Overview

The article focuses on the top seven 15-ton cranes that should be considered for construction projects, emphasizing their unique features and benefits. It provides insights into various types of cranes, such as mobile lifts and crawler cranes, and highlights how their specific characteristics—like load capacity, stability, and versatility—are crucial for enhancing efficiency and safety in diverse building environments.

Introduction

In the ever-evolving construction landscape, the demand for efficient lifting solutions has never been greater. As projects grow in complexity and scale, the role of 15-ton cranes becomes increasingly vital for ensuring timely and safe operations.

From mobile cranes that offer unparalleled flexibility to robust crawler cranes designed for challenging terrains, understanding the various types and their unique advantages can empower project managers to make informed decisions.

This article delves into the diverse range of 15-ton cranes available, key features to consider, top recommended models, and the myriad benefits they bring to construction projects.

By equipping teams with the right tools, organizations can enhance safety, improve efficiency, and ultimately drive project success in today's competitive environment.

Exploring the Range of 15-Ton Cranes Available

In the dynamic environment of the building sector, the use of a 15 ton crane is essential for effectively lifting and moving heavy materials. Every kind of hoist fulfills unique functions, enabling managers to enhance their operations, along with the essential role of forklifts. Notably, forklifts enhance construction efficiency and safety through features such as high load capacities, excellent maneuverability, and advanced safety mechanisms like stability systems and operator training programs, which complement lifting operations on-site.

The Asia-Pacific area is witnessing a surge in demand for sturdy crawler machines, driven by rapid urbanization and massive infrastructure projects. Here are the key types of 15-ton hoisting machines available:

- Mobile Lifts: Renowned for their versatility, mobile lifts can be easily relocated from one job site to another. Their adaptability makes them ideal for projects where flexibility is paramount, allowing for quick mobilization and efficient material handling, often working alongside forklifts to streamline operations.

- Crawler Lifts: These machines excel in stability and are engineered to navigate rough terrains, providing exceptional lifting capabilities. Crawler machines are especially beneficial for building areas with uneven terrain or substantial loads, ensuring safety and operational efficiency. Considering the present market trends, building firms are progressively depending on crawler lifts to satisfy the requirements of intricate tasks, frequently using forklifts for accurate material positioning.

- Tower Structures: Tower structures are essential in high-rise building projects, providing impressive height and reach. Their design allows them to raise significant loads vertically, making them vital for urban projects where space is constrained and vertical development is crucial. As reported, building firms are anticipated to dominate the tower lifting equipment market during the forecast period, emphasizing their significance in modern building, often necessitating forklifts for ground-level logistics.

- Truck-mounted Equipment: Merging mobility with power, truck-mounted equipment facilitates rapid setup and transportation to various job sites. This kind is especially advantageous for tasks needing quick reactions and the capability to span great distances without compromising lifting strength, often collaborating with forklifts for effective workflow.

Moreover, a recent case study on the equipment rental market highlights the importance of these types across residential, commercial, and industrial fields, offering insights into their uses and market trends. This case analysis demonstrates how the combination of lifting devices and forklifts can improve overall efficiency and security.

By comprehending the distinct characteristics and benefits of each type of 15 ton crane, along with the crucial function of forklifts in boosting security and efficiency, managers can make informed choices to choose the most suitable equipment for their specific building requirements. This strategic approach not only boosts productivity but also aligns with current market trends, as the lifting equipment market is projected to grow at a CAGR of 5.8% from 2024 to 2033.

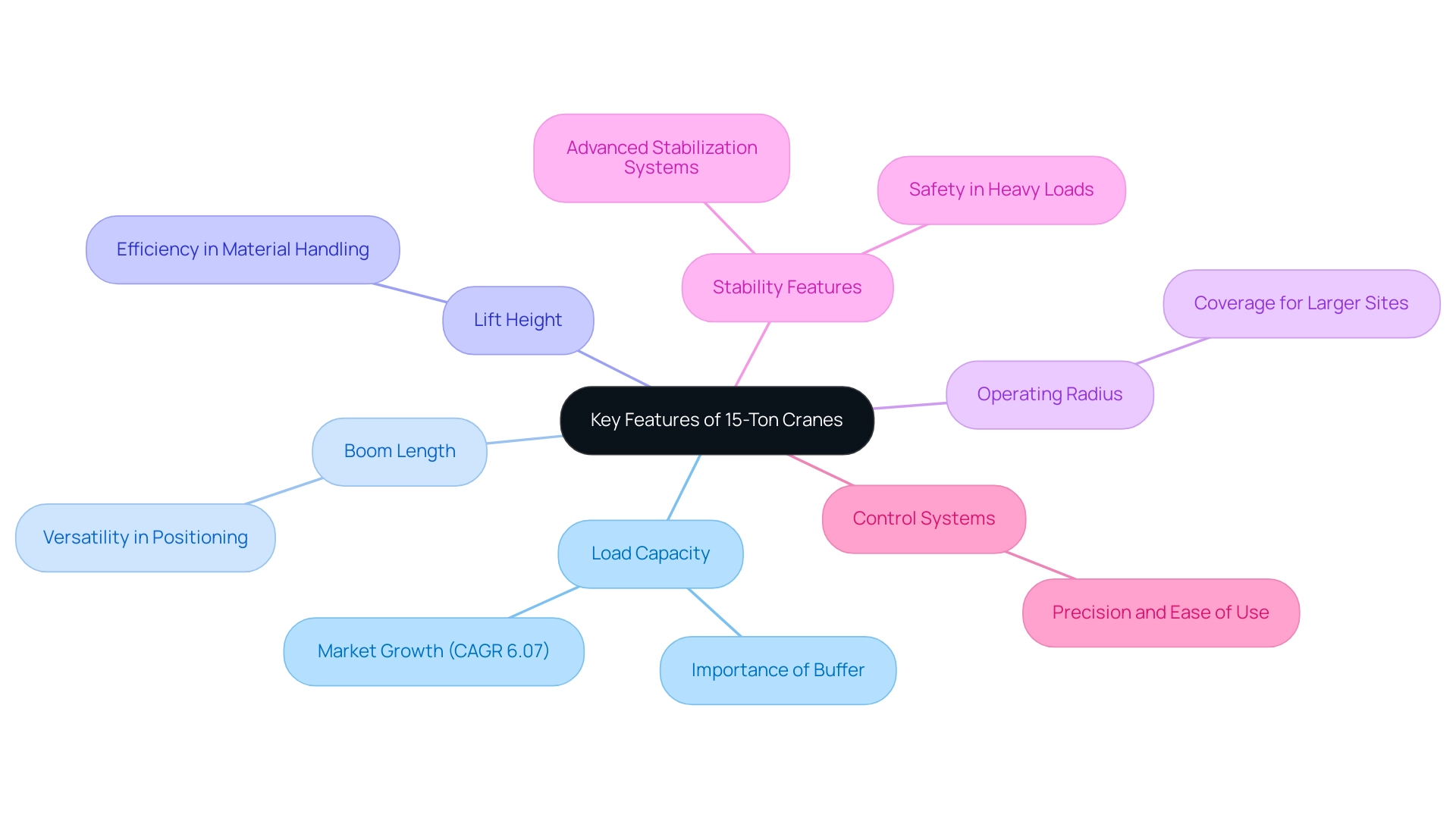

Key Features to Consider in 15-Ton Cranes

When choosing a 15-ton hoisting machine, it’s crucial to evaluate various important characteristics that can greatly influence the success of your construction endeavor:

- Load Capacity: Ensure that the equipment can support the maximum weight needed, including a buffer to account for unforeseen circumstances. According to industry reports, understanding load capacity is increasingly critical as the Tower Market is projected to grow at a CAGR of 6.07%, reaching nearly USD 9.41 Billion by 2030.

- Boom Length: The length of the structure's boom is crucial for reaching materials at various heights or across wider distances on the job site. A longer boom can improve versatility in positioning.

- Lift Height: Evaluate the machine’s maximum lift height to ensure it satisfies your specific needs, allowing for efficient material handling in elevated areas.

- Operating Radius: Understanding the equipment's operating radius is crucial in determining how much area it can cover effectively, which is particularly important for larger sites with multiple tasks.

- Stability Features: Choose machines equipped with advanced stabilization systems that enhance safety and reduce the risk of tipping during operation. Stability is paramount, especially when managing heavy loads.

- Control Systems: Modern lifting machines often feature sophisticated control systems that enhance precision and ease of use, allowing operators to maneuver loads with greater accuracy.

Incorporating insights from experts, such as the importance of stability and control systems, can elevate your selection process. Furthermore, examining case studies, such as those showcasing the effect of load capacity in various building endeavors, can offer valuable real-world implications. These characteristics are essential to guaranteeing that the machine functions efficiently and securely in various building situations, ultimately enhancing operational effectiveness and safety.

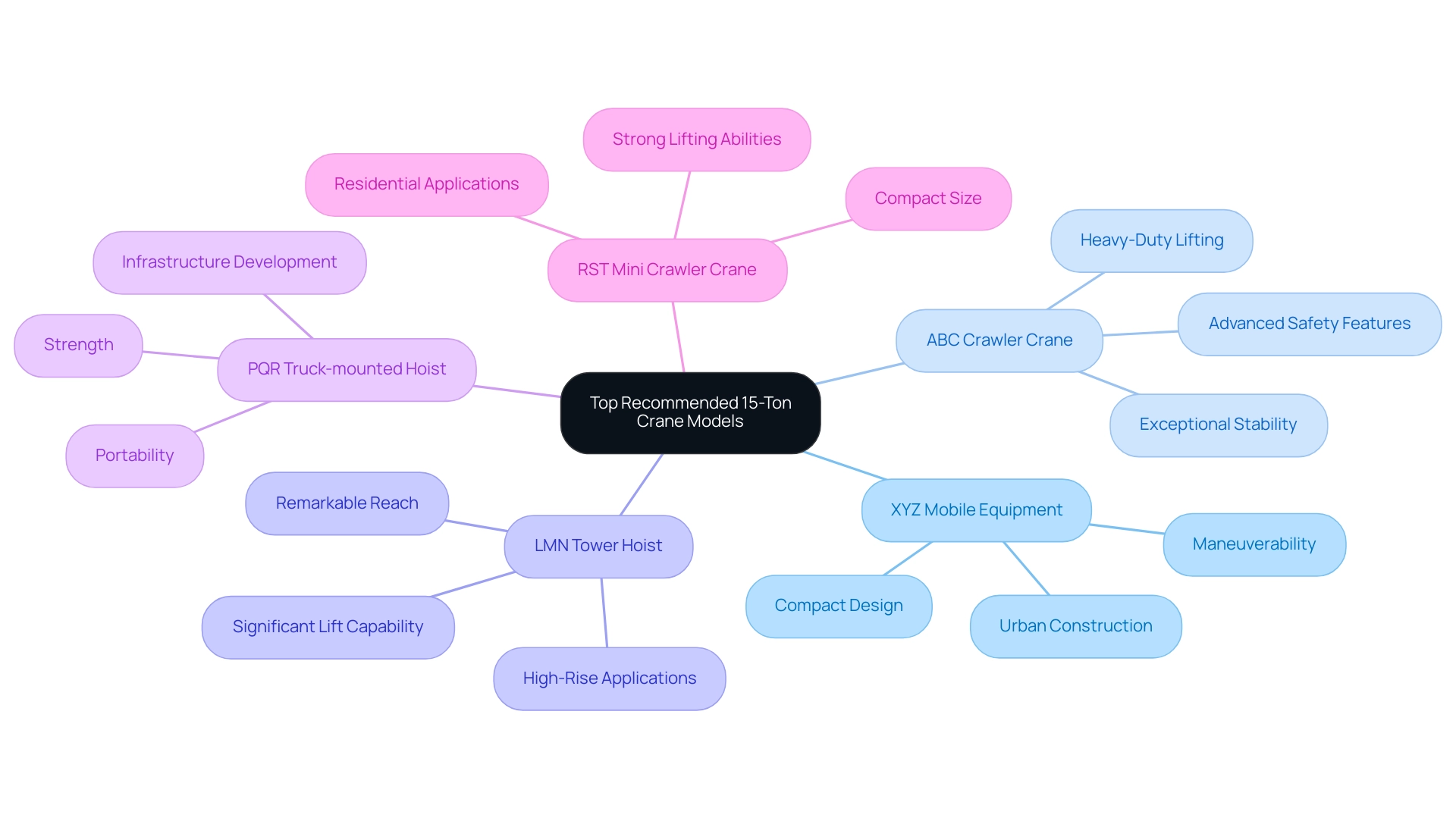

Top Recommended 15-Ton Crane Models

When it comes to choosing the appropriate 15-ton hoist for your building endeavor, the following models excel in their performance and versatility:

- XYZ Mobile Equipment: Renowned for its compact design and excellent maneuverability, this mobile equipment is particularly suited for the demands of urban construction sites. Its ability to navigate tight spaces and perform efficiently under various conditions makes it a top choice for project managers. According to Cognitive Market Research, on-road lifting machines like the XYZ are increasingly popular due to their versatility in urban environments.

- ABC Crawler Crane: This model is celebrated for its exceptional stability and advanced safety features, ensuring reliable performance during heavy-duty lifting operations. Its robust design allows it to handle challenging terrains, making it a dependable option for demanding job sites. This machine is particularly effective in industrial and marine applications, where stability is paramount.

- LMN Tower Hoist: With a significant lift capability and remarkable reach, this tower hoist is perfect for high-rise endeavors and intricate building tasks. Its advanced engineering allows for efficient material handling at great heights, which is essential in today’s rapidly urbanizing environments. The LMN Tower Crane is frequently used in logistics and construction sectors, highlighting its versatility.

- PQR Truck-mounted Hoist: Merging portability with strength, this equipment is versatile for multiple uses, including infrastructure development and commercial endeavors. Its mobility allows for quick repositioning, enhancing productivity on the job site. This machine is particularly valuable in the mining sector, where mobility and adaptability are critical.

- RST Mini Crawler Crane: This compact option excels in confined spaces, making it ideal for residential tasks where space is at a premium. Despite its smaller dimensions, it provides strong lifting abilities, guaranteeing that no task is too minor to gain from advanced machinery technology. The application of mini hoists is becoming more pertinent in urban building initiatives, as emphasized in the Crane Rail Global Market Report 2025, which offers insights into market trends and predictions.

Selecting one of these suggested models can not only boost efficiency but also greatly enhance safety, which is crucial in the building sector, especially when operating a 15 ton crane. As the rental market for lifting equipment continues to grow—projected to reach USD 21.12 million in 2024—it’s vital to align your equipment choices with the latest trends and capabilities across various sectors.

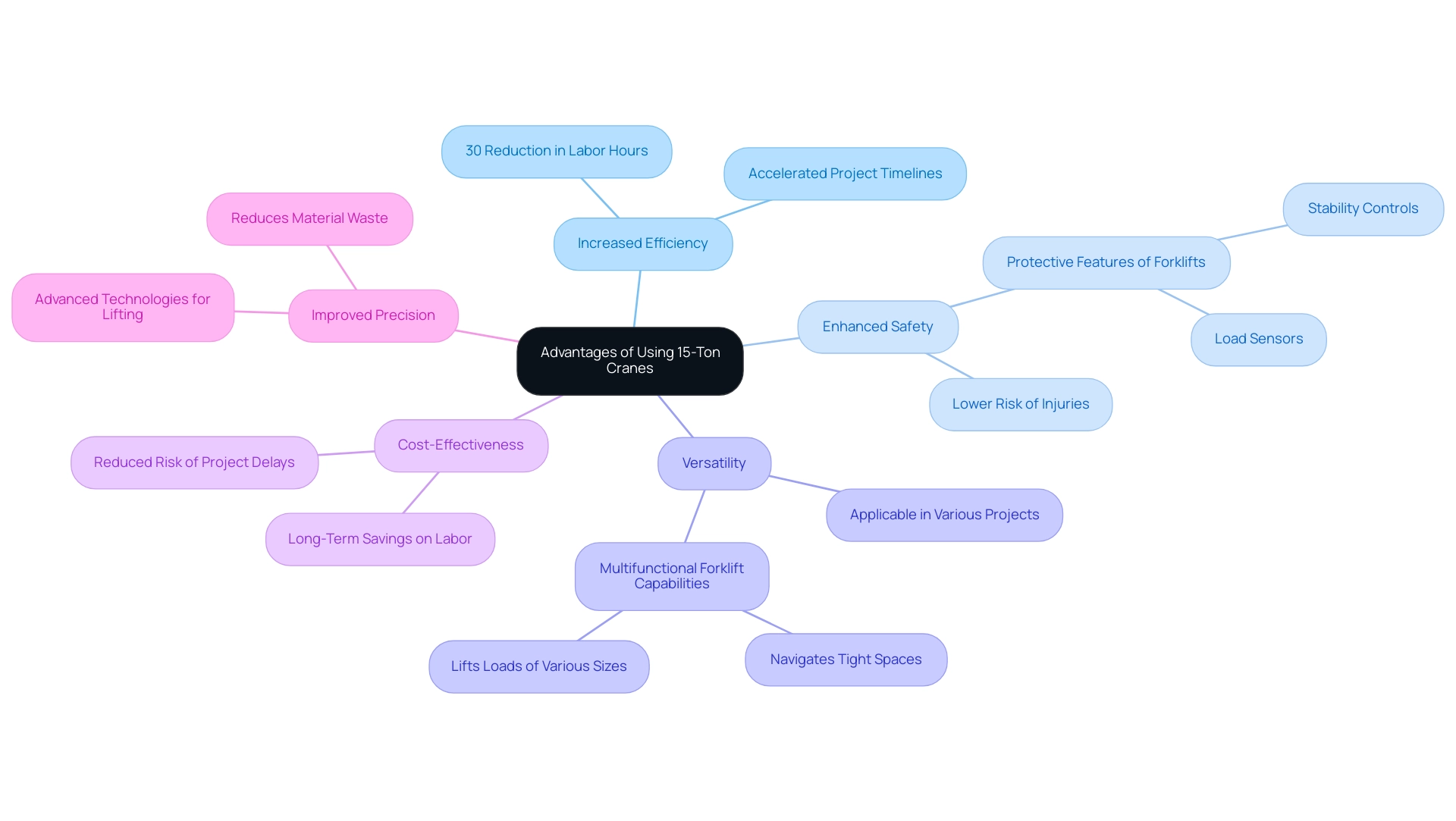

Advantages of Using 15-Ton Cranes in Projects

Employing 15-ton cranes in construction projects presents numerous advantages that can significantly enhance operational performance:

- Increased Efficiency: Capable of swiftly lifting heavy materials, 15-ton cranes drastically reduce reliance on manual labor, effectively accelerating project timelines. Research indicates that employing lifting equipment can lead to a reduction in labor hours by as much as 30%, allowing teams to focus on other critical tasks. Forklifts, with their high lifting capacity and maneuverability, play a pivotal role in this efficiency as well, further streamlining operations on building sites. With 60% of construction executives anticipating industry growth in 2023, investing in lifting equipment and forklifts is timely and strategic.

- Enhanced Safety: When operated correctly, the use of a 15 ton crane and forklifts substantially lowers the risk of injuries associated with manual lifting. Forklifts are equipped with protective features such as stability controls and load sensors, which enhance operational security. The construction sector presently encounters a labor deficit, with 88% of contractors having difficulty locating skilled workers, making enhancements crucial for safeguarding current team members. As mentioned by Akash Anand, Head of Business Development & Strategy, "Investing in advanced equipment such as a 15 ton crane is crucial for tackling concerns and enhancing overall efficiency of the work."

- Versatility: These machines can be utilized across a broad spectrum of applications, from residential constructions to large-scale commercial endeavors, thus making them an essential addition to any fleet. Their adaptability, alongside the multifunctional capabilities of forklifts—such as their ability to navigate tight spaces and lift loads of various sizes—ensures they can meet diverse lifting needs efficiently.

- Cost-Effectiveness: By promoting efficiency and enhancing safety, investing in a 15 ton crane translates to long-term savings on labor expenses and reduces the risk of project delays. With industry leaders expecting growth in 2023, utilizing economical solutions, including hoists and forklifts, becomes progressively vital.

- Improved Precision: Modern 15 ton cranes are equipped with advanced technologies that facilitate precise lifting and placement of materials. This accuracy not only improves quality but also reduces material waste, aligning with current trends highlighting sustainability and efficiency in building.

These persuasive benefits place the 15 ton crane as a vital instrument for industry professionals seeking to enhance their operations amid the challenges confronting the field, especially the notable labor shortage that has resulted in higher costs and delays. Testimonials from industry specialists further highlight that the integration of hoists and forklifts is essential for maximizing efficiency and safety on building sites.

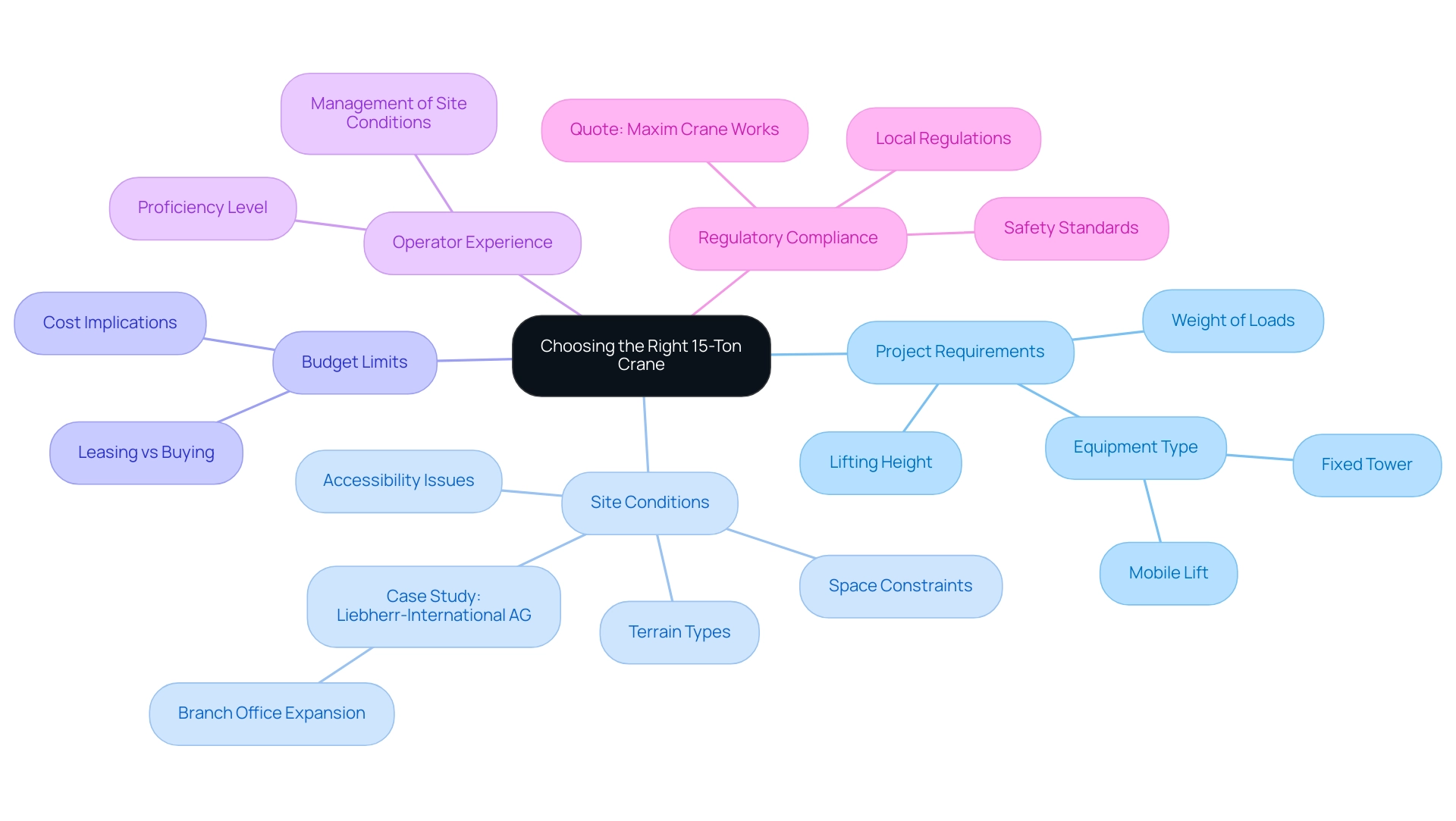

Choosing the Right 15-Ton Crane for Your Project

Selecting the right 15-ton crane for your construction project requires a thorough evaluation of several critical factors:

- Project Requirements: Begin by assessing the specific lifting needs of your project, including the weight of the loads and the required lifting height. This aids in assessing whether a mobile lift or another type is more suitable, as mobile lifts are often favored for their portability compared to fixed tower structures. For instance, the A1 Brand-L. 4.2 is identified as a highly appropriate alternative to meet various project requirements.

- Site Conditions: Examine the job site meticulously for any space constraints, terrain types, and accessibility issues that may impact equipment operation. For example, uneven terrain or restricted maneuvering space can significantly affect the selection of equipment. The recent expansion of Liebherr-International Ag's branch office illustrates how site conditions can dictate equipment selection, as they adjusted their offerings based on geographical needs and site specifications.

- Budget Limits: Set a clear budget for either leasing or buying the equipment, ensuring it aligns with your overall financial strategy. Understanding cost implications can help you avoid overspending while still meeting project demands.

- Operator Experience: The proficiency of the hoist operator is crucial, as it directly influences the security and effectiveness of lifting operations. Experienced operators are better prepared to manage intricate site conditions and utilize the machine's capabilities effectively.

- Regulatory Compliance: It is essential to ensure that the chosen equipment adheres to all local regulations and standards for security. This not only ensures legal compliance but also improves the security of your endeavor. As Maxim Crane Works states, "Our content is intended for general informational purposes only and does not constitute advice or necessarily reflect the range of services Maxim Crane Works, LP provides," highlighting the importance of tailored advice in equipment selection.

By carefully weighing these factors, project managers can make informed decisions that lead to the successful selection of the most appropriate 15 ton crane, thereby enhancing project efficiency and safety.

Conclusion

The diverse range of 15-ton cranes available today provides essential lifting solutions tailored to meet the complexities of modern construction projects. Understanding the unique capabilities of mobile, crawler, tower, and truck-mounted cranes allows project managers to optimize operations effectively. These cranes, when used alongside forklifts, enhance efficiency, safety, and versatility on job sites, addressing the increasing demands of urbanization and infrastructure development.

Key features such as load capacity, boom length, lift height, and stability systems must be carefully considered to ensure the selected crane aligns with specific project requirements. By choosing the right model—whether it be a mobile crane for urban flexibility or a robust crawler crane for challenging terrains—teams can significantly boost productivity and minimize risks associated with heavy lifting.

Ultimately, investing in 15-ton cranes not only streamlines operations but also contributes to long-term cost savings and improved safety outcomes. As the construction industry continues to evolve, leveraging the advantages of these cranes becomes vital for staying competitive and meeting project deadlines. By making informed decisions, project managers can ensure their teams are equipped with the right tools to navigate the challenges of today’s construction landscape, paving the way for successful project execution.

Frequently Asked Questions

Why is a 15-ton crane essential in the building sector?

A 15-ton crane is essential for effectively lifting and moving heavy materials, enhancing operational efficiency and safety on construction sites.

What are the key types of 15-ton hoisting machines available?

The key types of 15-ton hoisting machines include Mobile Lifts, Crawler Lifts, Tower Structures, and Truck-mounted Equipment, each serving unique functions in construction.

What are the advantages of Mobile Lifts?

Mobile Lifts are versatile and can be easily relocated between job sites, making them ideal for projects where flexibility and efficient material handling are important.

What makes Crawler Lifts suitable for construction?

Crawler Lifts excel in stability and can navigate rough terrains, providing exceptional lifting capabilities, especially in areas with uneven terrain or substantial loads.

Why are Tower Structures important in high-rise building projects?

Tower Structures provide impressive height and reach, allowing for the vertical lifting of significant loads, which is crucial for urban projects with space constraints.

What benefits do Truck-mounted Equipment offer?

Truck-mounted Equipment combines mobility with power, facilitating rapid setup and transportation to various job sites, which is advantageous for tasks requiring quick responses.

How do forklifts complement hoisting machines in construction?

Forklifts enhance construction efficiency and safety by providing high load capacities, excellent maneuverability, and advanced safety mechanisms, working alongside hoisting machines for effective operations.

What characteristics should be evaluated when choosing a 15-ton hoisting machine?

Key characteristics include load capacity, boom length, lift height, operating radius, stability features, and control systems, all of which influence the success of a construction project.

Why is understanding load capacity critical in selecting a hoisting machine?

Understanding load capacity is critical to ensure the equipment can support the maximum weight needed, including a buffer for unforeseen circumstances, which is increasingly important in the growing lifting equipment market.

How does the market for lifting equipment project to grow in the coming years?

The lifting equipment market is projected to grow at a CAGR of 5.8% from 2024 to 2033, highlighting the increasing demand for efficient and safe hoisting solutions in construction.