Key Highlights:

- Electric heaters are suitable for small, enclosed spaces with limited ventilation.

- Propane heaters can warm larger areas quickly but require proper ventilation for safety.

- Kerosene devices are cost-effective for outdoor use, with operational costs up to 35% lower than electric or gas systems.

- Infrared heaters are efficient for outdoor conditions as they heat objects directly.

- Key site conditions for heater selection include area size, insulation levels, ventilation, and external weather conditions.

- Heater placement should be on stable surfaces, away from flammable materials, and proper ventilation is crucial to prevent carbon monoxide buildup.

- Regular inspections of heaters are necessary to ensure safety and functionality.

- Using heaters with integrated thermostats can optimise energy consumption and reduce costs.

- Scheduling heater use only when needed and establishing warming zones can enhance efficiency.

- Monitoring heater performance helps identify inefficiencies and improve resource utilisation.

Introduction

Selecting the appropriate space heater for construction sites presents a significant challenge, particularly given the varied requirements of different projects. With a range of heater types available - each tailored for specific conditions - project managers must navigate the complexities of ensuring both safety and efficiency.

How can construction teams effectively choose the optimal heating solutions while addressing potential hazards and maintaining productivity? This article explores best practices for space heater rentals in construction, providing insights that can enhance heating strategies and improve site safety.

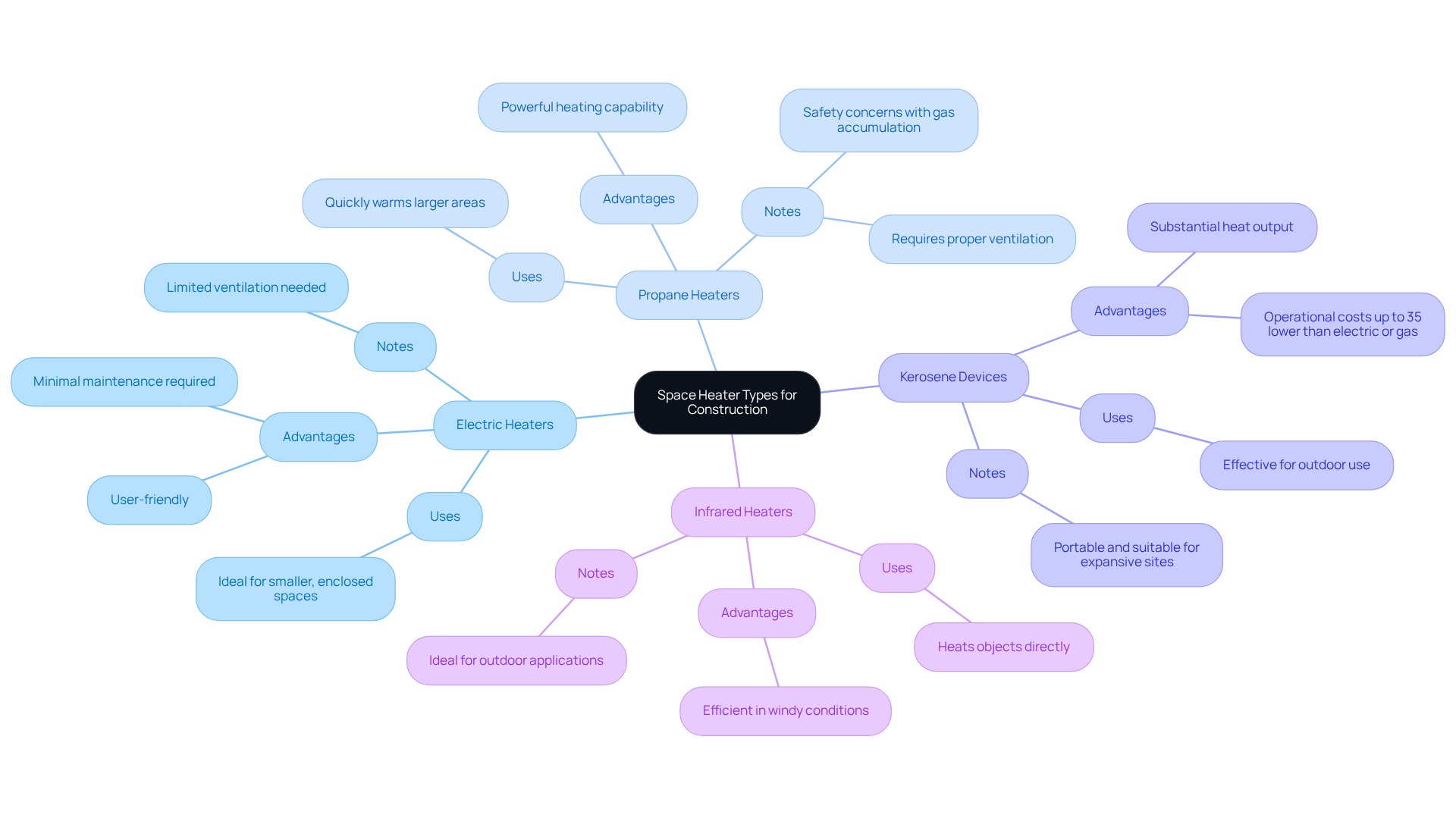

Identify Suitable Space Heater Types for Construction Needs

When selecting space warmers for building sites, it's essential to consider the specific needs of the project. Different types of heaters serve various purposes:

- Electric Heaters: These are ideal for smaller, enclosed spaces where ventilation is limited. They are user-friendly and require minimal maintenance, making them suitable for indoor applications.

- Propane Heaters: Known for their power, these heaters can quickly warm larger areas. However, they necessitate proper ventilation to prevent the accumulation of harmful gases, which is vital for safety on job sites.

- Kerosene Devices: Effective for outdoor use, these portable appliances deliver substantial heat output, making them appropriate for expansive building sites. Notably, their operational costs can be up to 35% lower than electric or gas systems, presenting a cost-effective choice over time.

- Infrared Heaters: These units heat objects directly rather than the surrounding air, making them efficient for outdoor use, especially in windy conditions.

Understanding the strengths and limitations of each type ensures that building teams can maintain productivity and safety on site. Furthermore, with approximately 78% of annual sales occurring in Q3 and Q4, project managers should strategically plan their equipment needs to avoid seasonal shortages. Integrating insights from industry specialists can further enhance the selection process, ensuring that teams choose the most efficient solutions tailored to their specific requirements.

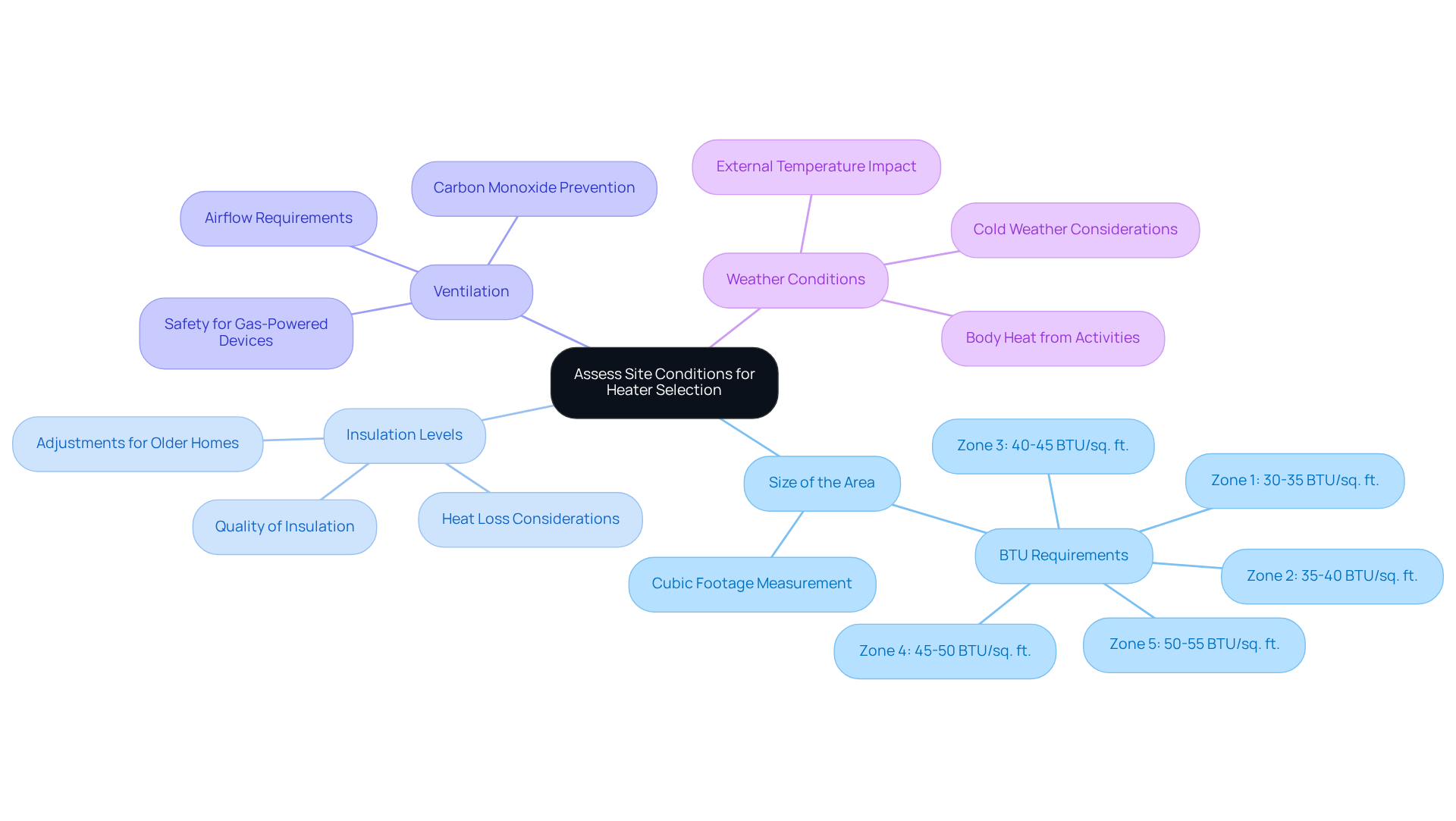

Assess Site Conditions for Optimal Heater Selection

Before considering space heater rentals, it is crucial to conduct a thorough assessment of the construction site conditions. Key factors to consider include:

-

Size of the Area: Accurately measuring the cubic footage of the space is essential for determining heating requirements. Larger areas necessitate more powerful units, as the BTU output must correspond to the volume of air that needs warming. For instance, Zone 1 requires 30-35 BTU per square foot, which can guide your heater selection based on the specific area size.

-

Insulation Levels: Evaluating the insulation quality of the building or area is vital. Poorly insulated spaces can result in significant heat loss, necessitating more heating power to maintain comfortable temperatures. Conversely, well-insulated properties typically require fewer BTUs, enhancing energy efficiency.

-

Ventilation: Ensuring adequate airflow is critical, particularly for gas-powered devices, to prevent the buildup of harmful gases. Proper airflow is essential for safety and efficiency, especially in enclosed spaces.

-

Weather Conditions: External weather conditions must also be taken into account. Extreme cold can greatly influence heating needs, often requiring more robust heating solutions to ensure worker safety and comfort. Additionally, recognizing that activities within a room can generate body warmth may reduce BTU requirements, allowing for more efficient appliance utilization.

By understanding these factors, project managers can make informed decisions regarding heating equipment, ensuring that the devices operate efficiently and safely in their specific environments.

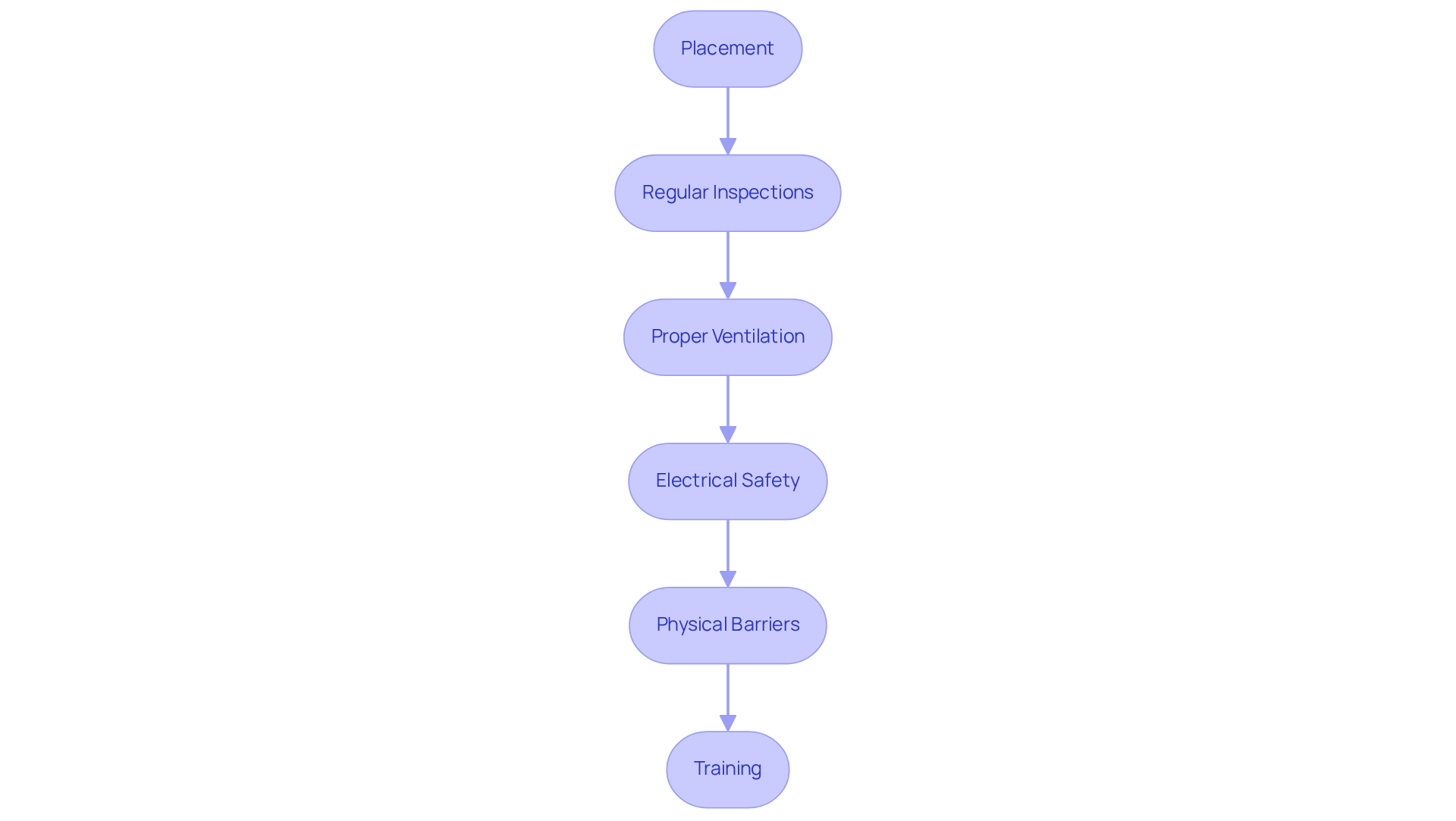

Implement Safe Operation and Maintenance Practices

To ensure the safe operation of space heaters on construction sites, it is essential to adhere to the following best practices:

-

Placement: Position warming devices on stable, non-combustible surfaces, ensuring they are at least three feet away from flammable materials. This distance helps prevent accidental ignition and allows for adequate airflow. Be aware that direct fired units, also referred to as salamanders, pose greater risks compared to indirect devices due to their open flame.

-

Regular Inspections: Conduct routine inspections to identify any signs of wear or damage, particularly in cords and connections. Quickly resolving any problems reduces potential risks and ensures the units operate safely.

-

Proper Ventilation: Gas appliances must be utilized in well-ventilated areas to minimize the risk of carbon monoxide poisoning. The body absorbs carbon monoxide 200 times faster than oxygen, making adequate ventilation crucial for maintaining air quality and preventing dangerous gas buildup.

-

Electrical Safety: Ensure that the electrical circuit is rated for the size of the electric appliance being used to prevent electrical hazards.

-

Physical Barriers: Implement physical barriers around fuel tanks to enhance safety and prevent accidental contact.

-

Training: Provide thorough instruction for all personnel on the safe use of warming devices, including emergency procedures for handling malfunctions. Ensuring that workers are knowledgeable about safety protocols can significantly reduce risks on the job site.

By implementing these practices, building teams can foster a safer working environment while optimizing the effectiveness of their heating solutions.

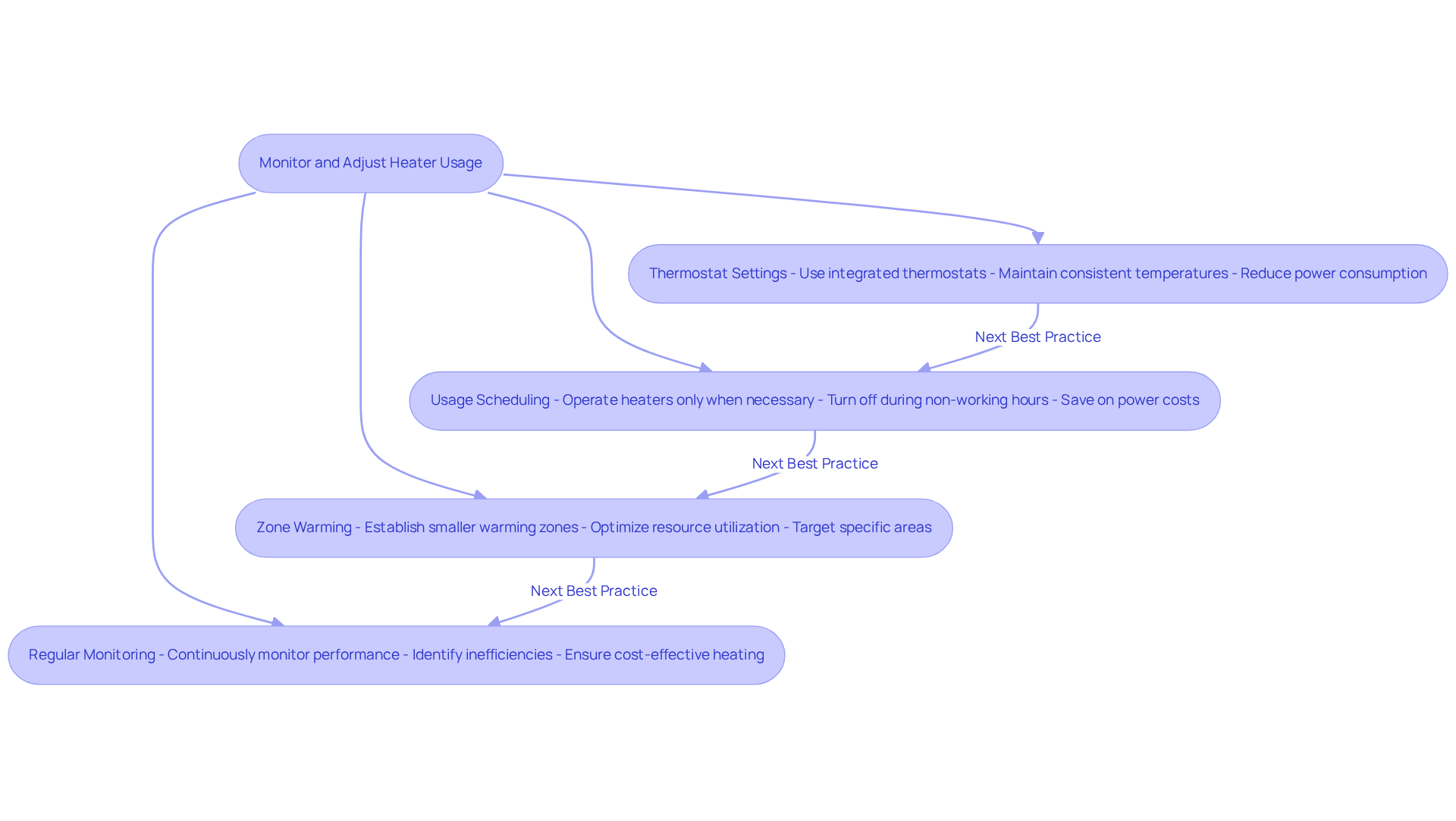

Monitor and Adjust Heater Usage for Efficiency

To maximize the efficiency of space heater usage on construction sites, consider implementing the following best practices:

-

Thermostat Settings: Opt for heaters equipped with integrated thermostats to maintain consistent temperatures, significantly reducing power consumption. Research shows that effective thermostat management can lead to considerable resource savings. As Malcolm Turnbull noted, there is a strong link between resource efficiency and economic performance, underscoring the importance of proper thermostat adjustments in construction heating.

-

Usage Scheduling: Operate heaters only when necessary. Turning them off during non-working hours or when the site is unoccupied can lead to substantial savings on power, as highlighted by efficiency specialists. For instance, a case study on high-efficiency ductless heat pumps demonstrated that strategic scheduling can effectively lower utility costs.

-

Zone Warming: Establish smaller warming zones using temporary enclosures. This targeted approach allows for effective heating in specific areas where it is most needed, optimizing resource utilization. Implementing zone warming can prevent unnecessary resource expenditure, aligning with best practices observed in successful construction projects.

-

Regular Monitoring: Continuously monitor the performance and energy consumption of the heaters. This practice helps identify inefficiencies and opportunities for improvement, ensuring that heating needs are met in a cost-effective manner. By keeping track of performance, construction teams can avoid common challenges associated with heater usage, such as excessive reliance on heating in unoccupied spaces.

By actively managing heater usage, construction teams can effectively meet their heating requirements while minimizing energy costs.

Conclusion

Selecting the appropriate space heater for construction projects is essential for maintaining productivity and ensuring safety on job sites. By understanding the various types of heaters available and their specific applications, project managers can make informed decisions tailored to their unique needs. A careful assessment of site conditions - such as area size, insulation levels, ventilation, and weather - plays a vital role in optimizing heater selection and usage.

Key insights emphasize the importance of safe operation and maintenance practices, including:

- Proper placement

- Regular inspections

- Adequate ventilation

Furthermore, monitoring and adjusting heater usage through thermostat settings and scheduling can lead to significant energy savings. By implementing these best practices, construction teams can foster a safer work environment while maximizing efficiency and reducing costs.

Ultimately, the effective use of space heaters in construction not only enhances worker comfort but also contributes to overall project success. Embracing these strategies ensures that heating solutions are both safe and efficient, allowing teams to concentrate on their core tasks without unnecessary disruptions.

Frequently Asked Questions

What are the different types of space heaters suitable for construction needs?

The main types of space heaters suitable for construction needs are electric heaters, propane heaters, kerosene devices, and infrared heaters.

When are electric heaters most appropriate for use?

Electric heaters are ideal for smaller, enclosed spaces where ventilation is limited, making them suitable for indoor applications.

What are the advantages of using propane heaters on construction sites?

Propane heaters are powerful and can quickly warm larger areas, but they require proper ventilation to prevent the accumulation of harmful gases.

Why are kerosene devices considered cost-effective for outdoor use?

Kerosene devices are effective for outdoor use and can deliver substantial heat output, with operational costs that can be up to 35% lower than electric or gas systems.

How do infrared heaters function, and where are they best used?

Infrared heaters heat objects directly rather than the surrounding air, making them efficient for outdoor use, especially in windy conditions.

Why is it important to understand the strengths and limitations of each heater type?

Understanding the strengths and limitations of each type ensures that building teams can maintain productivity and safety on site.

When do most space heater sales occur, and why is this important for project managers?

Approximately 78% of annual sales occur in Q3 and Q4, so project managers should strategically plan their equipment needs to avoid seasonal shortages.

How can integrating insights from industry specialists benefit the selection process for heaters?

Integrating insights from industry specialists can enhance the selection process, ensuring that teams choose the most efficient solutions tailored to their specific requirements.

List of Sources

- Identify Suitable Space Heater Types for Construction Needs

- A Guide to the Best Construction Site Heaters Pro Tool & Supply (https://protoolandsupply.com/resources/articles/a-guide-to-the-best-construction-site-heaters)

- Radiant Kerosene Heaters Market Outlook 2026-2032 (https://intelmarketresearch.com/radiant-kerosene-heaters-market-25101)

- How to Choose the Perfect Job Site Heater (https://partnerrentals.com/guide-to-selecting-the-right-construction-site-heaters)

- Assess Site Conditions for Optimal Heater Selection

- Complete Guide to Temporary Heating for Construction Sites (https://mobileair.com/the-complete-guide-to-temporary-heating-for-construction-sites)

- Recommended BTU per Square Foot of Heating | Warmup (https://warmup.com/blog/btu-per-square-foot-heating-rule-of-thumb)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- How to Choose the Perfect Job Site Heater (https://partnerrentals.com/guide-to-selecting-the-right-construction-site-heaters)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- Implement Safe Operation and Maintenance Practices

- How to Safely Use Heaters on Your Construction Site (https://hugghall.com/news/construction-site-heater-safety)

- GBCA Safety Toolbox Talk: Space Heaters and Carbon Monoxide (https://gbca.com/hard-hat-chat/gbca-safety-toolbox-talk-space-heaters-and-carbon-monoxide-2)

- Heat - Case Studies | Occupational Safety and Health Administration (https://osha.gov/heat-exposure/case-studies)

- Monitor and Adjust Heater Usage for Efficiency

- TOP 25 ENERGY EFFICIENCY QUOTES | A-Z Quotes (https://azquotes.com/quotes/topics/energy-efficiency.html)

- Guides and Case Studies for All Climates (https://energy.gov/eere/buildings/guides-and-case-studies-all-climates)

- Case Studies - Efficiency Maine (https://efficiencymaine.com/energyinformation/case-studies)

- Case Studies | Building America Solution Center (https://basc.pnnl.gov/case-studies?items_per_page=25&f%5B0%5D=climate_zone%3A63&f%5B1%5D=organization%3A2137)