Key Highlights:

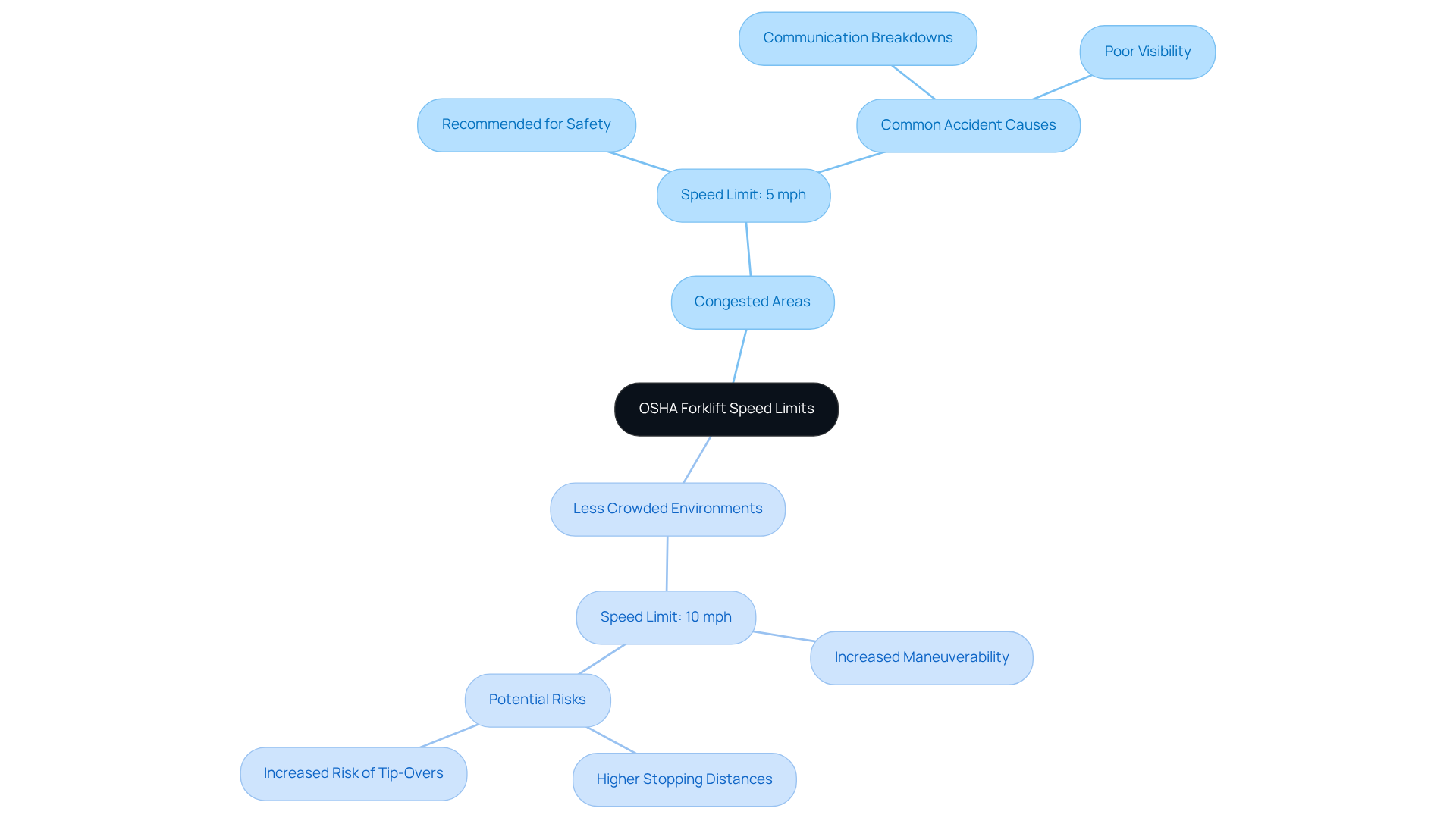

- OSHA does not set a specific forklift speed limit but advises operators to maintain safe speeds for stopping under all conditions.

- Recommended speed limits are 5 mph in congested areas and 10 mph in less crowded environments.

- Heavier loads require slower speeds to maintain control and prevent accidents, with rollovers being a common hazard.

- Visibility is critical; poor sightlines can lead to pedestrian accidents, which account for 36% of forklift-related fatalities.

- Real-world examples show that adhering to speed limits can significantly reduce accident rates, such as a 30% reduction in a warehouse after implementing OSHA standards.

- Operators must regularly assess load characteristics, including weight and stability, to determine safe speeds.

- Calculating safe stopping distances is essential; for example, a forklift travelling at 6 km/h needs about 3 metres to stop safely.

- Frequent violations occur in pedestrian zones, highlighting the need for compliance training and monitoring systems.

- Advanced technology, like speed limiters and collision prevention systems, can enhance safety by automatically adjusting speeds.

- Operators should adapt speeds based on environmental conditions, particularly in wet or confined spaces.

- Comprehensive training programmes can reduce incidents by up to 70% and improve adherence to safety protocols.

- Consistent monitoring of operations and compliance with speed limits is crucial for fostering a culture of safety.

Introduction

Understanding the dynamics of forklift operation is essential for ensuring safety in industrial environments. Forklifts serve as the backbone of many warehouses and distribution centers, and operating them within specific speed limits is vital to prevent accidents and protect both operators and pedestrians. This article explores the key OSHA forklift speed limit guidelines, emphasizing essential practices that can significantly enhance safety compliance. Given the varying environmental conditions and the complexities of load management, operators must effectively navigate these challenges while adhering to regulations.

Understand OSHA's Established Forklift Speed Limits

OSHA does not specify an exact forklift speed limit, but it requires operators to maintain a speed that allows for safe stopping under all conditions. Generally, the forklift speed limit OSHA is considered to be approximately:

- 5 mph in congested areas

- 10 mph in less crowded environments

Operators must remain aware of their surroundings and adjust their speed accordingly to ensure safety. This vigilance is crucial in preventing accidents and ensuring a secure working environment.

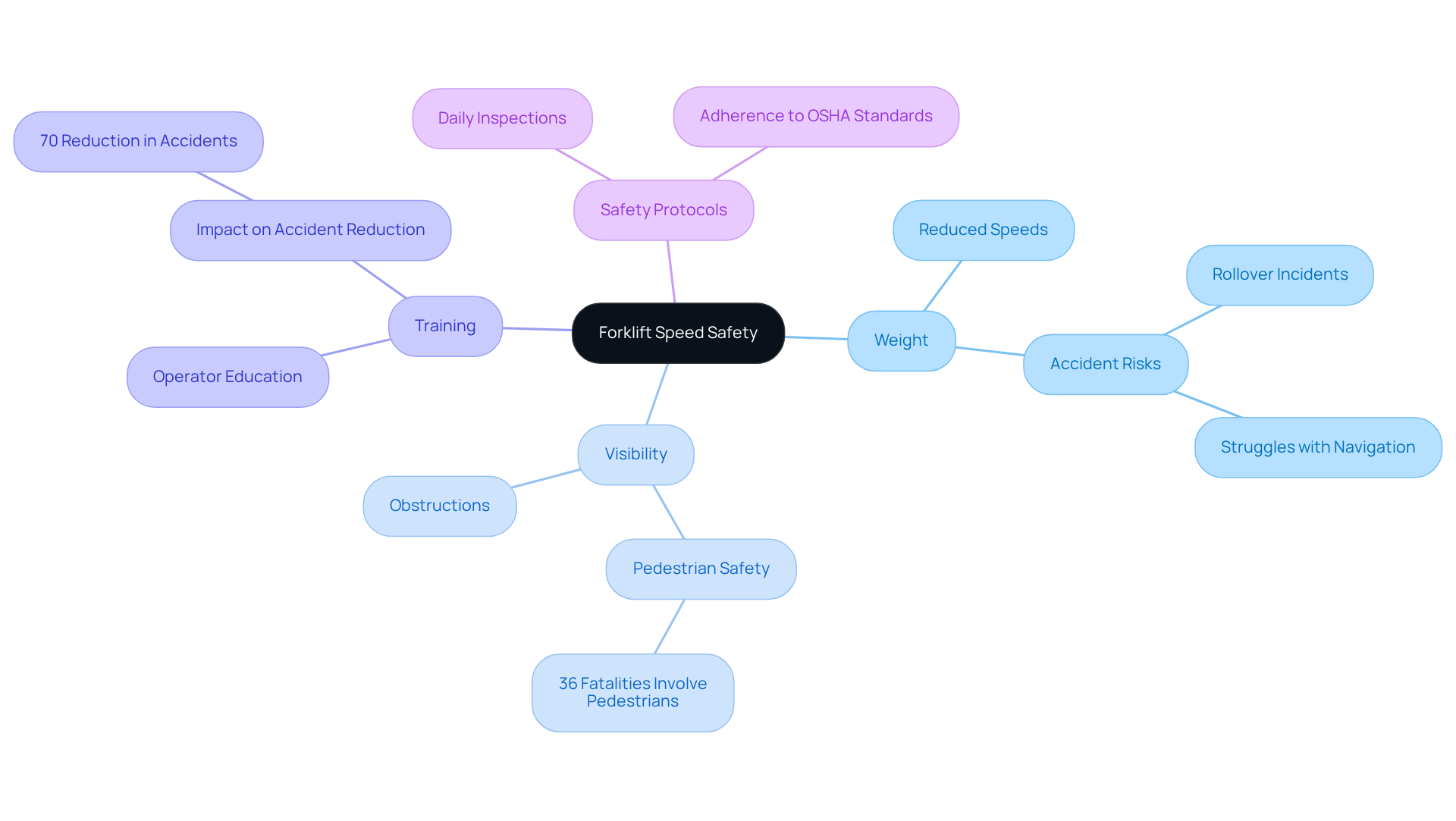

Evaluate Factors Affecting Forklift Speed Safety

Multiple elements significantly impact the safety of lifting equipment, particularly weight and visibility. Heavier loads necessitate reduced speeds to maintain control and prevent tipping, as the risk of accidents increases with the mass being transported. For example, a lifting vehicle carrying a weight that exceeds its rated capacity may struggle to navigate safely, leading to potential rollovers or collisions. In fact, rollovers represent the most common type of fatal forklift incident, underscoring the critical need for adhering to the forklift speed limit OSHA in relation to weight.

Visibility also plays a vital role in speed management. Operators must navigate aisles and corners with caution, especially in areas with limited sightlines. Poor visibility can arise from obstructions or the height of the cargo, which may obstruct the operator's view of pedestrians and other hazards. Statistics reveal that 36% of forklift-related fatalities involve pedestrians, highlighting the importance of the forklift speed limit OSHA in pedestrian zones to ensure safe navigation and prevent accidents.

Real-world examples illustrate the importance of speed control concerning weight and visibility. In one instance, a warehouse implemented a forklift speed limit according to OSHA standards for transporting heavy loads, resulting in a 30% reduction in accidents over six months. Similarly, a distribution center that improved lighting and visibility around corners saw a significant decrease in near-miss incidents, reinforcing the necessity for operators to adjust their speed based on environmental conditions.

Experts emphasize that understanding the forklift speed limit OSHA and other operational factors is crucial for ensuring safety. As one risk advisor stated, "Operators must be trained to recognize how load weight and visibility influence their speed." Proper training can reduce accidents by up to 70%. Furthermore, OSHA estimates that if companies adopted more stringent training policies, approximately 70% of forklift accidents in the US could be prevented. This highlights the importance of ongoing education and adherence to protocols in preventing forklift-related incidents. Additionally, OSHA mandates daily inspections of industrial trucks to enhance safety and identify both major and minor issues, ensuring that equipment is maintained for safe operation.

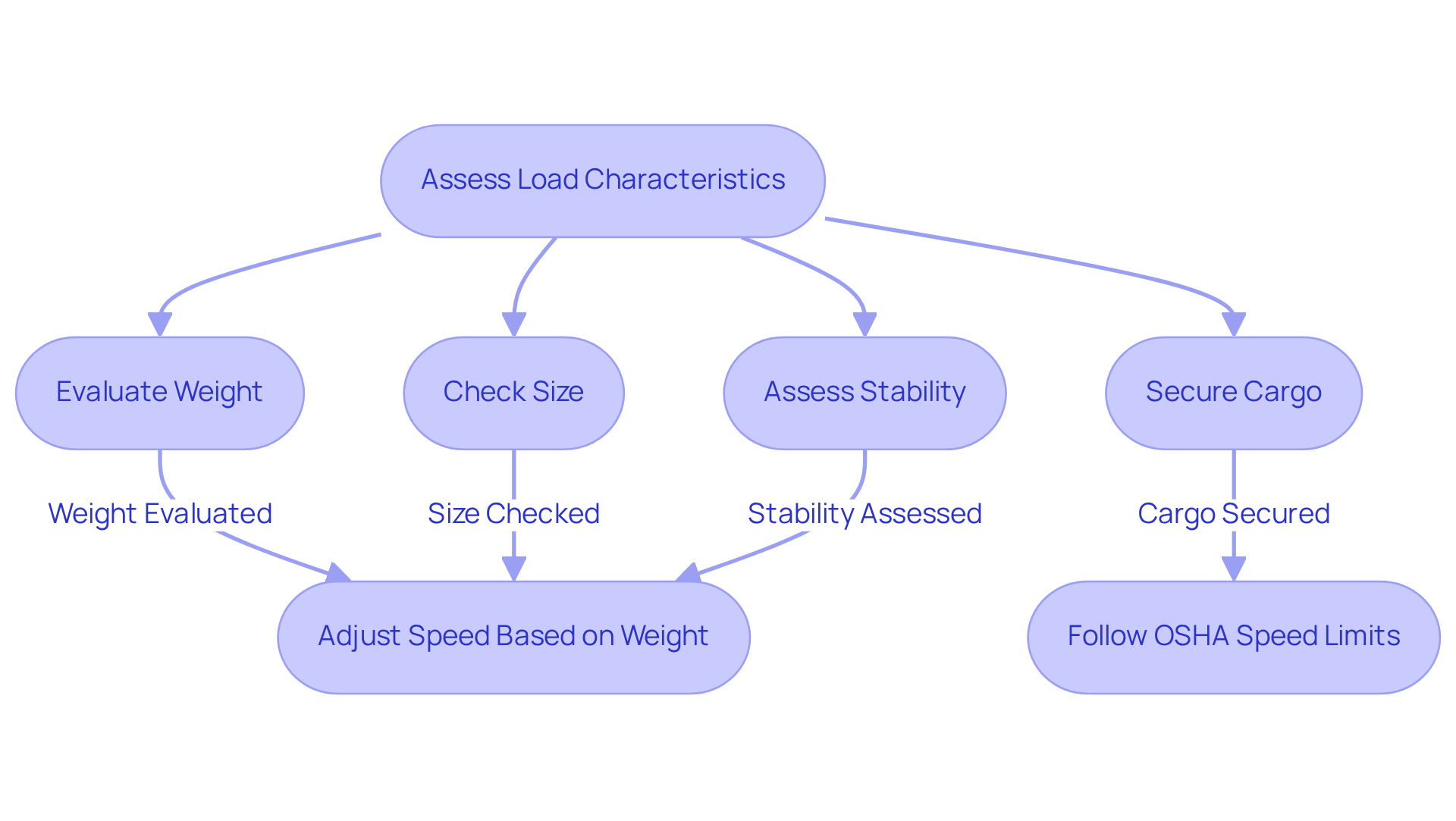

Assess Load Characteristics for Safe Speed Management

Evaluating handling characteristics - such as weight, size, and stability - is essential for safe forklift operation. To minimize the risk of toppling, high or uneven weights necessitate following the forklift speed limit OSHA. Operators must ensure that cargo is secured properly to prevent shifting during transport; improper arrangement can lead to hazardous situations. The steadiness of a burden directly affects the rate at which a forklift can operate safely. Heavier weights generally require slower speeds, adhering to the forklift speed limit OSHA, typically ranging from 3 to 5 mph, while lighter weights may allow for somewhat higher speeds, though caution is always advised.

In practice, operators should maintain a low weight position and avoid rapid acceleration or sudden stops to enhance stability. Consistent practice in weight management and velocity control is vital, emphasizing the importance of adhering to safety procedures and understanding how various weights and arrangements influence handling. For instance, a well-balanced load positioned close to the forklift's masts can significantly improve stability, facilitating safer navigation through tight spaces.

By regularly assessing weight stability and adjusting velocity accordingly, operators can mitigate risks and foster a safer working environment. As noted, the forklift speed limit OSHA indicates that heavier loads demand slower velocities for stability, while indoor or crowded settings require lowered limits to ensure security. Furthermore, most facilities adhere to the forklift speed limit OSHA of 10 mph for lifting trucks, underscoring the necessity for operators to evaluate their surroundings and adjust speeds based on environmental factors.

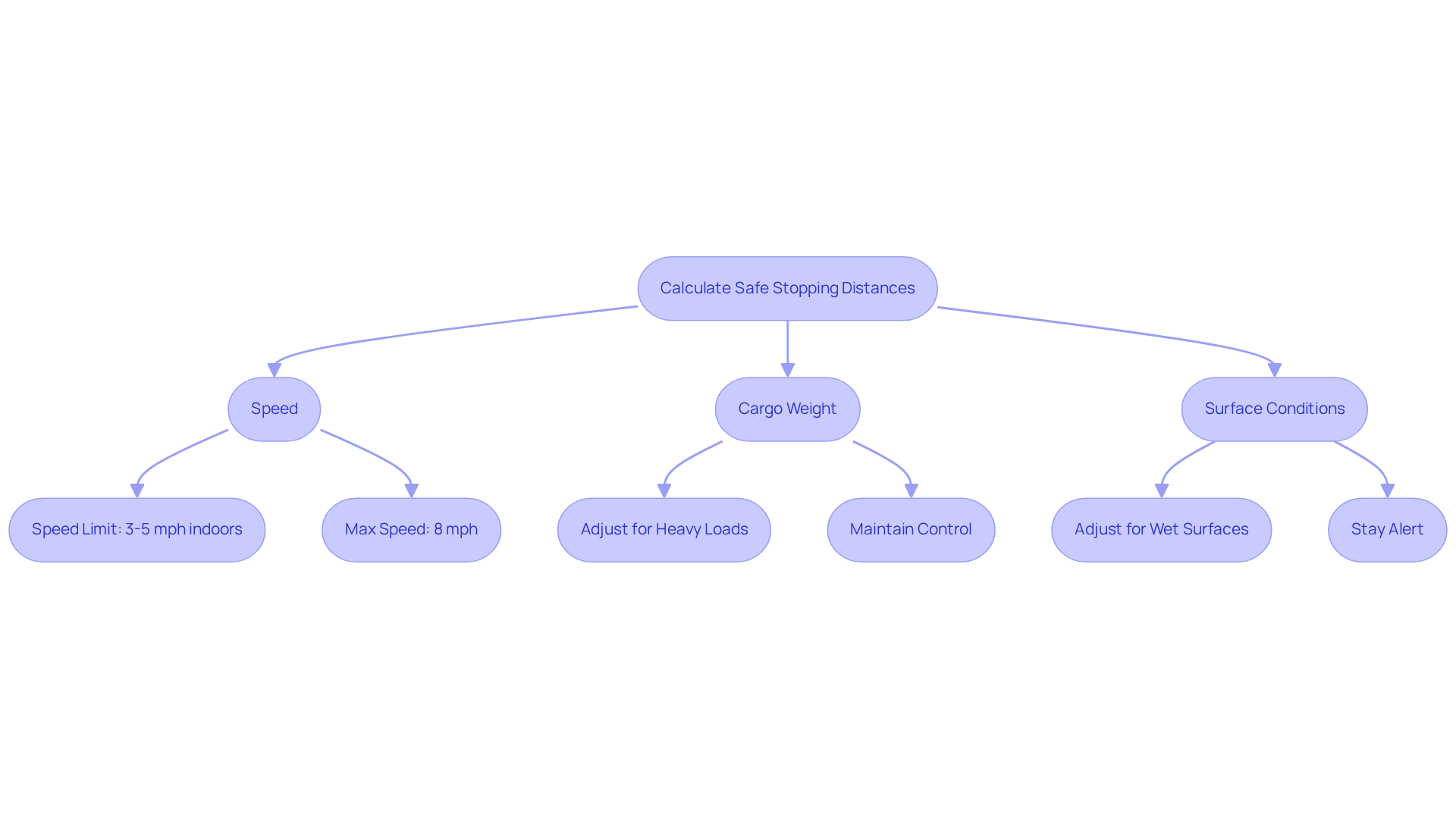

Calculate Safe Stopping Distances for Forklifts

Calculating safe stopping distances for industrial trucks is essential for workplace safety. Operators must take into account the vehicle's speed, cargo weight, and surface conditions. For instance, a forklift traveling at 6 km/h (approximately 4 mph) requires about 3 meters (10 feet) to stop safely. In contrast, at 12 km/h (around 8 mph), this distance more than doubles, highlighting the necessity for operators to adjust their speed based on their environment and the characteristics of the cargo. In crowded areas or when handling heavy loads, it is prudent to allow for additional stopping distance.

Safety experts recommend that operators maintain the forklift speed limit OSHA of 3-5 mph in indoor warehouses, with adjustments for areas with high pedestrian traffic. Furthermore, the Material Handling Equipment Distributors Association (MHEDA) recommends that the forklift speed limit OSHA should be set at a maximum of 8 mph in general and 3 mph in pedestrian-heavy zones to enhance safety. Employers should ensure that operators are well-trained on how velocity and weight impact stopping distances. Heavier loads, for example, require slower speeds to maintain control and prevent tipping. Additionally, environmental factors, such as wet or uneven surfaces, can significantly increase stopping distances, making it crucial for operators to stay alert and modify their driving accordingly.

By adhering to these guidelines, operators can mitigate risks and enhance safety in lift truck operations. At EZ Equipment Rental, we offer a diverse selection of well-maintained lifting machines, ensuring that clients find the perfect fit for their specific needs, which is vital for maintaining safety and efficiency in elevated work tasks.

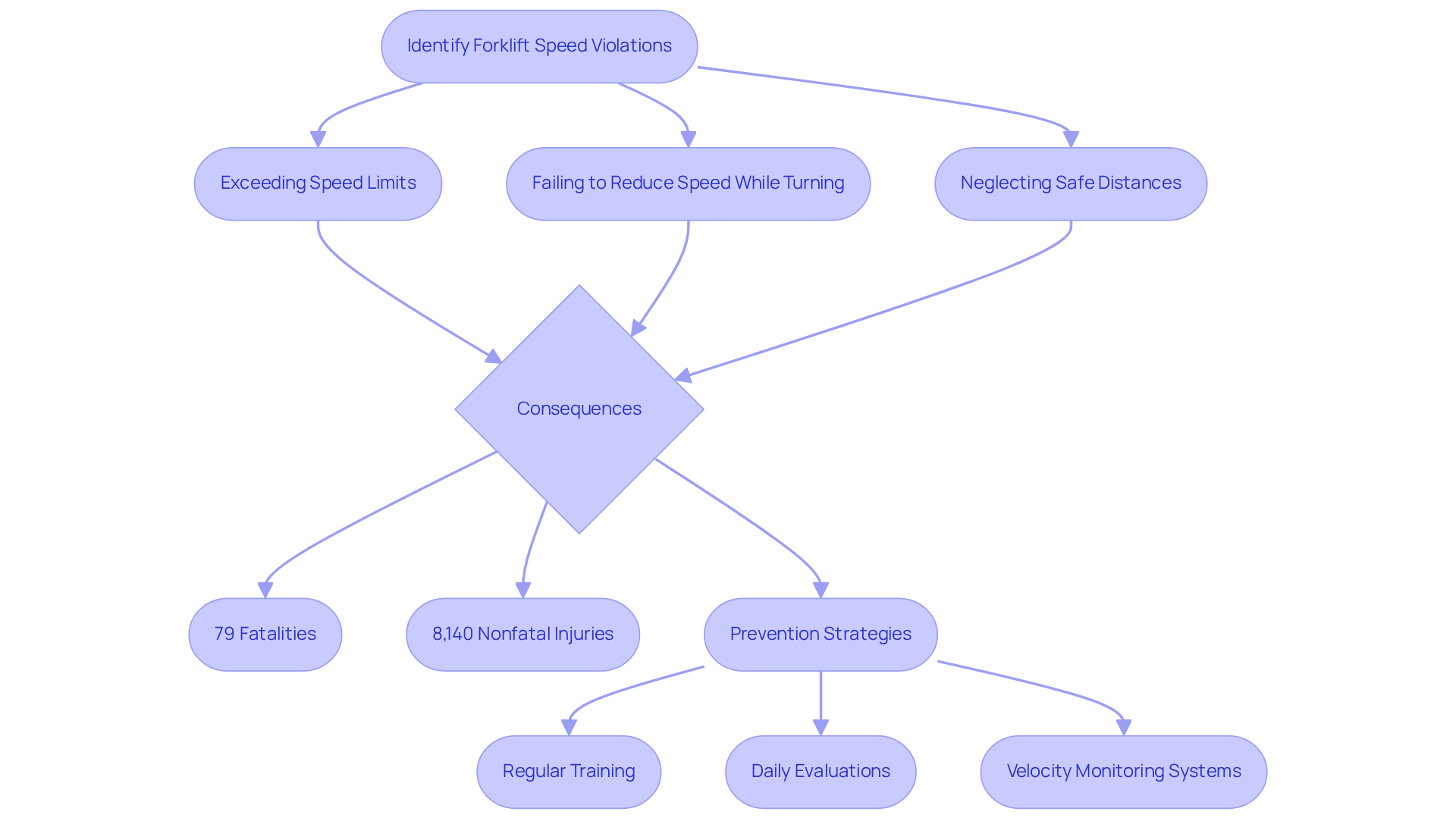

Identify Common Forklift Speed Violations and Prevention Strategies

Frequent violations of forklift velocity often occur in pedestrian zones, where operators may exceed speed limits, fail to reduce speed while turning, or neglect to maintain safe distances from other vehicles. Statistics reveal that in one year, 79 workers lost their lives due to forklift-related incidents, with an additional 8,140 experiencing nonfatal injuries. This underscores the critical need for compliance training. To mitigate these risks, it is essential for operators to engage in regular training that emphasizes the importance of adhering to the forklift speed limit OSHA and being aware of their surroundings.

OSHA mandates daily evaluations of forklifts to identify mechanical issues that could lead to accidents, which underscores the importance of complying with the forklift speed limit OSHA. Implementing velocity monitoring systems can enhance adherence, providing real-time feedback on operator performance. Facilities that prioritize rapid compliance training and conduct refresher courses every three years have reported a notable decrease in incidents, demonstrating the effectiveness of proactive safety measures.

Establishing a culture of safety through continuous education and monitoring not only safeguards employees but also improves overall operational efficiency.

Utilize Advances in Forklift Speed Control Technology

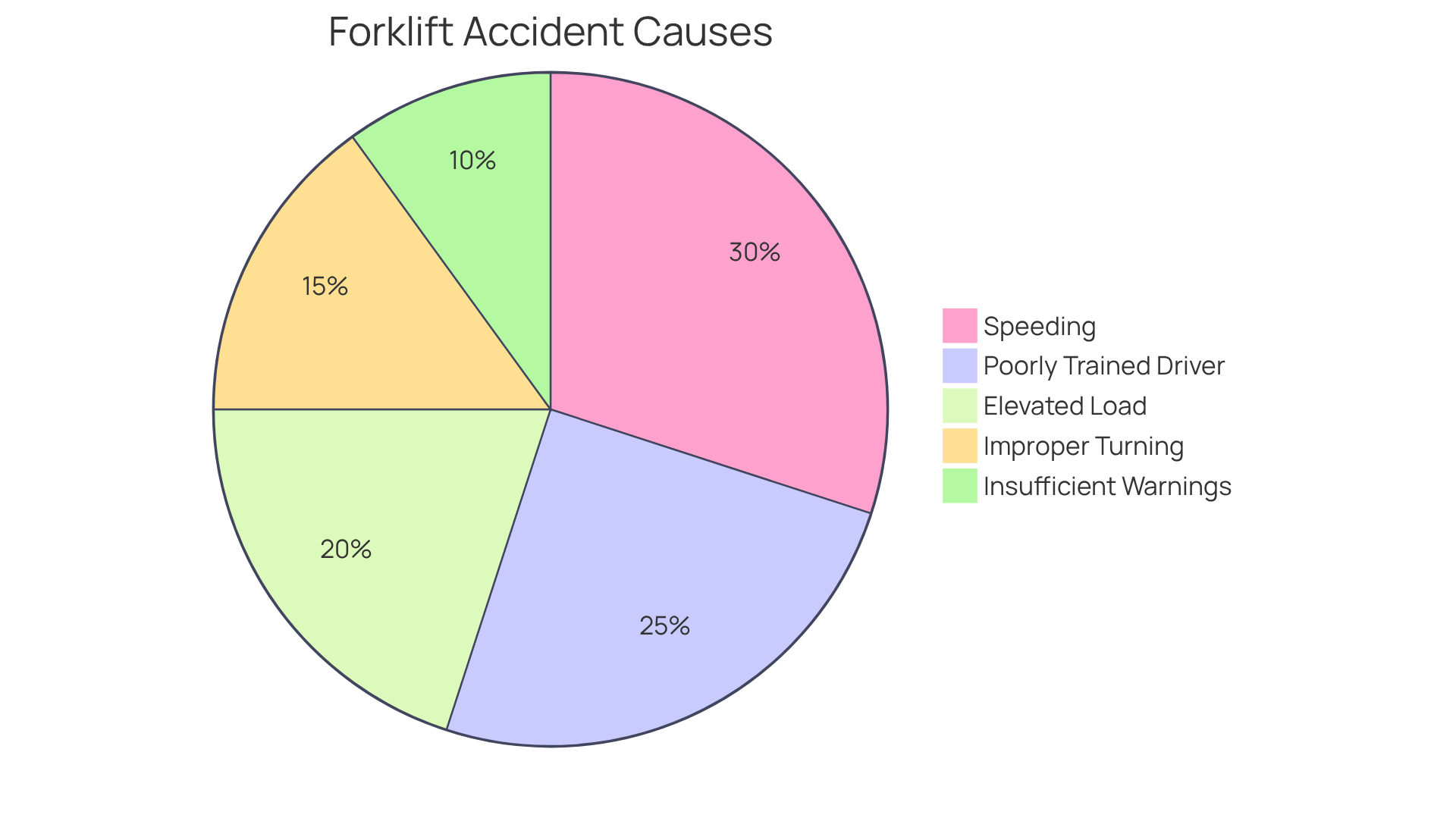

Contemporary lifting machines are increasingly equipped with advanced velocity control technologies, such as velocity limiters and collision prevention systems. These innovations automatically adjust the vehicle's speed according to environmental conditions and cargo characteristics, significantly reducing the risk of accidents. According to OSHA, the forklift speed limit OSHA indicates that speeding ranks as the second most common cause of forklift accidents, with the top five causes being:

- Speeding

- Poorly trained driver

- Operating with an elevated load

- Improper turning

- Insufficient warning & markings

By implementing the forklift speed limit OSHA, facilities can anticipate a decrease in accidents attributed to excessive speed, which constitutes a substantial portion of forklift-related incidents.

Moreover, collision avoidance systems enhance safety by providing real-time alerts and interventions, effectively managing risks in busy work environments. Practical applications of these technologies, such as the WTsafe Forklift Speed Limiter Solution, have demonstrated their effectiveness in reducing accident rates and fostering a culture of safety within organizations. As Chris Webre, President of Safety Systems & Controls, Inc., emphasizes, investing in advanced safety technologies not only protects workers but also enhances operational efficiency, making them an essential component of modern material handling operations.

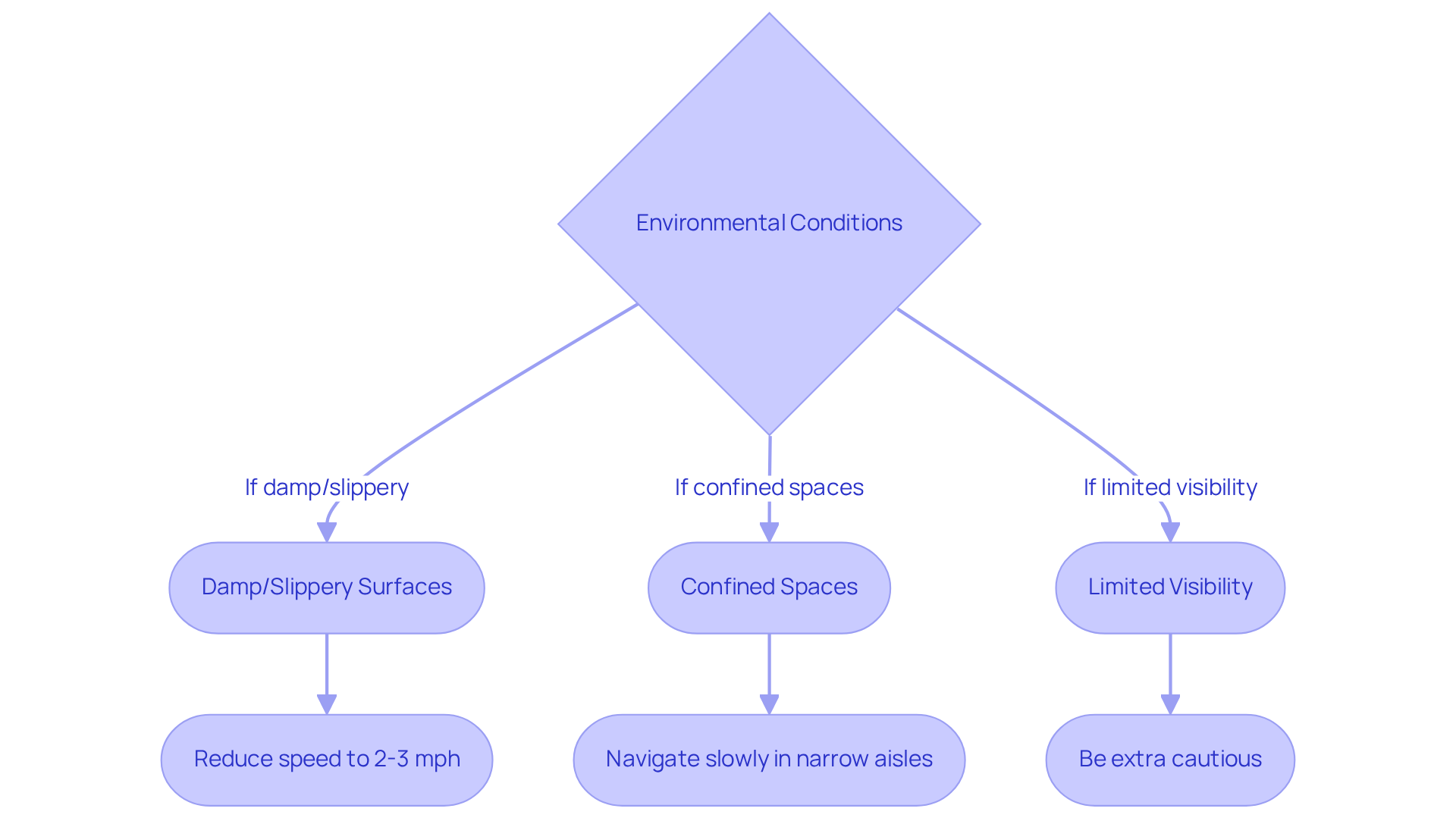

Adapt Forklift Speed to Environmental Conditions

Operators must adjust the pace of their lifting vehicles according to environmental conditions, particularly on damp or slippery surfaces, in confined spaces, and in areas with limited visibility. For example, in wet conditions, it is essential to reduce speed to approximately 2-3 mph to prevent slipping and maintain control. Accelerating can increase the stopping distance for lifting trucks, leading to potential collisions and falls, which account for about 25% of reported injuries at loading docks. In narrow aisles, a slower pace is vital for safe navigation, as the risk of tip-overs significantly rises when operators do not modify their speed.

According to OSHA, lift truck tip-overs rank as the second leading cause of fatal incidents in warehouses and factories, emphasizing the importance of following the forklift speed limit OSHA for careful pace management. Operators should also familiarize themselves with the data plate to ensure safe operation and remain aware of their surroundings, adjusting their driving as necessary, especially in adverse weather conditions. Regular maintenance and thorough pre-operation inspections can greatly enhance safety and operational efficiency.

By following these guidelines, operators can effectively mitigate risks and foster a safer working environment.

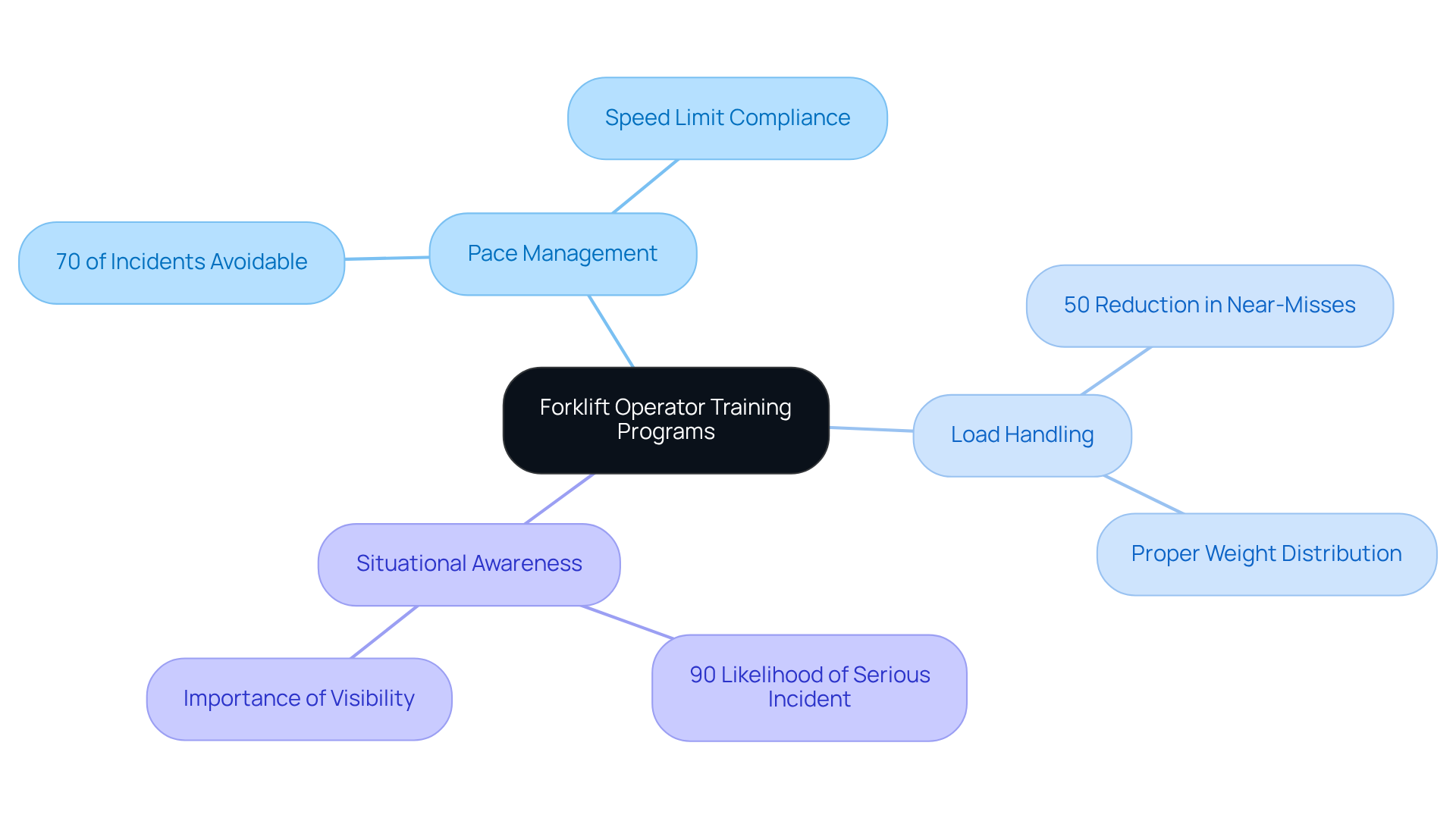

Implement Training Programs for Forklift Operators

Efficient training programs for lift truck operators should include modules on pace management, load handling, and situational awareness. Regular refresher courses reinforce safe practices and ensure compliance with the forklift speed limit OSHA guidelines. Notably, forklift injuries typically result in an average of 16 days away from work, which is double the average for other injuries. This statistic underscores the urgency of implementing effective training programs. Furthermore, an individual lift truck has a 90% likelihood of being involved in a severe incident during its operational lifespan, highlighting the necessity for robust training and precautionary measures.

Data indicates that 70% of lift truck incidents could have been avoided with improved hazard prevention methods, particularly emphasizing the importance of education on forklift speed limit OSHA. Organizations that have established comprehensive training programs reported a 50% reduction in near-miss incidents within the first year, demonstrating the effectiveness of such training in enhancing adherence to regulations. By investing in these training programs, companies can significantly minimize risks associated with lift truck operation and improve overall workplace safety.

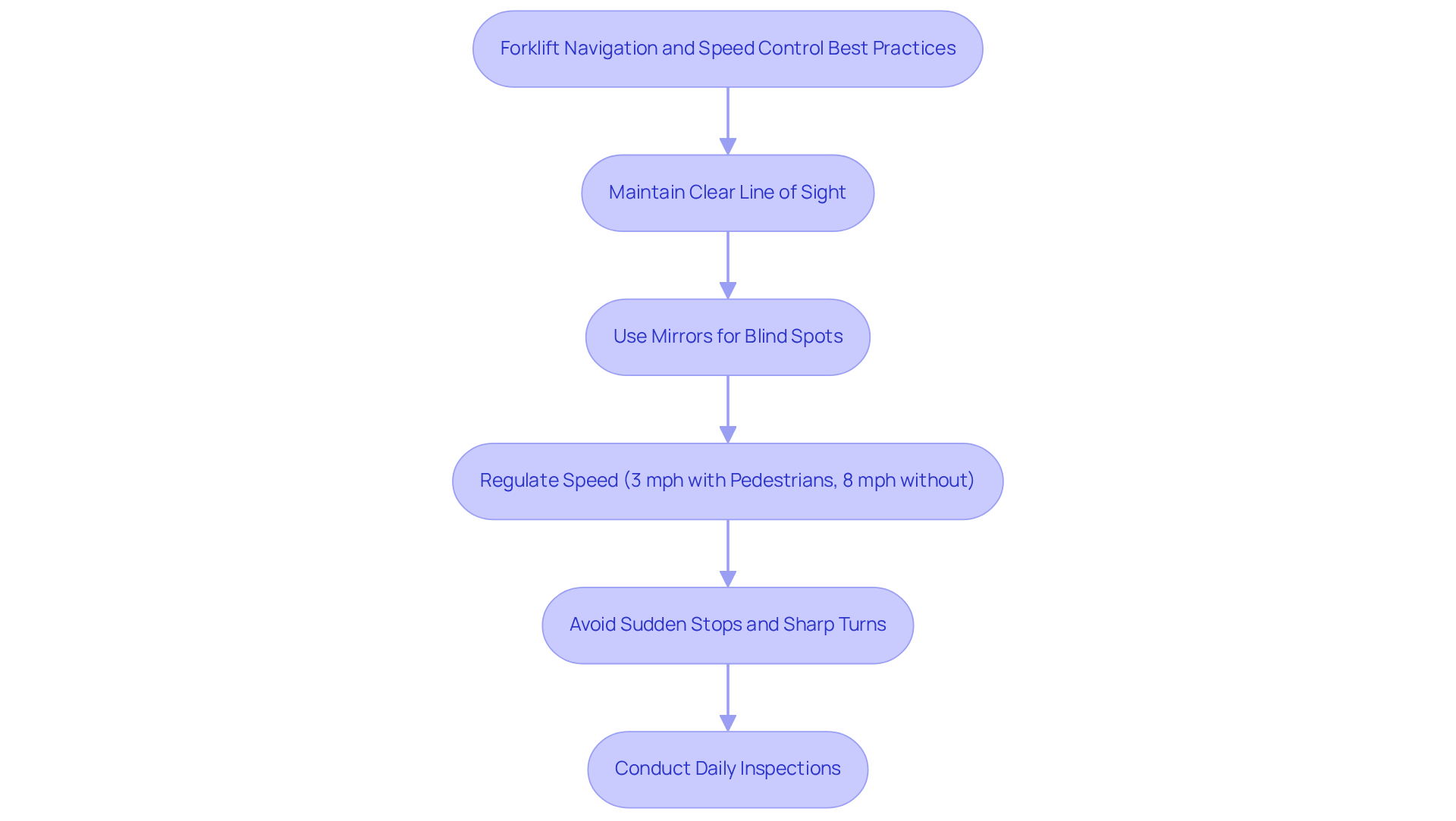

Adopt Best Practices for Forklift Navigation and Speed Control

Effective forklift navigation is essential for both safety and operational efficiency. Operators must prioritize maintaining a clear line of sight and utilize mirrors to monitor blind spots, especially in congested areas. Regulating pace is critical; the forklift speed limit OSHA guidelines stipulate a maximum speed of three mph when pedestrians are present and eight mph when no pedestrians are nearby, particularly near intersections or areas with limited visibility (29 CFR 1910.178(n)(15)). To maintain control and prevent accidents, operators should avoid sudden stops and sharp turns, as these maneuvers can lead to instability and increase the risk of collisions.

Statistics indicate that in 2018, there were 20 forklift-related fatalities due to being struck by equipment, highlighting the importance of careful navigation practices. For instance, at a speed of four mph, it takes approximately 17 feet to come to a complete stop, underscoring the significance of controlled driving. Real-world examples demonstrate that implementing clear traffic separation strategies and adhering to the forklift speed limit OSHA can significantly enhance safety in the workplace.

As Ashton Tufts notes, "Daily inspections prevent accidents and ensure compliance with OSHA regulations." By following these optimal procedures, operators can effectively manage their speed and maintain control, ultimately reducing the likelihood of incidents and ensuring adherence to regulations.

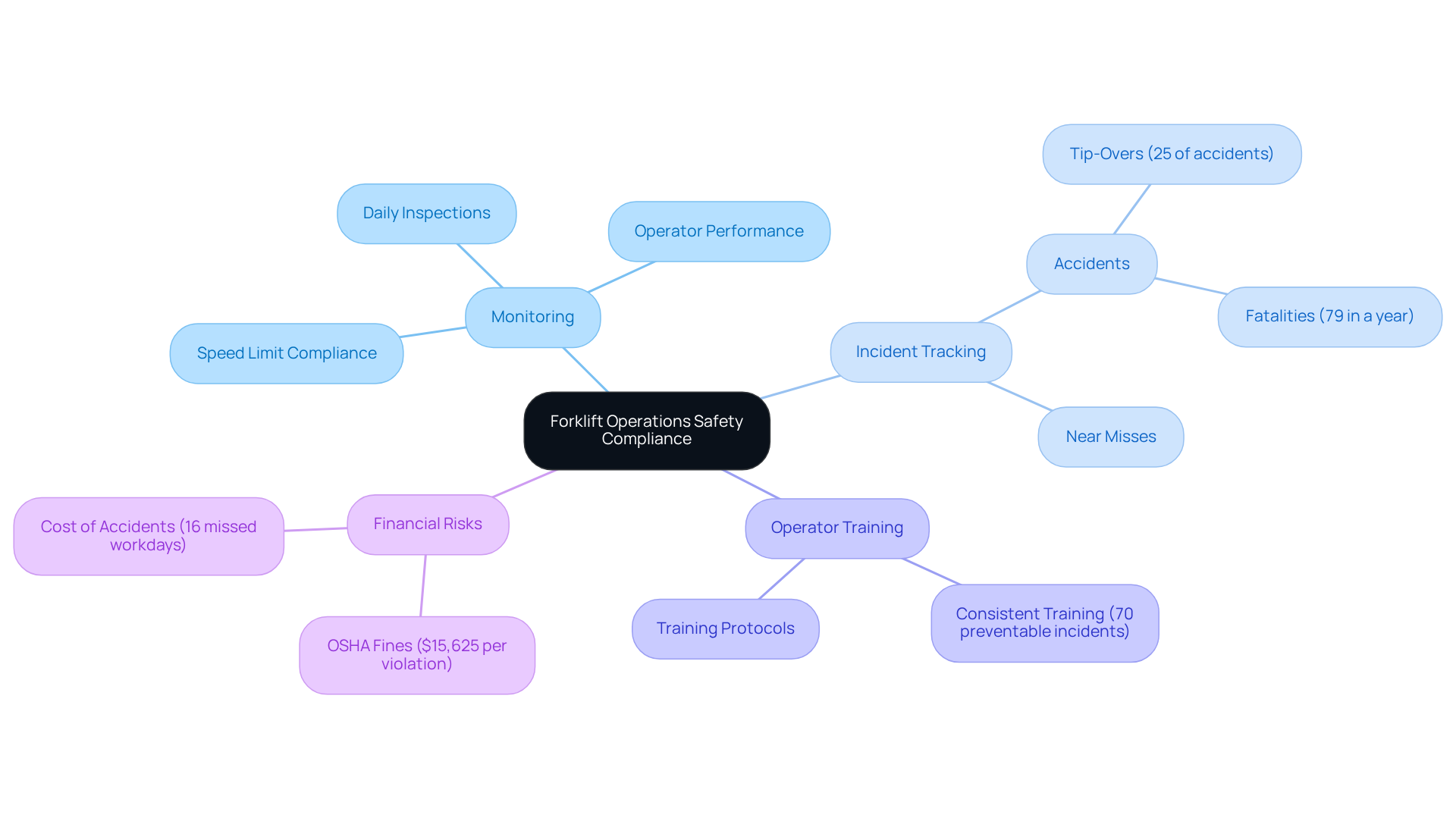

Monitor and Evaluate Forklift Operations for Safety Compliance

Consistent monitoring and assessment of forklift operations are essential for ensuring compliance with the forklift speed limit OSHA guidelines. This includes thorough evaluations of compliance with the forklift speed limit OSHA, operator performance, and adherence to established protocols. Implementing a robust incident tracking system that records both accidents and near misses can significantly enhance safety by identifying areas needing improvement. For example, tip-overs, which account for nearly 25% of all forklift-related accidents, often result from exceeding the forklift speed limit OSHA or improper maneuvering. By closely monitoring these factors, organizations can foster a culture of safety that not only reduces incidents but also improves overall operational efficiency.

Furthermore, data indicates that approximately 70% of lift truck incidents could be prevented with consistent operator training, highlighting the importance of ongoing evaluations and adjustments to training programs. Facilities should also recognize that OSHA fines for forklift accident non-compliance can reach $15,625 per violation, underscoring the financial risks associated with inadequate protective measures. Daily inspections, mandated by OSHA, are crucial for identifying mechanical issues before they lead to accidents. Real-world examples show that facilities prioritizing the forklift speed limit OSHA compliance and operator performance evaluations experience significant improvements in safety outcomes, ultimately contributing to a safer work environment.

Conclusion

Maintaining safe forklift operation is essential in any workplace, and understanding OSHA's guidelines on speed limits plays a crucial role in this. While OSHA does not specify exact speed limits, it emphasizes that operators must adjust their speed to ensure safe stopping and navigation under various conditions. Recommended limits of 5 mph in congested areas and 10 mph in less crowded environments serve as foundational guidelines for enhancing safety and preventing accidents.

Key factors affecting forklift speed safety include:

- Load characteristics

- Visibility

- Environmental conditions

Heavier loads necessitate slower speeds, highlighting the importance of proper training and the implementation of advanced speed control technologies. This comprehensive approach fosters a culture of safety. Real-world examples demonstrate the effectiveness of adhering to these guidelines, with significant reductions in accidents reported by facilities that prioritize speed compliance and operator education.

Ultimately, both operators and employers share the responsibility of prioritizing safety through continuous training, adherence to speed limits, and regular equipment evaluations. By integrating these practices into daily operations, organizations can significantly reduce the risk of accidents and injuries, ensuring a safer working environment for everyone involved. Embracing OSHA forklift speed limit guidelines is not merely a regulatory requirement; it is a vital step toward operational excellence and employee safety.

Frequently Asked Questions

What are OSHA's established forklift speed limits?

OSHA does not specify an exact speed limit for forklifts but advises operators to maintain a speed that allows for safe stopping under all conditions. Generally, the recommended speeds are approximately 5 mph in congested areas and 10 mph in less crowded environments.

What factors affect forklift speed safety?

Key factors affecting forklift speed safety include the weight of the load and visibility. Heavier loads require reduced speeds to maintain control and prevent tipping, while poor visibility due to obstructions or cargo height can increase the risk of accidents.

How does load weight influence forklift speed?

Heavier loads necessitate slower speeds to ensure stability and prevent accidents, as they can lead to rollovers or collisions. Operators must adhere to the forklift speed limit, typically ranging from 3 to 5 mph for heavier loads.

Why is visibility important in managing forklift speed?

Visibility is crucial for safe navigation, especially in areas with limited sightlines. Poor visibility can lead to accidents, particularly involving pedestrians, as 36% of forklift-related fatalities involve them. Operators must adjust their speed in pedestrian zones to ensure safety.

What are some real-world examples of the importance of speed control?

One warehouse implemented OSHA's forklift speed limit for heavy loads and saw a 30% reduction in accidents over six months. A distribution center that improved lighting and visibility around corners experienced a significant decrease in near-miss incidents.

How can training impact forklift safety?

Proper training on recognizing how load weight and visibility affect speed can reduce accidents by up to 70%. OSHA estimates that stricter training policies could prevent approximately 70% of forklift accidents in the US.

What are OSHA's requirements for forklift inspections?

OSHA mandates daily inspections of industrial trucks to enhance safety and identify issues, ensuring that equipment is maintained for safe operation.

How should operators assess load characteristics for safe speed management?

Operators should evaluate handling characteristics such as weight, size, and stability, ensuring cargo is secured properly to prevent shifting. Maintaining a low weight position and avoiding rapid acceleration or sudden stops enhance stability and safety.

List of Sources

- Understand OSHA's Established Forklift Speed Limits

- Forklift Speed and Navigation | OSHA Limits and Safety Best Practices | CME (https://certifyme.net/osha-blog/forklift-speed-and-navigation)

- Forklift Accidents Statistics: How to Increase Forklift Safety and Prevent Accidents – Powerfleet (formerly Fleet Complete) Blog (https://blog.fleetcomplete.com/forklift-accidents-statistics-how-to-increase-forklift-safety-and-prevent-accidents)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- 10 Rules for Forklift Safety (https://forkliftsafety101.com/10-rules-for-forklift-safety)

- Evaluate Factors Affecting Forklift Speed Safety

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Assess Load Characteristics for Safe Speed Management

- How Fast Can Forklifts Go? (https://zonemfc.com/forklift-speed-limits)

- Forklift Speed and Navigation | OSHA Limits and Safety Best Practices | CME (https://certifyme.net/osha-blog/forklift-speed-and-navigation)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Blogs (https://logisnextamericas.com/en/logisnext/resources/load-capacity)

- eTool : Powered Industrial Trucks (Forklift) - Load Handling - Load Composition | Occupational Safety and Health Administration (https://osha.gov/etools/powered-industrial-trucks/load-handling/load-composition)

- Calculate Safe Stopping Distances for Forklifts

- Forklift Speed Limits and Braking in the Warehouse (https://adaptalift.com.au/articles/2013-02-01-forklift-speed-limits-and-braking-in-the-warehouse)

- Forklift Speed: Everything You Need to Know (https://conger.com/forklift-speed)

- Forklift Speed and Navigation | OSHA Limits and Safety Best Practices | CME (https://certifyme.net/osha-blog/forklift-speed-and-navigation)

- Identify Common Forklift Speed Violations and Prevention Strategies

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- Powered Industrial Trucks (Forklifts) Stats and Facts (https://icwgroup.safetynow.com/powered-industrial-trucks-forklifts-stats-and-facts?print=pdf)

- 5 Common Forklift Accidents and How to Prevent Them - OSHA.com (https://osha.com/blog/5-most-common-forklift-accidents-and-how-to-prevent-them)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Utilize Advances in Forklift Speed Control Technology

- Forklift Speed Limiter Increases Safety AND Productivity - Workplace Material Handling & Safety (https://workplacepub.com/material-handling/forklift-speed-limiter-increases-safety-and-productivity)

- The WTsafe Forklift Speed Limiter Solution (https://wt-safe.com/Article/speedlimiter.html)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Intelligent Forklift Safety System Market, Global Outlook and Forecast 2026-2034 (https://statsmarketresearch.com/global-intelligent-forklift-safety-system-forecast-market-8070998)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Adapt Forklift Speed to Environmental Conditions

- Forklift Speed and Navigation | OSHA Limits and Safety Best Practices | CME (https://certifyme.net/osha-blog/forklift-speed-and-navigation)

- Forklift Speed: Everything You Need to Know (https://conger.com/forklift-speed)

- Forklift Safety Tips for Inclement Weather | Bryan & Caldwell, TX (https://kmcequipment.com/blog/forklift-safety-tips-for-inclement-weather--93837)

- Forklift safety for rainy weather - ACE (https://acelifting.com/blog/forklift-safety-for-rainy-weather)

- Implement Training Programs for Forklift Operators

- Measuring the Impact of Forklift Training on Workplace Safety: Key Metrics and Evaluation Methods (https://roisafetyservices.com/impact-of-forklift-training-on-workplace-safety)

- 10 Forklift safety statistics for 2025 | SC Training (https://training.safetyculture.com/blog/forklift-safety-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Top Forklift Accident Statistics & Prevention Tips for 2025 | CertifyMe (https://certifyme.net/osha-blog/forklift-accidents)

- OSHA Top 10 Citations for 2024 (https://forklifttraining.com/osha-top-10-citations-2024)

- Adopt Best Practices for Forklift Navigation and Speed Control

- Forklift Speed and Navigation | OSHA Limits and Safety Best Practices | CME (https://certifyme.net/osha-blog/forklift-speed-and-navigation)

- 28 Forklift Safety Tips for Operators, Pedestrians, and Managers (https://conger.com/forklift-safety-tips)

- 18 Important Forklift Statistics | BigRentz (https://bigrentz.com/blog/forklift-statistics?srsltid=AfmBOorXTWwU6Wbp7c5jZNYxr0QD10cDO7V9lxHmsDyj5xdJQytRQj6Q)

- 20 Forklift Safety Tips For Your Operation | Hyster (https://hyster.com/en-us/north-america/support-resources/safety/20-tips-for-safe-handling)

- 7 Essential Forklift Safety Rules for 2025 Compliance - Top Osha Forklift Certification (https://forkliftacademy.com/forklift-safety-rules-2025?srsltid=AfmBOop5_0ScxhCoXPX-gP4Cbl3iygWjAwvtB4BYKO0w0AvPwI2DN811)

- Monitor and Evaluate Forklift Operations for Safety Compliance

- Forklift Injury Statistics 2025 | How to Reduce Forklift Accident Risks (https://certifyme.net/osha-blog/forklift-injuries-key-statistics)

- National Forklift Safety Day Statistics │ MHEDA (https://mheda.org/journal/national-forklift-safety-day-statistics)

- Forklift Accident Statistics (https://mccue.com/blog/forklift-accident-statistics)

- Work Safety: Forklifts - Injury Facts (https://injuryfacts.nsc.org/work/safety-topics/forklifts)