Key Highlights:

- Skid steers are compact vehicles used in construction, landscaping, and agriculture, known for their tight turning radius and manoeuvrability.

- They come in various sizes, with mid-size machines (1,501 to 2,500 lbs) dominating the market share in 2023 due to their balance of power and agility.

- Most skid steers utilise diesel engines for torque and fuel efficiency, crucial for heavy-duty tasks.

- The hydraulic system is essential for operating implements, influencing the selection of accessories and overall productivity.

- Key performance indicators (KPIs) for skid steers include Rated Operating Capacity (ROC), horsepower, breakout force, and hydraulic flow rate, all critical for matching machines to specific project needs.

- Attachment compatibility is vital; operators must ensure that implements match the skid steer’s hydraulic requirements and weight capacity to avoid overloading.

- Operator comfort and usability impact productivity and safety, emphasising the importance of ergonomic design, visibility, control systems, and cab features.

Introduction

Choosing the right skid steer is crucial for the success of any construction, landscaping, or agricultural project. With numerous options available, it’s essential to grasp the fundamentals of skid steers, including their performance metrics and the significance of operator comfort. This understanding is vital for making an informed decision. Given the many factors to consider, how can one ensure they select the best skid steer for their specific needs? This article explores best practices for choosing the ideal compact loader, providing readers with the knowledge necessary to navigate the complexities of skid steer selection and enhance their project outcomes.

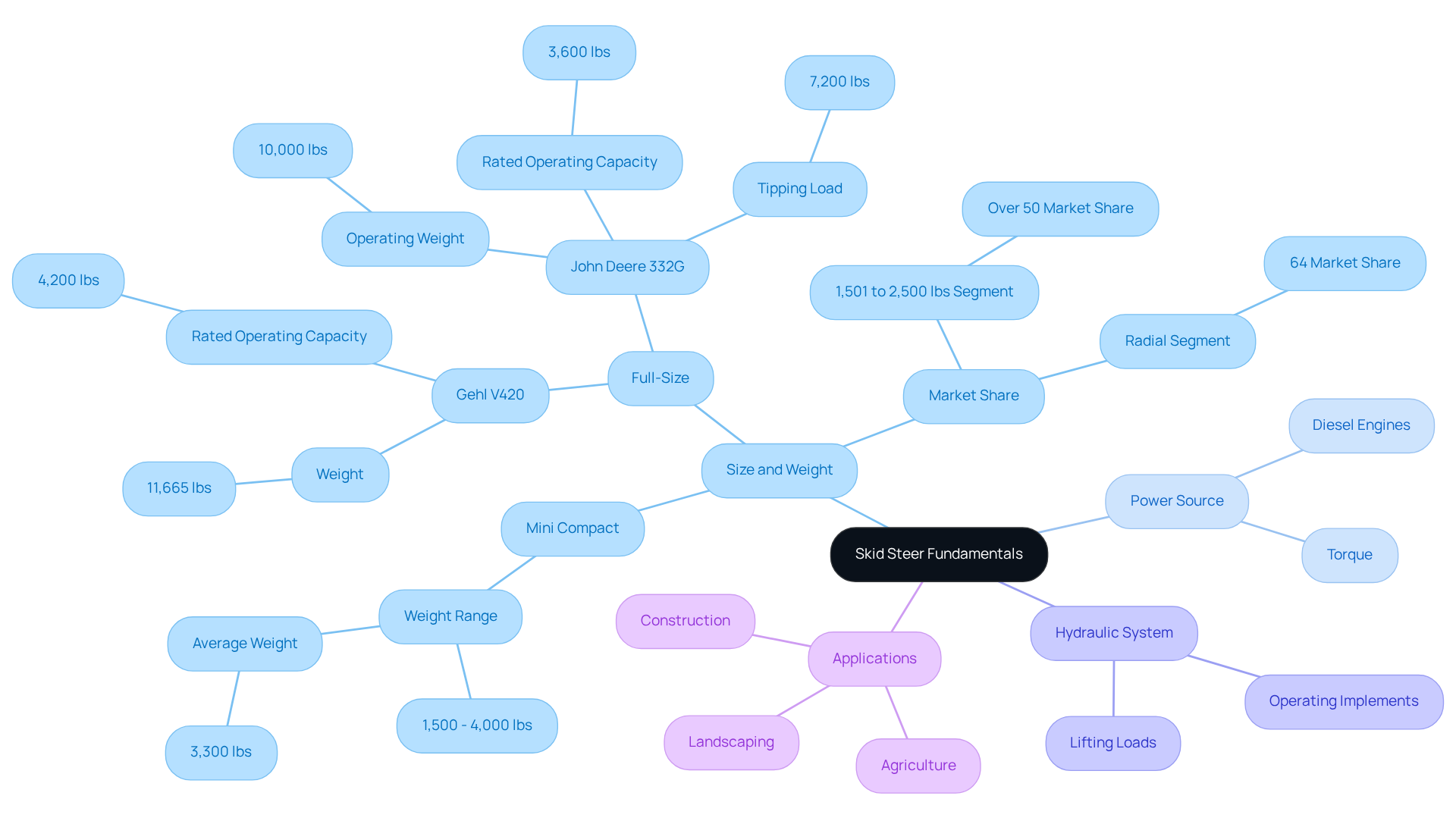

Understand Skid Steer Fundamentals

A compact and versatile vehicle is commonly utilized in construction, landscaping, and agricultural applications. Its distinctive steering system, where the wheels on each side are mechanically linked, enables tight turns and exceptional maneuverability in confined spaces. Key features include:

- Size and Weight: Skid steers come in various sizes, typically categorized as small, medium, and large, each designed for specific tasks. Mini compact vehicles usually weigh around 3,300 pounds, while full-size versions can be significantly heavier, with the Gehl V420 reaching up to 11,665 pounds. Understanding these dimensions is essential for effective operation in the intended environment. Notably, the segment of 1,501 to 2,500 lbs, which features the best skid steer models, accounted for over 50% of the market share in 2023, underscoring the popularity of mid-size machines that balance power and maneuverability.

- Power Source: Most skid steers are equipped with diesel engines, providing the necessary torque and fuel efficiency for demanding tasks. Engine specifications are crucial for evaluating the machine's capability, particularly in heavy-duty applications.

- Hydraulic System: The hydraulic system is vital for operating implements and lifting loads. Familiarity with the hydraulic capabilities can significantly influence the selection of accessories, enhancing overall performance and productivity.

Real-world applications of the best skid steer in landscaping and agriculture highlight their versatility. They are frequently used for grading, digging, and transporting materials, making them indispensable on job sites. Construction experts often emphasize the adaptability of compact loaders, noting their ability to manage various attachments, from buckets to augers, which further enhances their utility. As one construction manager remarked, "The adaptability of compact machines enables us to address a wide variety of tasks effectively, making them an essential element on our job sites."

By grasping these fundamentals, operators can effectively match compact loaders to their specific project requirements, ultimately boosting efficiency and productivity on the job site. Additionally, understanding potential pitfalls, such as the impact of attachments on Rated Operating Capacity (ROC) and the importance of tipping loads, can help avoid common mistakes in equipment selection.

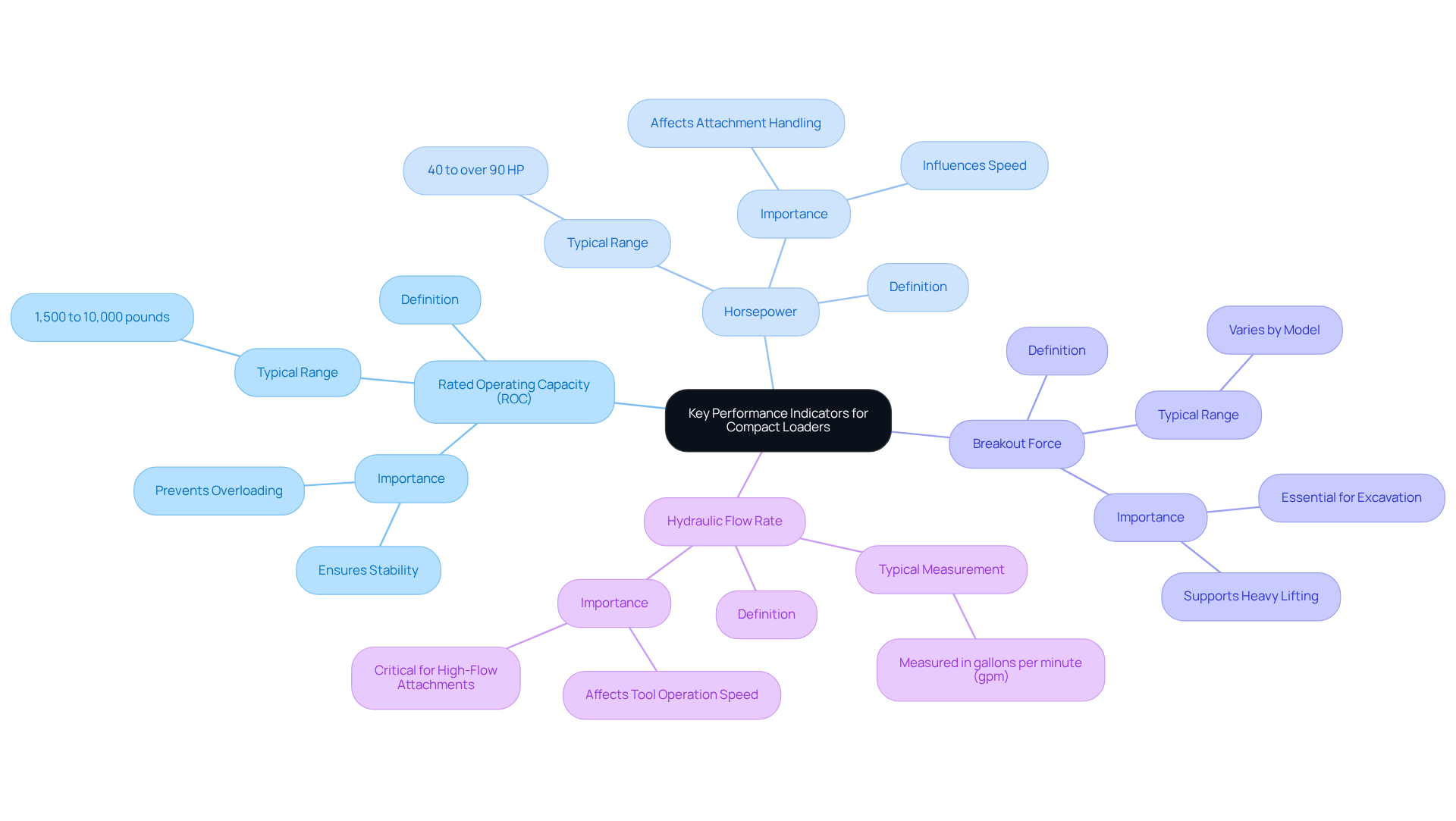

Evaluate Key Performance Indicators

When selecting a compact loader, evaluating key performance indicators (KPIs) is crucial to ensure the machine meets your project requirements. The primary KPIs to consider include:

-

Rated Operating Capacity (ROC): This metric indicates the maximum weight the skid steer can safely lift and carry, typically ranging from 1,500 pounds to over 10,000 pounds. A higher ROC is essential for heavy-duty tasks, while a lower ROC may suffice for lighter jobs. Understanding the ROC helps prevent overloading, which can lead to tipping or loss of control.

-

Horsepower: The engine's horsepower influences the machine's speed and its ability to handle various attachments. Compact loaders generally possess horsepower ranging from 40 to over 90 HP. More horsepower typically translates to better performance in demanding conditions, allowing for quicker cycle times and enhanced efficiency.

-

Breakout Force: This represents the maximum force the skid steer can exert to lift or dig. A higher breakout force is advantageous for tasks such as excavation or lifting heavy materials, ensuring effective operation. For example, models like the ASV VS75, with a breakout force of 192 lb-ft, excel in heavy-duty applications.

-

Hydraulic Flow Rate: This determines how quickly the hydraulic system can operate with tools. A higher flow rate enables faster operation of hydraulic tools, improving overall efficiency. For instance, high-flow attachments require compact loaders with robust hydraulic systems to function effectively.

By thoroughly assessing these KPIs, operators can select a compact loader that aligns with their specific operational needs, ensuring optimal performance on the job site. Additionally, insights from industry leaders, such as Caterpillar's focus on durability and Bobcat's commitment to setting industry standards, can further inform decision-making. Real-world examples, like the effective use of compact equipment in construction projects, underscore the importance of choosing the right machine based on these metrics.

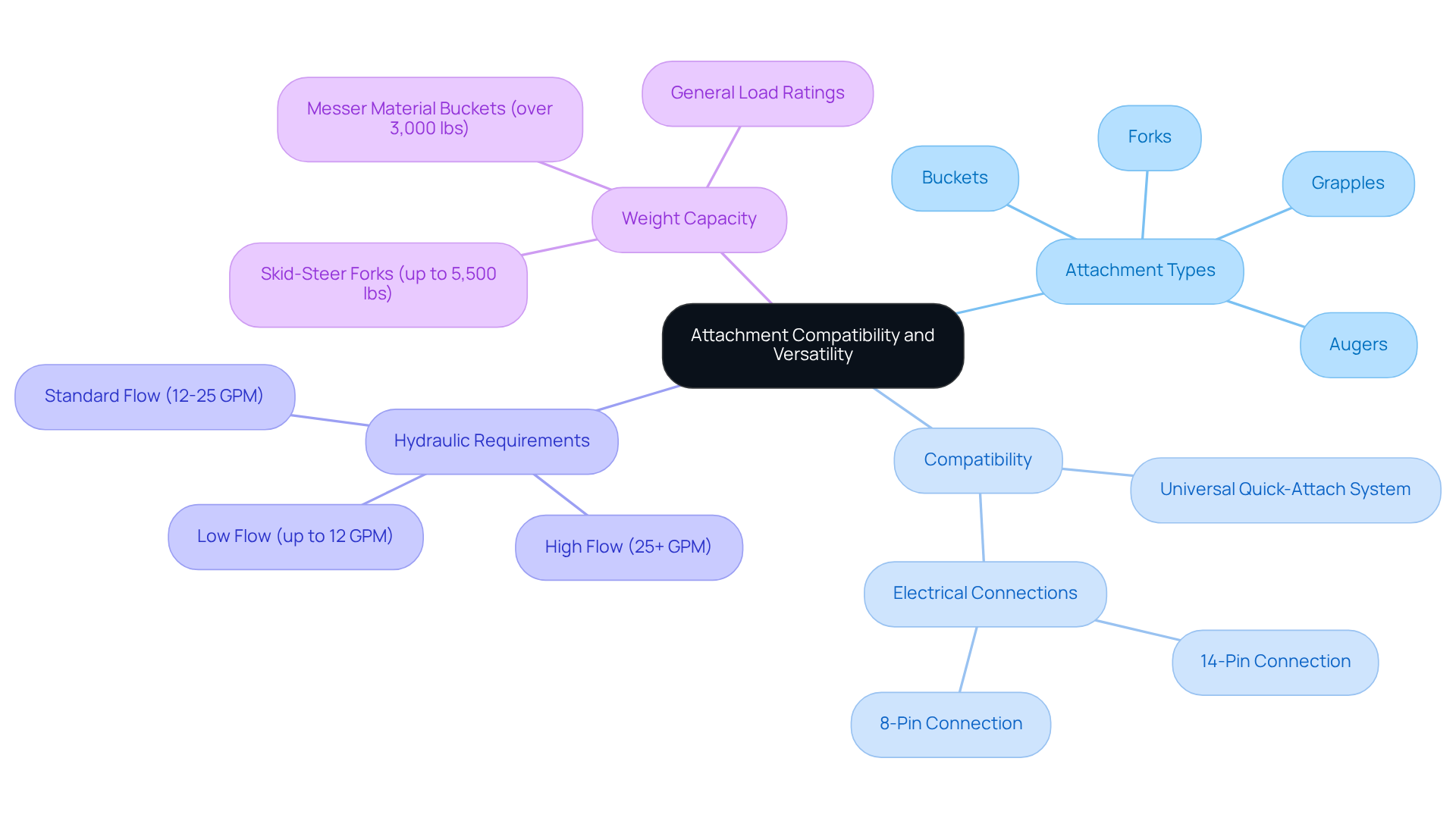

Assess Attachment Compatibility and Versatility

Skid loaders are renowned for their adaptability, primarily due to their compatibility with a wide array of implements, making them indispensable for various applications. When selecting a skid steer, consider the following key factors:

- Attachment Types: Common attachments include buckets, forks, grapples, and augers, each tailored for specific tasks. Understanding the requirements of your project is essential to select the appropriate attachment.

- Compatibility: Most modern compact loaders feature a universal quick-attach system; however, it is crucial to confirm compatibility with specific implements. This ensures secure operation and prevents potential damage to both the vehicle and the tools. Additionally, verify the presence of 14-pin and 8-pin electrical connections, as these are vital for ensuring compatibility with different skid steer models.

- Hydraulic Requirements: Different implements require varying hydraulic flow rates. For example, standard flow implements typically demand 12-25 gallons per minute (GPM), while high-flow tools require over 25 GPM. Low flow accessories need up to 12 GPM. Ensuring that your loader meets these requirements is critical for efficient operation. It is advisable to consult with dealers or accessory suppliers regarding plug compatibility and adapter kits for specific models.

- Weight Capacity: Each accessory comes with a weight rating, and it is important to ensure that the skid steer can manage the combined weight of the accessory and the load without exceeding its rated operating capacity. For instance, skid-steer forks can lift loads up to 5,500 lbs, while specialized tools like Messer Material Buckets can handle over 3,000 lbs. Ignoring load and capacity ratings or using non-certified implements can jeopardize both equipment and personnel.

By thoroughly assessing attachment compatibility and versatility, operators can significantly enhance the functionality of their compact loaders, which can be considered the best skid steer for effectively tackling a broader range of tasks across diverse projects.

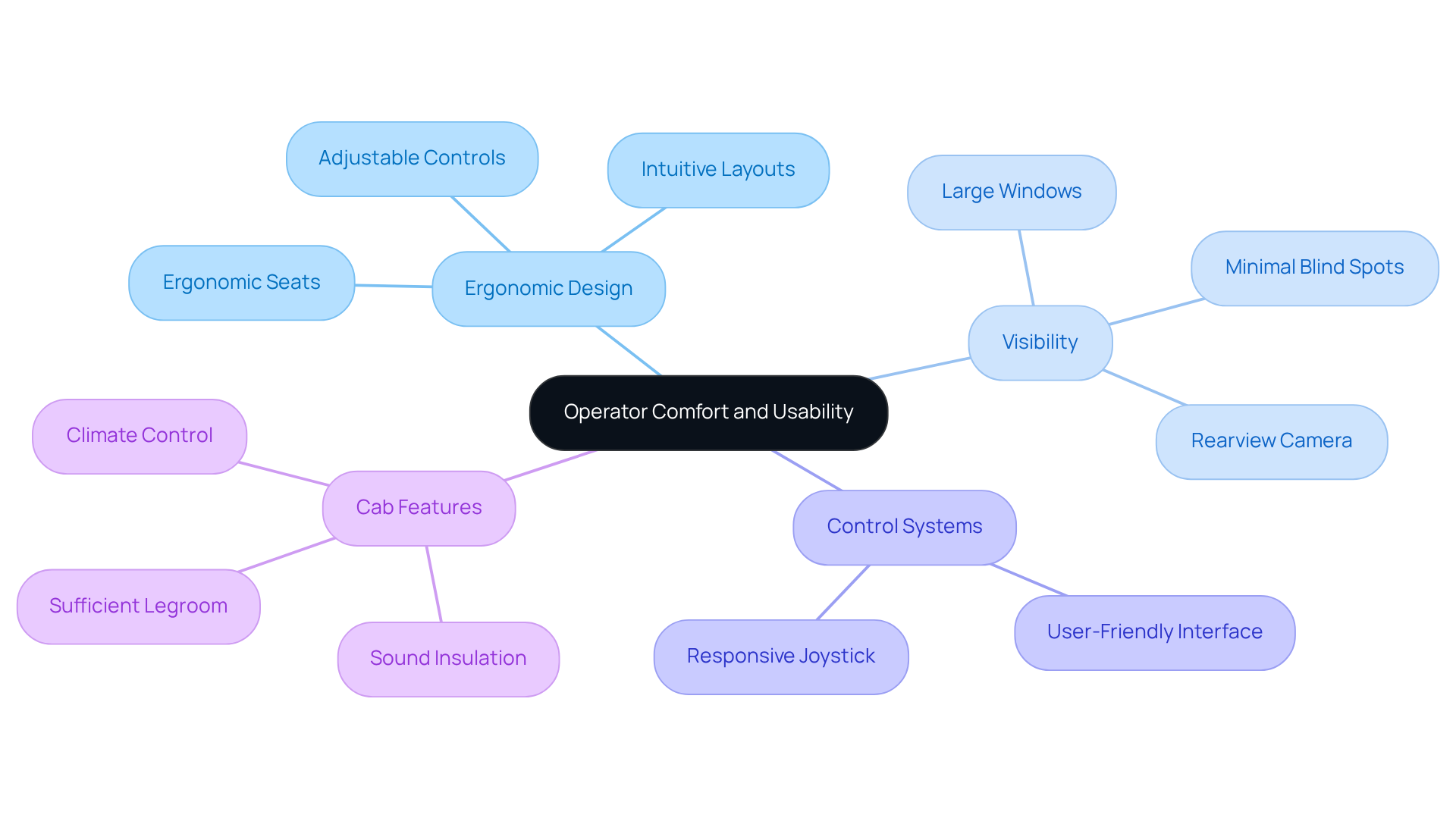

Prioritize Operator Comfort and Usability

Operator comfort and usability are crucial factors that significantly impact productivity and safety when operating a compact loader. Consider the following aspects:

- Ergonomic Design: Choose skid steers equipped with ergonomic seats, adjustable controls, and intuitive layouts. A well-designed operator station minimizes fatigue and enhances comfort during extended hours of operation.

- Visibility: Adequate visibility from the operator's seat is vital for safe operation. Operators can clearly see their surroundings with the best skid steer, which features large windows and minimal blind spots, thereby reducing the risk of accidents.

- Control Systems: Assess the control systems for user-friendliness. Joystick controls should be responsive and easy to manage, allowing operators to perform tasks effectively without unnecessary strain.

- Cab Features: Elements such as climate control, sound insulation, and sufficient legroom contribute to a comfortable working environment. An operator who is comfortable is more likely to maintain focus and execute tasks efficiently.

By prioritizing operator comfort and usability in the best skid steer, you can enhance productivity and safety on the job site, ultimately leading to improved project outcomes.

Conclusion

Selecting the ideal skid steer for a project is a crucial decision that can greatly influence efficiency and productivity. To navigate this process effectively, operators must understand the fundamentals, evaluate key performance indicators, assess attachment compatibility, and prioritize operator comfort. By concentrating on these aspects, they can choose a machine that not only meets their specific needs but also enhances overall job site performance.

Key considerations include:

- Size and weight

- Power sources

- Hydraulic systems

All of which play a vital role in determining the right skid steer for various applications. Evaluating performance metrics such as:

- Rated Operating Capacity

- Horsepower

- Breakout force

Enables informed decisions that align with project demands. Additionally, considering attachment types and ensuring compatibility can maximize the versatility of these machines, allowing them to tackle a wide range of tasks effectively.

Ultimately, selecting the right skid steer transcends mere specifications; it impacts operational safety, comfort, and productivity. By applying these best practices, operators can confidently navigate the complexities of skid steer selection, ensuring they invest in a machine that delivers optimal results across diverse projects. Embracing these insights not only enhances immediate project outcomes but also fosters a safer and more efficient working environment.

Frequently Asked Questions

What is a skid steer and where is it commonly used?

A skid steer is a compact and versatile vehicle commonly utilized in construction, landscaping, and agricultural applications.

What are the key features of skid steers?

Key features of skid steers include their size and weight, power source, and hydraulic system, which contribute to their maneuverability and operational capabilities.

How are skid steers categorized by size?

Skid steers are categorized as small, medium, and large, with mini compact vehicles typically weighing around 3,300 pounds and full-size versions, like the Gehl V420, weighing up to 11,665 pounds.

What is the market share of mid-size skid steers?

The segment of skid steers weighing between 1,501 to 2,500 lbs accounted for over 50% of the market share in 2023, indicating their popularity for balancing power and maneuverability.

What type of engine do most skid steers have?

Most skid steers are equipped with diesel engines, which provide the necessary torque and fuel efficiency for demanding tasks.

Why is the hydraulic system important in skid steers?

The hydraulic system is vital for operating implements and lifting loads, and understanding its capabilities can influence the selection of accessories to enhance performance and productivity.

What are some common applications of skid steers in landscaping and agriculture?

Skid steers are frequently used for grading, digging, and transporting materials, making them indispensable on job sites.

How do attachments affect the use of skid steers?

Skid steers can manage various attachments, such as buckets and augers, which enhance their utility and adaptability for different tasks on job sites.

What should operators consider to avoid common mistakes with skid steers?

Operators should understand the impact of attachments on Rated Operating Capacity (ROC) and the importance of tipping loads to avoid common mistakes in equipment selection.

List of Sources

- Understand Skid Steer Fundamentals

- How Much Does a Skid Steer Weigh? (https://skidsteersdirect.com/blogs/news/how-much-does-a-skid-steer-weight?srsltid=AfmBOoqu6RG_PR6Lb3aFBbanNUtQV_QR2YwjGCpMNeGafVlEVp7jWlwN)

- Skid Steer Loaders Market Size, Share & Growth Report, 2032 (https://gminsights.com/industry-analysis/skid-steer-loaders-market)

- Skid Steer Loader Market Share and Statistics 2025-2035 (https://factmr.com/report/389/skid-steer-loader-market)

- Skid Steer Loaders Market Size, Share, Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/skid-steer-loaders-market)

- Skid Steer Loader Market Size & Forecast 2025 to 2035 (https://futuremarketinsights.com/reports/skid-steer-loader-market)

- Evaluate Key Performance Indicators

- Skid Steer Lifting Capacity: Everything You Need To Know (https://landmarktools.com/blogs/guides/skid-steer-lifting-capacity-everything-you-need-to-know?srsltid=AfmBOooKZIyG9kUqVH9eWWYNTXGlrvBKpvM8cQF6vKwzYSbkbBl4586G)

- Skid Steer Loader Market Report, Industry Size & Revenue, Share, Forecast 2024–2030 (https://strategicmarketresearch.com/market-report/skid-steer-loader-market)

- Top 7 Skid Steers Ever Produced | Big Bear Engine Company (https://4btengines.com/top-10-skid-steers-ever-produced?srsltid=AfmBOopfbIMmPkPidFVacmwoDa34UcM6SxUBzDcufdU8QUs8slpTAYO1)

- Skid Steer Lift Capacity: What You Need to Know (https://fivestarequipment.com/skid-steer-lift-capacity-what-you-need-to-know)

- Skid-Steer Loaders - Bobcat Company (https://bobcat.com/na/en/equipment/loaders/skid-steer-loaders)

- Assess Attachment Compatibility and Versatility

- A Complete Guide to Skid-Steer Attachments - Star Industries (https://starindustries.com/a-complete-guide-to-skid-steer-attachments)

- Everything You Need to Know About Skid Steer Attachments [Complete 2024 Guide] - Messer Attachments (https://messerattach.com/everything-you-need-to-know-about-skid-steer-attachments-complete-2021-guide?srsltid=AfmBOopOnR9L2fqRLq2dewMr55geL-wLVe230hWihfdQOriTrWPnLb_2)

- Compatibility Guide | Forge Equipment (https://forgeattachments.com/compatibility?srsltid=AfmBOooBizjoWuYqM6qbfK9LurYgWMh5r3_cWVlrFsPhqKoGjZPHkSuJ)

- Skid Steer Attachment Compatibility: What Fits Your Model? (https://skidpro.com/attachment-compatibility-what-works-with-my-skid-steer-model)

- 17 Best Skid Steer Attachments & Their Uses | BigRentz (https://bigrentz.com/how-to-guides/best-attachments-skid-steer-loader?srsltid=AfmBOopfF25wBngepanC_mePBrhm-UMU2W5Am-1fMn-McujujyTzNatA)

- Prioritize Operator Comfort and Usability

- Why Operator Comfort Matters | Access Equipment | JLG (https://jlg.com/en/directaccess/how-operator-comfort-affects-productivity)

- A Comfortable Operator is a Productive Operator: A Guide to Comfort-Enhancing Features - Stewart Martin Kubota (https://stewartmartinkubota.com/blog/a-comfortable-operator-is-a-productive-operator-a-guide-to-comfort-enhancing-features)

- Skid Steer Loaders for Construction Market Size, Share, and Analysis Report 2032 (https://databridgemarketresearch.com/reports/global-skid-steer-loaders-for-construction-market?srsltid=AfmBOorioVq9ufFQWJ5yqJzUsUaX8ZSOV4asboXNN8v_gxvgARCaRVyJ)

- Skid Steer Loader Market Share and Statistics 2025-2035 (https://factmr.com/report/389/skid-steer-loader-market)

- Injuries and Fatalities Related to Skid Steers: 2015–2020 | MDPI (https://mdpi.com/2313-576X/8/3/56)