Overview

Efficient pallet jack forklift rental hinges on three key practices:

- Understanding the types of pallet jacks available.

- Evaluating rental terms for cost-effectiveness.

- Implementing comprehensive training and safety protocols.

First, recognizing the variety of pallet jacks—manual, electric, and walkie models—allows businesses to select the right equipment for their specific needs. Furthermore, evaluating flexible rental agreements can significantly minimize costs, ensuring that businesses only pay for what they need. Lastly, emphasizing proper training and safety measures not only reduces workplace accidents but also enhances operational efficiency, making it a critical component of any rental strategy. By prioritizing these practices, companies can optimize their pallet jack rental experience and drive success in their operations.

Key Highlights:

- Pallet jacks are vital for material handling, available in manual, electric, and rider types.

- Manual pallet jacks are cost-effective for short-distance transport of lighter loads.

- Electric hand trucks are battery-powered, suitable for heavier loads, and reduce operator strain.

- Rider pallet lifters allow operators to ride while transporting goods, enhancing speed and efficiency.

- Evaluating rental terms is crucial for cost-effectiveness, including rental duration and cost structure.

- Understanding pricing models and hidden fees is essential for informed rental decisions.

- Flexibility in rental agreements can lead to significant savings during extended use.

- Comprehensive operator training is necessary to ensure safe operation and reduce accidents.

- Regular inspections of equipment help identify mechanical issues and prevent injuries.

- Establishing clear safety protocols can significantly lower incident rates and improve efficiency.

Introduction

Navigating the world of pallet jack forklift rentals presents unique challenges, particularly given the extensive array of options and the essential role these machines serve in material handling. A thorough understanding of the various types of pallet jacks—ranging from manual to electric and rider models—can significantly bolster operational efficiency and safety within any warehouse environment. As the demand for effective leasing solutions continues to rise, businesses must prioritize making informed, cost-effective, and safe choices. This article explores three key practices designed to streamline the rental process while minimizing risks associated with improper equipment use and unexpected costs.

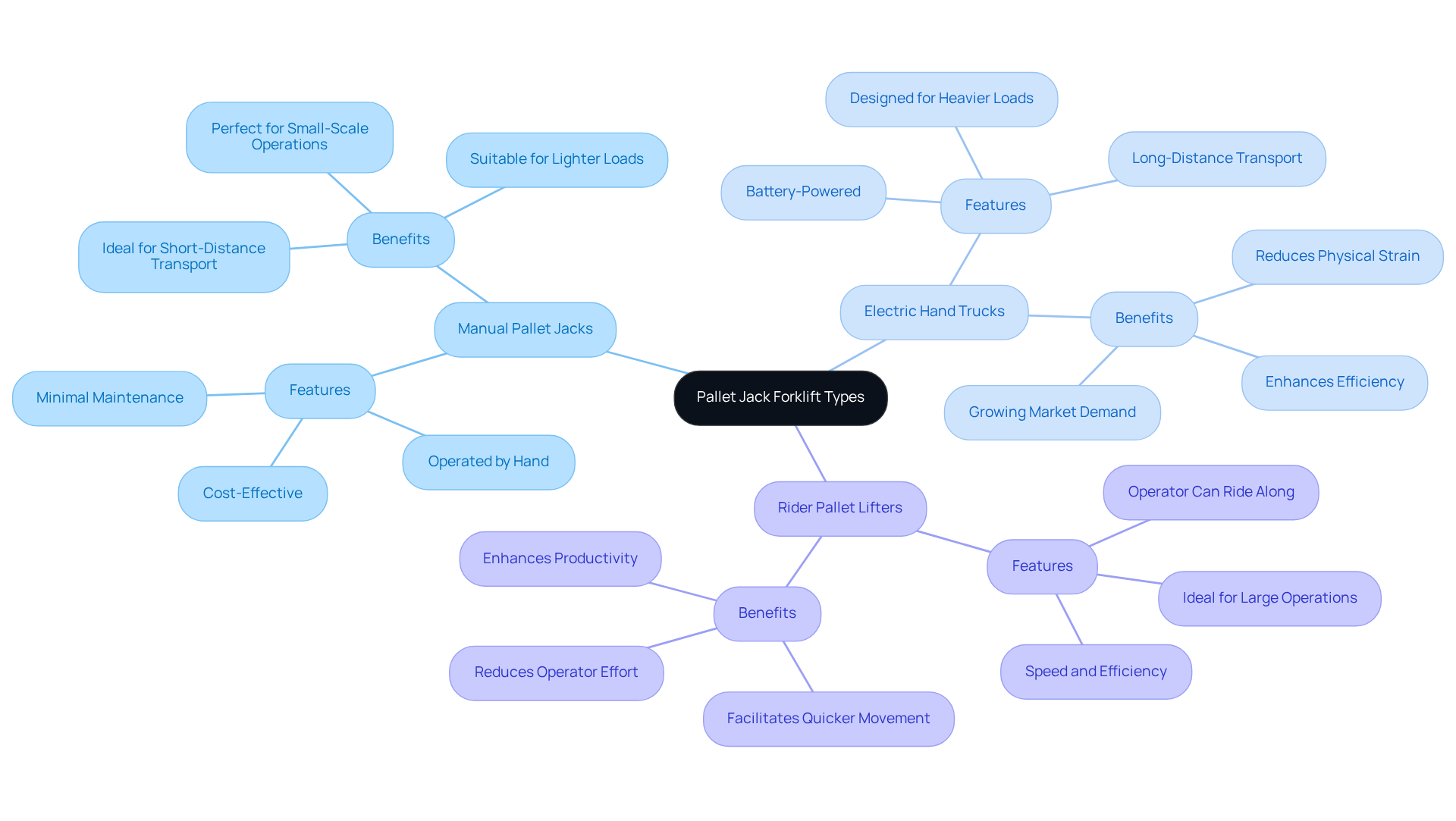

Understand Pallet Jack Forklift Types and Features

Pallet lifters are essential tools in material handling, available in various types, including manual, electric, and rider models. Understanding these options is vital for optimizing warehouse operations:

-

Manual Pallet Jacks: Operated by hand, these jacks excel in short-distance transport and lighter loads. They are cost-effective, require minimal maintenance, and are particularly suited for small-scale operations where budget constraints are a priority.

-

Electric Hand Trucks: Powered by batteries, electric hand trucks are designed for heavier loads and longer distances. They significantly reduce physical strain on operators, enhancing efficiency in busy environments. The market for electric lifting devices is projected to capture a substantial share, driven by the increasing demand for automated material handling solutions. According to industry reports, the electric transport vehicle market is expected to grow at a CAGR of 4.5% from 2025 to 2035, indicating a notable shift towards powered solutions.

-

Rider Pallet Lifters: These devices allow operators to ride along while transporting goods, making them ideal for larger operations and extensive warehouse tasks. They are particularly advantageous in environments where speed and efficiency are paramount, facilitating quicker movement across expansive areas. Industry leaders, such as Toyota Material Handling, emphasize that rider transport devices enhance productivity by enabling operators to cover more ground with reduced effort.

Each type of lifting device possesses unique characteristics, including load capacity, fork length, and maneuverability. Aligning these features with the operational needs of your project is essential for improving efficiency and ensuring safety in material handling tasks. As the industry evolves, trends indicate a growing preference for electric and rider lifting devices, reflecting a shift towards more efficient and ergonomic solutions in warehouse operations. However, it is crucial to avoid common pitfalls, such as selecting the wrong type of lifting equipment for specific tasks, which can lead to safety issues and operational inefficiencies.

Evaluate Rental Terms for Cost-Effectiveness

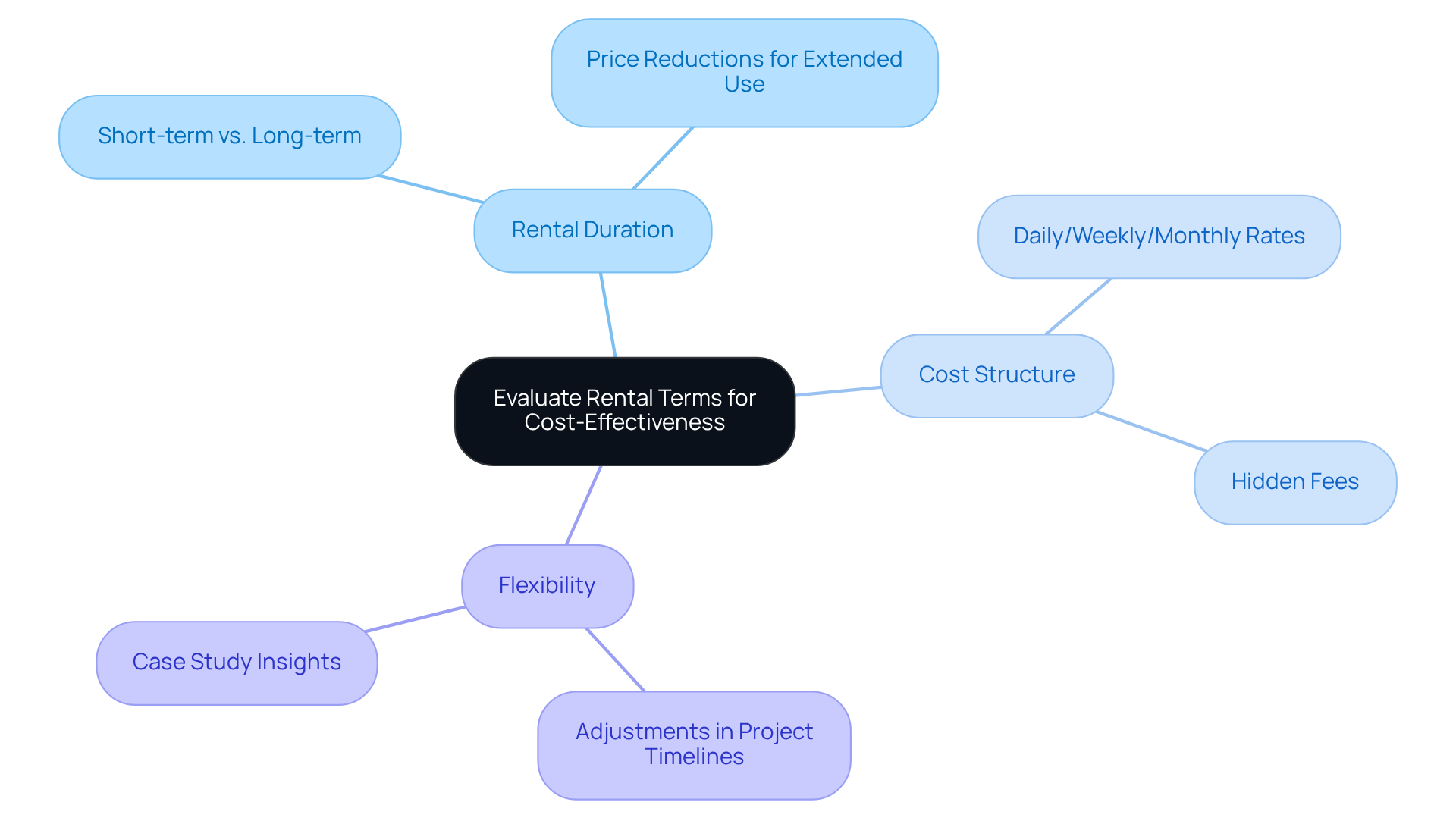

When renting a pallet jack forklift rental, evaluating key terms is essential for ensuring cost-effectiveness.

Rental Duration: Determine whether your project necessitates the equipment for a short-term or long-term basis. Many leasing firms provide price reductions for extended usage, significantly lowering total costs. Notably, market forecasts indicate that the global pallet jack forklift rental market is projected to reach USD 3,660.9 million by 2033, highlighting the growing demand for efficient leasing solutions.

Cost Structure: It is vital to understand the pricing model, which includes daily, weekly, and monthly rates. Be cautious of hidden fees that may arise, such as delivery charges, maintenance costs, and insurance, as these can inflate the overall expense. Industry experts emphasize that a comprehensive understanding of the cost structure is crucial for making informed decisions.

Flexibility: Ensure that the lease agreement allows for adjustments in project timelines. This flexibility is critical, as it can result in significant savings if equipment is required for a longer duration than initially planned. For example, the case study on 'Pallet Jack Forklift Rental Demand in the Middle East & Africa' illustrates how companies with flexible pallet jack forklift rental agreements successfully adapted to changing project needs without incurring additional costs.

By carefully evaluating these terms, you can align your rental decision with your budget and project requirements, ultimately fostering cost savings and enhancing operational efficiency.

Implement Training and Safety Protocols

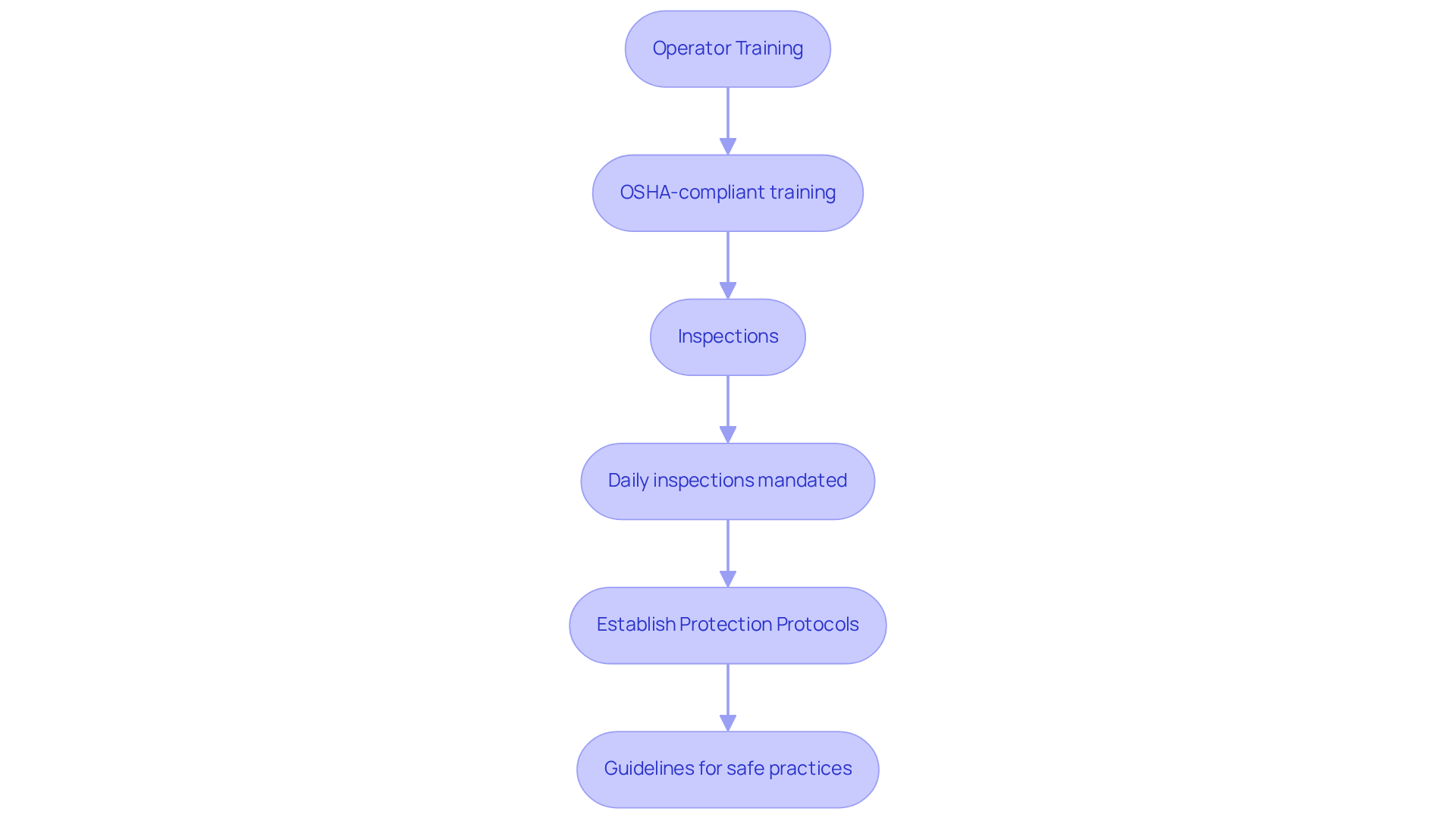

To ensure the safe and efficient operation of a pallet jack forklift rental, implementing robust training and safety protocols is essential.

Operator Training: Comprehensive training for all operators is crucial. This training should encompass the correct use of pallet jack forklift rental, along with load handling techniques and emergency procedures. Employing OSHA-compliant training programs not only meets regulatory standards but also fosters a culture of well-being within the organization. Research indicates that proper training can reduce accidents by up to 70%, underscoring its significance in preventing workplace injuries. Moreover, forklift incidents result in approximately 85 fatalities each year, highlighting the urgent need for precautionary measures and training.

Inspections: Regular assessments of equipment before use are vital. Operators should inspect for visible damage, ensure all components are functioning properly, and confirm that protective features are operational. According to OSHA, daily inspections are mandated to catch mechanical issues that could lead to injuries or fatalities. This proactive approach minimizes risks associated with equipment failure. It is also important to note that workers who operate machinery suffer approximately 18,000 amputations, lacerations, crush injuries, and abrasions per year, emphasizing the necessity of thorough inspections.

Establish Protection Protocols: Clear protection protocols must be established, including guidelines for load limits, proper lifting techniques, and safe maneuvering practices. Motivating operators to report any concerns promptly can aid in identifying potential dangers before they lead to incidents. As highlighted by experts in risk management, fostering a culture of security and adherence is crucial for lowering incident rates and improving operational efficiency. Furthermore, OSHA estimates a sixfold return on investment for every dollar allocated to protection, providing a strong financial incentive for organizations to prioritize training and protocols. A single manufacturing incident related to production can have significant cost implications, making it imperative to implement effective protection measures.

By prioritizing comprehensive training and stringent safety protocols, organizations can significantly reduce the risk of accidents and enhance the overall efficiency of their operations.

Conclusion

Understanding the nuances of pallet jack forklift rental is essential for enhancing operational efficiency and ensuring safety in material handling. By recognizing the diverse types of pallet jacks available and aligning their features with specific project needs, organizations can significantly improve their workflow and productivity. This strategic approach not only optimizes equipment usage but also mitigates potential safety hazards associated with improper selection.

This article highlights three key practices:

- Understanding the different types of pallet jacks

- Evaluating rental terms for cost-effectiveness

- Implementing thorough training and safety protocols

Each aspect plays a vital role in creating a seamless rental experience. From choosing the right equipment based on operational demands to scrutinizing rental agreements for hidden costs and ensuring proper operator training, these practices collectively contribute to a safer and more efficient workplace.

Ultimately, prioritizing these best practices in pallet jack forklift rental transcends immediate cost savings or operational efficiency; it fosters a culture of safety and responsibility within the organization. By investing in proper training and adhering to safety protocols, companies can protect their workforce while enhancing productivity. Embracing these strategies will lead to better equipment utilization and create a more secure and effective working environment for all involved.

Frequently Asked Questions

What are the main types of pallet jacks?

The main types of pallet jacks are manual pallet jacks, electric hand trucks, and rider pallet lifters.

What are the features of manual pallet jacks?

Manual pallet jacks are operated by hand, excel in short-distance transport and lighter loads, are cost-effective, require minimal maintenance, and are suited for small-scale operations.

How do electric hand trucks differ from manual pallet jacks?

Electric hand trucks are powered by batteries, designed for heavier loads and longer distances, significantly reduce physical strain on operators, and enhance efficiency in busy environments.

What is the expected growth trend for the electric transport vehicle market?

The electric transport vehicle market is projected to grow at a CAGR of 4.5% from 2025 to 2035, indicating a notable shift towards powered solutions in material handling.

What are the advantages of rider pallet lifters?

Rider pallet lifters allow operators to ride along while transporting goods, making them ideal for larger operations. They enhance productivity by enabling quicker movement across expansive areas.

What factors should be considered when choosing a pallet jack?

Factors to consider include load capacity, fork length, maneuverability, and aligning these features with the operational needs of your project to improve efficiency and ensure safety.

What trends are emerging in the pallet jack industry?

There is a growing preference for electric and rider lifting devices, reflecting a shift towards more efficient and ergonomic solutions in warehouse operations.

What common pitfalls should be avoided when selecting lifting equipment?

Common pitfalls include selecting the wrong type of lifting equipment for specific tasks, which can lead to safety issues and operational inefficiencies.