Key Highlights:

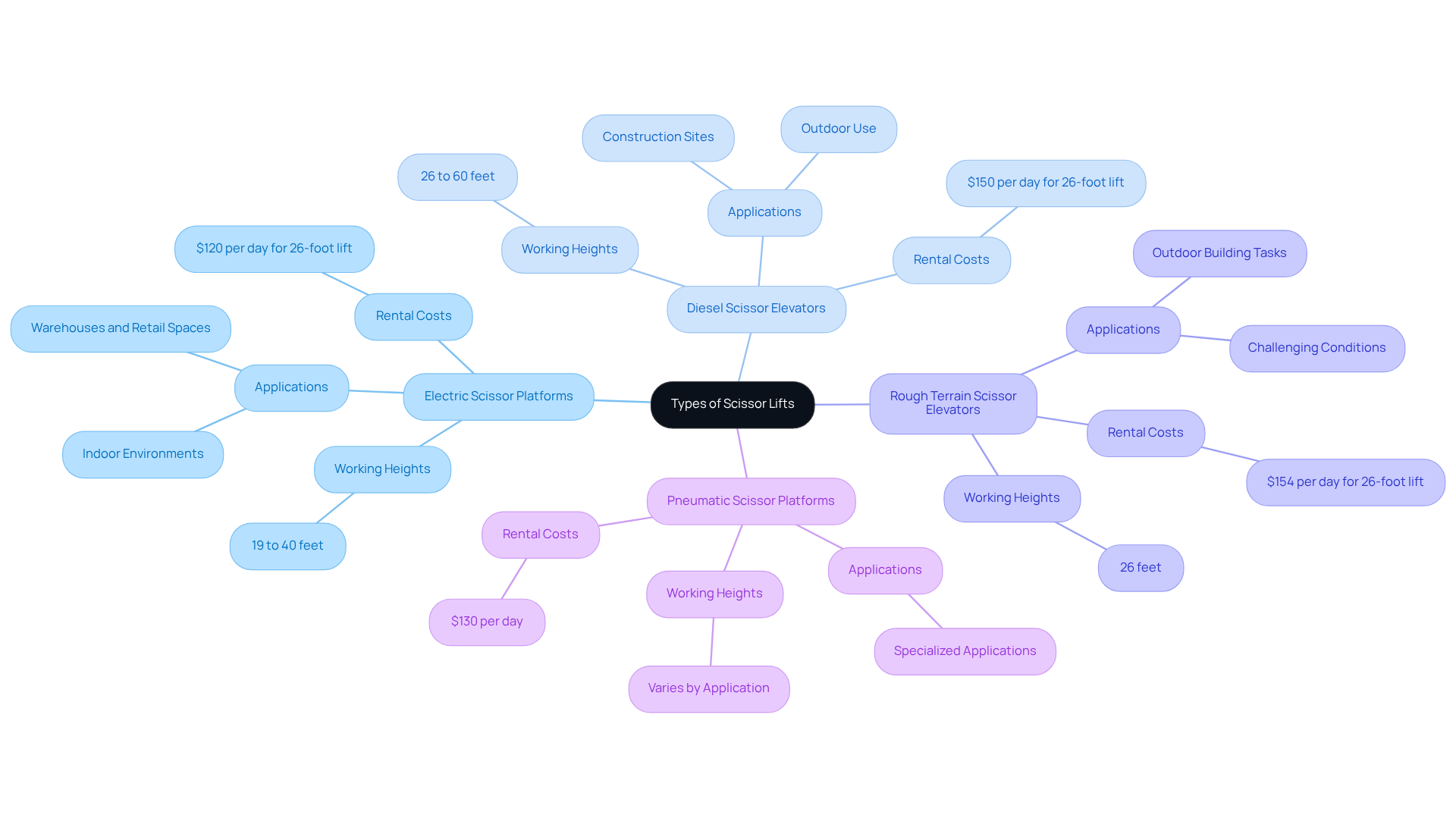

- Scissor lifts come in various types: electric, diesel, rough terrain, and pneumatic, each suited for specific applications.

- Electric scissor platforms are ideal for indoor use, offering heights from 19 to 40 feet, with rental costs starting around $120 per day.

- Diesel scissor elevators are robust for outdoor use, with height ranges from 26 to 60 feet, typically renting for $150 per day.

- Rough terrain scissor elevators feature larger tyres for stability, suitable for building tasks in challenging outdoor conditions, costing around $154 per day.

- Pneumatic scissor platforms operate using air pressure, suitable for specialised applications, with rentals starting at approximately $130 per day.

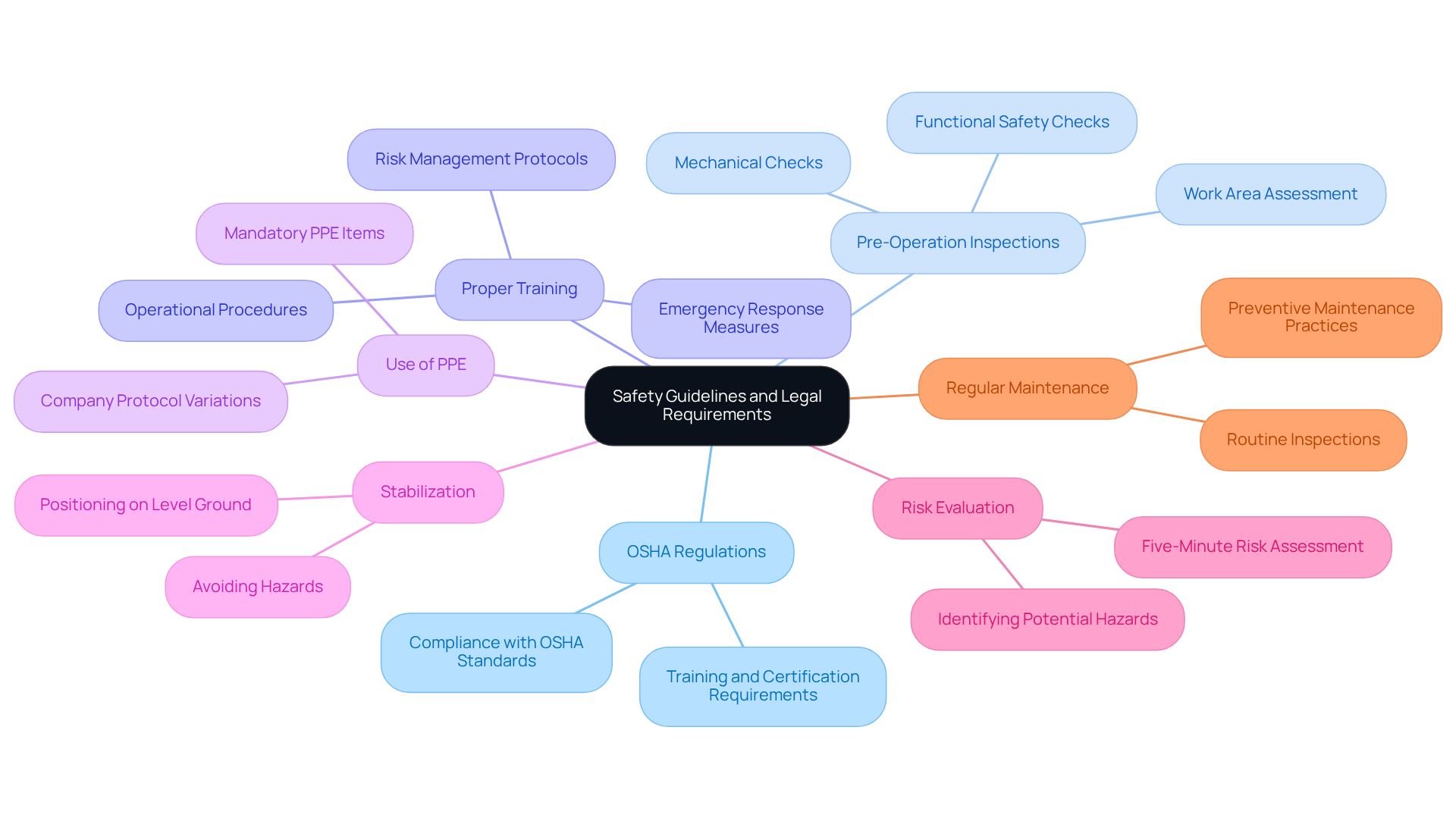

- Safety guidelines include adherence to OSHA regulations, conducting pre-operation inspections, and ensuring proper training for operators.

- Personal protective equipment (PPE) is essential, and platforms must be positioned on stable ground to prevent accidents.

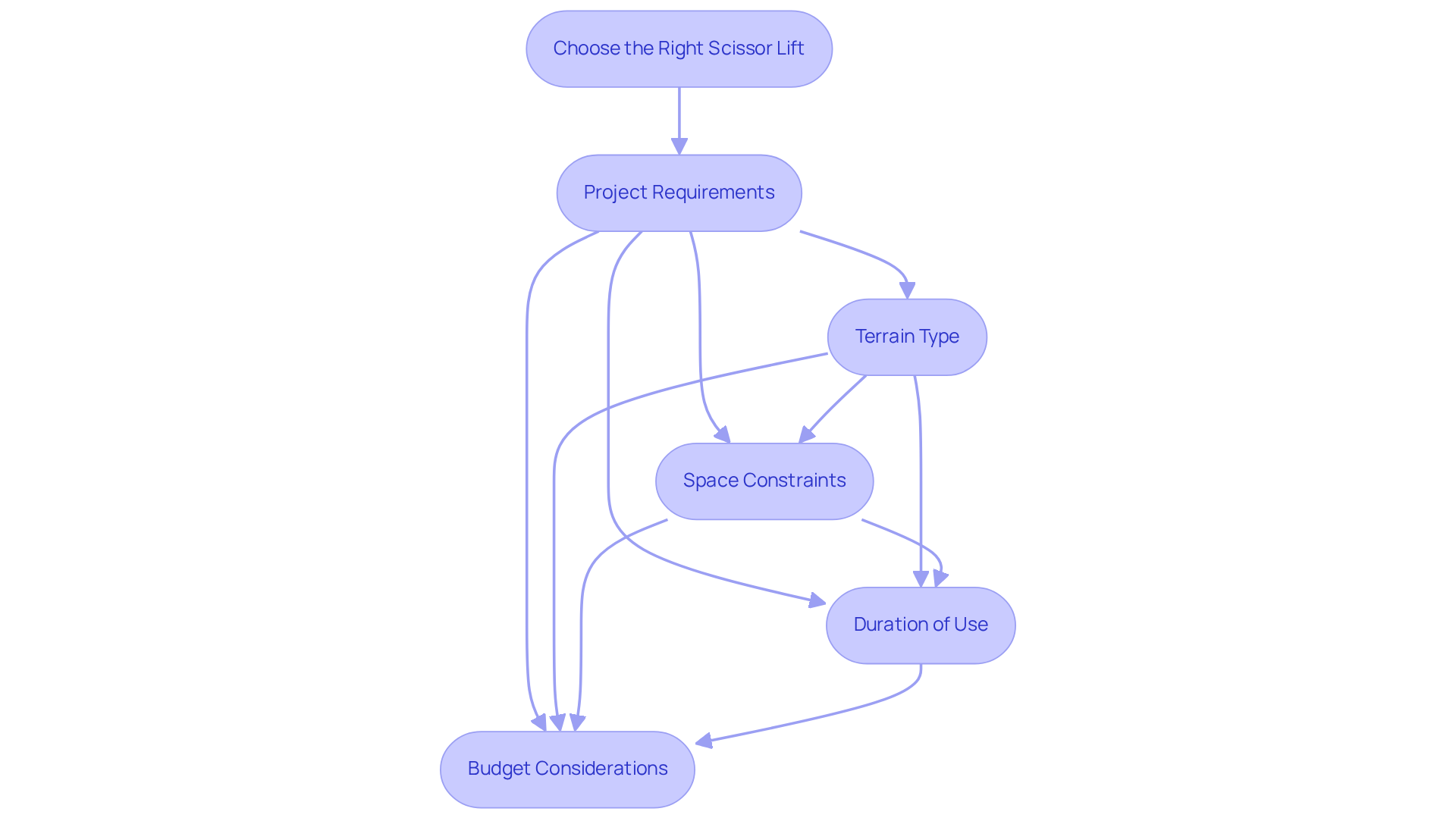

- Selecting the right scissor lift involves assessing project requirements, terrain type, space constraints, duration of use, and budget considerations.

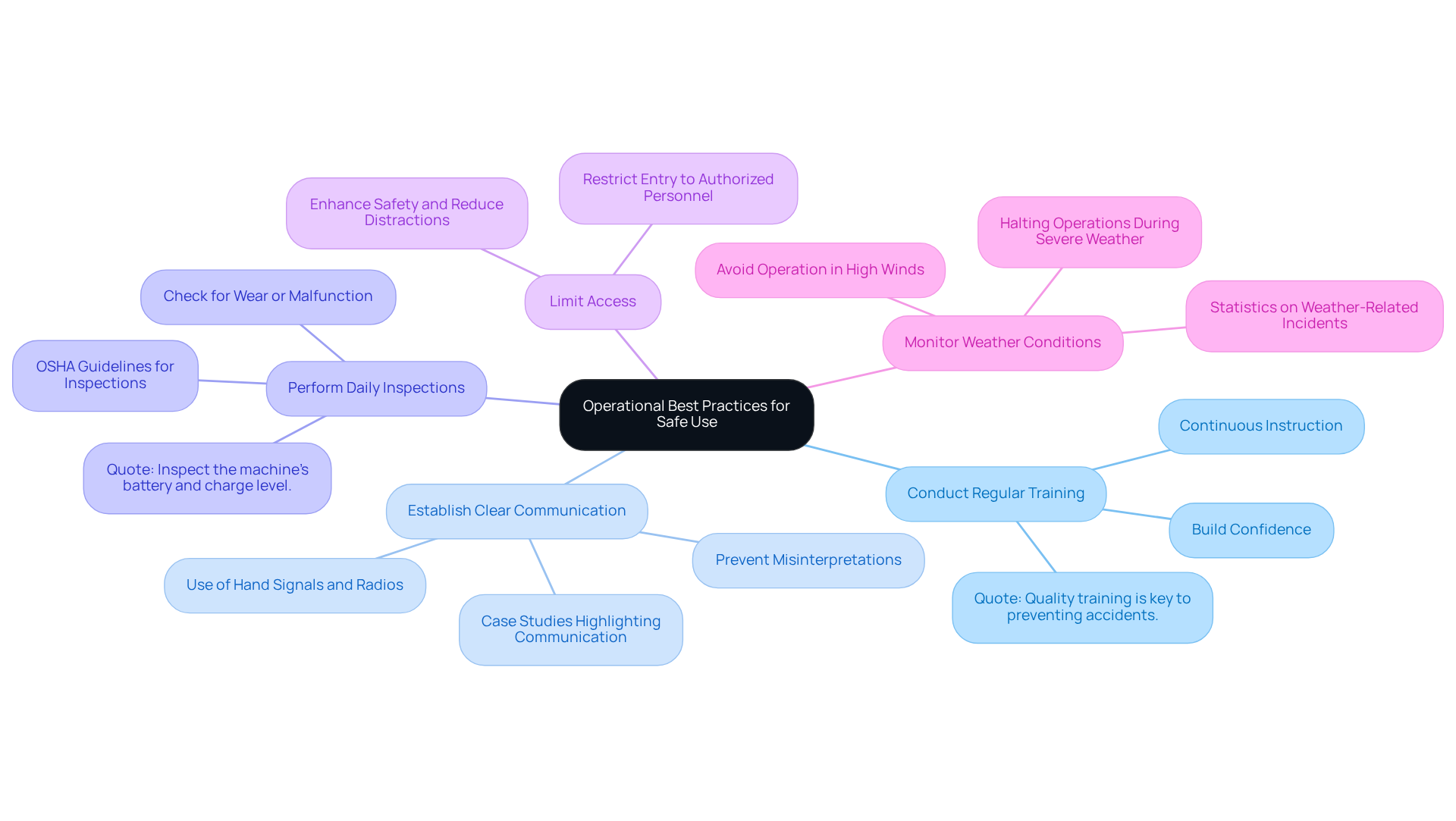

- Best practises for safe operation include regular training, clear communication, daily inspections, limiting access, and monitoring weather conditions.

Introduction

Understanding the nuances of scissor lifts is essential for project managers who want to optimize safety and efficiency on job sites. With a variety of types available - ranging from electric models perfect for indoor tasks to robust diesel versions built for rugged terrains - selecting the right lift can significantly influence project outcomes. However, the complexities of equipment selection and safety compliance raise critical questions. How can project managers ensure they are making the best choices while adhering to strict safety regulations? This article explores 26 best practices for scissor lift rentals, providing managers with the insights needed to elevate their projects while minimizing risks.

Understand Scissor Lifts: Types and Functions

Understanding Scissor Platforms for Your Projects

When it comes to selecting the right equipment for your project, understanding the various types of scissor platforms is essential. Each type is tailored for specific applications, ensuring that project managers can make informed decisions that enhance safety and efficiency.

-

Electric Scissor Platforms: Perfect for indoor environments such as warehouses and retail spaces, electric scissor platforms operate quietly and produce zero emissions. With working heights ranging from 19 to 40 feet, they are versatile for tasks like maintenance and inventory management. Rental prices for a 26 scissor lift rental typically start around $120 per day, making it a cost-effective choice for many projects.

-

Diesel Scissor Elevators: Designed for outdoor use, diesel scissor elevators are robust and capable of navigating uneven terrain. The 26 scissor lift rental is indispensable on construction sites where power and mobility are paramount, offering height ranges from 26 to 60 feet. Their all-weather functionality ensures reliability in demanding conditions, with rental costs generally starting at $150 per day.

-

Rough Terrain Scissor Elevators: Equipped with larger tires and enhanced stability features, rough terrain scissor elevators excel in outdoor building tasks. They provide secure platforms for workers and equipment, even in challenging conditions. For instance, a 26 scissor lift rental with a platform height of 26 feet for rough terrain may cost around $154 per day, making it a practical option for project managers.

-

Pneumatic Scissor Platforms: Utilizing air pressure for operation, pneumatic scissor platforms are ideal for specialized applications where electric or diesel options may not suffice. Their unique functionality allows for flexibility across various industrial settings, with rental prices starting at approximately $130 per day.

Understanding these categories is vital for managers to select the appropriate elevation based on specific project requirements. As one construction specialist noted, "Selecting the appropriate elevating platform is essential for completing your task safely, securely, and efficiently." This knowledge not only enhances safety-using boom platforms and elevating work platforms significantly reduces risks associated with working at heights-but also boosts operational efficiency across diverse job sites.

Take Action: Equip your team with the right tools for success. Explore our range of scissor platforms today and ensure your project runs smoothly and safely.

Follow Safety Guidelines and Legal Requirements

Safety is paramount when using platform elevating equipment. Project managers must prioritize adherence to established guidelines to mitigate risks effectively. By implementing these key practices, you can ensure a safer work environment:

-

OSHA Regulations: Understand and comply with OSHA standards for the operation of a 26 scissor lift rental. These regulations mandate adequate training and precautions to protect workers.

-

Pre-Operation Inspections: Establish a thorough inspection protocol before each use. This includes checking for mechanical issues, ensuring protective devices are functional, and assessing the work area for potential hazards. Regular inspections can prevent incidents and are essential for meeting regulatory standards.

-

Proper Training: Guarantee that all operators are properly trained and certified. Training should cover operational procedures, risk management protocols, and emergency response measures. Untrained operators significantly heighten the risk of accidents, making certification vital for workplace safety.

-

Use of Personal Protective Equipment (PPE): Mandate the use of appropriate PPE, such as hard hats, safety goggles, and harnesses when necessary. While workers are not required to wear harnesses if guardrails are present, company protocols may differ. PPE is a crucial line of defense against potential injuries.

-

Stabilization: Always position elevating platforms on stable, level ground, away from hazards like traffic and overhead power lines. With 26 scissor lift rental options available in gas or electric and various sizes, proper stabilization is critical to prevent tip-overs, which are a leading cause of fatalities in elevating platform operations.

-

Risk Evaluation: Conduct a brief five-minute risk evaluation at ground level before operating a platform to identify potential hazards.

-

Regular Maintenance: Ensure that elevating platforms receive routine maintenance and inspections to keep them in safe working condition.

By adhering to these guidelines, project managers can cultivate a safer work environment, significantly reducing the likelihood of accidents. Statistics reveal that elevating platforms are involved in an average of 20-25 fatalities each year, with the Bureau of Labor reporting eight workplace deaths annually. This highlights the critical need for rigorous safety practices and compliance with regulations.

Choose the Right Scissor Lift for Your Project

Selecting the right 26 scissor lift rental is crucial for maximizing project efficiency and ensuring safety on the job site. Project Requirements are the first consideration; it’s essential to assess the necessary height and weight capacity for your specific task. Scissor platforms come in various maximum heights and load limits, with smaller electric models supporting around 500 pounds and heavy-duty rough-terrain versions exceeding 1,500 pounds. Understanding these specifications is vital for aligning the hoist to the task at hand. As Renison Canesso Moreira, Sales Director, states, "Selecting the perfect elevating platform for your job site requires a thorough evaluation of your particular needs, the working environment, access to grid for recharging batteries, and safety criteria."

Next, consider the Terrain Type. The working environment significantly influences equipment selection. For rough or uneven terrain, a rough terrain scissor platform is essential, while electric models are better suited for indoor, flat surfaces. Terrain compatibility is crucial; using the wrong equipment can lead to safety hazards and operational inefficiencies. The Herc-U-Lift Team emphasizes, "We’re not just an equipment provider; we’re your partner in creating safer job sites and more productive workplaces."

Space Constraints also play a vital role. Evaluate the dimensions of your workspace. Compact models are ideal for tight areas, allowing for maneuverability in confined spaces, whereas larger equipment is more suitable for open environments. Assessing the job site layout beforehand can prevent delays and ensure the right equipment is chosen.

When considering the Duration of Use, determine whether the elevator will be needed for a short-term task or a long-term application. For short-term needs, a 26 scissor lift rental may be more cost-effective, especially considering the significant investment required for purchasing quality equipment. The aerial work platform market is projected to expand at a CAGR of 3.5% from 2025 to 2035, indicating a growing reliance on rental services for management choices.

Lastly, Budget Considerations are paramount. Factor in both rental and purchase expenses, particularly if the equipment will be used frequently. The total cost can significantly impact small to mid-sized contractors, making it essential to weigh the financial implications of each option. Regular maintenance is also crucial, as it extends the life of the equipment and reduces the risk of accidents due to wear and tear, as highlighted by Renison Canesso Moreira.

By thoughtfully evaluating these elements, managers can ensure they choose the most appropriate elevating platform for their specific needs, enhancing both security and efficiency on the work site. Furthermore, recognizing the potential drawbacks of selecting the incorrect elevating platform can help prevent frequent errors that lead to delays and hazards.

Implement Operational Best Practices for Safe Use

To ensure the safe and efficient operation of scissor lifts, project managers must implement essential best practices:

-

Conduct Regular Training: Continuous instruction is vital for operators to stay informed about safety protocols and operational techniques. Regular training sessions not only reinforce knowledge but also build confidence in handling equipment, significantly reducing the risk of accidents. As specialists emphasize, "Quality training is key to preventing accidents and building confidence while handling an elevating machine the right way."

-

Establish Clear Communication: Effective communication strategies, such as using hand signals or radios, are crucial for maintaining coordination between operators and ground personnel, especially in busy environments. Transparent communication can prevent misinterpretations that might lead to incidents, as highlighted in case studies that stress the importance of communication techniques in scissor equipment procedures.

-

Perform Daily Inspections: Operators must conduct thorough daily assessments of the equipment, checking for signs of wear or malfunction. This practice is essential for identifying potential hazards before they result in accidents. Regular pre-use inspections help ensure that all protective features are functional. According to OSHA guidelines, "Inspect the machine’s battery and charge level" and "Verify horns, lights, backup alarms and gauges are working."

-

Limit Access: Restricting entry to the elevator area to authorized personnel only minimizes the risk of accidents. By regulating who is allowed in the operational area, project managers can enhance safety and reduce distractions for operators.

-

Monitor Weather Conditions: Awareness of weather conditions that may affect operation is critical. For example, aerial platforms should not be used in winds exceeding 28 miles per hour, and operations should be halted during severe weather to ensure safety. In 2023, there were 7 fatalities and 3 major injuries related to MEWP overturns, underscoring the importance of monitoring environmental factors.

By adhering to these operational best practices, project managers can significantly enhance the safety and efficiency of operations involving 26 scissor lift rental on their job sites. This commitment ultimately contributes to a safer working environment.

Conclusion

Understanding the complexities of scissor lift rentals is crucial for project managers who want to boost safety and efficiency on job sites. Selecting the right type of scissor lift, following safety guidelines, and implementing operational best practices are key to ensuring projects run smoothly while minimizing risks.

Different scissor lift types - electric, diesel, rough terrain, and pneumatic - each serve specific environments and tasks. It's vital to emphasize safety through compliance with OSHA regulations, proper training, and regular inspections to prevent accidents. Furthermore, choosing the right lift based on project requirements, terrain type, and budget can significantly influence operational success.

Effective management of scissor lift rentals not only fosters a safer work environment but also enhances overall project productivity. By prioritizing safety and embracing best practices, project managers can guide their teams toward successful project completion while cultivating a culture of safety and efficiency. Equip your projects with the right tools and knowledge to navigate the complexities of scissor lift operations effectively.

Frequently Asked Questions

What are scissor lifts and why are they important for projects?

Scissor lifts are types of elevating platforms designed for various applications, enhancing safety and efficiency in projects. Understanding their different types helps project managers select the right equipment for specific tasks.

What are electric scissor platforms, and where are they used?

Electric scissor platforms are used primarily in indoor environments like warehouses and retail spaces. They operate quietly and produce zero emissions, with working heights ranging from 19 to 40 feet, making them suitable for maintenance and inventory management.

What are the rental costs for electric scissor lifts?

Rental prices for a 26-foot electric scissor lift typically start around $120 per day.

What are diesel scissor elevators, and what are their key features?

Diesel scissor elevators are designed for outdoor use and can navigate uneven terrain. They offer height ranges from 26 to 60 feet and are ideal for construction sites due to their power and mobility.

How much does it cost to rent a diesel scissor elevator?

Rental costs for a diesel scissor elevator generally start at $150 per day.

What distinguishes rough terrain scissor elevators from other types?

Rough terrain scissor elevators are equipped with larger tires and enhanced stability features, making them suitable for outdoor building tasks in challenging conditions.

What are the rental costs for rough terrain scissor elevators?

A 26-foot rough terrain scissor lift rental may cost around $154 per day.

What are pneumatic scissor platforms, and when are they used?

Pneumatic scissor platforms operate using air pressure and are ideal for specialized applications where electric or diesel options may not be suitable. They offer flexibility across various industrial settings.

How much does it cost to rent a pneumatic scissor platform?

Rental prices for pneumatic scissor platforms start at approximately $130 per day.

Why is it important to choose the right type of scissor lift for a project?

Selecting the appropriate elevating platform is essential for completing tasks safely, securely, and efficiently, which reduces risks associated with working at heights and boosts operational efficiency across job sites.