Overview

Horizontal boring machine rental involves the process of renting specialized equipment for creating horizontal passages in construction projects, offering advantages such as reduced upfront costs and access to the latest technology. The article outlines key considerations for rental agreements, costs, and applications, emphasizing the importance of selecting the right machinery to meet specific project needs while minimizing environmental disruption.

Introduction

In the ever-evolving landscape of construction and civil engineering, horizontal boring machines have emerged as indispensable tools, revolutionizing the way underground utilities and infrastructure projects are executed. These machines not only streamline the drilling process but also minimize environmental disruption, making them a preferred choice for contractors facing the complexities of modern projects.

With the market projected for growth and advancements in technology, understanding the nuances of these machines—from rental costs to brand comparisons—becomes crucial for project managers aiming to enhance efficiency and ensure successful outcomes.

As the demand for reliable and precise drilling solutions continues to rise, navigating the intricacies of horizontal boring machines can empower contractors to make informed decisions that align with their project needs and budget constraints.

Understanding Horizontal Boring Machines: An Overview

Horizontal boring equipment represents a crucial asset in modern construction and civil engineering, specifically designed for creating horizontal passages through diverse materials such as soil, rock, and concrete. These machines play a crucial role in various tasks, including the installation of underground utilities, pipelines, and drainage systems. Their advanced design typically incorporates powerful rotary drills and augers, enabling efficient and precise drilling that significantly reduces the need for extensive excavation.

This capability minimizes disruption to the surrounding environment, which is increasingly important in urban settings. Current statistics reveal that 22% of contractors frequently encounter voids in the ground, underscoring the necessity for reliable equipment that can navigate complex subsurface conditions. Significantly, the trend towards personalized solutions is clear, with 47% of Maxi rigs surveyed being adjusted to meet specific requirements.

Additionally, contractors surveyed possess a total of 185 drilling units, with:

- 38% classified as Mini size

- 33% as Midi rigs

- 29% as Maxi rigs

This highlights the diverse market landscape. As Mike Manna, General Manager of Milwaukee Machine Works, points out,

We also have a G&L MC 1250, on which we run our most critical tolerance parts, and it has an excellent performance history.

This highlights the significance of choosing the appropriate machinery for attaining optimal results in various endeavors.

Furthermore, the industrial market presents unique challenges for HDD due to the complexity of crossing numerous buried utilities, as discussed in recent case studies. Comprehending the mechanics and functions of lateral drilling equipment is crucial for any construction supervisor considering horizontal boring machine rental for their upcoming assignments, particularly given recent advancements and the market's anticipated growth in 2024.

The Rental Process: Costs and Considerations for Horizontal Boring Machines

Renting a horizontal boring machine rental involves a systematic approach that begins with selecting a reputable rental company. Understanding the intricacies of rental agreements is essential, as these documents contain vital information about costs and responsibilities. Rental prices are affected by various elements, including the size of the machine, the length of the rental, and any extra features needed for the task.

On average, renters can expect to pay between $10 and $30 per linear foot, with total expenses generally varying from $1,000 to $9,000, depending on specifics. It's important to note that additional costs, such as:

- Tree removal (ranging from $300 to $2,000)

- Boulder excavation (costing between $50 and $200 per cubic yard)

can significantly impact the overall budget. Additionally, costs for delivery, maintenance, and insurance may apply.

As noted by industry experts, "Factors such as scope and terrain can significantly influence the overall costs of a horizontal boring machine rental endeavor, making it essential to carefully evaluate these elements during the budgeting process." Before finalizing a rental agreement, it is crucial to meticulously review the terms and conditions, paying special attention to clauses related to damages, usage limits, and maintenance responsibilities. Being aware of these factors allows renters to avoid unforeseen costs and choose the most appropriate device for their requirements.

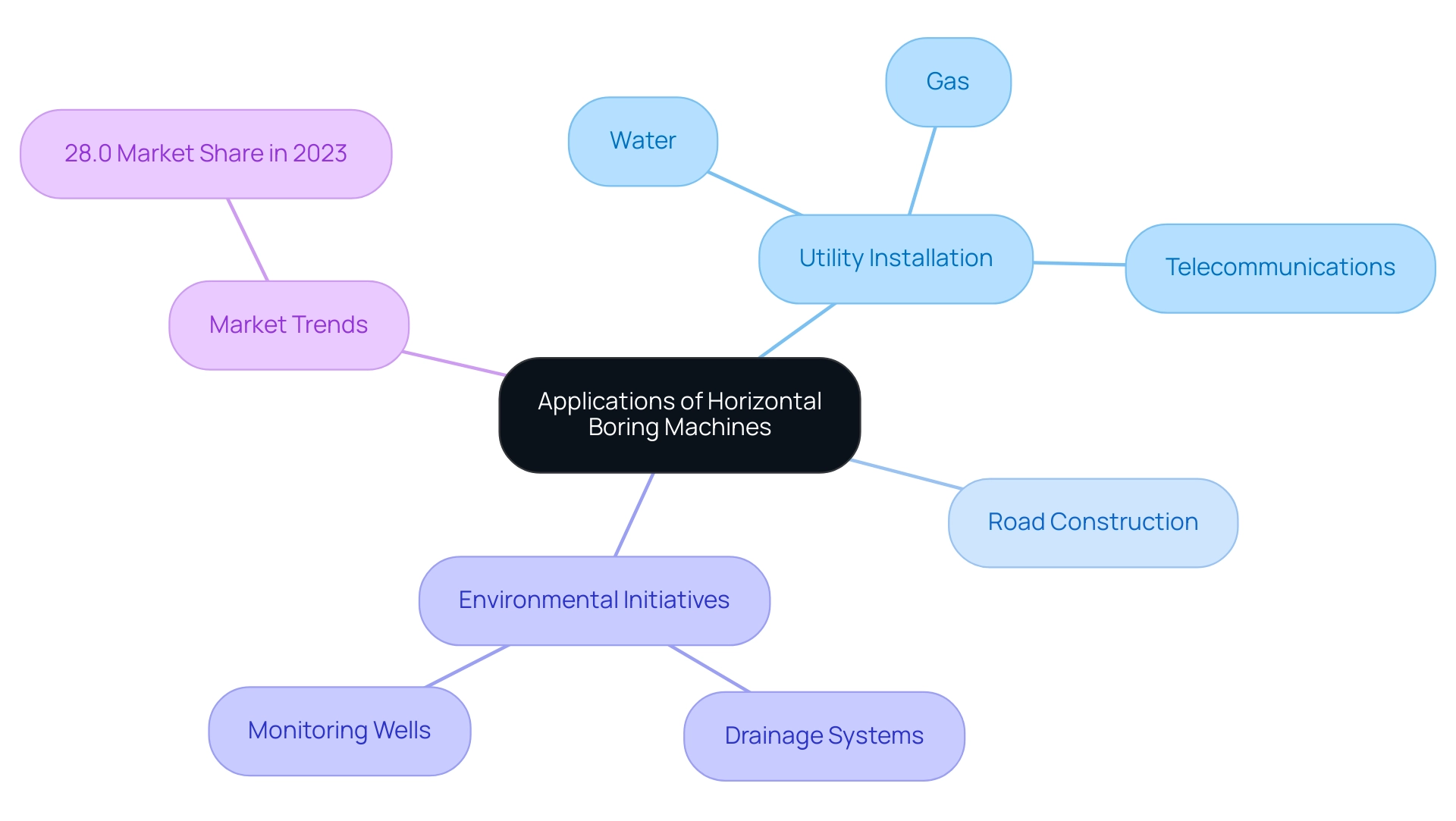

Applications of Horizontal Boring Machines in Various Projects

Horizontal boring machine rental has become crucial in various construction endeavors, especially for the installation of underground utilities like water, gas, and telecommunications lines. Their application is particularly evident in road construction, where the use of horizontal boring machine rental to bore beneath existing infrastructure helps minimize surface disruption, ensuring that traffic and local environments remain largely unaffected. Furthermore, these devices are pivotal in environmental initiatives, and the horizontal boring machine rental facilitates the installation of drainage systems and monitoring wells crucial for ecological assessments.

Their capacity for precise and controlled drilling through horizontal boring machine rental not only enhances efficiency but also addresses the challenges posed by traditional excavation methods, which can be both disruptive and costly. A recent examination of horizontal boring machine rental for directional drilling (HDD) initiatives emphasizes that as infrastructure investment grows, the anticipated rise in HDD initiatives further highlights the significance of these horizontal boring machines. According to a survey, 74% of contractors acquire between 75% and 100% of their work through a competitive bidding process, suggesting that the use of advanced technologies such as tunneling equipment can offer a competitive advantage.

Furthermore, the case study titled 'Horizontal Directional Drilling (HDD) Damage Analysis' reveals that excavators are the primary source of damage reports, emphasizing the need for careful planning and execution in HDD endeavors. Industry experts, like Brian Moore from NICCA USA, emphasize the quality of research and technological advancements that support these applications, stating,

The quality of research they have done for us has been excellent.

This indicates a wider acknowledgment of the function of lateral drilling equipment and the use of horizontal boring machine rental in utility installation, with projects progressively embracing this technology to satisfy contemporary needs.

Moreover, the transition rod segment captured the largest market share at 28.0% in 2023, emphasizing the technological progress and market trends associated with lateral drilling equipment.

Renting vs. Buying: Evaluating the Benefits of Horizontal Boring Machine Rental

When assessing the option between horizontal boring machine rental and buying a horizontal boring device, contractors must consider several essential factors. Renting equipment, such as a horizontal boring machine rental, offers distinct advantages, particularly for those needing it for a limited timeframe. This option not only removes the burden of high upfront costs but also alleviates concerns regarding ongoing maintenance and depreciation.

Furthermore, horizontal boring machine rental provides access to the latest models and technologies, ensuring that contractors can leverage the best available equipment for their tasks. A recent analysis indicates that if a machine is owned and utilized for only eight months, the effective monthly cost can escalate to $9,750, highlighting the financial implications of ownership. In contrast, purchasing may be more beneficial for companies that frequently undertake tasks requiring such machinery, as it can yield substantial long-term savings.

Craig, an industry expert, notes,

Incorporating rental equipment into a fleet program with a critical and strategic mindset enables the company to be more effective in the usage of resources and capital.

The case study of Holt of California exemplifies this approach, as they offer a wide selection of rental equipment, particularly horizontal boring machine rental, and emphasize the importance of professionalism and experience in rental partnerships. Their commitment to compliance with emissions standards and customer support helps businesses navigate equipment rental effectively.

Ultimately, the decision should be carefully guided by the frequency of upcoming endeavors, budget constraints, and the specific operational needs for horizontal boring machine rental. Current trends reveal that contractors are increasingly analytical about equipment costs, leading to improved business efficiency, whether they choose to rent, lease, or buy. Additionally, utilizing construction administration software can maximize value and streamline processes, further supporting informed decisions regarding equipment rental and purchasing.

Top Brands and Models for Horizontal Boring Machine Rentals

The market for horizontal boring machines features several top brands renowned for their quality and performance, with Vermeer, Ditch Witch, and Case leading the way. Notably, the transition rod segment held the largest share, accounting for 28.0% in 2023, reflecting significant trends in the industry. Each manufacturer offers a diverse range of models suited to different sizes and specific requirements.

For instance, Vermeer’s D24x40S3 model is renowned for its compact design and efficiency, making it particularly suited for urban infrastructure initiatives where space is limited and precision is key. Conversely, Ditch Witch’s JT20 is highly regarded for its robust drilling capabilities, ideal for navigating tougher terrains and larger installations. As Pama, a prominent tools company, states, "Now the organization produces the best quality drilling and milling equipment in the world," underscoring the importance of quality in selection.

When assessing horizontal boring machine rental choices, it is crucial to examine particular characteristics of each model—including drilling depth, torque, and user-friendliness—to ensure the equipment meets the requirements of your endeavor. Additionally, understanding the impact of the COVID-19 pandemic on the horizontal boring milling machine market can provide insights into market resilience and potential challenges. By recognizing these distinctions, project managers can make informed decisions that align with project requirements and operational efficiency.

Conclusion

Horizontal boring machines have transformed the construction and civil engineering industries, offering efficient solutions for underground utility installation while minimizing environmental disruption. Understanding the mechanics, applications, and market trends surrounding these machines is crucial for construction project managers aiming to optimize their project outcomes.

The rental process for horizontal boring machines involves careful consideration of costs and project requirements. By evaluating rental agreements and understanding the factors influencing pricing, contractors can make informed decisions that align with their budget and operational needs. The choice between renting and buying further emphasizes the need for a strategic approach, balancing immediate project demands against long-term financial implications.

As the market for horizontal boring machines continues to grow, selecting the right brand and model becomes essential for maximizing performance. Top manufacturers provide a range of options tailored to different project specifications, reinforcing the importance of choosing equipment that meets specific operational demands.

Navigating the complexities of horizontal boring machines not only enhances project efficiency but also positions contractors to meet the increasing demands of modern infrastructure projects. By leveraging the insights gained from this article, stakeholders can make strategic decisions that lead to successful project execution and sustainable growth in an evolving market.

Frequently Asked Questions

What is horizontal boring equipment used for?

Horizontal boring equipment is designed for creating horizontal passages through materials such as soil, rock, and concrete, primarily for tasks like installing underground utilities, pipelines, and drainage systems.

How does horizontal boring equipment benefit urban construction?

It minimizes disruption to the surrounding environment, which is particularly important in urban settings, by reducing the need for extensive excavation.

What percentage of contractors encounter voids in the ground?

Statistics reveal that 22% of contractors frequently encounter voids in the ground, highlighting the necessity for reliable equipment.

What types of drilling units do contractors typically possess?

Contractors surveyed possess a total of 185 drilling units, with 38% classified as Mini size, 33% as Midi rigs, and 29% as Maxi rigs.

Why is it important to choose the appropriate machinery for horizontal boring?

Choosing the right machinery is crucial for achieving optimal results in various construction endeavors, as highlighted by industry experts.

What challenges does the industrial market face regarding horizontal directional drilling (HDD)?

The industrial market faces unique challenges due to the complexity of crossing numerous buried utilities, which requires a comprehensive understanding of lateral drilling equipment.

What should one consider when renting a horizontal boring machine?

It's essential to select a reputable rental company, understand rental agreements, and evaluate costs based on machine size, rental length, and additional features.

What are the average rental costs for horizontal boring machines?

Renters can expect to pay between $10 and $30 per linear foot, with total expenses generally ranging from $1,000 to $9,000, depending on specific factors.

What additional costs might affect the overall budget for renting a horizontal boring machine?

Additional costs can include tree removal ($300 to $2,000), boulder excavation ($50 to $200 per cubic yard), as well as delivery, maintenance, and insurance fees.

What should renters pay attention to in rental agreements?

Renters should carefully review terms and conditions, focusing on clauses related to damages, usage limits, and maintenance responsibilities to avoid unforeseen costs.