Key Highlights:

- Equipment repair is essential in construction for maintaining productivity and safety on job sites.

- Timely repairs prevent minor issues from escalating into major failures, reducing downtime and costs.

- Routine maintenance enhances safety by minimising risks of accidents caused by faulty machinery.

- There are four main maintenance strategies: preventive, predictive, corrective, and condition-based maintenance.

- Implementing effective maintenance scheduling practises can significantly reduce machinery downtime.

- Creating a comprehensive inventory and using management software can streamline maintenance operations.

- Training staff on maintenance procedures fosters a culture of accountability and proactive care.

- Common causes of equipment failure include lack of preventive maintenance, operator error, environmental factors, and poor quality parts.

Introduction

In the construction industry, machinery serves as more than just a tool; it is essential for productivity and safety on job sites. Grasping the nuances of effective equipment repair can significantly impact operational efficiency, preventing costly delays. This article explores key best practices that construction managers can implement to enhance machinery reliability and reduce downtime.

With a multitude of strategies at their disposal, how can managers identify the most effective methods to avert equipment failures and maintain project momentum?

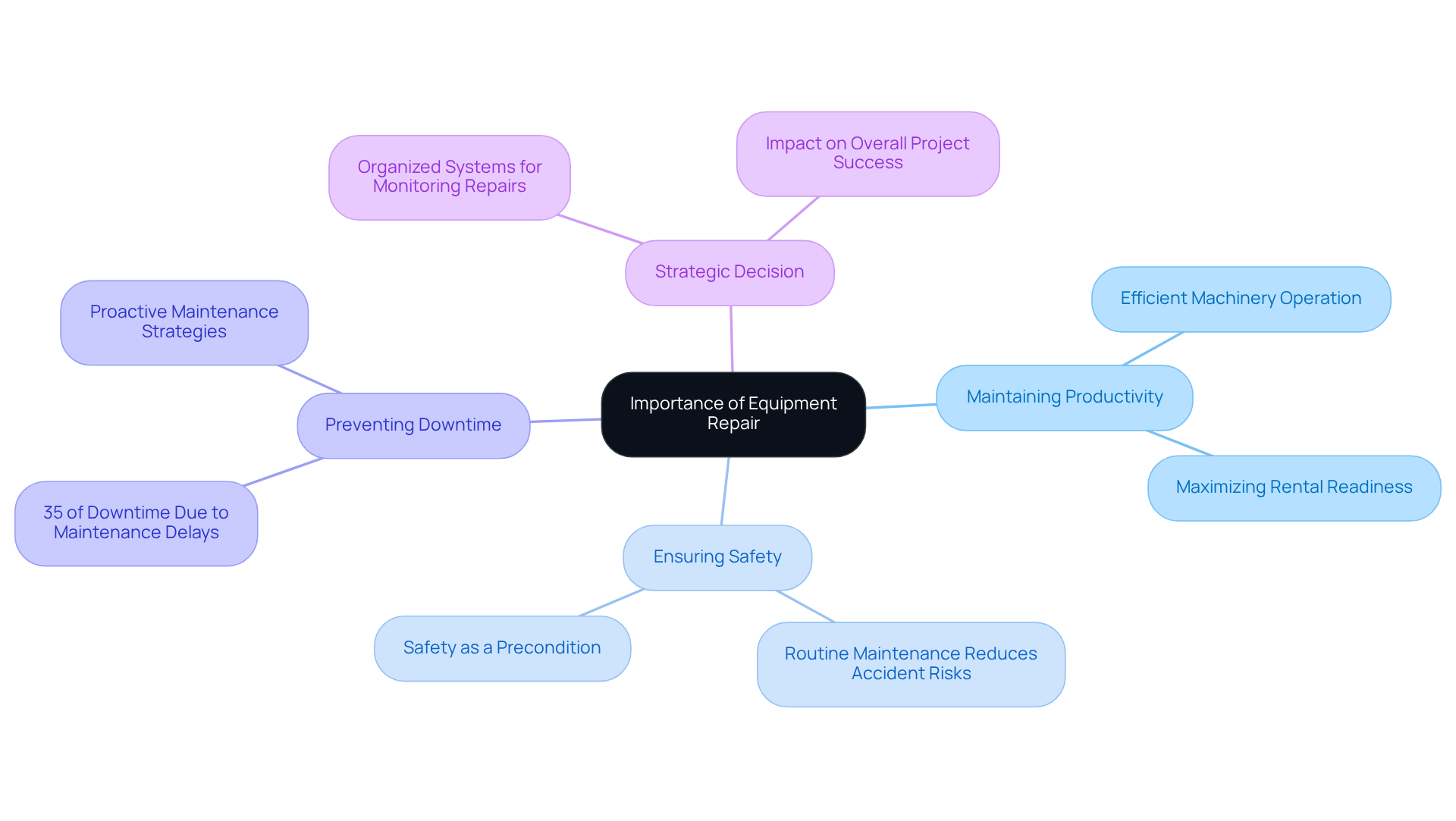

Understand the Importance of Equipment Repair

In the construction sector, machinery serves as the backbone of operations, making an understanding of equipment repair essential for maintaining productivity and ensuring safety on job sites. Timely equipment repair is crucial as it prevents minor issues from escalating into major failures, which can lead to costly downtime and project delays. For instance, a well-maintained excavator can operate efficiently for years, while neglecting repairs can result in breakdowns that halt work and incur significant repair costs. Statistics show that approximately 35% of machinery downtime is attributed to maintenance delays, highlighting the necessity for proactive maintenance strategies.

Moreover, routine maintenance enhances the safety of operators and workers by reducing the risk of accidents caused by faulty machinery. Boom lifts, for example, offer exceptional vertical and horizontal reach, enabling workers to access elevated areas safely and navigate around obstacles with ease. This capability is vital for tasks such as painting, repairs, or construction work, where secure working environments are paramount. As noted, 'Safety should never be a priority. It should be a precondition.' This perspective cultivates a culture where safety is integral to daily operations.

Prioritizing equipment repair is not merely a maintenance task; it is a strategic decision that significantly impacts the overall success of construction projects. By implementing organized systems for monitoring and managing repairs, construction teams can ensure that machinery, including forklifts that play a crucial role in enhancing efficiency, is always rental-ready, thereby maximizing productivity and minimizing risks associated with downtime.

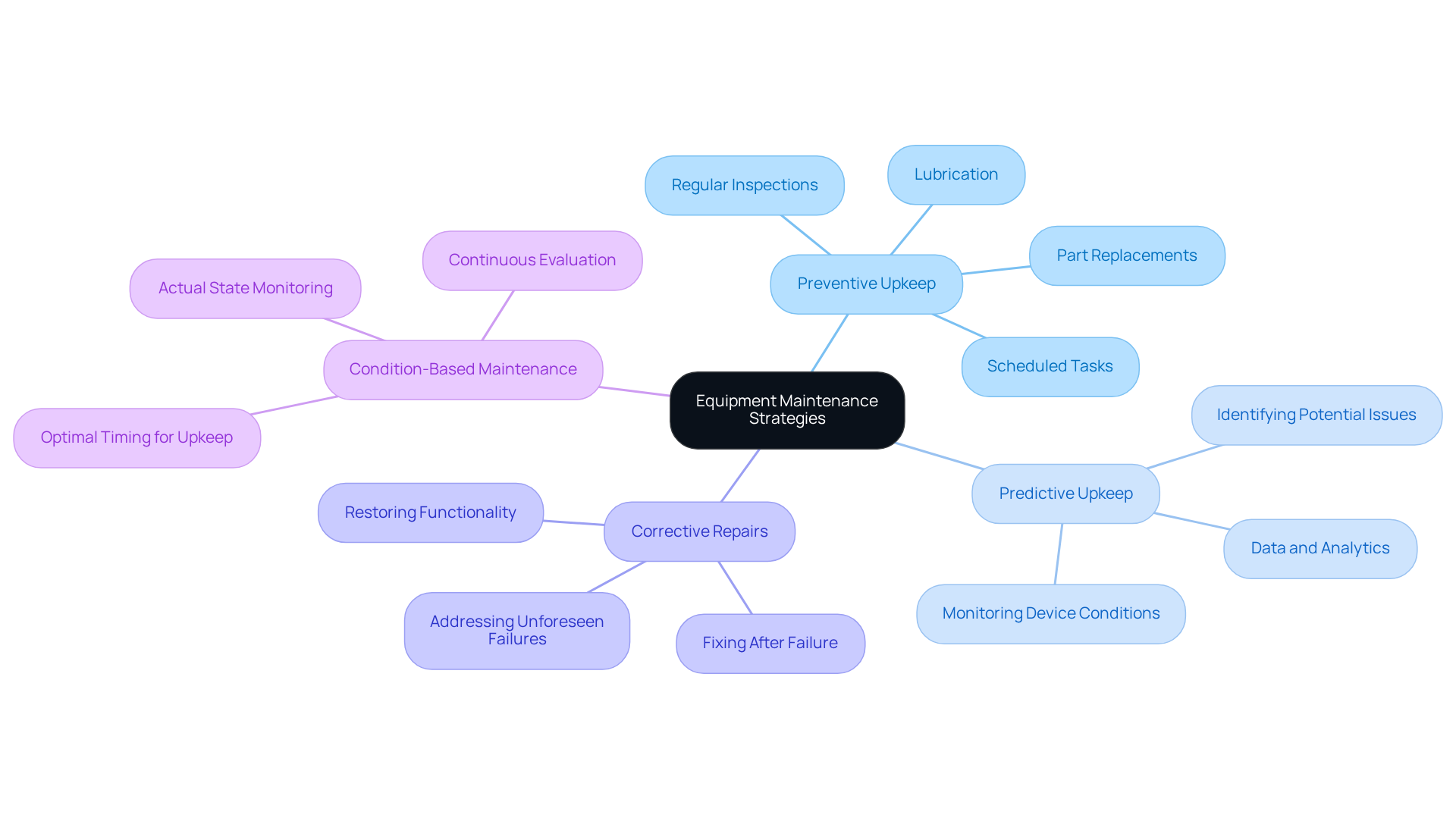

Explore Types of Equipment Maintenance Strategies

Construction managers have several machinery upkeep strategies at their disposal to ensure optimal performance and longevity of their tools. These strategies include:

-

Preventive Upkeep: This involves scheduled tasks designed to prevent machinery failures before they occur. Regular inspections, lubrication, and part replacements based on manufacturer recommendations are key components of this approach.

-

Predictive Upkeep: This strategy leverages data and analytics to predict when servicing should take place. By monitoring device conditions through sensors and diagnostic tools, managers can identify potential issues before they escalate into breakdowns.

-

Corrective Repairs: This approach focuses on fixing machinery after a failure has occurred. Although often reactive, it is essential for addressing unforeseen failures and restoring functionality.

-

Condition-Based Maintenance: Maintenance is performed based on the actual state of the machinery rather than adhering to a fixed schedule. This method requires continuous monitoring and evaluation to determine the optimal timing for upkeep tasks.

By understanding and implementing these strategies, construction managers can enhance the reliability of their tools, reduce downtime, and ultimately lower costs associated with equipment repair and replacements.

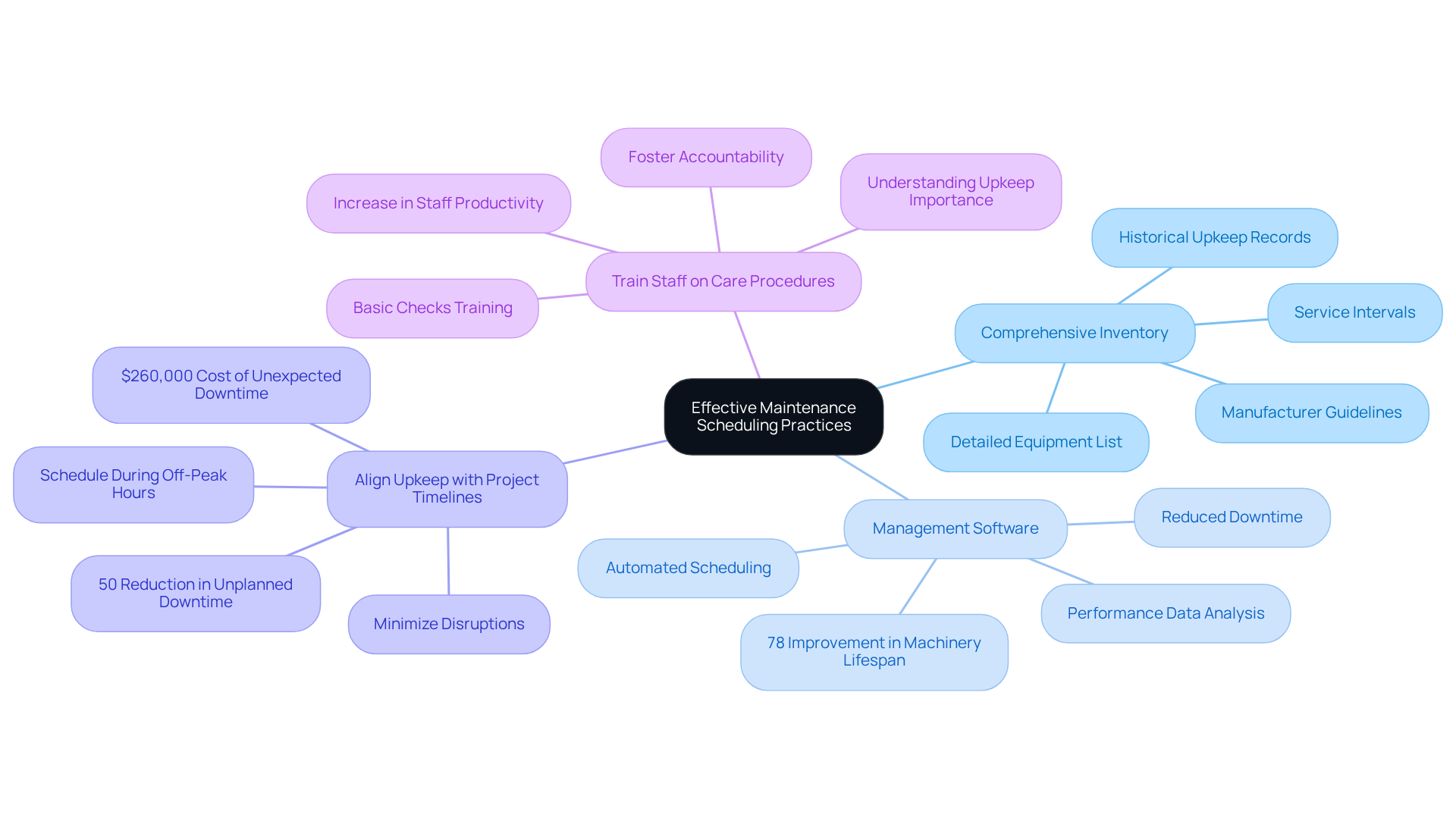

Implement Effective Maintenance Scheduling Practices

Efficient upkeep planning is essential for keeping machinery functional and reliable throughout the project lifecycle. Here are effective practices for implementing maintenance schedules:

-

Create a Comprehensive Inventory: Compile a detailed list of all equipment along with their specific upkeep requirements. This inventory should include manufacturer guidelines, service intervals, and historical upkeep records, ensuring that all necessary information is readily accessible.

-

Utilize Management Software: Implement technology to automate the scheduling and tracking of upkeep tasks. Maintenance management software can send reminders for upcoming maintenance, track service history, and analyze performance data of machinery. This approach not only streamlines operations but also enhances the lifespan of machinery; studies show that companies using such software reported significant improvements in reliability and reduced downtime. In fact, in 2017, 78% of organizations that utilized a CMMS to oversee their assets indicated observing enhancements in machinery lifespan.

-

Align Upkeep with Project Timelines: Schedule upkeep during off-peak hours or between project phases to minimize disruptions. This proactive strategy ensures that equipment is ready for use when needed, thereby enhancing productivity. For instance, facilities that effectively coordinate upkeep with operational schedules can reduce unplanned downtime by as much as 50%. Moreover, the average cost of unexpected downtime per hour is approximately $260,000, underscoring the financial advantages of efficient upkeep methods.

-

Train Staff on Care Procedures: Ensure that all team members understand the importance of upkeep and are trained on how to perform basic checks and report issues. This fosters a culture of accountability and proactive care, which is vital for operational efficiency. Organizations that invest in employee training often see a significant increase in staff productivity and a decrease in machinery failures.

By implementing these practices, construction managers can significantly reduce machinery downtime and enhance overall project efficiency, ultimately leading to better project outcomes. However, it is also crucial to recognize potential pitfalls in implementing management software, such as inadequate training or failure to fully utilize the software's capabilities, which can impede the expected benefits.

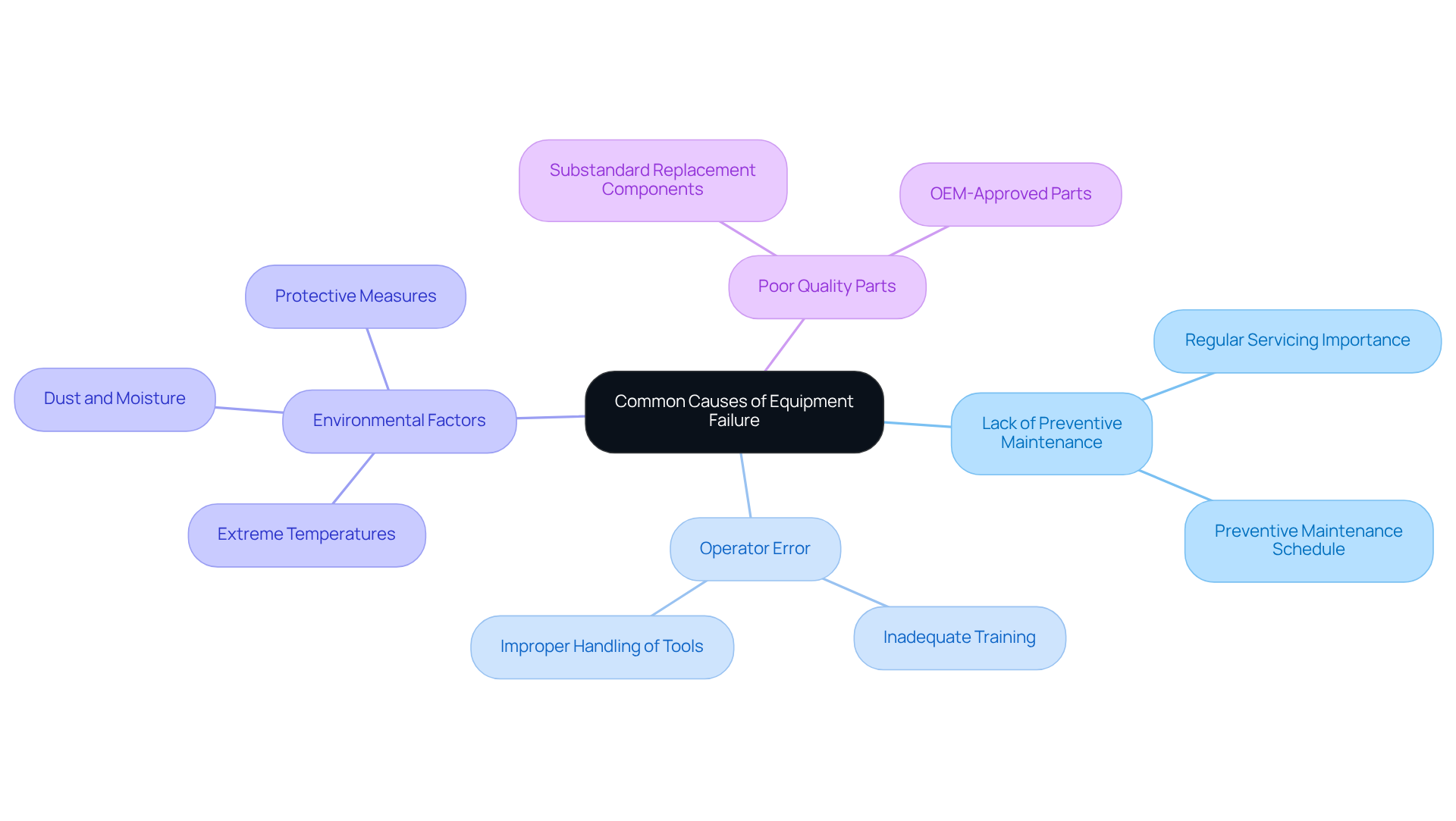

Identify Common Causes of Equipment Failure

Understanding the common reasons for device failure is crucial for implementing effective preventive strategies. Here are some of the most frequent causes:

- Lack of Preventive Maintenance: Failing to perform regular servicing can lead to machinery deterioration and unexpected failures. Establishing a preventive maintenance schedule is vital to mitigate this risk.

- Operator Error: Inadequate training or improper handling of tools can cause significant damage. It is essential to ensure that operators receive thorough training and understand the machinery's functionalities.

- Environmental Factors: Challenging working conditions, such as extreme temperatures, dust, and moisture, can accelerate wear and tear on equipment. Implementing protective measures and selecting appropriate tools for specific environments can help reduce these risks.

- Poor Quality Parts: Utilizing substandard replacement components can compromise equipment integrity and lead to failures. Always choose high-quality, OEM-approved parts to ensure reliability.

By recognizing and addressing these common causes, construction managers can significantly decrease the likelihood of equipment failures, thereby enhancing the success of equipment repair and overall project outcomes.

Conclusion

In the construction industry, effective equipment repair is not merely a routine task; it is a critical component that underpins the success of any project. By prioritizing timely maintenance and adopting strategic repair practices, construction teams can ensure that their machinery operates at peak efficiency. This approach safeguards productivity and enhances safety on job sites.

The article highlights several best practices, emphasizing the importance of:

- Preventive and predictive maintenance strategies

- Effective scheduling

- Identification of common causes of equipment failure

Implementing a comprehensive inventory system, utilizing management software, and training staff on maintenance procedures are essential steps that can significantly reduce downtime and repair costs. These practices not only prolong the lifespan of equipment but also foster a culture of accountability and proactive care among team members.

Ultimately, the significance of proper equipment repair in construction cannot be overstated. By adopting these best practices, construction managers can mitigate risks, prevent costly failures, and ensure that projects remain on schedule. Embracing a proactive approach to equipment maintenance is not just beneficial; it is imperative for achieving operational excellence and maintaining a competitive edge in the construction sector.

Frequently Asked Questions

Why is understanding equipment repair important in the construction sector?

Understanding equipment repair is essential in the construction sector because machinery is crucial for operations, and timely repairs prevent minor issues from escalating into major failures, which can lead to costly downtime and project delays.

What are the consequences of neglecting equipment repairs?

Neglecting equipment repairs can result in breakdowns that halt work, incur significant repair costs, and contribute to machinery downtime, with statistics showing that approximately 35% of downtime is attributed to maintenance delays.

How does routine maintenance enhance safety on job sites?

Routine maintenance enhances safety by reducing the risk of accidents caused by faulty machinery, ensuring that equipment like boom lifts operates safely, which is vital for tasks that require secure working environments.

What is the significance of prioritizing equipment repair in construction projects?

Prioritizing equipment repair is a strategic decision that significantly impacts the overall success of construction projects by maximizing productivity and minimizing risks associated with downtime.

How can construction teams ensure their machinery is always rental-ready?

Construction teams can ensure machinery is always rental-ready by implementing organized systems for monitoring and managing repairs, which helps maintain efficiency and readiness of equipment like forklifts.

List of Sources

- Understand the Importance of Equipment Repair

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- 25 Inspiring Workplace Safety Quotes for Safer Workspaces (https://yodeck.com/use-cases/workplace-safety-quotes)

- The Real Cost of Equipment Downtime in Construction Rentals (And Why Most Businesses Underestimate It) (https://antmyerp.com/en/blogs/the-real-cost-of-equipment-downtime-in-construction-rentals-and-why-most-businesses-underestimate-it)

- Top 100 Inspirational Workplace Safety Quotes (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Top 90 Industrial Safety Quotes for a Strong Safety Culture (https://rubberhoseindia.com/industrial-safety-quotes)

- Explore Types of Equipment Maintenance Strategies

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- 9 Key Statistics About Predictive Maintenance (https://worktrek.com/blog/predictive-maintenance-statistics)

- Implement Effective Maintenance Scheduling Practices

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)

- Maintenance Statistics: Predictive & Preventive, Labor & Costs (https://upkeep.com/learning/maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Manufacturing Maintenance Statistics & Data You Need to Know (https://caisoft.com/resources/manufacturing-maintenance-statistics)

- Identify Common Causes of Equipment Failure

- The Transformative Impact of Preventive Maintenance in Construction (https://maintworld.com/Asset-Management/The-Transformative-Impact-of-Preventive-Maintenance-in-Construction)

- Equipment manufacturers discuss struggles and future plans (https://equipmentworld.com/market-pulse/article/15769715/equipment-manufacturers-discuss-struggles-and-future-plans)

- The Latest Statistics from the Maintenance Industry [2025] (https://getsockeye.com/blog/maintenance-statistics)

- Don’t Let Operator Error Destroy Your Business (https://daily.financialexecutives.org/dont-let-operator-error-destroy-business)

- Enhancing Asset Utilization with Preventative Maintenance Plan (https://tbmcg.com/resources/blog/extending-equipment-life-with-preventive-maintenance-the-heart-of-your-operations)