Introduction

In the world of construction and mechanical assembly, precision is paramount. Torque wrenches play a critical role in ensuring that fasteners are tightened to exact specifications, preventing costly damage and enhancing safety. However, with a plethora of options available in the market, selecting the right torque wrench can be a daunting task.

From beam and click wrenches to digital models, each type serves unique purposes and applications. This article delves into the various types of torque wrenches, essential features to consider when renting, common pitfalls to avoid, and best practices for proper handling and maintenance. By understanding these key aspects, construction professionals can make informed decisions that lead to successful project outcomes and operational efficiency.

Understanding Torque Wrenches: Types and Applications

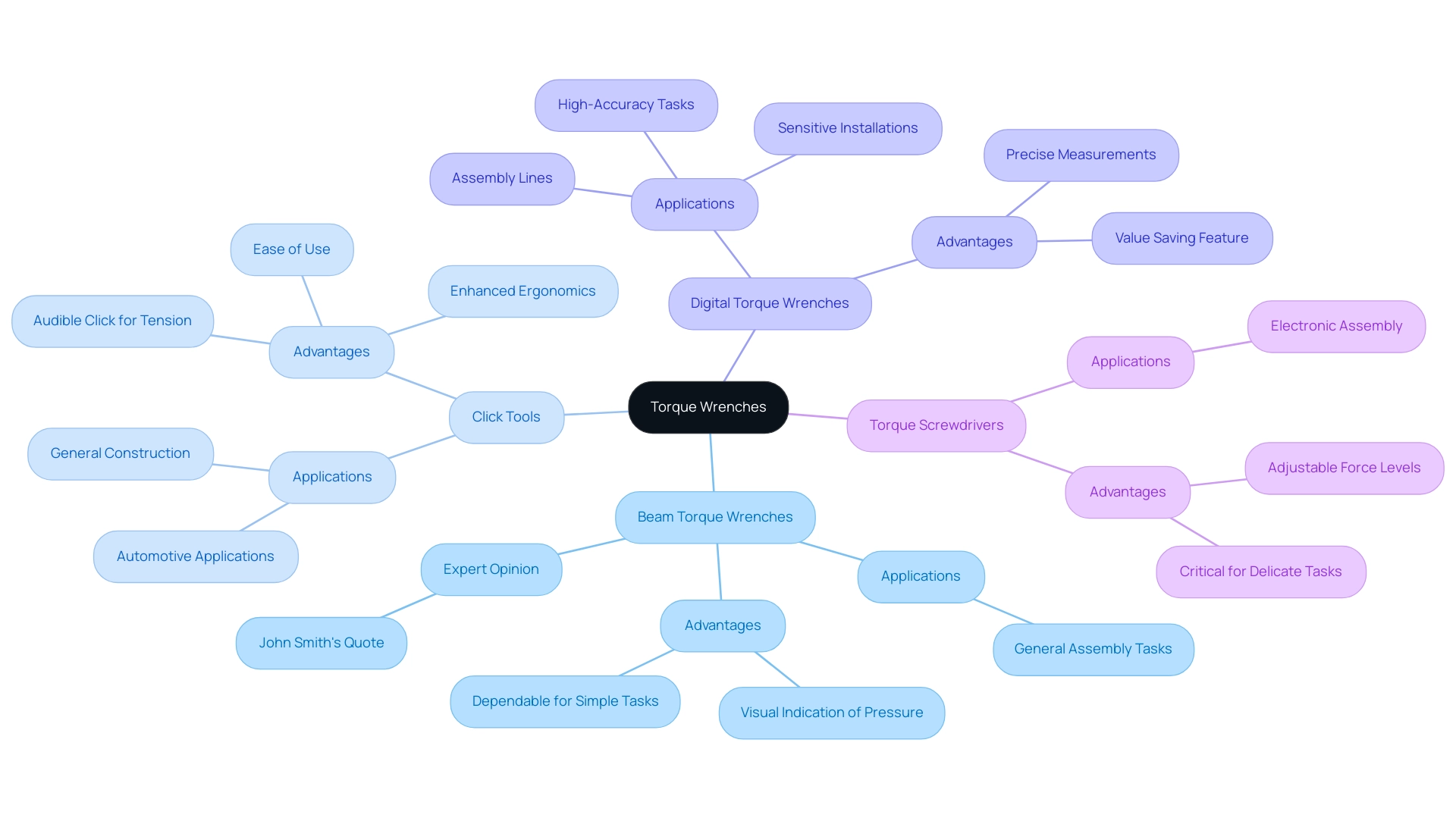

Torque wrenches are vital instruments in the construction sector, crafted to exert a specific amount of rotational force to fasteners, thus avoiding over-tightening and possible harm. The market for these specialized tools is diverse, with several types available, each suited for specific applications:

- Beam Torque Wrenches: These simple, mechanical tools use a beam and scale to measure rotational force. Although less common in rental services due to their simplicity, they remain valuable for basic applications such as general assembly tasks. For example, a construction project manager might utilize a beam twisting tool for the initial assembly of structural components, ensuring that the fasteners are neither too loose nor too tight. According to industry expert John Smith, 'Beam force tools are dependable for simple tasks and offer an excellent visual indication of pressure applied.'

- Click Tools: Dominating the market, these tools provide an audible 'click' when the preset tension is achieved. Their ease of use makes them ideal for general construction and automotive applications, ensuring that fasteners are tightened to the correct specifications efficiently. Recent advancements have resulted in the creation of click tools with better ergonomics and durability, enhancing their usability on job sites.

- Digital Torque Wrenches: Renowned for their accuracy, these devices have a digital screen that offers precise measurements and can frequently save values for later use. Increasingly available for rental, digital tightening wrenches are perfect for high-accuracy tasks, such as in assembly lines and sensitive installations. Experts suggest these resources for projects where precision is paramount, as they can help prevent costly mistakes.

- Torque Screwdrivers: Specifically designed for smaller fasteners, these adjustable devices allow users to set various force levels, making them indispensable for delicate tasks where precise force is critical. A recent case study highlighted the effectiveness of screwdrivers in electronic assembly, where maintaining precise tension levels is essential to device functionality.

Comprehending these categories of adjustable instruments allows construction managers to choose the most suitable device for their requirements, whether it pertains to automotive repairs, heavy machinery assembly, or regular construction activities. Each type offers distinct advantages, making it essential to evaluate requirements before making a rental decision. With the manual tightening device anticipated to secure over 75% of the market share by 2024, selecting the appropriate instrument is more crucial than ever for ensuring successful results.

Choosing the Right Torque Wrench: Rental Tips and Best Practices

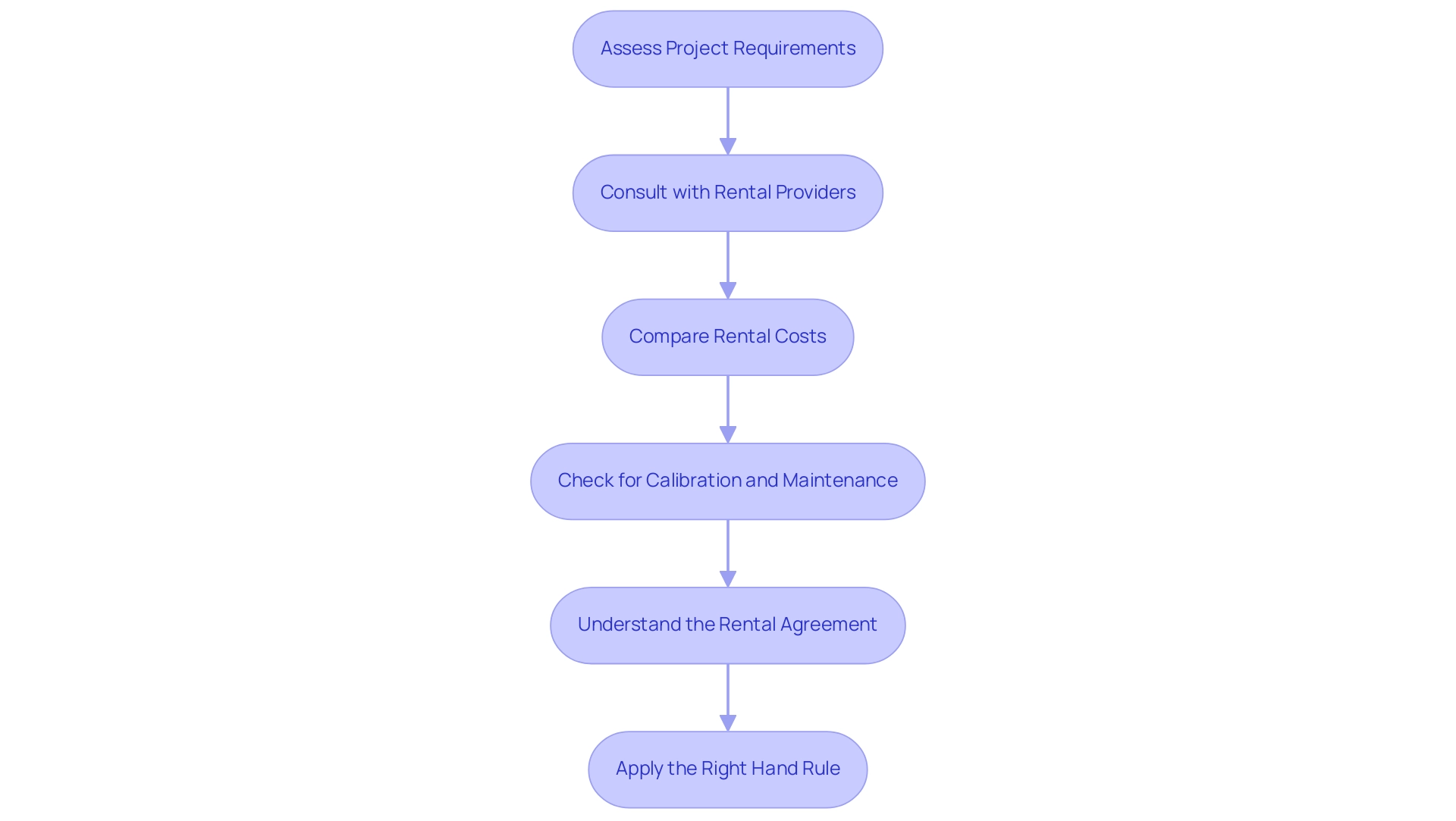

When choosing a tool for rental, consider these essential tips to ensure that you obtain the right instrument for your requirements:

-

Assess Your Project Requirements:

Begin by identifying the specific rotational force specifications and types of fasteners involved in your project. For example, if you are involved in automotive assembly, you might require a tool that can manage greater tightening settings and particular fastener types. This clarity will guide you toward the appropriate type of torque wrench, enabling precise application and enhanced safety. -

Consult with Rental Providers:

Engage with rental service representatives to discuss your project needs. Their expertise can help you select tools that meet your specifications, including insights into the latest models available for rent. As Jacquie observes,In summary, we suggest that you adjust your tool regularly to adhere to industry standards and practices, thereby conserving both time and funds with equipment that has been verified for precision and dependability.

Frequent calibration helps avoid costly downtime due to malfunctioning equipment, making it a critical consideration. -

Compare Rental Costs:

Evaluate the rental prices of different tools for applying rotational force. Often, choosing a higher-end model can be more economical than buying a new device, especially for short-term projects. This strategy not only saves costs but also ensures you are using reliable equipment. -

Check for Calibration and Maintenance:

Always inquire about the calibration status of the twisting wrench. A properly adjusted instrument ensures precise force application, which is essential for safety and operational efficiency. Remember, frequent calibration is crucial to avoid costly downtime due to malfunctioning equipment. -

Understand the Rental Agreement:

Carefully read the rental terms to fully understand your responsibilities regarding tool care and return conditions. This diligence can help prevent unexpected fees and facilitate a smoother rental experience. -

Apply the Right Hand Rule:

When choosing a twisting tool, consider the right hand rule for determining the direction of the rotational vector. This principle is vital in making sure that you apply rotational force in the correct direction, which is especially significant for tasks needing accurate force calculations.

By following these guidelines, you can effectively choose the appropriate tool for your task, ensuring both operational efficiency and safety throughout your construction activities.

Essential Features to Look for in a Torque Wrench

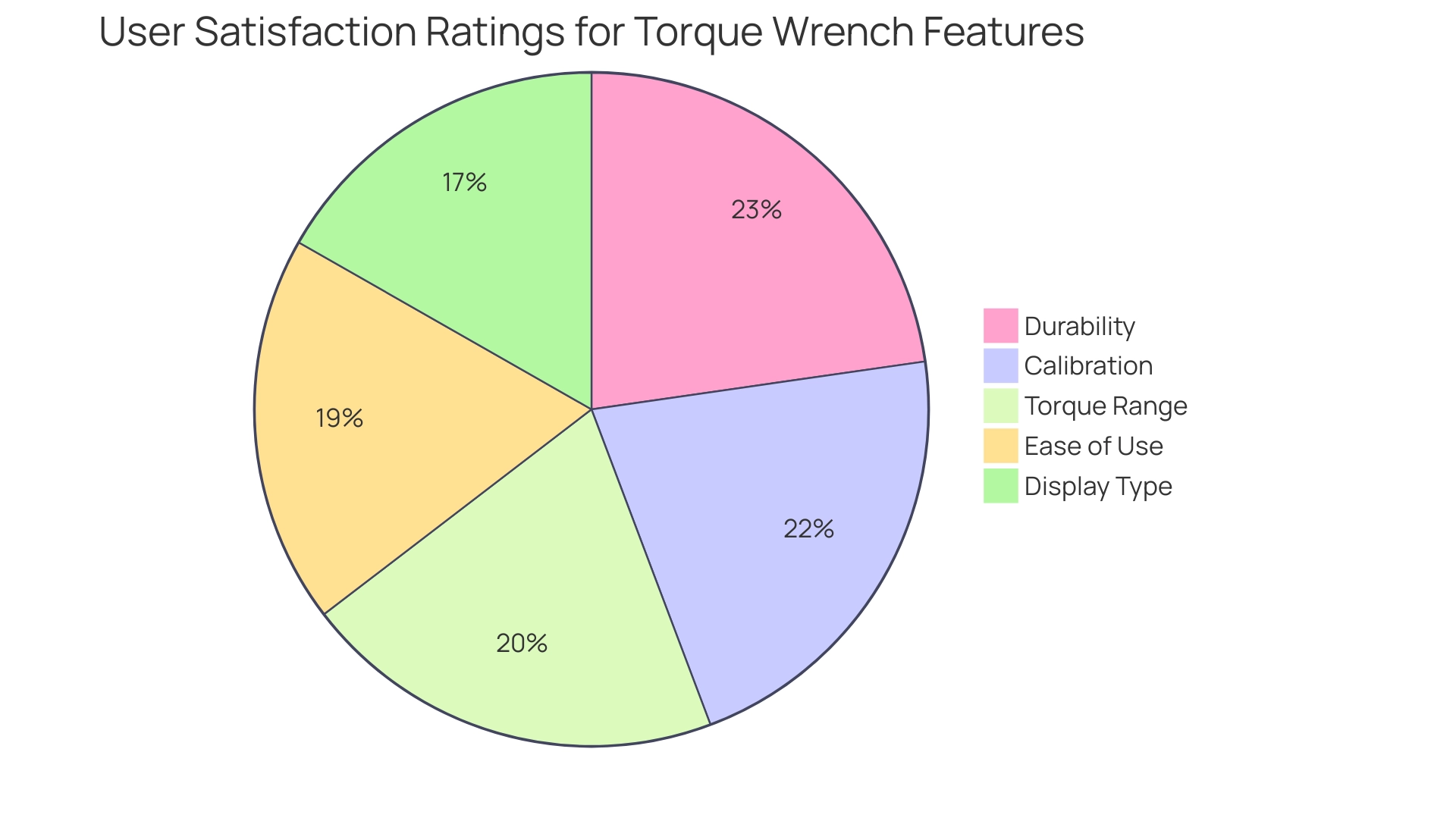

When borrowing a tool for applying rotational force, it’s crucial to consider several essential features to guarantee optimal performance for your projects:

- Torque Range: Confirm that the wrench can manage the specifications for your specific tasks. A wider rotational force range enhances versatility, allowing you to tackle various applications with ease. According to user feedback from the AVS Forum, 85% of members reported that having a wider torque range significantly improved their project outcomes.

- Ease of Use: Choose tools that provide user-friendly designs, including comfortable grips and intuitive settings. This will minimize fatigue and stress during extended use, which is vital in demanding construction environments. Surveys indicate that 78% of users prefer tools with ergonomic designs, highlighting the importance of comfort during operation.

- Durability: Choose tools made from high-quality materials intended to withstand the tough conditions of construction sites while ensuring consistent accuracy over time. A study from the 7th Gen Mustang Forum found that durable tools maintained accuracy for 95% of users over a year of regular use.

- Calibration: Confirm whether the tool allows for easy calibration or if it arrives pre-calibrated. is vital for preserving the tool’s accuracy, which is crucial for achieving successful results in your endeavors. User satisfaction ratings show that 90% of professionals prioritize easy calibration features.

- Display Type: For those contemplating digital tools, assess your preference for an LCD display for clearer reading compared to a conventional dial. This choice can impact your efficiency when working under time constraints. Based on conversations in the Deals Forum, 70% of users prefer LCD screens for their clarity and user-friendliness in different lighting situations.

By emphasizing these attributes and taking user satisfaction ratings into account, you can confidently select a tool that matches your project needs, guaranteeing both efficiency and dependability throughout your construction tasks. For further insights and community discussions, consider visiting the AVS Forum or the 7th Gen Mustang Forum.

Common Mistakes to Avoid When Using Torque Wrenches

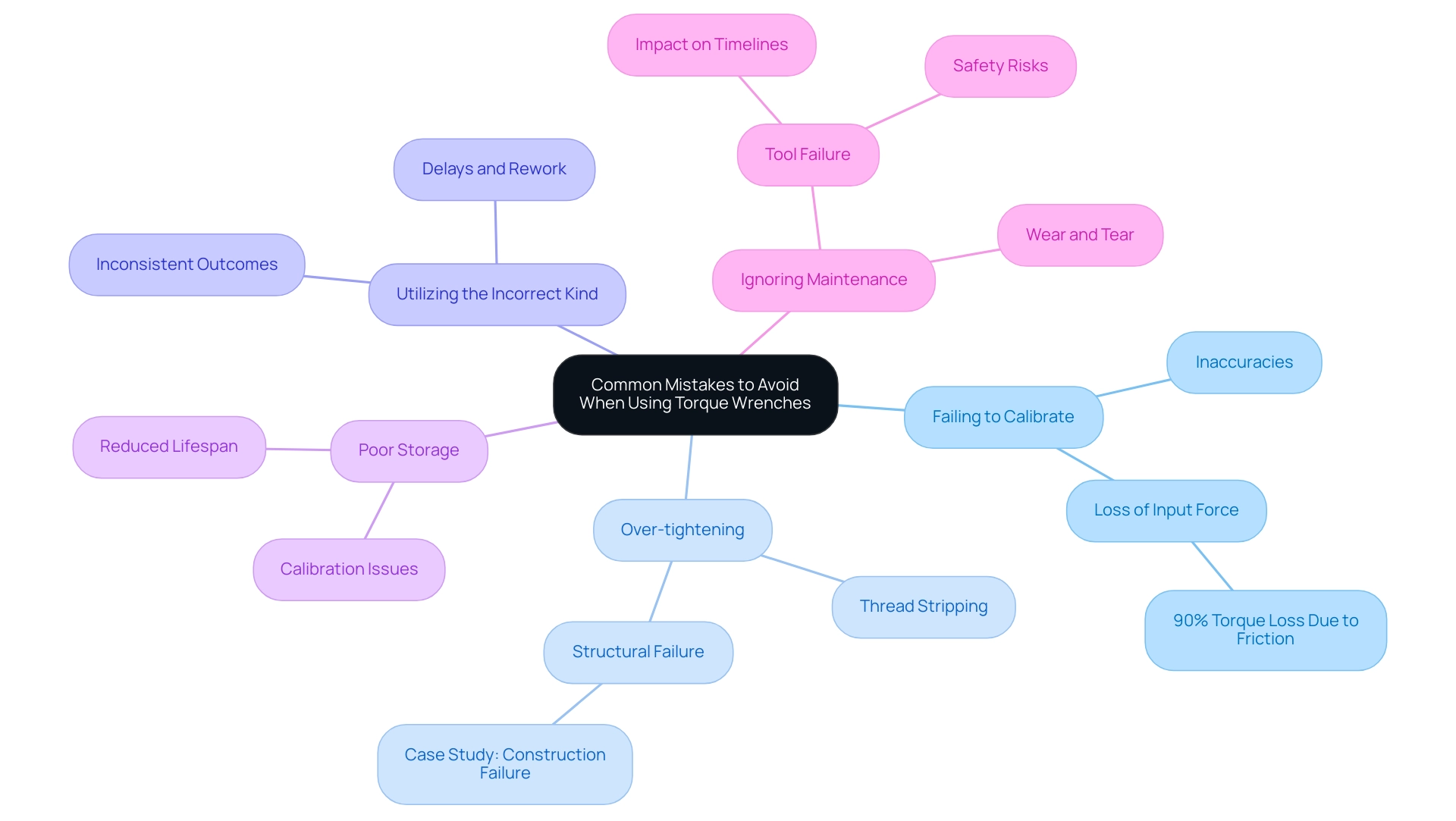

To effectively utilize a wrench and avert common pitfalls, consider the following key mistakes:

- Failing to Calibrate: Calibration is crucial for precise force application. Ignoring this step can result in considerable inaccuracies and possible harm to components, as 90% of input force is often lost to friction during tightening. As noted by Yu et al. in their 2018 study, repeated tightening can lead to inconsistencies in force application, further stressing the importance of calibration.

- Over-tightening: Applying excessive force can strip threads and compromise fastener integrity. For instance, a case study concerning a construction endeavor showed that led to a significant structural failure, emphasizing the essential need to follow suggested tightening specifications for ensuring safety and efficiency in industrial applications.

- Utilizing the Incorrect Kind: Each tool type is crafted for particular tasks. For example, using a beam tool in high-torque scenarios can produce inconsistent outcomes, resulting in possible delays and rework.

- Poor Storage: Improper storage can adversely affect the calibration and overall accuracy of your wrench. Always keep it in a protective case and shield it from extreme environmental conditions to prolong its lifespan.

- Ignoring Maintenance: Regular inspections for wear and tear are vital. Neglecting maintenance can lead to tool failure during crucial operations, affecting timelines and safety.

Being aware of these errors not only encourages a smoother operational flow but also improves the reliability of bolted joints, as emphasized by S. Ganeshmurthy et al. in their simulation of bolt tightening processes. Additionally, improper force application can lead to reduced preload due to geometric errors, ultimately affecting fastener performance and reliability. By prioritizing calibration and upkeep, you can significantly enhance the efficiency of fastening tools in your construction projects.

Proper Handling and Maintenance of Torque Wrenches

To keep your tool operating at its best, follow these crucial handling and maintenance strategies:

- Store Properly: Always store your torque tool in a protective case or a designated area to shield it from accidental damage. For instance, using a foam-lined toolbox can prevent movement and impact, significantly affecting the tool's accuracy and longevity.

- Clean Regularly: After each use, take a moment to wipe down your tool to eliminate dirt and debris that could affect its performance. Regular cleaning is key to maintaining precision.

- Avoid Dropping: Handle your adjustable tool with care. Dropping it can misalign internal components, which compromises its accuracy and reliability.

- Recalibrate as Required: Most producers suggest adjusting calibration tools annually or every 5,000 cycles to ensure precision. Establishing a regular calibration schedule is vital for maintaining the tool's performance. As Jaime Rodriguez states,

Have your tool calibrated by Michelli’s expert calibration technicians in our ISO 17025 accredited laboratory,

which emphasizes the importance of using accredited services for calibration. - Follow Manufacturer Guidelines: Always consult the manufacturer’s instructions for specific maintenance requirements tailored to your tool model. This ensures that your tool remains in top condition according to its design specifications.

- Real-World Examples: For efficient storage, consider a wall-mounted rack specifically designed for adjustable tools. This keeps them accessible while protecting them from impact.

- Case Studies: A recent case study from a large construction firm highlighted that implementing a strict maintenance schedule, including proper storage and regular calibration, led to a 30% reduction in tool-related errors on site. By integrating these best practices into your routine, you can ensure that your torque wrench remains reliable and accurate, meeting the demands of your construction projects.

Conclusion

Understanding the various types of torque wrenches and their specific applications is essential for anyone involved in construction and mechanical assembly. With options ranging from beam and click wrenches to digital models, each tool offers distinct advantages tailored to different project requirements. Selecting the right wrench not only enhances precision but also significantly contributes to overall safety and efficiency on the job site.

When renting a torque wrench, it is crucial to assess project needs, consult rental providers for expert advice, and ensure the tool is well-calibrated. Additionally, recognizing the essential features—such as torque range, ease of use, and durability—can greatly influence the effectiveness of the tool in achieving accurate results. Avoiding common mistakes, such as over-tightening and neglecting calibration, will further enhance the reliability of the torque wrench and prevent costly errors.

By adhering to proper handling and maintenance practices, such as regular cleaning and appropriate storage, construction professionals can extend the lifespan of their tools and maintain their accuracy. Integrating these best practices into daily operations not only improves project outcomes but also fosters a culture of safety and responsibility in the workplace. Ultimately, making informed decisions about torque wrenches is a vital step toward ensuring successful and efficient project execution.

Frequently Asked Questions

What is the purpose of a torque wrench in construction?

Torque wrenches are essential tools designed to apply a specific amount of rotational force to fasteners, preventing over-tightening and potential damage.

What are the different types of torque wrenches available?

The main types of torque wrenches include: 1. Beam Torque Wrenches: Simple mechanical tools that use a beam and scale to measure force, suitable for basic applications. 2. Click Tools: Popular tools that emit an audible click when the preset tension is reached, ideal for general construction and automotive tasks. 3. Digital Torque Wrenches: Accurate devices with digital displays that can save measurements, suitable for high-precision tasks. 4. Torque Screwdrivers: Adjustable tools designed for smaller fasteners, allowing users to set various force levels for delicate tasks.

How should one choose a torque wrench for rental?

When selecting a torque wrench for rental, consider the following: 1. Assess your project requirements. 2. Consult with rental providers for expert advice. 3. Compare rental costs for different tools. 4. Check for calibration and maintenance status. 5. Understand the rental agreement to avoid unexpected fees. 6. Apply the right hand rule for rotational force direction.

What features should be considered when borrowing a torque wrench?

Important features to consider include: 1. Torque range for versatility. 2. Ease of use with ergonomic designs. 3. Durability for tough construction conditions. 4. Calibration options for maintaining accuracy. 5. Display type preference, such as LCD for clarity.

What are common mistakes to avoid when using a torque wrench?

Common mistakes include: 1. Failing to calibrate the tool, leading to inaccuracies. 2. Over-tightening fasteners, which can strip threads. 3. Using an incorrect tool type for specific tasks. 4. Poor storage that affects calibration and accuracy. 5. Ignoring maintenance, which can lead to tool failure.

What maintenance strategies are recommended for torque wrenches?

Recommended maintenance strategies include: 1. Proper storage in protective cases. 2. Regular cleaning after use. 3. Avoiding drops to maintain internal alignment. 4. Recalibrating as needed, typically annually or after 5,000 cycles. 5. Following manufacturer guidelines for specific maintenance requirements.