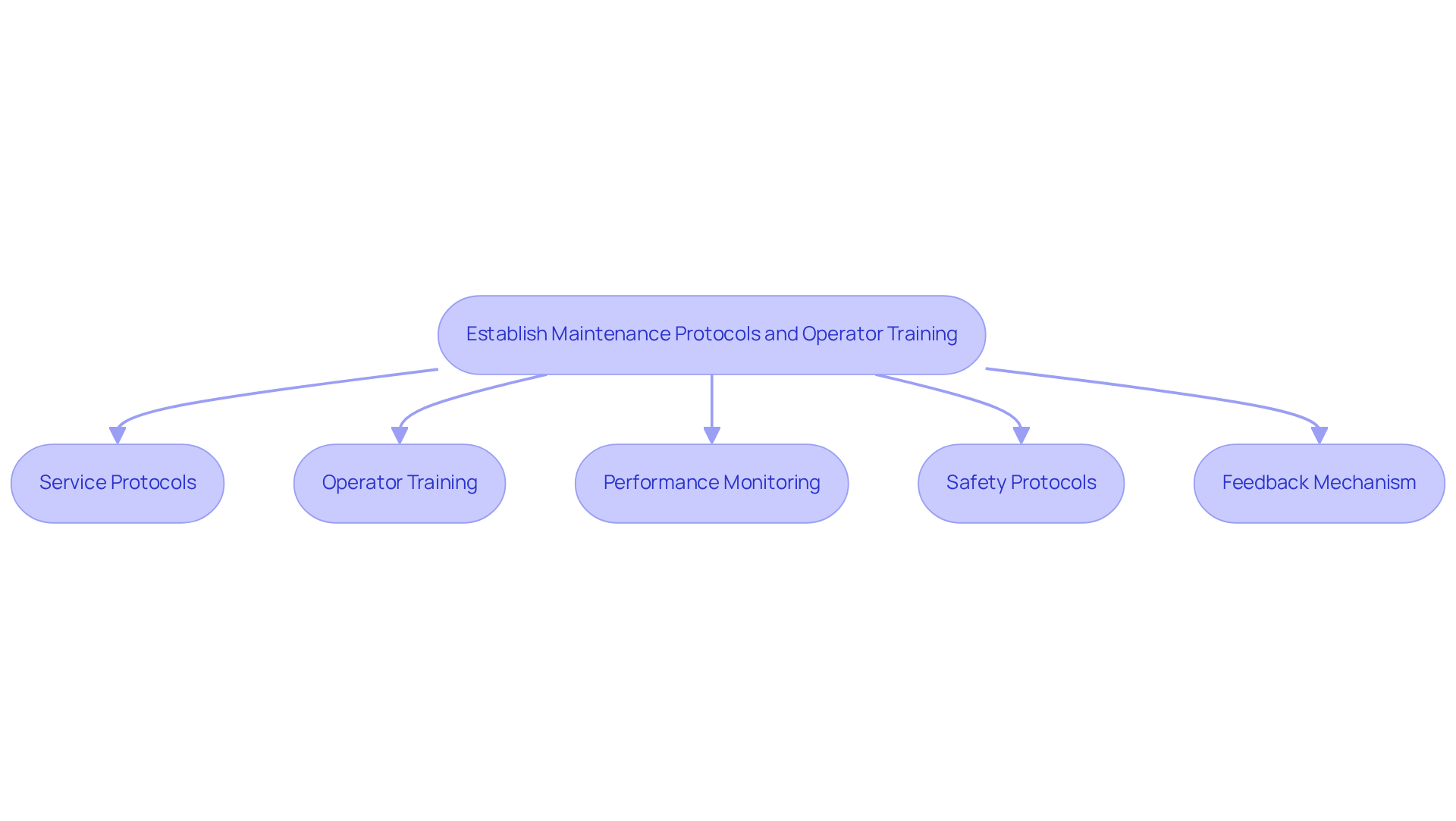

Establish Maintenance Protocols and Operator Training

To ensure the longevity and reliability of construction equipment, particularly forklifts rented from reputable companies like EZ Equipment Rental, it is essential to establish robust maintenance protocols and operator training programs.

Service Protocols: Create a comprehensive service checklist for every piece of equipment, encompassing daily inspections, lubrication schedules, and parts replacement timelines. EZ Equipment Rental offers routine upkeep services, including thorough inspections and prompt repairs, significantly lowering the chances of breakdowns during essential operations. It is crucial to record all upkeep activities for accountability.

Operator Training: Develop a structured training program for all machine operators, focusing on safe operation, troubleshooting, and emergency procedures. Incorporate hands-on training and simulations to enhance learning, ensuring operators are well-prepared for real-world scenarios.

Performance Monitoring: Establish a system for monitoring machinery performance and upkeep history. This data can help identify patterns and predict potential failures, allowing for proactive maintenance and minimizing unexpected downtime.

Safety Protocols: Establish clear safety guidelines for the use of devices, including personal protective equipment (PPE) requirements and emergency response procedures. Regular safety audits and operator refresher courses can further reinforce these protocols.

Feedback Mechanism: Encourage operators to provide feedback on equipment performance and any issues encountered. This input is invaluable for enhancing upkeep protocols and training programs, fostering a culture of continuous improvement.

By prioritizing maintenance and training, along with the comprehensive support provided by EZ Equipment Rental, construction managers can significantly reduce equipment-related obstacles in construction projects and enhance overall project efficiency.

Conclusion

Addressing equipment-related obstacles in construction projects is crucial for maintaining timelines and budgets. Recognizing common challenges—such as equipment breakdowns, inadequate tool selection, supply chain delays, operator errors, and adverse weather conditions—enables construction managers to craft effective strategies to mitigate these risks.

Implementing routine maintenance, ensuring proper tool selection, developing contingency plans, investing in operator training, and monitoring weather conditions are essential steps in overcoming these hurdles.

Proactive measures can significantly enhance project efficiency and reduce costly downtime. Regular maintenance programs lower the likelihood of equipment failures, while proper training for operators minimizes the risk of accidents and operational errors. Furthermore, establishing strong relationships with suppliers and having backup plans in place can effectively navigate supply chain disruptions.

Ultimately, prioritizing equipment management safeguards project timelines and contributes to the overall success of construction endeavors. Embracing these best practices and strategies leads to smoother operations, reduced costs, and a safer work environment, underscoring the importance of addressing equipment-related challenges in an industry where efficiency is paramount.

Frequently Asked Questions

What are the common equipment-related obstacles in construction?

Common obstacles include equipment breakdowns, inadequate equipment for the task, supply chain delays, operator errors, and adverse weather conditions.

How do equipment breakdowns impact construction projects?

Equipment breakdowns can halt work and lead to costly delays, with an average loss of $260,000 for companies for just 60 minutes of machinery inactivity. Routine upkeep and predictive maintenance programs can significantly reduce these risks.

What can be done to prevent equipment failures in construction?

Establishing a predictive upkeep program can decrease failures by 70 to 75%. Regular inspections and adequate maintenance practices are crucial to prevent machinery failures.

How does using inadequate equipment affect construction efficiency?

Utilizing the wrong type or size of equipment can lead to inefficiencies and increased labor costs. Investing in high-quality machinery and sourcing from trusted manufacturers can help mitigate these issues.

What are the consequences of supply chain delays in construction?

Delays in obtaining tools can stall project timelines. Strong communication with suppliers and having contingency plans are essential strategies to manage these risks.

Why is operator training important in construction?

Inadequate training can lead to improper handling of tools, resulting in accidents or damage. Comprehensive training programs for machinery operators are essential to ensure safety and avoid malfunctions.

How do weather conditions affect construction equipment?

Adverse weather can impact equipment performance and safety, necessitating flexible scheduling and planning. Incorporating weather contingency plans into project timelines can help maintain momentum during unfavorable conditions.

What is the significance of addressing equipment-related obstacles early in construction projects?

Identifying these obstacles early allows managers to develop targeted strategies to address them effectively, ensuring the success of the construction project.