Overview

The weight of a 60 ft boom lift, typically ranging from 10,000 to 15,000 pounds, significantly influences its operational capabilities, particularly in terms of stability and maneuverability on job sites.

- Heavier lifts provide greater stability, which is essential for outdoor tasks.

- However, this added weight can hinder navigation in confined spaces.

Therefore, it is crucial for project managers to balance weight considerations with site conditions to optimize both safety and efficiency.

Key Highlights:

- 60 ft boom lifts provide elevated access for construction, maintenance, and repair tasks.

- They feature a hydraulic platform with a bucket or platform on an extendable arm.

- Boom lifts can be powered by electricity or diesel, affecting their application environments.

- Electric models are suited for indoor use, while diesel models are better for outdoor tasks.

- Safety measures are critical; falls from height are a leading cause of fatalities in construction.

- Pre-operation inspections and personal protective equipment (PPE) are essential for safe operation.

- The weight of 60 ft boom lifts ranges from 10,000 to 15,000 pounds, influenced by model and features.

- Weight impacts manoeuvrability and stability; heavier lifts offer more stability but can be harder to navigate.

- Understanding ground pressure is vital for ensuring safe operation on various surfaces.

- Selecting the right boom lift requires evaluating height, reach, load capacity, and site conditions.

- Articulating lifts are better for confined spaces, while telescopic lifts offer greater horizontal reach.

- The aerial work platform market is projected to grow, indicating increasing demand for boom lifts.

Introduction

Understanding the weight of a 60 ft boom lift transcends mere technical specification; it stands as a cornerstone of project safety and efficiency. These powerful machines, deployed across diverse construction and maintenance tasks, have their weight influencing everything from maneuverability to ground pressure. Thus, it becomes essential for project managers to grasp these dynamics fully.

How does one strike a balance between the necessity for stability and the constraints imposed by weight, particularly in confined spaces? This article delves into the essentials of boom lift weight, exploring its implications for operational success and safety in demanding work environments.

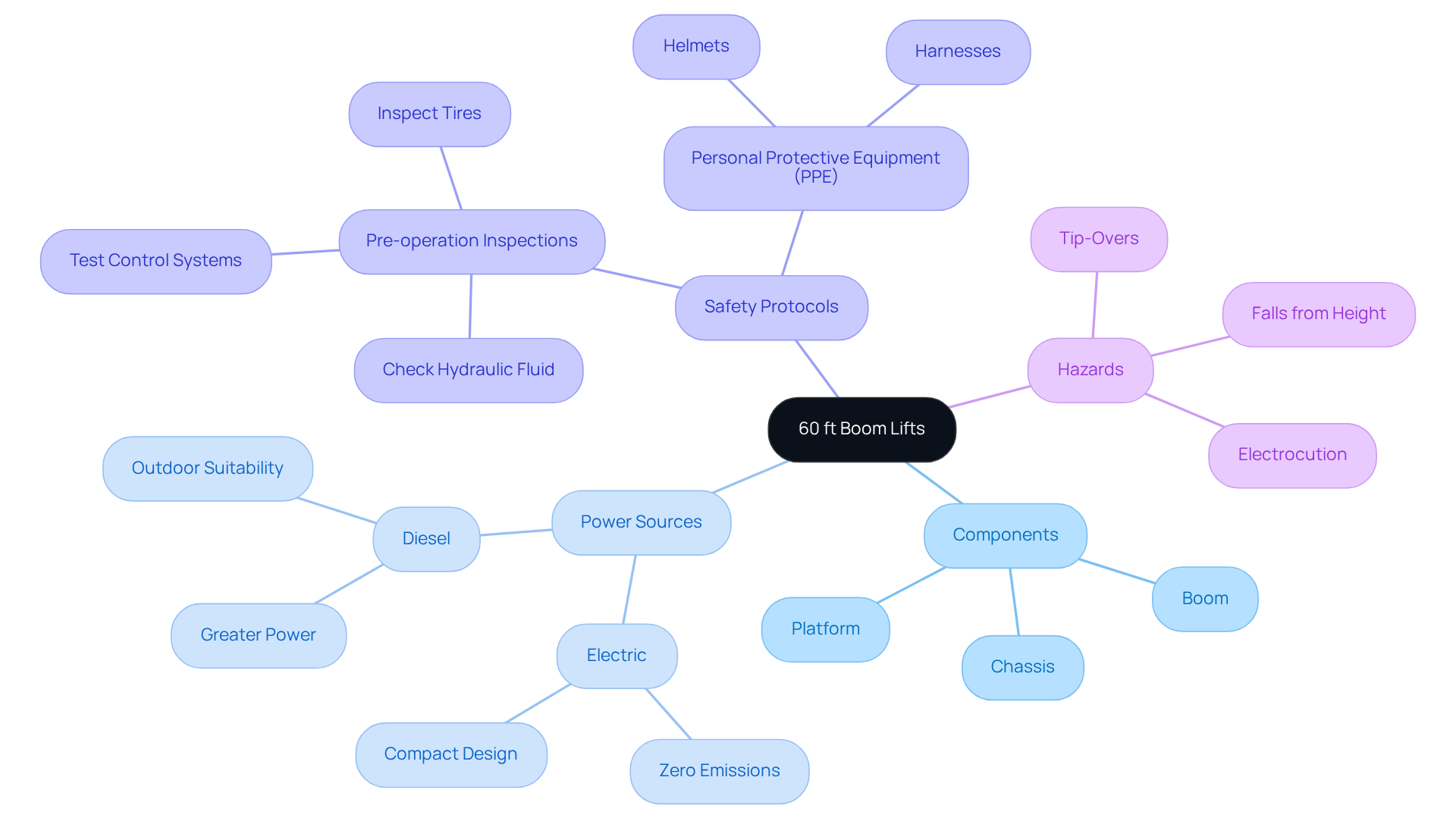

Explore the Basics of 60 ft Boom Lifts

A 60 ft aerial platform is essential equipment designed to provide elevated access to challenging work zones. These platforms are widely used in construction, maintenance, and repair tasks, enabling workers to operate safely at significant heights. The hydraulic platform features a bucket or platform attached to an arm, which can extend and retract to achieve the desired elevation. Key components include the chassis, boom, and platform, all vital for safe and effective operation.

Boom elevating platforms can be powered by either electricity or diesel, affecting their suitability for various environments. Electric models, such as LGMG's A30JE, are ideal for confined indoor spaces due to their zero emissions and compact design. In contrast, diesel-powered machines are better suited for outdoor applications where greater power and reach are required.

Safety is paramount when operating boom lifts. Statistics indicate that falls from height remain a leading cause of fatalities in construction, underscoring the importance of using harnesses and maintaining a clear work area to mitigate risks. Operators must adhere to strict operational protocols, including:

- Conducting pre-operation inspections to assess hydraulic fluid levels, tire conditions, and control systems.

- Donning appropriate personal protective equipment (PPE), such as helmets and harnesses, to enhance safety.

Understanding the operational mechanics of aerial platforms, including the 60 ft boom lift weight, and their weight capacities—typically ranging from 225 to 453 kg—enables project managers and equipment operators to make informed decisions regarding their use in various applications. It is also crucial to recognize the potential hazards associated with aerial platforms, such as electrocution and tip-overs, which can occur if safety measures are not observed. By familiarizing themselves with these fundamentals, project managers can enhance project efficiency and ensure worker safety while effectively utilizing aerial platforms.

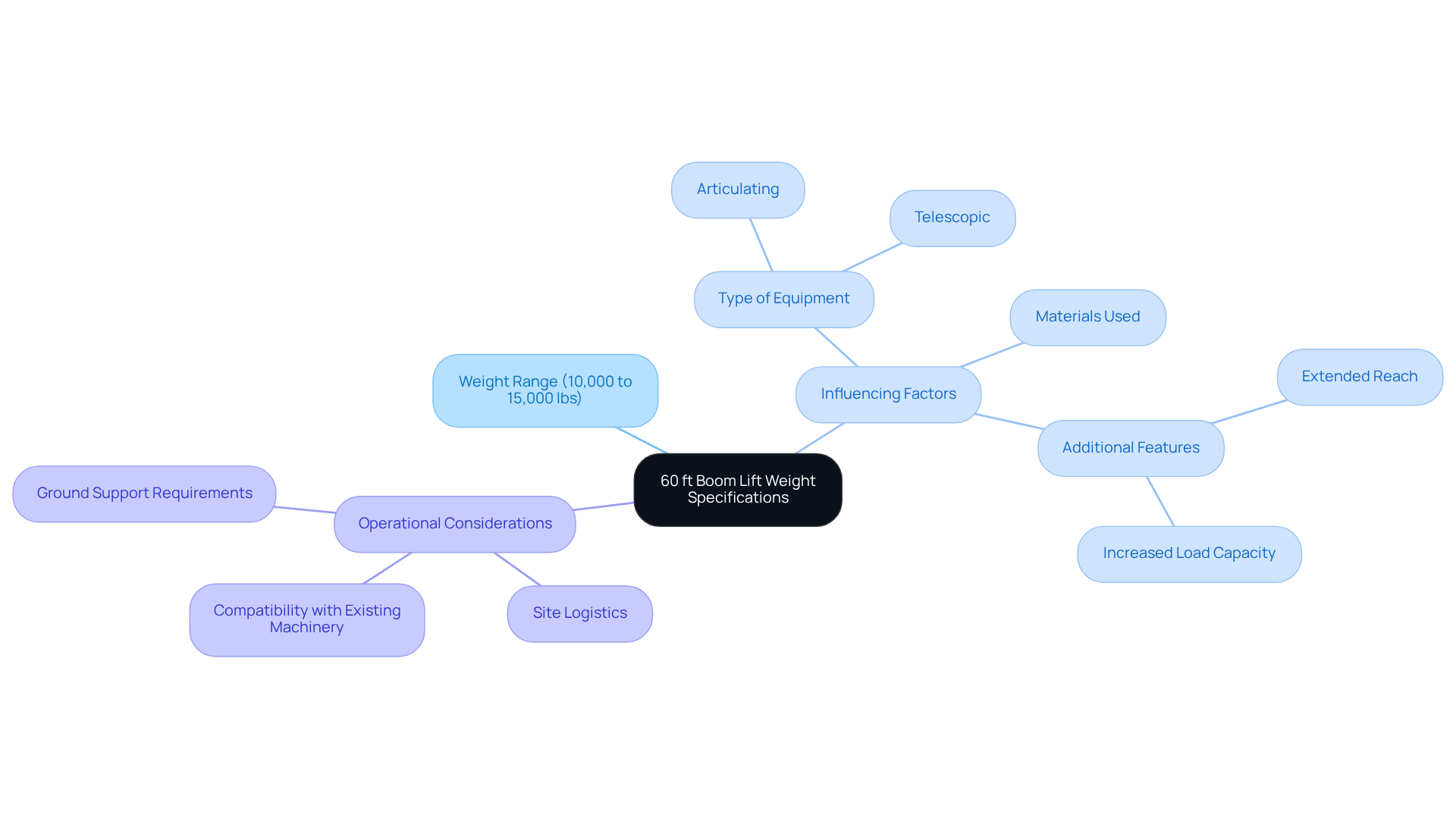

Analyze Weight Specifications and Factors

The 60 ft boom lift weight typically ranges from 10,000 to 15,000 pounds, influenced by the model and its characteristics. Factors such as the type of equipment—articulating or telescopic—materials used in construction, and additional features like extended reach or increased load capacity all play a role in determining the 60 ft boom lift weight.

Understanding these specifications is essential for ensuring the crane can be safely operated on the job site. For instance, heavier loads may require more robust ground support, impacting site logistics including transportation and setup.

Furthermore, grasping the mass is vital for assessing the equipment's compatibility with existing machinery and site conditions, thereby facilitating a seamless workflow.

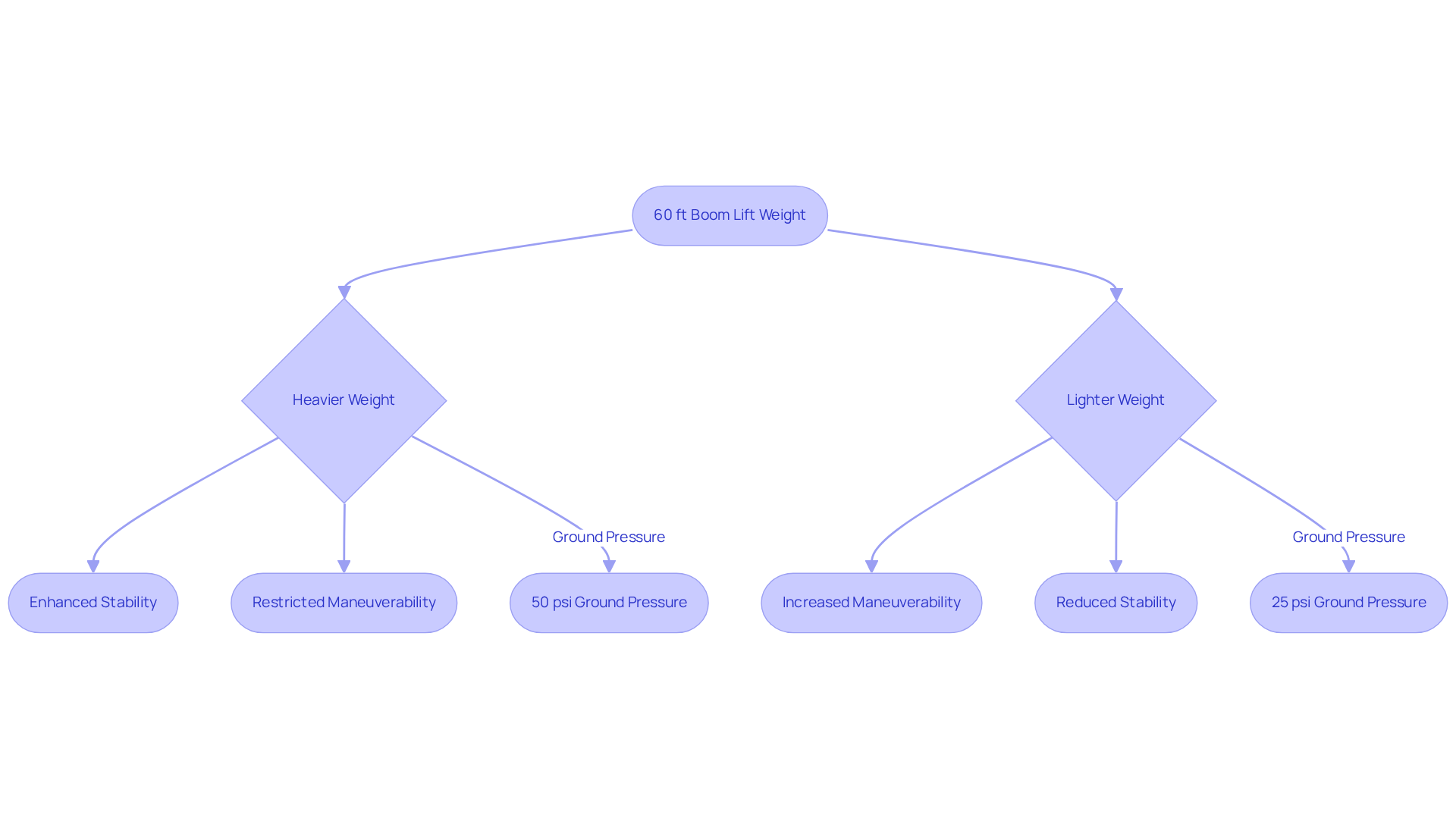

Evaluate Operational Impacts of Boom Lift Weight

The 60 ft boom lift weight is crucial to its operational capabilities, directly influencing both maneuverability and stability. Heavier raises typically provide enhanced stability, essential for tasks that require a solid foundation. However, the 60 ft boom lift weight can restrict maneuverability in confined spaces, complicating navigation around obstacles or fitting into tight areas. This trade-off is significant, as the 60 ft boom lift weight impacts the mass of the elevation, which in turn affects ground pressure—an important consideration for ensuring that the surface can adequately support the equipment without the risk of sinking or tipping. For instance, the 60 ft boom lift weight of a platform elevating device weighing 10,000 lbs may exert a ground pressure of approximately 50 psi, while a lighter variant at 5,000 lbs may exert around 25 psi, illustrating the impact of weight on ground pressure and site suitability.

For project managers, these considerations are vital when planning the deployment of boom equipment. Selecting a lighter hoist for locations with limited access can significantly enhance productivity by enabling easier navigation and quicker positioning. Conversely, for operations that demand greater stability, particularly in outdoor environments or on uneven terrain, a model with a 60 ft boom lift weight may be necessary. As compliance specialist Conger observes, "Utilizing aerial devices assists job sites in adhering to regulations," underscoring the importance of selecting the right equipment for the task. Recognizing the balance between the 60 ft boom lift weight, maneuverability, and ground pressure is essential for optimizing project efficiency and ensuring safety on the job site. Furthermore, renting aerial platforms can provide versatility and financial advantages, allowing project managers to choose the appropriate machinery without the burdens of ownership.

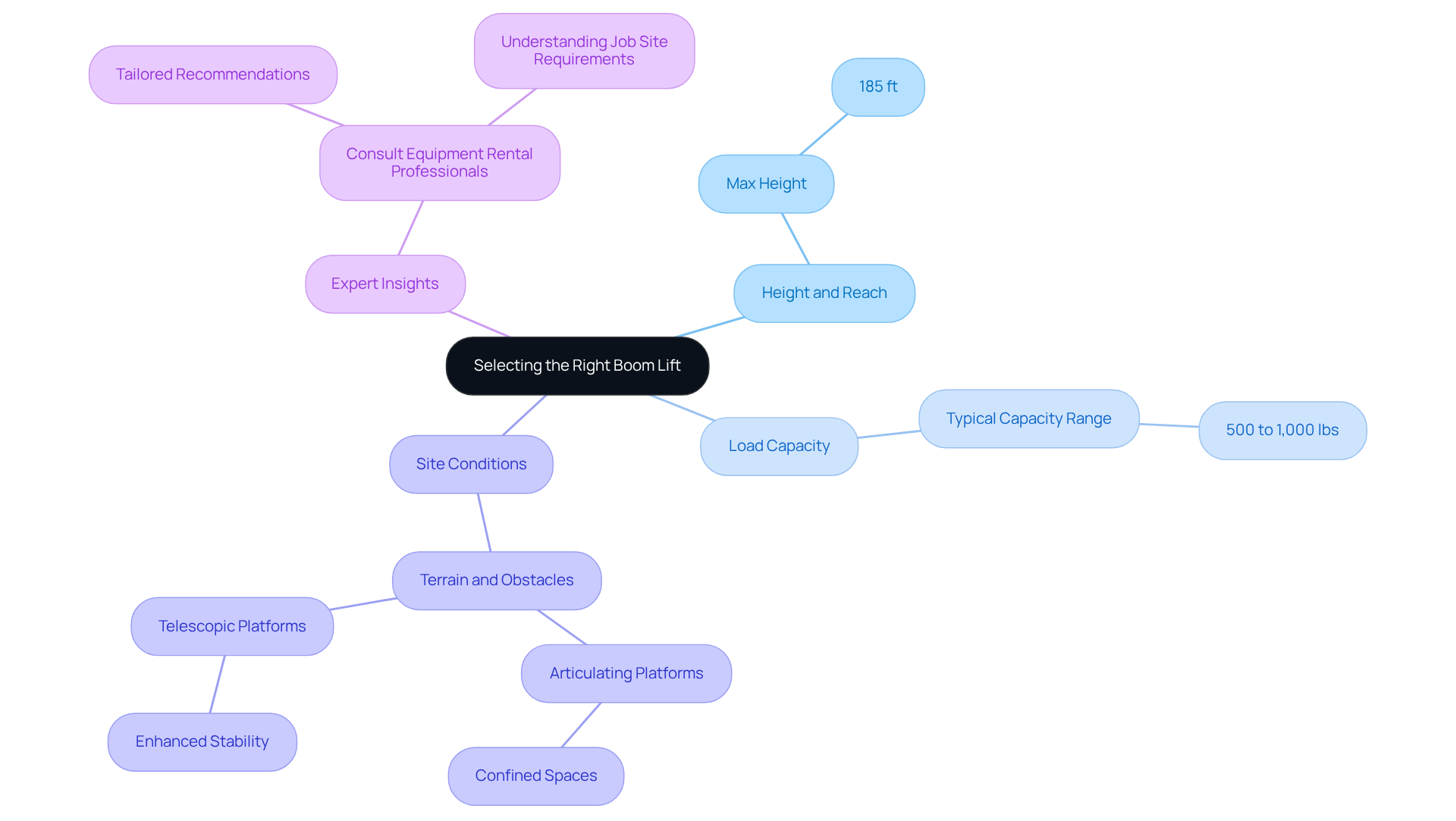

Select the Right Boom Lift for Your Project Needs

Selecting the right aerial platform for your project demands a thorough evaluation of several critical factors. Begin by determining the necessary height and reach; boom machines vary significantly in these specifications, with some models capable of reaching heights up to 185 feet. Next, assess the required load capacity for your tasks; typical capacities range from 500 to 1,000 pounds, depending on the apparatus's type and model. For instance, activities involving the lifting of heavy construction materials may require a device with a higher weight capacity. Aligning the platform's capabilities with your project's demands is crucial for ensuring safety and efficiency.

Consider the specific conditions of your site, including terrain and obstacles. Articulating aerial platforms excel in navigating confined spaces and uneven terrain, while telescopic platforms offer enhanced horizontal reach and stability, making them ideal for outdoor projects. Additionally, evaluate the 60 ft boom lift weight relative to ground conditions to ensure stability and mitigate the risk of accidents.

Engaging with equipment rental professionals can provide invaluable insights tailored to your project needs. Experts at EZ Equipment Rental highlight the significance of understanding the unique requirements of your job site, including factors like aisle widths and surface conditions. The aerial work platform market is projected to reach USD 13.03 billion by 2025, underscoring the growing demand for these versatile machines. By considering these factors, you can choose a boom lift that not only boosts productivity but also prioritizes safety on the job site.

Conclusion

Understanding the weight of a 60 ft boom lift is crucial for ensuring safety and efficiency across various project environments. The weight dictates the lift's operational capabilities and influences critical factors such as maneuverability and ground pressure. A comprehensive grasp of boom lift weight dynamics empowers project managers to make informed decisions, ultimately leading to successful project outcomes.

Throughout this article, we explored key insights, including:

- The varying weight specifications of boom lifts

- The operational impacts of weight on stability and maneuverability

- The significance of selecting the right lift for specific project needs

A thorough evaluation of factors such as height, reach, load capacity, and site conditions can significantly enhance productivity while minimizing risks associated with equipment use.

In a landscape where safety and efficiency are paramount, understanding boom lift weight is not merely a technical requirement but a vital aspect of project management. Engaging with equipment rental professionals and considering the unique demands of each job site will ensure that the right boom lift is chosen, fostering a safer and more efficient working environment. By prioritizing this knowledge, project managers can navigate the complexities of aerial work platforms and contribute to the overall success of their projects.

Frequently Asked Questions

What is a 60 ft boom lift and what is it used for?

A 60 ft boom lift is an aerial platform designed to provide elevated access to challenging work zones, commonly used in construction, maintenance, and repair tasks to enable safe operation at significant heights.

What are the key components of a 60 ft boom lift?

The key components of a 60 ft boom lift include the chassis, boom, and platform, all of which are vital for safe and effective operation.

What are the power options available for boom lifts?

Boom lifts can be powered by either electricity or diesel. Electric models are suited for confined indoor spaces due to their zero emissions, while diesel-powered machines are better for outdoor applications requiring greater power and reach.

What safety measures should be taken when operating a boom lift?

Safety measures include conducting pre-operation inspections, wearing appropriate personal protective equipment (PPE) such as helmets and harnesses, and maintaining a clear work area to mitigate risks.

What are the weight capacities of 60 ft boom lifts?

The weight capacities of 60 ft boom lifts typically range from 225 to 453 kg.

What potential hazards are associated with aerial platforms?

Potential hazards include electrocution and tip-overs, which can occur if safety measures are not properly observed.

Why is it important for operators to understand the operational mechanics of aerial platforms?

Understanding the operational mechanics, including weight and weight capacities, enables project managers and equipment operators to make informed decisions regarding the use of aerial platforms, enhancing project efficiency and ensuring worker safety.