Overview

This article serves as a comprehensive guide for those looking to rent a MIG welder. It outlines essential steps, including:

- Assessing project requirements

- Exploring local rental services

- Comparing prices and specifications

By detailing the process of identifying the right equipment based on power needs and project scope, it empowers readers to make informed decisions. Furthermore, practical tips for ensuring a successful rental experience, such as checking reviews and preparing the workspace, are provided to enhance reliability and quality.

When considering a rental, it is crucial to evaluate your specific project needs. This involves understanding the power requirements of the MIG welder and how it aligns with the scope of your project. By focusing on these aspects, you can ensure that you select the most suitable equipment for your tasks. In addition, exploring local rental services allows for a comparison of options, ensuring both quality and affordability.

To further enhance your rental experience, it is advisable to check reviews and testimonials from previous customers. Their insights can provide valuable information about the reliability of the rental service and the quality of the equipment offered. Preparing your workspace in advance also contributes to a smoother rental process, allowing you to focus on the task at hand.

In conclusion, renting a MIG welder can be a straightforward process if approached methodically. By assessing your needs, exploring options, and preparing adequately, you can ensure a successful rental experience. Take action now and explore local rental services to find the equipment that best meets your project requirements.

Key Highlights:

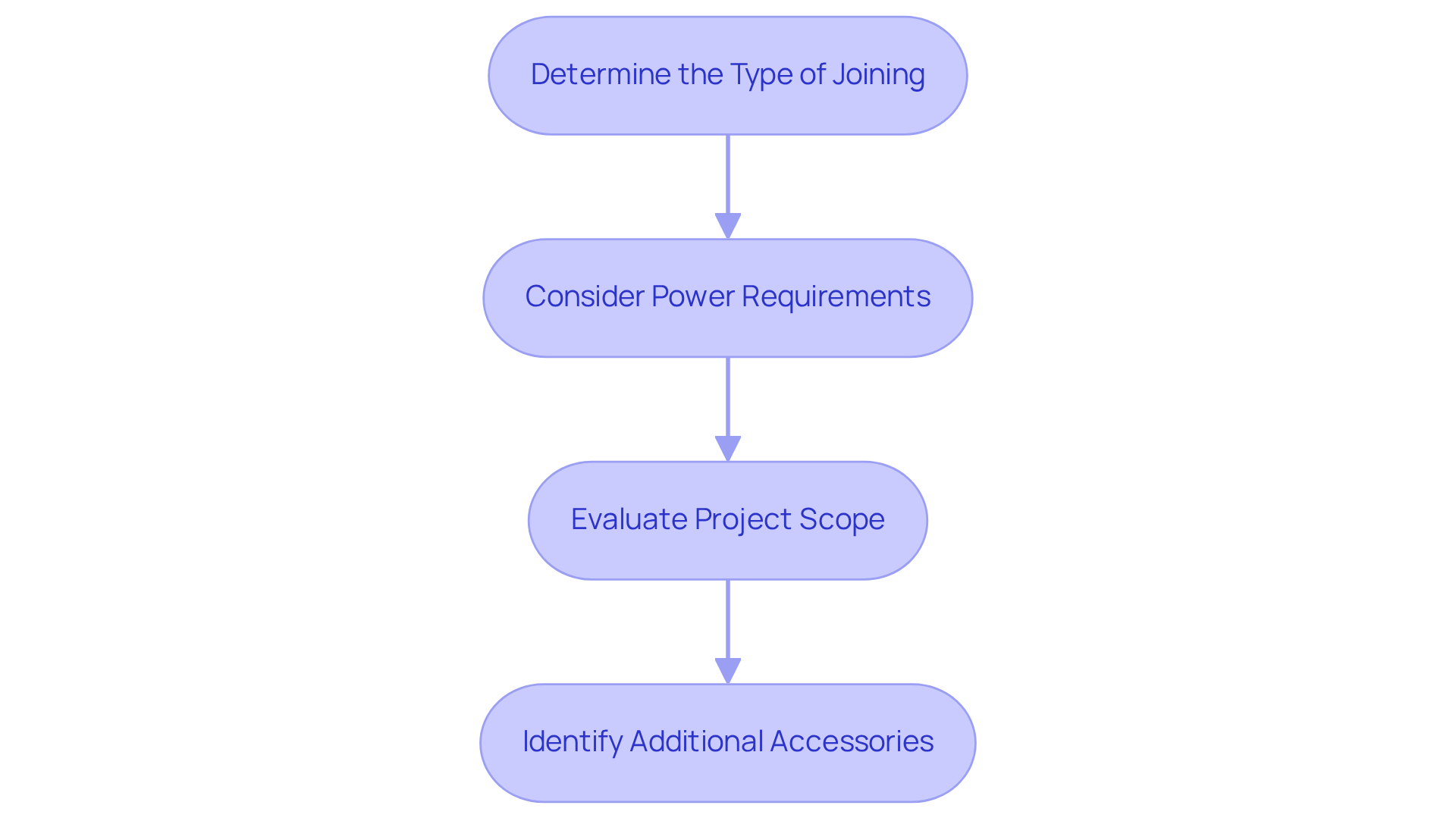

- Identify specific joining tasks to determine the type of MIG welder required for projects.

- Assess the power supply available, ensuring compatibility with the MIG welder's voltage needs (110V or 220V).

- Evaluate the project scope to choose a welder with appropriate amperage and capabilities.

- Consider essential accessories such as gas cylinders, protective gear, and safety training for effective welding.

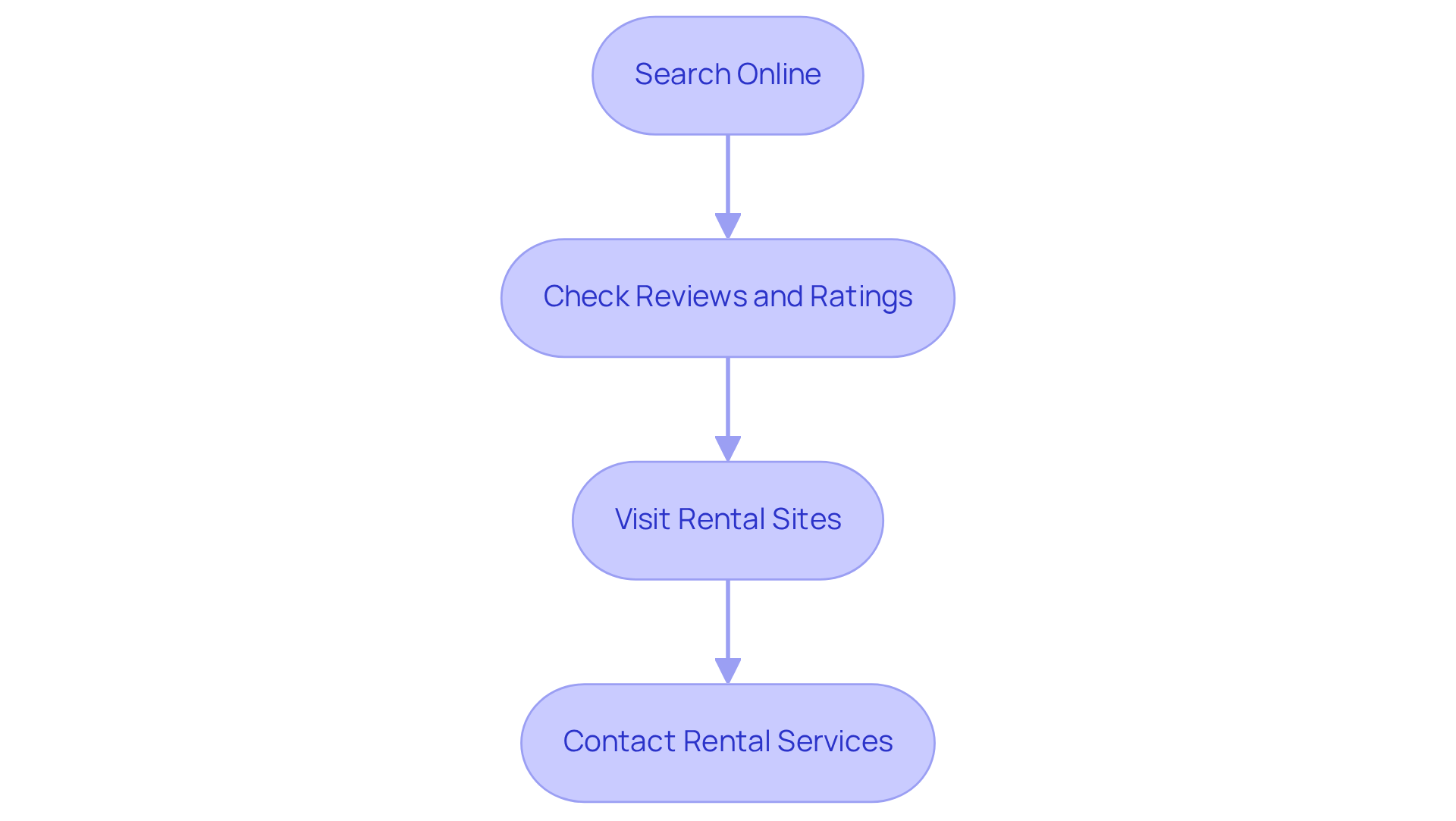

- Search online for local equipment rental services and cheque reviews to gauge reliability.

- Contact rental services for equipment availability and inquire about additional offerings like delivery.

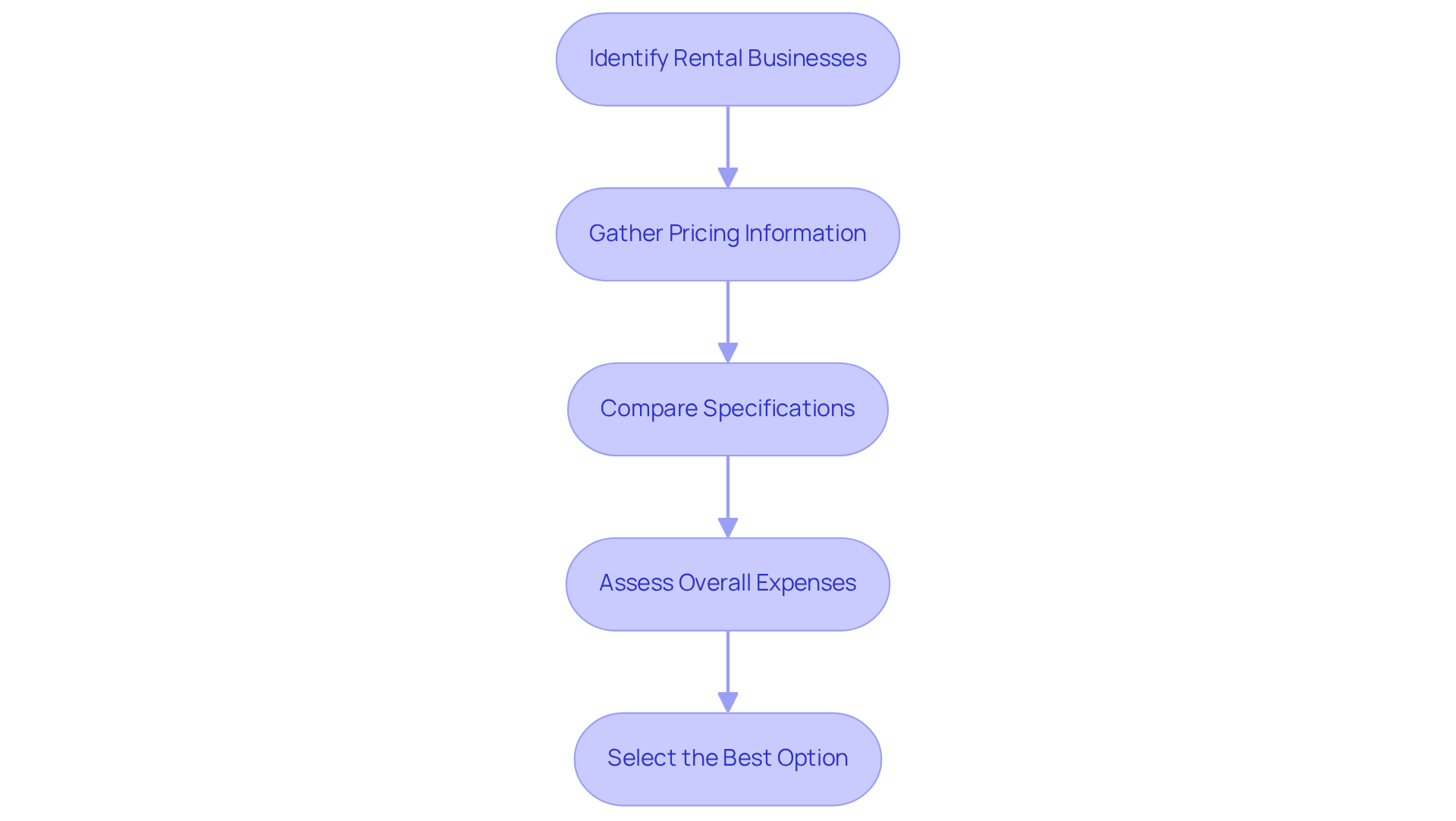

- Compare rental prices and specifications, including amperage and duty cycle, to find the best value.

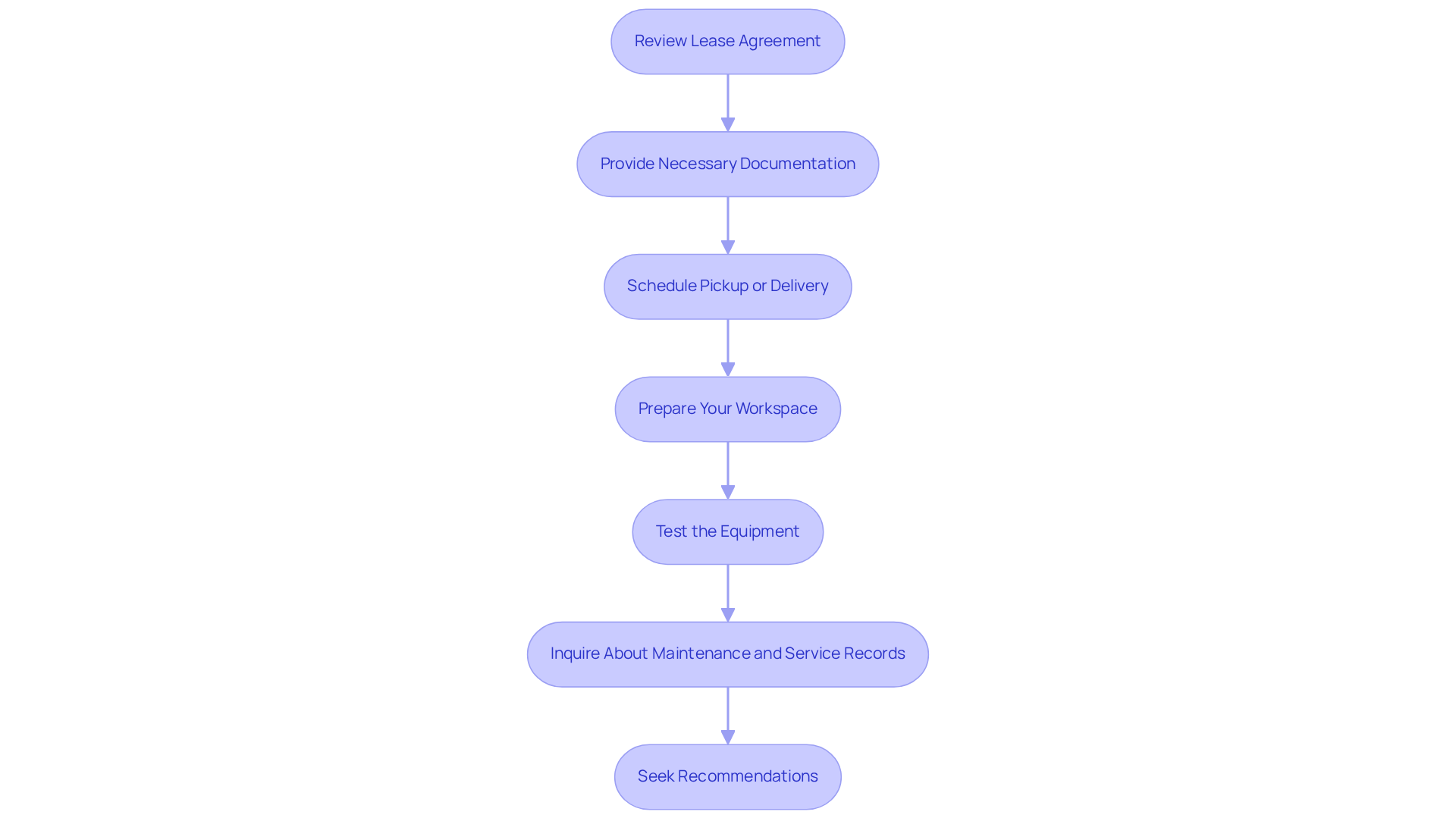

- Review the lease agreement carefully, providing necessary documentation for the rental.

- Prepare the workspace adequately for safety and efficiency before using the welder.

- Test the equipment to ensure comfort with its operation before starting the project.

Introduction

Navigating the world of welding can be daunting, particularly when selecting the right equipment for a project. MIG welders offer remarkable versatility, yet the challenge extends beyond understanding their specifications; it also involves identifying the ideal rental service that caters to specific needs. This guide serves as a comprehensive roadmap for assessing requirements, comparing rental options, and finalizing agreements. By following this guide, both novice and experienced welders can confidently tackle their metalworking projects.

But what factors truly determine the best rental choice? Understanding the nuances of each rental service is crucial to avoiding common pitfalls in the process. By evaluating the reliability and quality of equipment, you can make informed decisions that enhance your welding experience. In addition, testimonials from satisfied customers can provide insight into the effectiveness of various rental services, further guiding your selection process.

Assess Your MIG Welder Requirements

-

Determine the Type of Joining: Begin by identifying the specific joining tasks you need to accomplish. Whether it involves light fabrication, heavy-duty projects, or working with materials such as aluminum or stainless steel, the type of welding required will dictate the specifications for the individual performing the task.

-

Consider Power Requirements: Assess the power supply available at your worksite. Most MIG machines operate on either 110V or 220V. It is crucial to ensure that you have the appropriate outlet and extension cords to meet the equipment's requirements. For instance, a metal worker with a 60% duty cycle at 100 amps can operate continuously for 6 minutes before requiring a 4-minute rest. Additionally, 240V power has various levels designed to carry different amounts of current, including 10 Amp, 15 Amp, 20 Amp, 25 Amp, and 32 Amp, each suitable for specific types of welding machines and plasma cutters. This underscores the importance of aligning the operator's power needs with your project's requirements.

-

Evaluate Project Scope: Analyze the size and complexity of your project. Larger jobs typically demand a more powerful machine with higher amperage. For example, welders in the hobby to semi-professional market generally range from £200 to £500, with varying capabilities tailored for different project scales. Understanding these cost ranges can aid you in budgeting effectively for your metalworking needs.

-

Identify Additional Accessories: Do not overlook the necessity for essential accessories such as gas cylinders, protective helmets, gloves, and other safety gear. These items are vital for ensuring safe and effective metal joining operations. Proper personal protective equipment (PPE) and adherence to safety protocols are critical for compliance and safety during metalworking tasks. Regular safety training sessions for welding personnel are essential for compliance and to foster a safe working environment.

Explore Local Equipment Rental Services

-

Search Online: Harness the power of search engines to find local equipment leasing services. Using phrases like 'where can I rent a MIG welder' can yield valuable results that connect you with nearby providers.

-

Check Reviews and Ratings: Investigate customer feedback on platforms such as Yelp or Google. This assessment will help you gauge the reliability and quality of service offered by various leasing providers.

-

Visit Rental Sites: Take the time to explore the websites of local equipment providers, including EZ Equipment Leasing, Sunbelt Equipment, and United Equipment. Here, you can find out where can I rent a MIG welder and discover their available MIG machines and other essential tools.

-

Contact Rental Services: Engage directly with leasing providers to inquire about equipment availability, service terms, and any additional offerings they may have, such as delivery or setup assistance.

Compare Rental Prices and Equipment Specifications

When evaluating MIG rental options, it is essential to begin by identifying potential rental businesses in your area. EZ Equipment Rental stands out as a reliable choice, offering a diverse range of welding equipment designed to meet various project needs. Next, gather pricing information by contacting these companies for estimates on the MIG machines that interest you. Be sure to inquire about daily, weekly, and monthly leasing prices; for example, EZ Equipment Rental lists MIG machine leasing costs at $84 per day, $336 per week, and $1,008 for four weeks.

Once you have collected the pricing details, compare the specifications of the available welders. Key specifications to consider include:

- Amperage

- Duty cycle

- Additional features such as portability and included accessories

For instance, the Electric Wire MIG Welder available at EZ Equipment Rental has a compact width of 10.5 inches, making it suitable for a variety of applications.

Furthermore, it is crucial to assess the overall expenses associated with each leasing option. This includes not only the base lease rates but also any potential additional fees, such as delivery charges, insurance, or deposits. As noted by financial experts, renting equipment can help preserve cash flow for small businesses, making it a strategic financial decision. By calculating the total cost for each option, you can identify which leasing service provides the best value for your specific needs. This thorough evaluation process will ensure that you select the most suitable MIG welder for your project, effectively balancing quality and cost-effectiveness.

Finalize Your Rental Agreement and Prepare for Use

-

Review Lease Agreement: Carefully read through the lease agreement, paying close attention to terms regarding duration, fees, and responsibilities for damages. It is crucial to clarify terms regarding liability for accidents or injuries to fully understand your responsibilities.

-

Provide Necessary Documentation: Be prepared to present identification and any required documentation, such as a credit card for deposits. Statistics indicate that nearly 70% of leasing services demand proof of identity and financial accountability, underscoring the importance of having these documents readily available.

-

Schedule Pickup or Delivery: Arrange for the pickup of the MIG welder or schedule a delivery time that suits your needs. Many rental companies offer delivery services, which can save you time and ensure the equipment arrives in optimal condition.

-

Prepare Your Workspace: Ensure your workspace is adequately prepared for metal joining. This includes having proper ventilation, safety gear, and a clean area free of flammable materials. Proper workspace preparation is vital for safety and efficiency during your welding project.

-

Test the Equipment: Once you have the welder, conduct a test run to familiarize yourself with its settings and operation before starting your actual project. This step is essential to ensure that you feel comfortable with the equipment and can operate it safely.

-

Inquire About Maintenance and Service Records: Before concluding your lease, ask the provider about their maintenance plan and service records for the equipment. Understanding the maintenance history is crucial for ensuring the reliability of the rented equipment.

-

Seek Recommendations: Consider reading reviews and seeking recommendations from other contractors to ensure you choose a reliable rental company. This can provide valuable insights into the quality of service and equipment offered.

Conclusion

Understanding the process of renting a MIG welder is essential for anyone looking to undertake metalworking projects efficiently and safely. By carefully assessing your specific welding needs, considering power requirements, and evaluating the scope of your project, you can select the right equipment to ensure successful results. This guide outlines the critical steps involved in:

- Finding rental services

- Comparing prices

- Evaluating specifications to make an informed choice

Key insights from this guide highlight the importance of:

- Researching local equipment rental services

- Checking customer reviews

- Understanding the specifications of the MIG welders available

Furthermore, finalizing your rental agreement with attention to detail and adequately preparing your workspace are vital steps that contribute to a smooth rental experience. By following these guidelines, the process of renting a MIG welder can be streamlined, allowing you to focus on the project at hand.

Ultimately, taking the time to thoroughly assess your needs and explore rental options can lead to more efficient and cost-effective metalworking endeavors. Whether you are a hobbyist or a professional, leveraging local rental services not only saves money but also ensures access to the right tools for the job. Embrace the opportunity to enhance your skills and tackle your projects with confidence by utilizing the resources available in your area.

Frequently Asked Questions

How do I determine the type of joining required for my MIG welding project?

Begin by identifying the specific joining tasks you need to accomplish, such as light fabrication, heavy-duty projects, or working with materials like aluminum or stainless steel. The type of welding required will dictate the specifications for the individual performing the task.

What power requirements should I consider for my MIG welder?

Assess the power supply available at your worksite, as most MIG machines operate on either 110V or 220V. Ensure you have the appropriate outlet and extension cords for the equipment. For example, a metal worker with a 60% duty cycle at 100 amps can operate continuously for 6 minutes before requiring a 4-minute rest.

What are the different power levels available for 240V MIG welders?

240V power has various levels designed to carry different amounts of current, including 10 Amp, 15 Amp, 20 Amp, 25 Amp, and 32 Amp. Each level is suitable for specific types of welding machines and plasma cutters.

How does the size and complexity of a project affect the choice of MIG welder?

Larger jobs typically demand a more powerful machine with higher amperage. Welders in the hobby to semi-professional market generally range from £200 to £500, with varying capabilities tailored for different project scales.

What additional accessories should I consider when setting up for MIG welding?

Essential accessories include gas cylinders, protective helmets, gloves, and other safety gear. These items are vital for ensuring safe and effective metal joining operations.

Why is personal protective equipment (PPE) important in MIG welding?

Proper PPE and adherence to safety protocols are critical for compliance and safety during metalworking tasks. Regular safety training sessions for welding personnel are essential to foster a safe working environment.