Key Highlights:

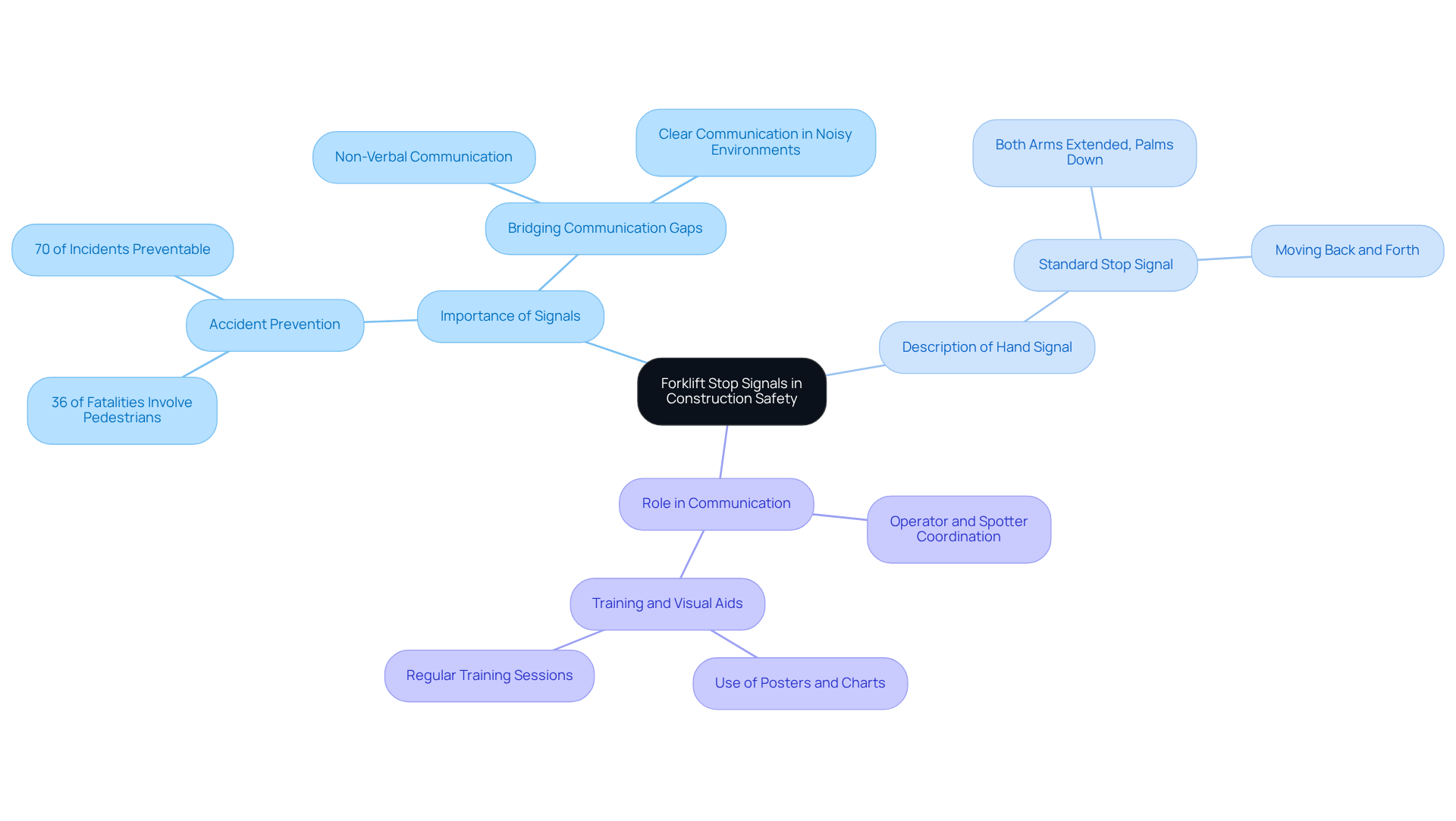

- Forklift stop signals are vital for safety on construction sites, allowing for swift non-verbal communication between operators and ground personnel.

- The hand signal to stop a forklift involves both arms extended with palms down, serving as a universally recognised gesture to halt operations.

- Ignoring hand signals can lead to serious accidents, including collisions and injuries, with historical data showing over 1,000 forklift-related deaths in the U.S. from 1980 to 1994.

- OSHA reports indicate that forklifts are responsible for approximately 85 fatalities and 34,900 serious injuries annually in the U.S.

- Common issues include insufficient training and lack of safety evaluations, highlighting the need for improved safety measures in forklift operations.

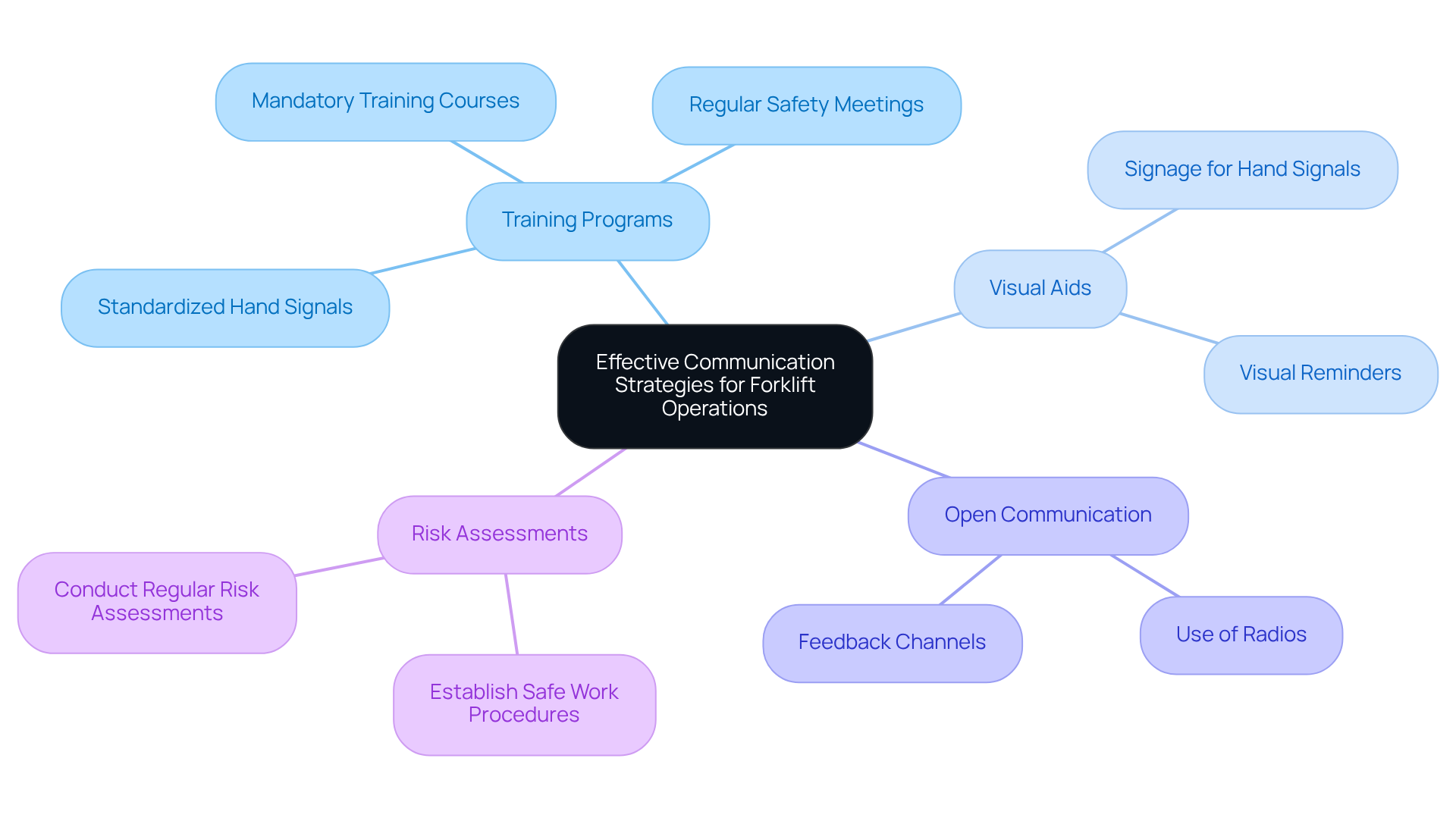

- Effective communication strategies, including training on standardised signals and regular safety meetings, are essential for reducing risks in construction environments.

- Visual aids and open communication channels between lift operators and ground staff can enhance safety, especially in noisy settings.

- Incorporating risk assessments and safe work procedures is crucial for accident prevention and fostering a culture of safety in the workplace.

Introduction

Effective communication stands as the backbone of safety on construction sites, especially when operating heavy machinery like forklifts. The hand signal to stop a forklift is not merely a gesture; it serves as a critical lifeline that can prevent accidents and save lives. In increasingly chaotic construction environments, the stakes are higher than ever, making it essential for workers to grasp and effectively utilize these signals.

What are the consequences when these signals are overlooked? Organizations must ensure their teams are equipped with the knowledge to prioritize safety, fostering a culture where communication is paramount.

Understand the Importance of Forklift Stop Signals in Construction Safety

Forklift stop signals are essential for safety on construction sites. These signals provide a non-verbal communication method that enables operators and ground personnel to relay critical information swiftly and effectively. In the often chaotic environment of a construction site, where machinery operates alongside workers, clear communication is vital.

The hand signal to stop a forklift is characterized by both arms extended with palms facing down and moving back and forth, making it a universally recognized gesture that commands immediate cessation of operations. This signal is crucial for accident prevention, allowing spotters to alert operators to potential hazards that may not be visible to them. Furthermore, relying on hand signals bridges communication gaps that can arise due to noise or distance, ensuring all team members are informed about the vehicle's operational status and can respond appropriately.

Explore the Consequences of Ignoring Forklift Hand Signals

Ignoring hand signals from the lift can lead to dire consequences for individuals and organizations in the construction sector. The risks are substantial; improper signaling can cause collisions between lifting trucks and pedestrians, resulting in injuries that are often preventable. From 1980 to 1994, statistics show there were 1,021 forklift-related deaths in the U.S., translating to a staggering 27,505 years of productive life lost, with many incidents arising from inadequate communication protocols. Furthermore, businesses that fail to comply with OSHA regulations regarding lift truck operations may face severe legal repercussions, including hefty fines and increased liability. For instance, Washington State's construction sector reported a fatality rate of 8.7 per 100,000 workers, underscoring the critical need for adherence to safety protocols.

As highlighted by Jasdev Grewal, common issues include insufficient training and a lack of safety evaluations related to lift truck operations, emphasizing the urgent need for improved safety measures. The financial ramifications of accidents extend beyond immediate costs; they can lead to soaring insurance premiums and long-lasting damage to a company's reputation. By recognizing these risks, construction teams can better understand that the hand signal to stop a forklift is an important aspect of consistent and clear signals through hand gestures, ultimately fostering a safer work environment. It's time to prioritize safety and communication in the workplace.

Investigate the Origins and Standards of Forklift Hand Signals

The need for efficient communication in the loud and hazardous environments typical of construction sites led to the development of what the hand signal to stop a forklift is. As the construction industry evolved, so did the methods of interaction among workers. The establishment of standardized hand signals, such as the hand signal to stop a forklift, emerged as a crucial response to the growing complexity of construction operations and the need for clear, concise communication. Organizations like OSHA, a recognized training provider for over 25 years, have developed guidelines that specify particular hand signals, including that the hand signal to stop a forklift is essential during material handling operations. This underscores the significance of their guidelines in preventing incidents, as OSHA statistics reveal that forklifts are responsible for approximately 85 fatalities and 34,900 serious injuries each year in the United States.

By adhering to these established protocols, construction teams not only enhance safety but also foster a culture of responsibility and professionalism. A culture of well-being necessitates ongoing education and reinforcement, highlighting the importance of a continuous commitment to safety practices. Furthermore, situational awareness is vital in ensuring that all personnel can respond effectively to potential hazards. By implementing these measures, construction teams can significantly mitigate the risk of accidents and cultivate a safer working environment for everyone involved.

Implement Effective Communication Strategies for Forklift Operations

To enhance security during lifting vehicle operations, implementing effective interaction strategies is essential. Training programs must be established to ensure all personnel are well-versed in standardized hand signals, such as the hand signal to stop a forklift, and their meanings. Regular safety meetings will reinforce these protocols and provide a platform for discussing challenges encountered on the job site. Alarmingly, statistics reveal that 20% of fatalities result from pedestrians being struck by industrial trucks, underscoring the critical need for efficient interaction.

In addition, utilizing visual aids, such as signage displaying that the hand signal to stop a forklift is a constant reminder for workers. Promoting open communication channels between lift operators and ground staff is vital; this can be achieved through radios or other messaging devices, especially in noisy environments. As Jasdev Grewal noted, inadequate training and awareness initiatives significantly increase risks for warehouse employees. By fostering a culture of safety and communication, construction teams can substantially reduce the likelihood of accidents, ensuring that all workers remain aware of their surroundings and the operational status of lifting machines.

Furthermore, incorporating risk assessments and safe work procedures is crucial in accident prevention, as highlighted in various case studies on forklift operations. By prioritizing these strategies, organizations can create a safer work environment, ultimately leading to improved operational efficiency and worker safety.

Conclusion

The importance of the hand signal to stop a forklift is paramount in the realm of construction safety. This essential gesture acts as a universal communication tool, significantly enhancing safety and preventing accidents on bustling job sites. By promoting clear, non-verbal communication, the hand signal enables operators and ground personnel to collaborate effectively, thereby minimizing the risk of injuries and fostering a safer working environment.

Key points throughout this discussion have underscored the critical role of these hand signals in accident prevention. Ignoring such signals can lead to severe consequences, including preventable injuries and fatalities, as supported by alarming statistics. Moreover, the establishment of standardized hand signals, backed by organizations like OSHA, highlights the necessity for consistent training and adherence to safety protocols. By implementing effective communication strategies - such as regular training sessions and the use of visual aids - construction teams can significantly lower the likelihood of accidents.

Ultimately, prioritizing the understanding and application of the hand signal to stop a forklift is vital for cultivating a safety-first culture in the construction industry. Given the high stakes involved, it is crucial for all personnel to engage in ongoing education and communication. By committing to these practices, organizations not only safeguard their workers but also enhance operational efficiency and bolster their reputation. Embracing these principles will lead to a safer, more responsible work environment where every team member contributes to the collective well-being.

Frequently Asked Questions

Why are forklift stop signals important in construction safety?

Forklift stop signals are essential for safety on construction sites as they provide a non-verbal communication method that enables operators and ground personnel to relay critical information swiftly and effectively, which is vital in the chaotic environment of a construction site.

What is the hand signal used to stop a forklift?

The hand signal to stop a forklift is characterized by both arms extended with palms facing down and moving back and forth, which is a universally recognized gesture that commands immediate cessation of operations.

How do forklift stop signals help prevent accidents?

Forklift stop signals help prevent accidents by allowing spotters to alert operators to potential hazards that may not be visible to them, ensuring that operations can be halted to avoid incidents.

In what ways do hand signals improve communication on construction sites?

Hand signals improve communication by bridging gaps that can arise due to noise or distance, ensuring all team members are informed about the vehicle's operational status and can respond appropriately.