Key Highlights:

- Walkie stacker forklifts, or pallet trucks, are electric-powered devices designed for lifting and transporting palletized loads.

- Key features include a lifting mast (800mm to 1500mm), compact design for narrow aisles, and user-friendly controls.

- They are suitable for confined spaces, making them ideal for warehouses, retail, and construction sites.

- Safety features like speed control and emergency stops reduce accident risks compared to manual pallet jacks.

- Pallet jacks handle standard pallet sizes (48" x 40") and do not require specialised licences, increasing accessibility.

- They are more than 50% cheaper than conventional forklifts, appealing to small and medium-sized businesses.

- In construction, walkie stackers improve logistics by transporting materials and enhancing workplace safety by reducing manual lifting.

- The evolution of walkie stackers includes advancements in battery technology and ergonomic controls, enhancing efficiency and safety.

- The market for pallet jacks is projected to grow from USD 3.4 billion in 2025 to USD 5.6 billion by 2035, reflecting their increasing importance.

- Different types of walkie stackers include straddle stackers, counterbalance lifters, reach lifters, and manual lifters, each serving specific operational needs.

Introduction

Walkie stacker forklifts are a significant advancement in material handling, combining efficiency and versatility across various operational environments. These electric-powered machines not only facilitate the movement of palletized loads but also improve safety and productivity, particularly in tight spaces such as warehouses and construction sites. As industries continue to evolve, businesses must consider how to effectively utilize the unique features of walkie stackers to enhance logistics and bolster workplace safety. This exploration highlights the considerable benefits and diverse applications of these vital tools in contemporary operations.

Define Walkie Stacker Forklift: Key Features and Functionality

A pedestrian forklift, commonly known as a pallet truck, is an electric-powered material handling device designed specifically for lifting and transporting palletized loads. Unlike traditional forklifts, these pedestrian-operated devices are controlled by an individual walking behind the machine, allowing for enhanced maneuverability in confined spaces. Key features include:

- A lifting mast that elevates loads to various heights, typically between 800mm and 1500mm

- A compact design for navigating narrow aisles

- A user-friendly control system that boosts operational efficiency

At EZ Equipment Rental, we offer a diverse range of well-maintained pallet jacks, ensuring clients find the perfect match for their specific needs. Walkie stacker forklifts are particularly suited for environments where space is limited, making them a preferred choice in warehouses, retail spaces, and construction sites. With expert guidance and support from our team, you can experience a seamless equipment rental process tailored to your project requirements.

Additionally, powered pallet trucks come equipped with safety features such as speed control and emergency stop buttons, significantly reducing the risk of accidents compared to manual pallet jacks. They are capable of handling standard pallet sizes, including the widely used 48" x 40" pallets, and do not require a specialized forklift license for operation, making them accessible to a broader range of employees.

Moreover, pallet jacks are often more than 50% less expensive than conventional forklifts, along with lower maintenance costs, making them an attractive option for small to medium-sized companies looking to improve their logistics operations.

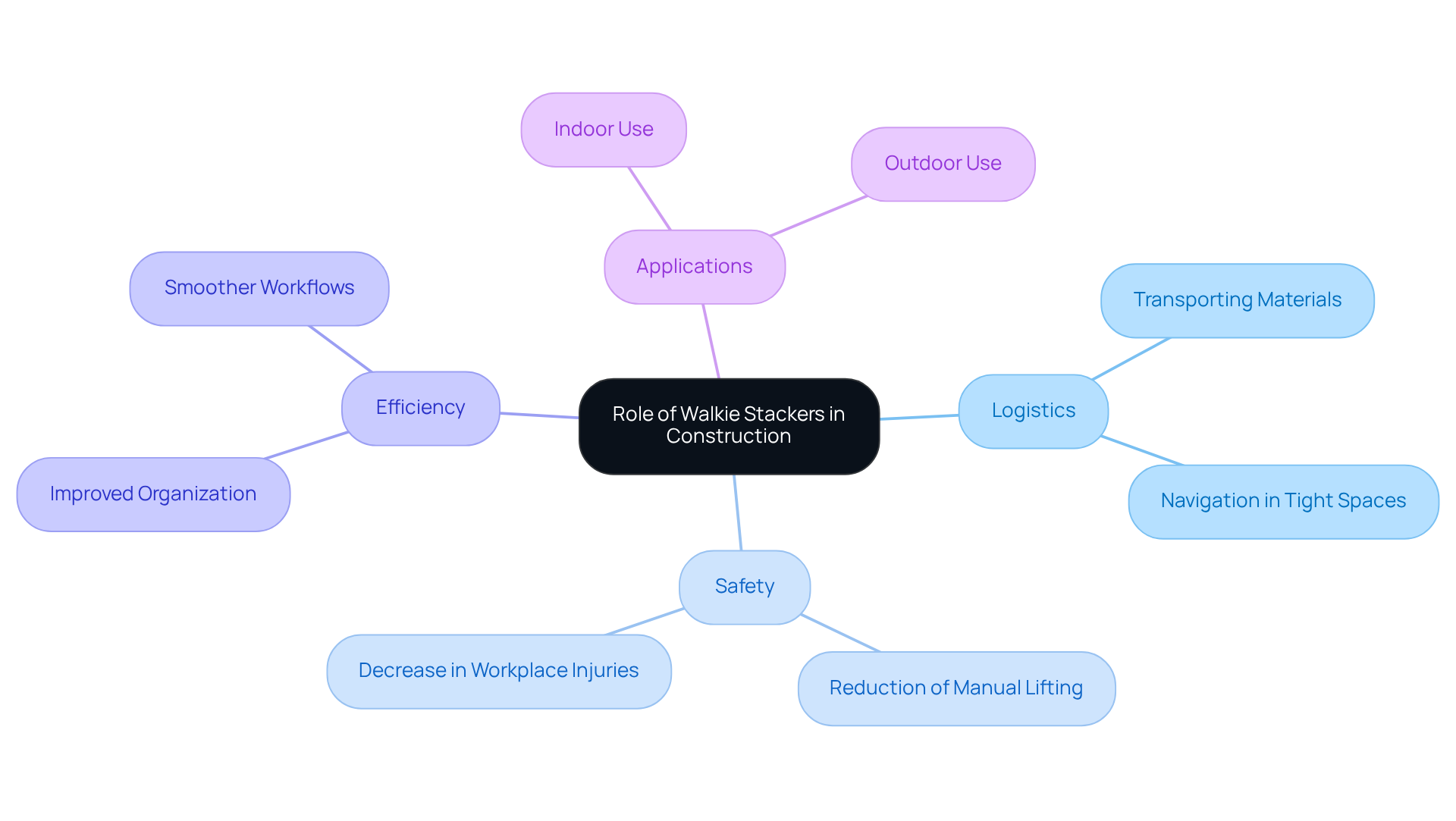

Explore the Role of Walkie Stackers in Construction Operations

In construction activities, forklifts play a vital role in effective logistics, particularly for transporting heavy items over short distances. These machines are commonly used to move materials such as bricks, tiles, and equipment across job sites. Their compact design facilitates easy navigation through tight spaces, making them suitable for both indoor and outdoor applications.

By significantly reducing the need for manual lifting, powered pallet jacks enhance workplace safety and minimize the risk of injuries, such as musculoskeletal disorders, which are prevalent in manual handling tasks. Research indicates that the use of pallet jacks can lead to a substantial decrease in workplace injuries, thereby fostering a safer environment for workers. Furthermore, their ability to stack materials efficiently contributes to improved organization on construction sites, facilitating smoother workflows and enhancing project timelines.

Real-world applications of pallet jacks illustrate their effectiveness in boosting operational efficiency, establishing them as a valuable asset in any construction project.

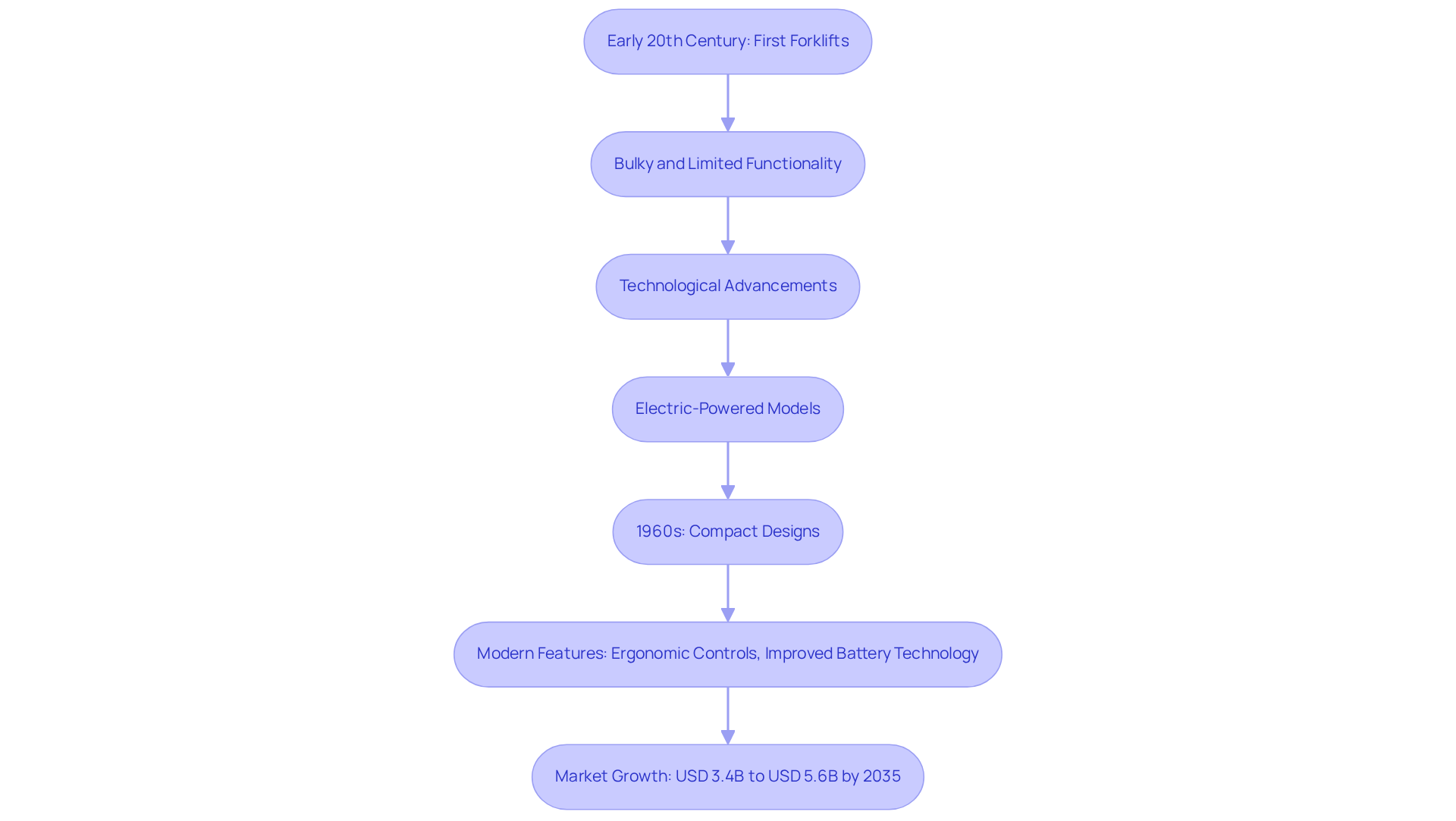

Trace the Evolution of Walkie Stackers: Historical Context

The development of mobile lift trucks dates back to the early 20th century, marking the inception of the first forklifts. Initially, these machines were bulky and limited in functionality. However, over the decades, technological advancements led to the introduction of electric-powered models, which provided greater efficiency and ease of use. A significant turning point occurred in the 1960s with the emergence of more compact and maneuverable designs, enhancing performance in confined spaces.

Today, pallet jacks are equipped with advanced features such as ergonomic controls, improved battery technology, and enhanced safety mechanisms, making them indispensable tools in modern material handling. The pallet jacks market is projected to expand from USD 3.4 billion in 2025 to USD 5.6 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.0%. This growth underscores their increasing importance in the sector. Notably, advancements in battery technology, particularly lithium-ion models, have reduced battery changeovers by 40% and energy costs by 18% compared to lead-acid units. Operators now report cycle times that are up to 14% quicker, thanks to smooth acceleration and precise lift control provided by contemporary equipment.

As the market continues to evolve, the adoption of electric forklifts is accelerating, driven by the demand for energy-efficient solutions and adherence to sustainability goals. This trend highlights the significance of the walkie stacker forklift as an essential piece of equipment in modern logistics and warehousing.

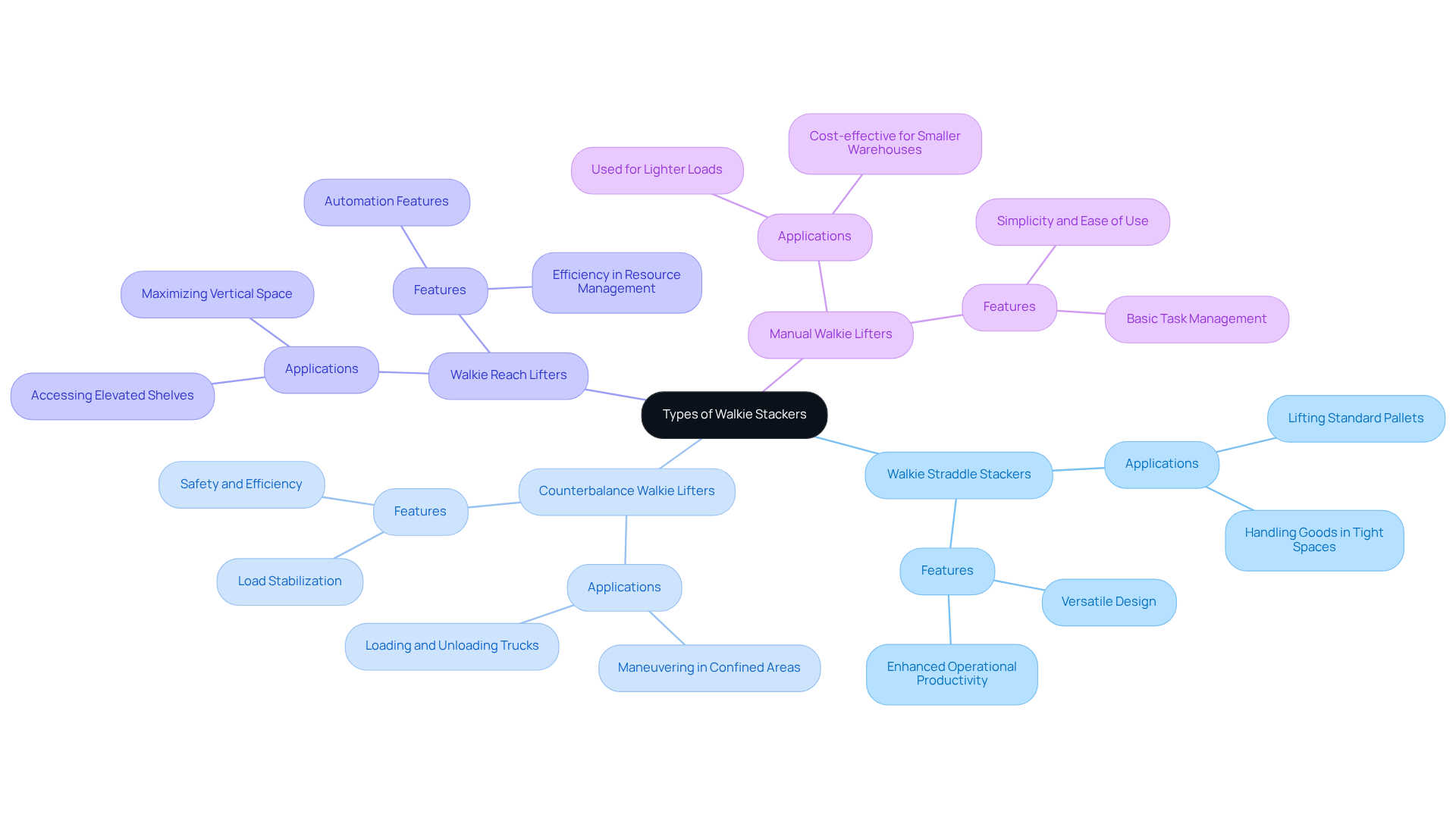

Identify Different Types of Walkie Stackers and Their Applications

Walkie stacker forklifts are essential tools in warehouse operations, designed in various types to cater to specific applications. The most common types include:

-

Walkie Straddle Stackers: These models feature straddle legs that enable them to lift standard pallets, making them versatile for a variety of warehouse tasks. Their design facilitates efficient handling of goods in tight spaces, thereby enhancing operational productivity. Industry specialists note that walkie stacker forklifts are increasingly favored in warehouses due to their adaptability and efficiency in moving items.

-

Counterbalance Walkie Lifters: Utilizing a counterbalance weight for load stabilization, these lifters are ideal for maneuvering in confined areas. They excel in loading and unloading trucks, ensuring both safety and efficiency in cargo management.

-

Walkie Reach Lifters: Designed for high-density storage environments, these lifters can extend their forks to access elevated shelves. This capability is essential for maximizing vertical space in warehouses, which aids in better inventory management. The incorporation of automation features in these models addresses the growing demand for efficiency in resource management.

-

Manual Walkie Lifters: Operated by hand, these devices are typically used for lighter loads, offering a cost-effective solution for smaller warehouses. Their simplicity and ease of use make them a preferred choice for basic task management.

Each type of mobile lifting device, such as the walkie stacker forklift, is crafted to meet specific operational needs, significantly enhancing efficiency and safety in material handling. As the pallet mover market continues to grow, with projections indicating a rise to $5 billion by 2032, the demand for these specialized tools is expected to increase, driven by advancements in automation and sustainability. Notably, electric models of walkie stackers align with global environmental goals, providing eco-friendly solutions with reduced operational costs.

Conclusion

Walkie stacker forklifts play a crucial role in modern material handling, seamlessly blending efficiency with safety across various operational environments. Their design enhances maneuverability in confined spaces, making them particularly suitable for warehouses, construction sites, and retail settings. As electric-powered devices, they not only streamline logistics but also foster a safer workplace by reducing manual lifting and minimizing injury risks.

This article has highlighted key features of walkie stacker forklifts, including their compact design, user-friendly controls, and the variety of types tailored for specific applications. The evolution of these machines from bulky models to advanced electric versions showcases significant technological advancements, which have improved their functionality and efficiency. The expanding market for walkie stackers emphasizes their importance in logistics, with projections indicating sustained demand driven by trends in sustainability and automation.

Adopting walkie stacker forklifts can significantly enhance operational efficiency and safety in material handling processes. As industries increasingly pursue cost-effective and eco-friendly solutions, the significance of these versatile machines will only grow. Investing in walkie stackers not only optimizes workflow but also aligns with broader objectives of sustainability and workplace safety, establishing them as essential tools for any organization aiming to boost productivity.

Frequently Asked Questions

What is a walkie stacker forklift?

A walkie stacker forklift, commonly known as a pallet truck, is an electric-powered material handling device designed for lifting and transporting palletized loads while being operated by an individual walking behind the machine.

What are the key features of a walkie stacker forklift?

Key features include a lifting mast that elevates loads to various heights (typically between 800mm and 1500mm), a compact design for navigating narrow aisles, and a user-friendly control system that enhances operational efficiency.

Where are walkie stacker forklifts typically used?

Walkie stacker forklifts are particularly suited for environments with limited space, making them ideal for warehouses, retail spaces, and construction sites.

What safety features do powered pallet trucks have?

Powered pallet trucks are equipped with safety features such as speed control and emergency stop buttons, which significantly reduce the risk of accidents compared to manual pallet jacks.

What types of pallets can walkie stacker forklifts handle?

Walkie stacker forklifts can handle standard pallet sizes, including the widely used 48" x 40" pallets.

Do operators need a specialized forklift license to use walkie stacker forklifts?

No, operators do not require a specialized forklift license to operate walkie stacker forklifts, making them accessible to a broader range of employees.

How do the costs of walkie stacker forklifts compare to conventional forklifts?

Walkie stacker forklifts are often more than 50% less expensive than conventional forklifts and also have lower maintenance costs, making them an attractive option for small to medium-sized companies looking to improve their logistics operations.

List of Sources

- Define Walkie Stacker Forklift: Key Features and Functionality

- What are the key features and capabilities of a walkie stacker?- Changxing Qiangsheng Machinery Co., Ltd. (https://qslift.com/news/industry-news/what-are-the-key-features-and-capabilities-of-a-walkie-stacker.html)

- What Is a Walk Behind Forklift? 7 Ways to Boost Operations (https://hyworthforklifts.com.au/what-is-a-walk-behind-forklift)

- Materials Handling and Forklift Case Studies | Hyster (https://hyster.com/en-us/north-america/support-resources/case-studies)

- Why Choose a Walkie Stacker over a forklift? (https://clarkforklifts.com.au/news-article/134/Why-Choose-a-Walkie-Stacker-over-a-forklift)

- Forklift Case Studies | Southeast Industrial Equipment Inc. (https://sielift.com/forklift-case-studies)

- Explore the Role of Walkie Stackers in Construction Operations

- Discussing How Pallet Stackers Can Enhance Workplace Safety - Cherry Picker (https://cherrypicker.ie/discussing-how-pallet-stackers-can-enhance-workplace-safety)

- Electric Stacker Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/electric-stacker-market)

- What are the key features and capabilities of a walkie stacker?- Changxing Qiangsheng Machinery Co., Ltd. (https://qslift.com/news/industry-news/what-are-the-key-features-and-capabilities-of-a-walkie-stacker.html)

- Benefits of Walkie Pallet Stackers: Improve Safety & Productivity (https://morrison-ind.com/blog/view/708/walkie-pallet-stackers)

- The Crucial Safety Benefits of Electric Walkie Stackers (https://bullmax.com.my/the-crucial-safety-benefits-of-electric-walkie-stackers)

- Trace the Evolution of Walkie Stackers: Historical Context

- Walkie Stackers Market | Global Market Analysis Report - 2035 (https://futuremarketinsights.com/reports/walkie-stackers-market)

- The Evolution of Forklift Technology: How New Advancements are Changing the Industry - Liftoff Certifications™ (https://liftoffcerts.com/blog/the-evolution-of-forklift-technology-how-new-advancements-are-changing-the-industry)

- Identify Different Types of Walkie Stackers and Their Applications

- Walkie Stacker Market (https://linkedin.com/pulse/walkie-stacker-market-edgesurvey-4azmf)

- Materials Handling and Forklift Case Studies | Hyster (https://hyster.com/en-us/north-america/support-resources/case-studies)