Overview

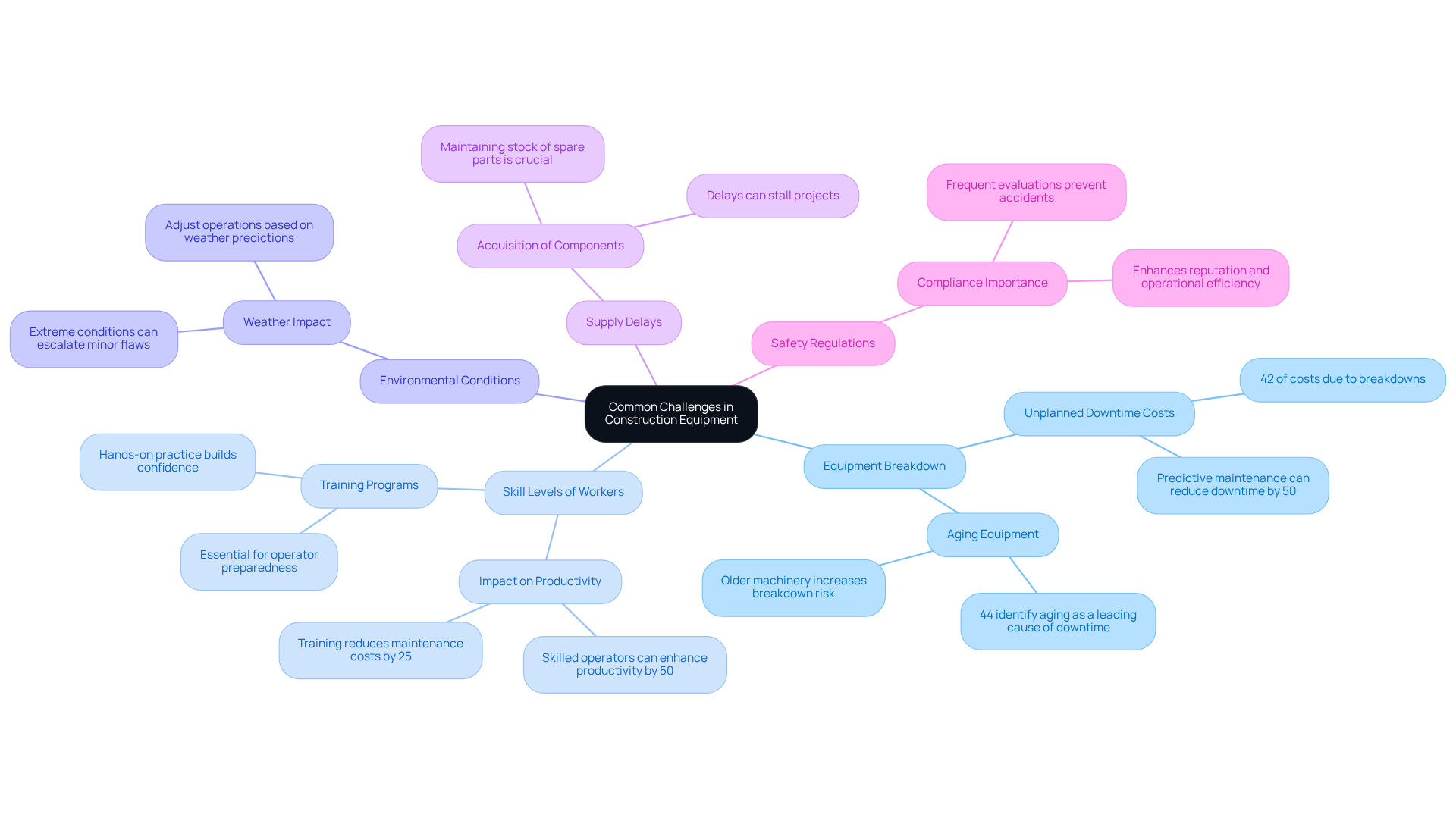

The article addresses the prevalent challenges associated with construction equipment. It highlights significant issues such as unexpected breakdowns, skilled labor shortages, environmental impacts, and supply chain delays. For example, it details specific problems like hydraulic failures in excavators and battery issues in forklifts. Emphasizing the importance of preventive maintenance strategies, training, and supplier relationships is crucial to mitigating these challenges and enhancing operational efficiency.

Moreover, implementing robust preventive maintenance can significantly reduce the frequency of unexpected breakdowns. By investing in training programs for skilled labor, companies can ensure that their workforce is equipped to handle equipment efficiently. Additionally, fostering strong supplier relationships can lead to quicker resolution of supply chain delays, ultimately supporting uninterrupted operations.

Furthermore, addressing environmental impacts is not just a regulatory requirement but also a commitment to sustainability. Companies that prioritize eco-friendly practices not only comply with regulations but also enhance their brand reputation. This dual benefit underscores the importance of integrating sustainable practices into operational strategies.

In conclusion, tackling these challenges head-on with a proactive approach is essential for improving operational efficiency in the construction industry. By focusing on preventive maintenance, skilled labor training, and strong supplier relationships, companies can navigate these issues effectively. Engage with us today to explore how our equipment rental services can support your operational needs and drive success.

Key Highlights:

- Unexpected equipment breakdowns account for 42% of unplanned downtime costs, which can be mitigated through predictive maintenance and renting well-maintained equipment.

- Skilled workers can enhance machinery productivity by up to 50%, while training programmes can reduce maintenance costs by 25% and improve safety.

- Environmental conditions can affect equipment performance; adapting operations based on weather predictions is essential to prevent breakdowns.

- Delays in acquiring components can stall projects; maintaining supplier relationships and stock of spare parts can alleviate this issue.

- Compliance with safety regulations through regular equipment evaluations can prevent accidents and enhance operational efficiency.

- Excavators often face hydraulic system failures; regular checks are essential for optimal functionality.

- Bulldozers experience undercarriage wear influenced by soil conditions; routine inspections and timely component replacements can mitigate maintenance costs.

- Forklifts require regular battery maintenance to avoid operational disruptions; proper management is crucial for efficiency.

- Generators are prone to fuel contamination; using clean fuel and regular inspections can prevent operational issues.

- Concrete mixers need thorough cleaning after each use to prevent clogging.

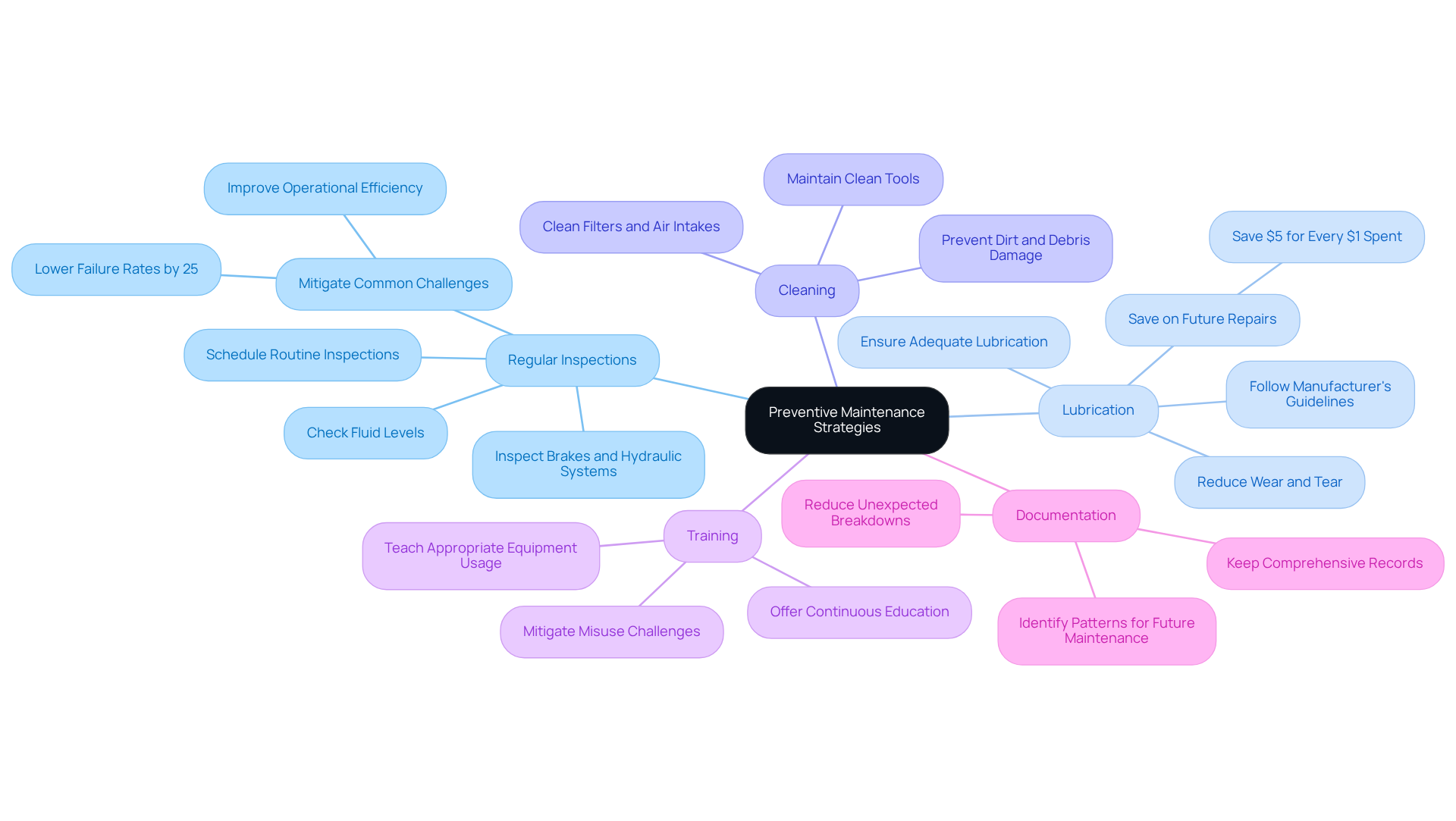

- Implementing preventive maintenance strategies, including regular inspections, lubrication, cleaning, training, and documentation, can significantly improve equipment reliability and reduce unexpected breakdowns.

Introduction

In the intricate realm of construction, project efficiency is fundamentally tied to the reliability of equipment. Common challenges—such as unexpected breakdowns, skill gaps among operators, and adverse environmental conditions—can disrupt even the most meticulously planned projects. This article explores these challenges in depth, providing valuable insights and practical solutions that not only enhance operational efficiency but also protect project timelines and budgets. With significant stakes involved, construction managers must effectively navigate these hurdles to ensure seamless project execution.

Identify Common Challenges in Construction Equipment

In the construction sector, the common challenges with construction equipment can significantly impact project timelines and budgets. Common challenges include:

-

Equipment Breakdown: Unexpected failures account for 42% of unplanned downtime costs, leading to costly delays. Renting from a reputable company like EZ Equipment Rental ensures access to well-maintained forklifts. Their equipment undergoes routine care, including thorough inspections and prompt repairs, thereby lowering the risk of failures during critical operations. Implementing a predictive maintenance program can help eliminate catastrophic breakdowns almost entirely, reducing unplanned machine downtime by 50%.

-

The skill levels of workers are one of the common challenges with construction equipment, as they directly influence construction efficiency. Skilled personnel can enhance machinery productivity by as much as 50%, while inexperienced individuals may struggle with intricate devices, increasing the likelihood of accidents and inefficiencies. Training programs are essential to ensure operators are well-prepared, as well-trained personnel can significantly reduce maintenance costs by 25% and enhance safety.

-

Environmental conditions, like weather, are among the common challenges with construction equipment, as they can affect device performance, particularly in extreme temperatures or wet conditions. Understanding how to adjust operations according to weather predictions is crucial for maintaining productivity and reducing strain on machinery, as severe conditions can escalate minor flaws into breakdowns.

-

Common challenges with construction equipment include delays in acquiring necessary components or tools, which can stall projects. Building dependable supplier connections and maintaining a stock of essential spare parts can alleviate this issue, ensuring operations proceed seamlessly.

-

Adhering to safety regulations addresses common challenges with construction equipment. Frequent evaluations and maintenance of machinery are essential for compliance, avoiding accidents and legal concerns. Organizations that prioritize safety compliance not only protect their workforce but also enhance their reputation and operational efficiency. Furthermore, the extensive assistance offered by EZ Equipment Rental, featuring round-the-clock support and swift response times, resolves any concerns promptly, further reducing downtime and ensuring that tools are always ready for use.

Examine Equipment-Specific Issues and Repairs

Different types of construction equipment present common challenges that require attention. Understanding these issues is essential for effective management and maintenance. Here’s a breakdown of common problems and their solutions:

Excavators face frequent hydraulic system failures. Regular checks for leaks and ensuring adequate fluid levels are crucial. When performance becomes sluggish, inspecting the hydraulic pump and hoses is necessary to maintain optimal functionality.

Bulldozers encounter significant undercarriage wear, which constitutes a considerable portion of maintenance costs. Research indicates that the lifespan of a bulldozer undercarriage is roughly 4,000 hours, with wear heavily influenced by soil conditions, particularly those with high quartz content or moisture levels. To mitigate these issues, implementing a routine inspection schedule is vital. Operators should monitor wear patterns and replace components like sprockets every 2,000 hours to avoid costly repairs. Additionally, regular cleaning and lubrication of pivot points can significantly extend undercarriage life, while proper track tension management prevents accelerated wear.

Forklifts are prone to battery issues that can disrupt operations. Ensuring batteries are charged, terminals are clean, and conducting regular maintenance checks can prevent unexpected failures. Key practices include checking hydraulic fluid levels, inspecting forks for damage, and ensuring that safety features are operational. Forklifts enhance construction efficiency and safety, making them indispensable for transporting materials and equipment on site. Their proper management is crucial for maintaining workflow and minimizing downtime.

Generators often suffer from fuel contamination, leading to operational issues. Always utilizing clean fuel and regularly inspecting fuel lines and filters can help prevent these complications.

Concrete Mixers can experience clogging if not cleaned properly. After each use, ensure that all components are thoroughly cleaned to prevent buildup.

By understanding the common challenges with construction equipment, construction managers can implement preventive measures, such as establishing a thorough upkeep program and maintaining detailed records, to ensure that their projects operate smoothly and efficiently.

Implement Preventive Maintenance Strategies

Implementing preventive maintenance strategies is crucial to ensure the longevity and reliability of construction machinery and to address common challenges with construction equipment.

Regular Inspections play a vital role in this process. Schedule routine inspections to identify potential issues before they escalate. This includes checking fluid levels, brakes, and hydraulic systems. Frequent inspections can mitigate common challenges with construction equipment by lowering failure rates of machinery by as much as 25%, greatly improving operational efficiency.

Lubrication is another key practice. Ensure all moving parts are adequately lubricated to reduce wear and tear. Proper lubrication not only minimizes friction but also extends the lifespan of machinery. Studies show that overcoming common challenges with construction equipment through preventive maintenance can save an average of five dollars in future repairs for each dollar spent. Following the manufacturer's guidelines for lubrication schedules is essential for optimal performance.

Cleaning is equally important. Maintain tools clean to prevent dirt and debris from causing damage. Frequently clean filters, air intakes, and other essential components to sustain the efficiency and reliability of the machinery.

Training personnel is also critical. Offer continuous education on appropriate equipment usage and care techniques. Well-trained operators can help mitigate common challenges with construction equipment caused by misuse, contributing to a safer and more efficient work environment.

Lastly, Documentation cannot be overlooked. Keep comprehensive records of upkeep activities, repairs, and inspections. This documentation can help identify patterns and inform future maintenance decisions, ensuring that all equipment remains in peak condition and reducing the likelihood of unexpected breakdowns.

Conclusion

Addressing the challenges associated with construction equipment is essential for maintaining project efficiency and minimizing costs. Recognizing the various obstacles—ranging from equipment breakdowns and skill gaps among operators to environmental impacts and supply chain delays—provides a roadmap for developing effective solutions. By focusing on preventive maintenance, proper training, and strong supplier relationships, construction managers can significantly enhance operational reliability and safety.

The article highlights critical strategies to mitigate these challenges, including:

- Regular inspections

- Effective lubrication

- Thorough cleaning of machinery

Furthermore, investing in training programs for personnel ensures that operators are equipped with the necessary skills to handle complex equipment, ultimately reducing the risk of accidents and costly downtime. The emphasis on documentation further supports proactive management, allowing for informed maintenance decisions that keep equipment in peak condition.

Ultimately, overcoming common challenges in construction equipment is not just about addressing immediate issues; it’s about fostering a culture of safety, efficiency, and preparedness. By implementing the outlined strategies, construction professionals can not only improve their operational outcomes but also contribute to a more sustainable and responsible industry. Taking action today will lead to a more resilient future in construction, where equipment challenges are met with confidence and expertise.

Frequently Asked Questions

What are the common challenges faced in construction equipment?

Common challenges include equipment breakdowns, skill levels of workers, environmental conditions, delays in acquiring necessary components or tools, and adherence to safety regulations.

How do equipment breakdowns impact construction projects?

Equipment breakdowns account for 42% of unplanned downtime costs, leading to costly delays. Implementing a predictive maintenance program can reduce unplanned machine downtime by 50%.

Why is the skill level of workers important in construction?

Skilled personnel can enhance machinery productivity by up to 50%, while inexperienced operators may struggle with complex devices, increasing the likelihood of accidents and inefficiencies. Training programs are essential to prepare operators effectively.

How do environmental conditions affect construction equipment?

Environmental conditions, such as extreme temperatures or wet conditions, can impact equipment performance. Adjusting operations according to weather predictions is crucial to maintain productivity and prevent minor flaws from escalating into breakdowns.

What can be done to address delays in acquiring construction equipment components?

Building dependable supplier connections and maintaining a stock of essential spare parts can alleviate delays, ensuring that operations proceed seamlessly.

How does adherence to safety regulations benefit construction operations?

Adhering to safety regulations through frequent evaluations and maintenance of machinery helps avoid accidents and legal issues, protects the workforce, and enhances the organization's reputation and operational efficiency.

What support does EZ Equipment Rental provide to address these challenges?

EZ Equipment Rental offers round-the-clock support and swift response times to resolve concerns promptly, reducing downtime and ensuring that tools are always ready for use.