Key Highlights:

- Plate compactors, or vibratory compactors, are vital for compressing soil, gravel, and asphalt in construction.

- They eliminate air pockets and increase material density, ensuring stable surfaces for foundations, driveways, and walkways.

- The U.S. market for soil compacting machines is projected to reach USD 244 million by 2026, indicating rising demand.

- The global vibratory surface compactor market is expected to grow to USD 1,942.90 million by 2034, with a CAGR of 4.5%.

- Plate compactors are essential in road construction for creating stable roadbeds and preventing future settling.

- Proper compaction enhances project timelines and structural integrity, making plate compactors crucial for construction managers.

- Modern plate compactors feature adjustable handles and vibration-reducing systems for improved user comfort.

- Rental costs for soil compacting machines range from $40 to $80 per day, impacting project budgets.

- Regular maintenance is necessary for optimal performance and longevity of plate compactors.

Introduction

Plate compactors are essential tools in the construction industry, playing a crucial role in ensuring ground stability and material density. These machines enhance the efficiency of various projects, ranging from road construction to landscaping, while significantly impacting the longevity and safety of structures. As the demand for effective soil compaction solutions increases, construction managers encounter challenges related to maintenance costs and technological integration. Understanding the key insights that can help navigate these complexities is vital for maximizing the benefits of plate compactors in construction projects.

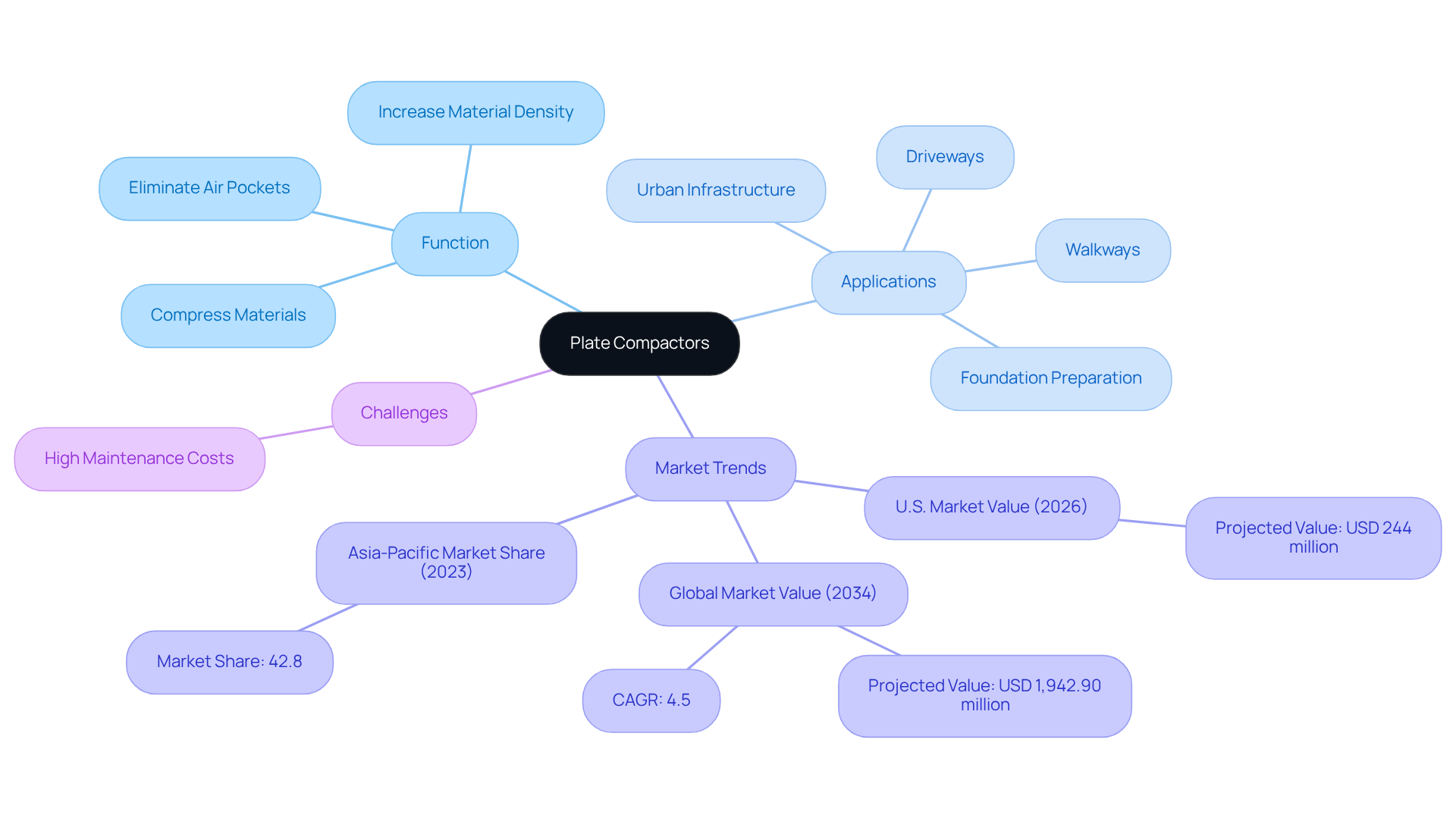

Define Plate Compactors: Essential Construction Equipment

A plate compactor, commonly known as a vibratory compactor, is an essential tool for compressing soil, gravel, asphalt, and other materials. It features a heavy, flat plate that vibrates rapidly, applying downward pressure on the ground. This vibration effectively eliminates air pockets and increases material density, resulting in a stable surface suitable for various construction applications. Plate compactors are particularly beneficial for foundation preparation, driveways, and walkways, ensuring that the ground can adequately support the weight of structures and vehicles.

Their compact size and maneuverability make them ideal for both large and small projects, solidifying their status as a staple in the construction industry. In 2026, the U.S. market for soil compacting machines is projected to reach USD 244 million, reflecting the growing demand for effective soil compaction solutions. Furthermore, the global vibratory surface compactor market is anticipated to reach USD 1,942.90 million by 2034, expanding at a CAGR of 4.5%.

Practical examples illustrate their efficiency; contractors have successfully utilized compaction machinery in urban infrastructure projects, where rapid urban growth necessitates reliable compaction tools. Industry leaders, including Rushikesh Dorge, emphasize that the integration of advanced technology in plate compactors significantly enhances their efficiency and safety, further encouraging their use in construction projects. However, challenges such as high maintenance costs persist, posing concerns for the industry and affecting overall market growth.

Explore the Role of Plate Compactors in Construction Projects

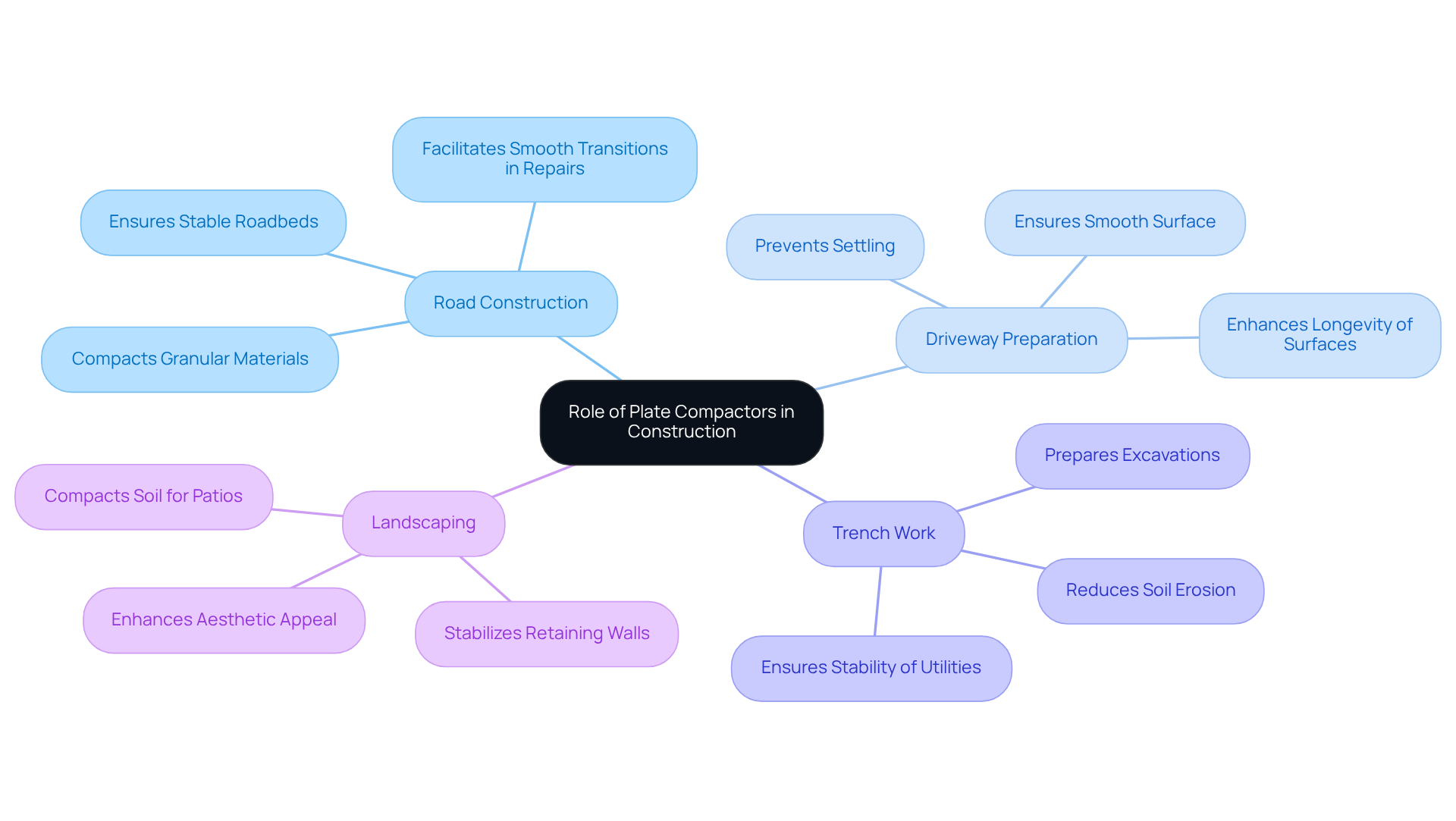

In construction, plate compactors are essential tools that ensure the ground is properly prepared before laying foundations, asphalt, or other materials. In road construction, they use plate compactors to compact granular materials and create stable roadbeds, which are crucial for supporting additional layers of asphalt or concrete. For example, when constructing a driveway, plate compactors compress the gravel foundation, preventing future settling and ensuring a smooth surface. In trench work, plate compactors are used to compact backfill material, significantly reducing the risk of soil erosion and enhancing site safety.

Their versatility extends to landscaping tasks, where plate compactors compact soil beneath features like patios and retaining walls, ensuring stability and longevity. The effectiveness of plate compactors not only aids in structural stability but also positively impacts timelines by enabling faster and more reliable compaction methods. As construction managers recognize the necessity of plate compactors, these machines become vital for achieving high-quality results across various applications.

According to Grand View Research, the global vibratory compactor market is projected to grow from USD 1,237.5 million in 2024 to USD 1,979.5 million by 2033, reflecting the increasing demand for efficient compaction solutions. Case studies on driveways and landscaping illustrate how proper compaction leads to durable surfaces and prevents future issues. Furthermore, insights from industry experts underscore the critical role of plate compactors in ensuring project efficiency and safety.

Understand How Plate Compactors Work: Mechanisms and Functionality

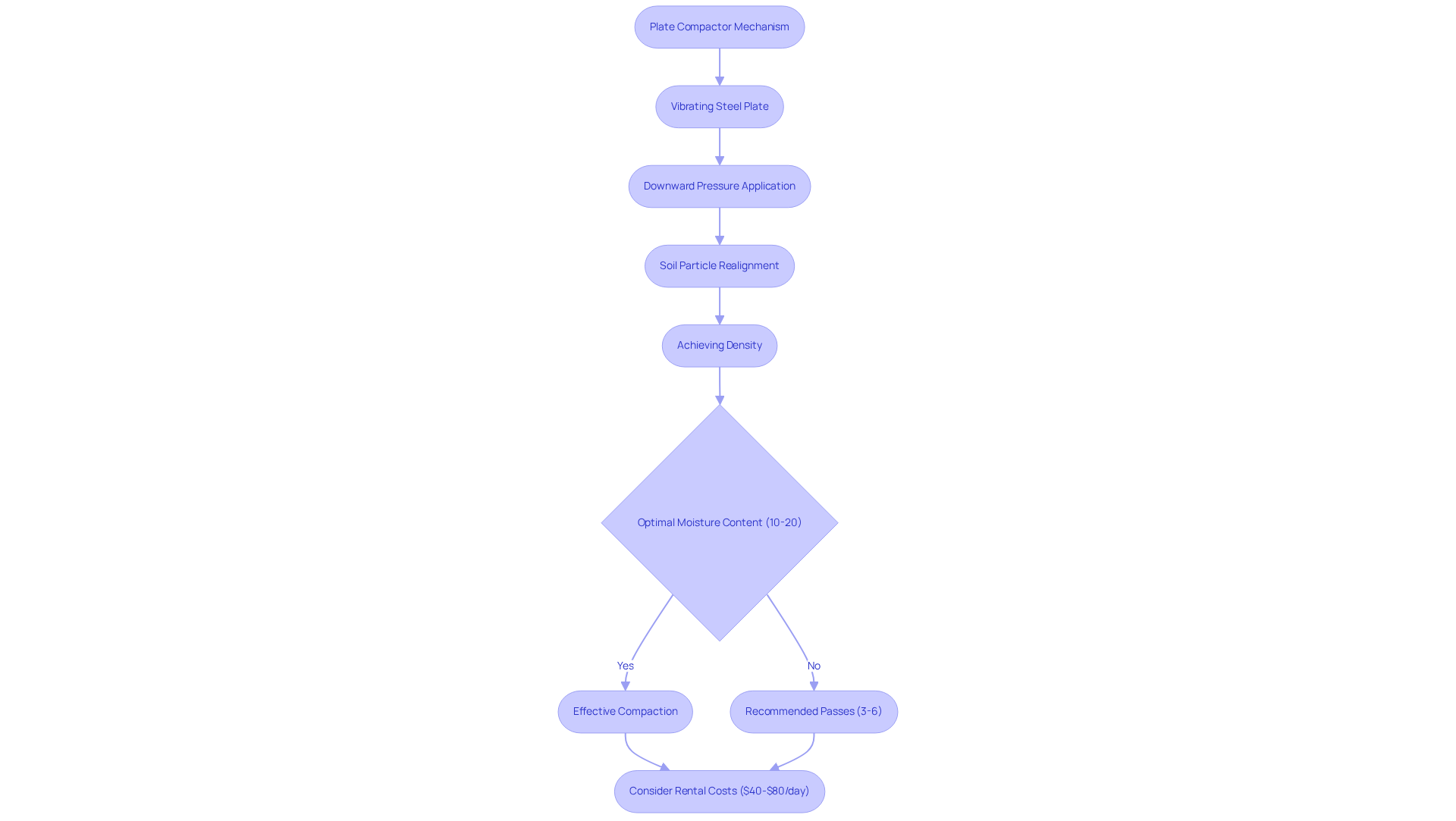

The mechanism of plate compactors is straightforward yet effective. At their core, these machines feature a heavy steel plate that vibrates at high frequencies, typically generated by an eccentric weight connected to the engine. As the plate vibrates, it applies downward pressure on the ground, compacting the material beneath. This vibration causes soil particles to realign and settle closer together, reducing void spaces and increasing density. Such compaction is vital for establishing a solid foundation capable of supporting structures and withstanding environmental factors.

The optimal moisture content for granular soils during compaction ranges from 10% to 20%, which is essential for achieving the best results. Additionally, many modern plate compactors are equipped with features like adjustable handles and vibration-reducing systems, enhancing user comfort and control. Mid to heavy-duty models typically weigh between 300 and over 1,000 lbs, making them suitable for a variety of construction applications. Generally, it is recommended to make 3 to 6 passes for effective compaction, ensuring the equipment is utilized efficiently.

Rental costs for soil compacting machines vary from $40 to $80 per day, a significant consideration for project budgets. Insufficient compaction can lead to issues such as potholes and sunken pavers, highlighting the importance of proper use of plate compactors.

Identify the Benefits of Using Plate Compactors in Construction

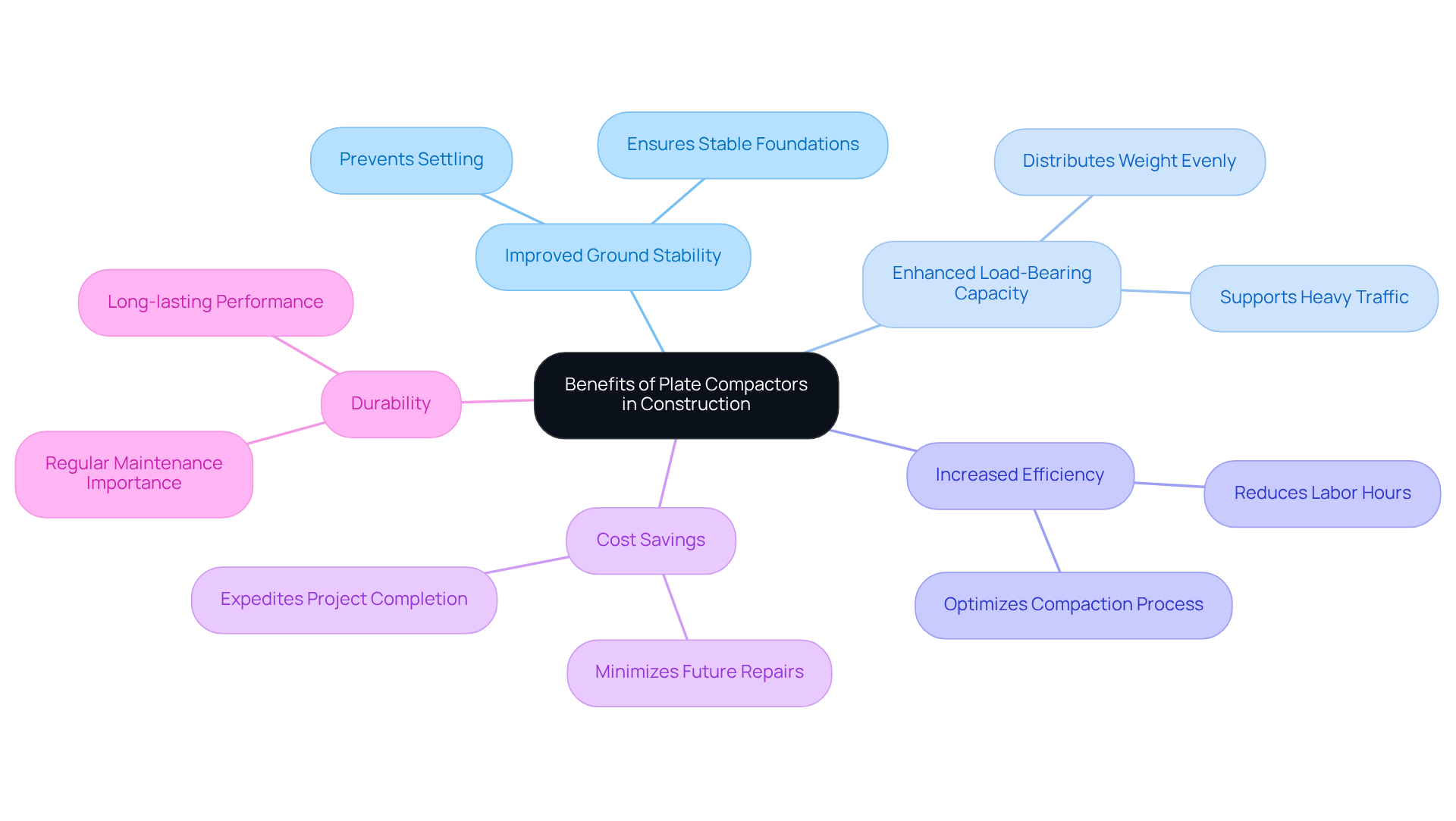

The use of surface compacting machines in construction offers numerous advantages, including improved ground stability, enhanced load-bearing capacity, and increased efficiency. By effectively compacting the soil, these machines help prevent future settling, which can lead to structural damage and costly repairs. For instance, in road construction, a well-compacted base ensures that the asphalt layer remains intact, reducing the likelihood of potholes developing over time.

Moreover, surface compacting machines are essential for ensuring adequate compression of the foundational layer of gravel or asphalt, highlighting their importance in construction projects. Compacting soil before pouring concrete is critical, as it prevents sinking or settling later on, thus ensuring a stable foundation. Additionally, surface densifiers can significantly reduce labor hours by optimizing the compaction process compared to manual techniques, leading to cost savings for contractors.

Regular maintenance is vital for the durability and efficiency of these machines, which includes cleaning after use and checking oil levels for gasoline-powered models. Their ability to operate in tight spaces makes them particularly suitable for urban construction sites where maneuverability is crucial. Overall, the use of plate compactors enhances project outcomes and contributes to long-term financial benefits by minimizing the risk of costly repairs and ensuring a solid foundation for various applications.

Conclusion

Plate compactors are essential tools in the construction industry, playing a vital role in preparing the ground for various projects. By effectively compressing soil and other materials, these machines enhance stability and support for structures, leading to successful construction outcomes. The projected growth in the vibratory compactor market underscores their increasing value in construction practices.

This article has explored key insights into the functionality, applications, and benefits of plate compactors. Their straightforward mechanism of vibration is crucial for creating stable foundations, facilitating efficient construction processes. The discussion highlighted their versatility across applications such as road construction, landscaping, and foundation preparation, while also addressing maintenance costs and the importance of proper compaction techniques.

Given these insights, construction managers are encouraged to adopt plate compactors for their immediate benefits in project efficiency and safety, as well as their long-term impact on construction quality. Investing in reliable compaction solutions can prevent costly repairs and ensure the durability of structures, making plate compactors a vital asset in any construction toolkit. As the demand for effective compaction solutions continues to rise, staying informed about advancements in this area will empower construction professionals to achieve superior results in their projects.

Frequently Asked Questions

What is a plate compactor?

A plate compactor, also known as a vibratory compactor, is a construction tool used for compressing soil, gravel, asphalt, and other materials. It features a heavy, flat plate that vibrates to apply downward pressure on the ground, eliminating air pockets and increasing material density.

What are the primary applications of plate compactors?

Plate compactors are primarily used for foundation preparation, driveways, and walkways, ensuring that the ground can support the weight of structures and vehicles.

Why are plate compactors important in construction?

They are essential for creating stable surfaces by effectively compacting materials, which is crucial for various construction applications. Their compact size and maneuverability make them suitable for both large and small projects.

What is the projected market growth for soil compacting machines in the U.S.?

The U.S. market for soil compacting machines is projected to reach USD 244 million by 2026, indicating a growing demand for effective soil compaction solutions.

What is the anticipated global market growth for vibratory surface compactors?

The global vibratory surface compactor market is expected to reach USD 1,942.90 million by 2034, growing at a compound annual growth rate (CAGR) of 4.5%.

How have contractors utilized plate compactors in urban infrastructure projects?

Contractors have successfully used compaction machinery in urban infrastructure projects to meet the demands of rapid urban growth, highlighting the reliability of these tools in construction.

What advancements have been made in plate compactors?

Industry leaders emphasize that the integration of advanced technology in plate compactors has significantly enhanced their efficiency and safety, promoting their use in construction projects.

What challenges do plate compactors face in the industry?

One of the main challenges is high maintenance costs, which pose concerns for the industry and can affect overall market growth.

List of Sources

- Define Plate Compactors: Essential Construction Equipment

- Ammann’s new plate compactors are built for speed (https://equipmentworld.com/construction-equipment/compact-equipment/article/15736179/ammanns-new-plate-compactors-are-built-for-speed)

- Global Vibratory Plate Compactors Market Size, Share 2033 (https://custommarketinsights.com/report/vibratory-plate-compactors-market)

- Vibratory Plate Compactor Market Size, Share & Trends [2034] (https://fortunebusinessinsights.com/vibratory-plate-compactor-market-109056)

- Vibratory Plate Compactor Market | Industry Report, 2033 (https://grandviewresearch.com/industry-analysis/vibratory-plate-compactor-market-report)

- Future of Plate Compactor Market: Expected CAGR of 6.3% Over 2026 to 2033 (https://linkedin.com/pulse/future-plate-compactor-market-expected-cagr-63-over-2026-2033-310ve)

- Explore the Role of Plate Compactors in Construction Projects

- Soil Compaction Machines Market Share and Statistics - 2035 (https://factmr.com/report/1978/soil-compaction-machines-market)

- From Driveways to Foundations: The Versatility of Plate Compactors in Construction (https://tomahawk-power.com/blogs/articles/from-driveways-to-foundations-the-versatility-of-plate-compactors-in-construction?srsltid=AfmBOorN7LOR-nJF4pKdCakBWJaO587YsDxMlY80HPkMjbVqkOtpcHK2)

- Innovative Plate Compactor Uses For DIY And Construction - Rentalex (https://rentalex.com/innovative-plate-compactor-uses-for-diy-and-construction)

- Vibratory Plate Compactor Market | Industry Report, 2033 (https://grandviewresearch.com/industry-analysis/vibratory-plate-compactor-market-report)

- Understand How Plate Compactors Work: Mechanisms and Functionality

- Evaluating the plate compactor frequency effect on compaction efficiency: numerical study with discrete element method | Request PDF (https://researchgate.net/publication/389438353_Evaluating_the_plate_compactor_frequency_effect_on_compaction_efficiency_numerical_study_with_discrete_element_method)

- What Is Plate Compactor? How Does It Work & How to Use - Chicca Machinery (https://chiccabm.com/news/what-is-plate-compactor-how-does-it-work-how-to-use)

- Volvo launches new and upgraded machines for the compaction market (https://volvoce.com/united-states/en-us/about-us/news/2025/volvo-launches-new-and-upgraded-machines-for-the-compaction-market)

- New Ammann Plate Compactors Are the Fastest on the Market (https://ammann.com/en-BD/news/new-ammann-plate-compactors-are-the-fastest-on-the-market)

- Identify the Benefits of Using Plate Compactors in Construction

- Is It Worth Buying a Plate Compactor for Your Projects? - Ideal machinery (https://hnmachines.com/is-it-worth-buying-a-plate-compactor-for-your-projects)

- Why a Plate Compactor is Essential for Your Construction Projects-Runsun Industrial (https://runsunequip.com/news_1/1955630470203375616.html)