Overview

This article serves as a vital resource for selecting and utilizing welding tools for rent. Understanding the different types of welders available is crucial, as is recognizing the advantages of renting over purchasing equipment. Key factors to consider during the rental process are outlined, ensuring that users can navigate their options effectively.

The article details the specific features and applications of various welding tools, highlighting the cost-effectiveness and flexibility that renting provides. By emphasizing the reliability and quality of rented equipment, it aims to generate desire among readers to take advantage of these offerings. Furthermore, practical advice is provided to help avoid common pitfalls, thereby empowering users to make informed and efficient choices for their projects.

In conclusion, this guide encourages immediate engagement with the rental process, ensuring that users are well-equipped to select the right tools for their needs. With a confident and knowledgeable approach, the article aims to build rapport with its audience while delivering essential insights into the welding equipment rental industry.

Key Highlights:

- MIG welders are user-friendly and versatile, suitable for both light and heavy-duty applications.

- TIG welders offer precision and are ideal for intricate work on thin materials, providing clean and strong welds.

- Stick welders are robust and effective for outdoor use, excelling with thick materials.

- Multi-process welders can perform MIG, TIG, and Stick welding, offering flexibility for diverse tasks.

- Plasma cutters are essential for precise cutting of materials before joining, enhancing efficiency.

- Key factors in choosing welding equipment include project requirements, power source compatibility, skill level, rental duration, and budget.

- Renting welding tools is cost-effective, provides access to the latest technology, and eliminates maintenance responsibilities.

- Important steps in the rental process include reviewing leasing terms, inspecting tools, understanding maintenance responsibilities, seeking support, and familiarizing with return procedures.

- Common pitfalls in renting include not researching equipment options, ignoring lease terms, neglecting inspections, overlooking maintenance needs, and underestimating requirements.

- The growing trend in the construction industry emphasizes the importance of informed decision-making and adapting to market demands.

Introduction

In the realm of construction and metal fabrication, the selection of welding tools is pivotal to the success of any project. With a wide array of options available for rent, it is crucial to grasp the intricacies of each type of equipment to achieve optimal results.

- MIG and TIG welders, celebrated for their versatility and precision, stand alongside robust stick welders and adaptable multi-process machines, each designed to fulfill specific project requirements.

- As the industry progresses, trends reveal a rising inclination towards rental solutions that not only ease financial constraints but also grant access to cutting-edge technology.

This article explores the diverse welding tools available for rent, outlines key considerations for choosing the right equipment, and discusses the advantages of renting over purchasing, all while underscoring the significance of informed decision-making in the ever-evolving landscape of welding projects.

Understanding the Different Types of Welding Tools Available for Rent

When evaluating tool rentals, understanding the various types available is crucial to ensure you select the right equipment for your specific needs. Here are some common categories:

- MIG Welders: Particularly well-suited for beginners, MIG welders offer ease of use and versatility across different materials. With a continuous wire feed, they enable rapid and effective joining, making them suitable for both light and heavy-duty applications.

- TIG Welders: Known for their precision, TIG welders utilize a non-consumable tungsten electrode, making them ideal for intricate work on thin materials. This method provides a clean and strong weld, essential in industries where aesthetics and strength are paramount.

- Stick Welders: Renowned for their robustness, stick welders excel in outdoor environments and can effectively handle thick materials. Their simplicity and reliability make them a favored choice in construction projects, especially where portability is required.

- Multi-Process Welders: These versatile machines can perform multiple joining processes, including MIG, TIG, and Stick. This flexibility allows users to adapt to various tasks without needing multiple machines, making them a cost-effective solution for diverse requirements.

- Plasma Cutters: While not strictly categorized as joining tools, plasma cutters play a vital role in metal fabrication by enabling precise cutting of materials prior to joining. Their ability to cut through thick metals quickly enhances overall task efficiency.

Current trends indicate a growing demand for advanced joining technologies, such as laser and ultrasonic machines, as companies seek high-end solutions without the burden of ownership costs. By 2025, the market share for MIG, TIG, Stick, and Multi-Process welders reflects a competitive landscape, with each type catering to specific applications and user preferences. For instance, MIG welders are favored for their speed, while TIG welders are preferred for their precision.

As noted by Steve Mau, president and owner of Brainerd General Rental, "That’s actually been working well for us," highlighting the importance of adapting to market demands. Understanding these choices and their uses will enable you to make informed decisions when renting welding tools, ensuring you have the appropriate equipment to meet your project needs efficiently. Furthermore, the implementation of electronic contracts and online booking systems enhances the experience, making it easier for customers to access the tools they require.

The competitive environment of the rental market for tools emphasizes the need for companies to distinguish themselves through service quality and innovation.

Key Factors to Consider When Choosing Welding Equipment

When selecting fabrication tools, several critical factors must be considered to ensure optimal performance and safety.

- Project Requirements: Assess the materials and their thicknesses involved in your project. Various techniques, such as MIG, TIG, or stick methods, are suited for specific materials and thicknesses. Understanding these requirements is essential for selecting the appropriate technique and equipment.

- Power Source: Evaluate the power supply available at your job site. Welding tools can be powered by gas, electricity, or diesel; ensuring compatibility with your power source is crucial for uninterrupted operation. This factor greatly influences the effectiveness and practicality of your fabrication tasks.

- Skill Level: The complexity of the apparatus should match the operator's skill level. Using advanced tools without sufficient training can lead to accidents and subpar results. It is vital to align the capabilities of welding tools for rent with the operator's expertise to maintain safety and quality standards on the job site.

- Rental Duration: Consider the length of time you will need the welding equipment. Many rental companies offer better rates for extended rental periods, which can help manage costs effectively. Understanding your timeline aids in making a cost-effective decision.

- Budget: Finally, evaluate your budget constraints. It is crucial to locate tools that satisfy your requirements without exceeding your budget. Balancing quality and expense is essential, particularly in a competitive construction setting.

By thoughtfully assessing these elements, you can choose the appropriate welding tools tailored to your undertaking's specific needs. In 2025, statistics show that 67% of construction managers emphasize reliability and compatibility with requirements when making rental choices. This statistic underscores the importance of informed decision-making in equipment selection.

As Kruttika Dwivedi, research manager at Deloitte, notes, understanding the evolving landscape of construction is crucial for those managing projects. Moreover, case studies demonstrate that initiatives using the suitable joining equipment based on comprehensive evaluations encounter a 30% boost in efficiency and a notable decrease in safety incidents. The adoption of emerging technologies, such as drones for surveying and monitoring, further illustrates how innovation can enhance efficiency and safety in welding tasks.

Key trends in construction, including safety technology and sustainability practices, also play a vital role in shaping choices regarding machinery selection. This comprehensive approach ensures that managers are well-equipped to make the best choices for their initiatives.

The Advantages of Renting Welding Tools Over Buying

Renting welding tools presents numerous advantages that can significantly benefit construction projects:

- Cost-Effectiveness: One of the primary benefits of renting is the elimination of substantial upfront costs associated with purchasing welding equipment. This enables managers to distribute resources more effectively across different needs, improving overall budget management. In 2024, the analysis of revenue, establishment, wages, and employment by state indicates a growing trend in the leasing market, further supporting the cost-effective nature of renting.

- Access to Latest Technology: Companies that provide welding tools for rent frequently update their inventory with the latest models, offering access to advanced features and capabilities that can enhance efficiency and quality. For example, Northern Tool & Equipment features a 2-in-1, 150-amp stick welder and 4.5 kW generator designed for construction and outdoor applications, showcasing the practical offerings available in the rental market.

- Flexibility: Renting welding tools provides the flexibility to choose equipment customized to specific task requirements without the long-term commitment of ownership. This adaptability is essential in a dynamic construction setting where scopes can change unexpectedly.

- Maintenance-Free: With lease agreements, maintenance and repairs are typically handled by the leasing company. This not only reduces the workload for managers but also ensures that the equipment remains dependable and in optimal working condition throughout the rental period.

- Storage Savings: The option of renting welding tools eliminates the need for dedicated storage space, which can be a significant cost-saving factor for many businesses. This is especially relevant for smaller companies or those with limited storage capabilities.

These advantages make renting welding tools a practical and strategic choice for many construction projects. In fact, recent trends indicate that a growing percentage of construction companies are opting to rent welding tools rather than buy, reflecting a shift towards more flexible and cost-effective operational strategies. Industry leaders stress that, "Often, leasing is the right choice," underscoring the growing acknowledgment of the advantages linked to leasing services.

Moreover, case studies reveal that distributors who effectively manage relationships with leasing companies and adapt to market demands are better positioned to thrive in a competitive landscape. This highlights the significance of exploring leasing alternatives as a practical resolution for fabrication requirements in 2025.

Navigating the Rental Process: Terms, Maintenance, and Support

Navigating the leasing process for welding tools involves several essential steps that can significantly enhance your experience.

- Review Leasing Terms: Before finalizing your lease, it is crucial to thoroughly read the leasing agreement. Pay close attention to the rental duration, associated fees, and your responsibilities as a renter. Grasping these terms in advance can avert confusions afterward, ensuring a smooth leasing experience.

- Inspect Tools: Always perform a thorough examination of the tools before accepting them. Look for any signs of damage or wear, and document these findings. This proactive approach helps avoid disputes regarding the state of the tools upon return, safeguarding your interests.

- Understand Maintenance Responsibilities: Clarifying maintenance responsibilities is vital. Some leasing companies may require you to perform basic upkeep during the leasing period. Understanding what is anticipated can assist you in preventing unforeseen fees and ensuring the apparatus stays in proper working order. Leasing welding tools from a reputable firm like EZ Equipment Rental guarantees you receive well-maintained machinery, including forklifts, as they prioritize regular upkeep to minimize the chance of breakdowns during essential operations.

- Seek Support: Should you face any problems with the machinery, do not hesitate to contact the leasing company for assistance. A reputable company, like EZ Equipment Rental, will provide comprehensive support, including troubleshooting and repair services, addressing any issues promptly to minimize downtime on your work. Their commitment to exceptional customer service ensures that you can rely on them for quick resolutions.

- Return Procedures: Familiarize yourself with the return process, including any cleaning requirements and necessary documentation. Comprehending these processes beforehand can simplify the return and guarantee adherence to the lease agreement.

By adhering to these steps, you can maneuver through the leasing process efficiently, ensuring a favorable experience that satisfies your machinery requirements. Furthermore, with the ongoing trend of experienced welders growing older—around 25% of skilled welders are 55 or above, according to the Bureau of Labor Statistics—having dependable access to quality tools is more crucial than ever to sustain productivity in your endeavors. EZ Equipment Rental, recognized for its dedication to quality and client satisfaction, is an outstanding option for your requirements related to welding tools for rent.

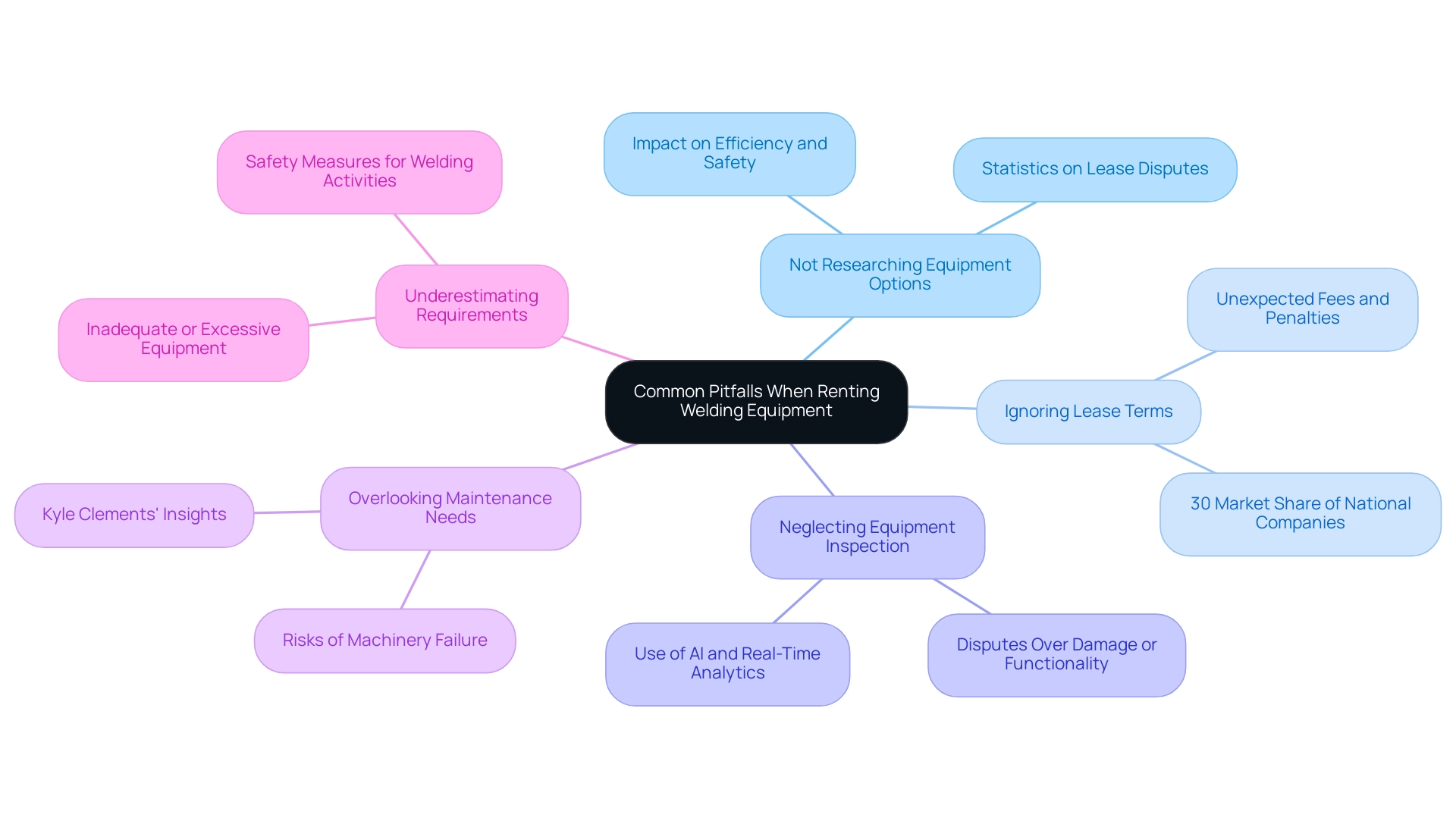

Common Pitfalls to Avoid When Renting Welding Equipment

To guarantee a successful leasing experience, it is essential to avoid these common pitfalls:

- Not Researching Equipment Options: Failing to explore various types of welding equipment can lead to selecting the wrong tool for the task, potentially impacting efficiency and safety. In 2025, statistics indicate that a significant portion of lease disputes stem from these common mistakes, underscoring the importance of diligence in the leasing process.

- Ignoring Lease Terms: A lack of understanding of the lease agreement can result in unexpected fees or penalties, straining budgets and timelines. With 30% of the US leasing market represented by national companies like United, Sunbelt, and Herc Rentals, comprehending the competitive environment is crucial.

- Neglecting Equipment Inspection: Skipping the inspection process can lead to disputes over damage or functionality issues, complicating the leasing experience and potentially delaying tasks. Embracing AI and real-time analytics can help streamline this process and enhance decision-making.

- Overlooking Maintenance Needs: Being unaware of maintenance responsibilities can result in machinery failure during crucial phases, jeopardizing timelines and increasing costs. Efficient operations are vital, as highlighted by Kyle Clements, who supports independent leasing firms to improve their service provision.

- Underestimating Requirements: Failing to accurately evaluate needs can result in acquiring inadequate or excessive equipment, obstructing productivity and increasing costs. Furthermore, safety factors are crucial; isolating metal joining tasks from other workplace activities with non-flammable screens and barriers is advised to safeguard workers from radiation risks.

Understanding these challenges is vital for making informed choices, ultimately improving your leasing experience and ensuring success. Moreover, recent developments, such as United Rentals' acquisition of H&E Equipment Services Inc., illustrate the evolving nature of the leasing industry and its impact on leasing decisions. By prioritizing research and understanding, construction project managers can navigate the complexities of welding tools for rent more effectively.

Conclusion

Understanding the variety of welding tools available for rent is essential for ensuring project success. From MIG and TIG welders to stick and multi-process machines, each type of equipment serves unique purposes that align with specific project requirements. The growing trend towards renting rather than purchasing welding tools not only addresses financial constraints but also provides access to the latest technology and equipment without the burden of ownership.

Key considerations when selecting welding equipment include:

- Project requirements

- Power source compatibility

- Skill level of the operator

- Rental duration

- Budget

Taking these factors into account can lead to more informed decisions, ultimately enhancing project efficiency and safety. Additionally, the advantages of renting—such as cost-effectiveness, flexibility, and maintenance-free operations—further solidify the rationale for utilizing rental services in the construction industry.

Navigating the rental process requires diligence, from understanding rental terms to conducting thorough inspections of equipment. Avoiding common pitfalls, such as neglecting equipment research and overlooking maintenance responsibilities, is crucial for a successful rental experience. With the construction landscape continually evolving, embracing rental solutions can empower project managers to adapt to changing needs while ensuring quality outcomes.

In conclusion, the informed selection and strategic rental of welding tools can significantly impact the efficiency and safety of construction projects. By prioritizing these considerations and leveraging rental advantages, project managers can navigate the complexities of welding equipment rentals effectively, securing the right tools to meet their specific needs.

Frequently Asked Questions

What are the common types of welding equipment available for rental?

The common types of welding equipment include MIG welders, TIG welders, Stick welders, Multi-Process welders, and Plasma cutters. Each type serves different needs, from ease of use for beginners to precision for intricate work.

What is a MIG welder, and what are its key features?

A MIG welder is particularly suited for beginners due to its ease of use and versatility. It features a continuous wire feed, allowing for rapid and effective joining of various materials, making it suitable for both light and heavy-duty applications.

How does a TIG welder differ from a MIG welder?

A TIG welder is known for its precision and uses a non-consumable tungsten electrode, making it ideal for intricate work on thin materials. It provides a clean and strong weld, which is essential in industries where aesthetics and strength are important.

What are the advantages of using Stick welders?

Stick welders are renowned for their robustness and excel in outdoor environments. They can effectively handle thick materials, and their simplicity and reliability make them a favored choice in construction projects, especially where portability is needed.

What is a Multi-Process welder?

A Multi-Process welder is a versatile machine that can perform multiple joining processes, including MIG, TIG, and Stick welding. This flexibility allows users to adapt to various tasks without needing multiple machines, making it a cost-effective solution.

What role do Plasma cutters play in metal fabrication?

Plasma cutters, while not strictly joining tools, are vital in metal fabrication as they enable precise cutting of materials before joining. Their ability to cut through thick metals quickly enhances overall task efficiency.

What factors should be considered when selecting welding tools for rental?

Key factors to consider include project requirements (materials and thickness), power source compatibility, operator skill level, rental duration, and budget constraints.

Why is it important to assess project requirements before renting welding equipment?

Assessing project requirements ensures that the selected equipment and techniques (MIG, TIG, or Stick) are suitable for the specific materials and their thicknesses involved in the project, which is essential for optimal performance.

How does the power source influence the choice of welding tools?

The power source available at the job site (gas, electricity, or diesel) must be compatible with the welding tools to ensure uninterrupted operation, greatly influencing the effectiveness and practicality of fabrication tasks.

What is the significance of matching equipment complexity to the operator's skill level?

Ensuring that the complexity of welding tools matches the operator's skill level is vital to maintain safety and quality standards, as using advanced tools without sufficient training can lead to accidents and poor results.

How can rental duration affect the cost of welding equipment?

Many rental companies offer better rates for extended rental periods, so understanding the timeline for equipment use can help manage costs effectively.

What trends are shaping the selection of welding tools in construction?

Trends such as safety technology, sustainability practices, and the growing demand for advanced joining technologies are influencing choices regarding machinery selection in the construction industry.