Key Highlights:

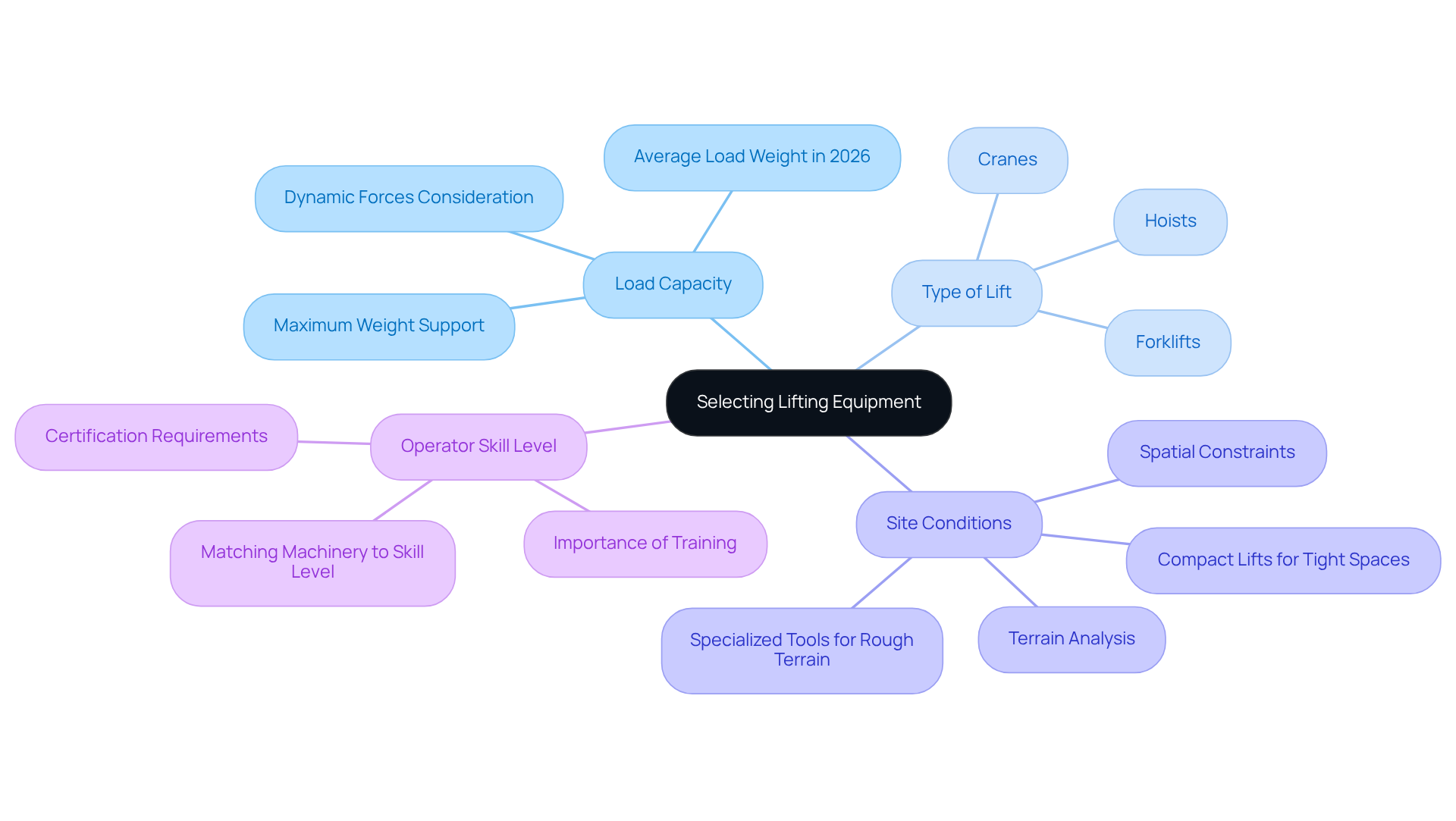

- Selecting appropriate lifting equipment requires assessing load capacity, type of lift, site conditions, and operator skill level.

- Proper load assessments and operator training are crucial to prevent accidents, with human error accounting for approximately 90% of crane incidents.

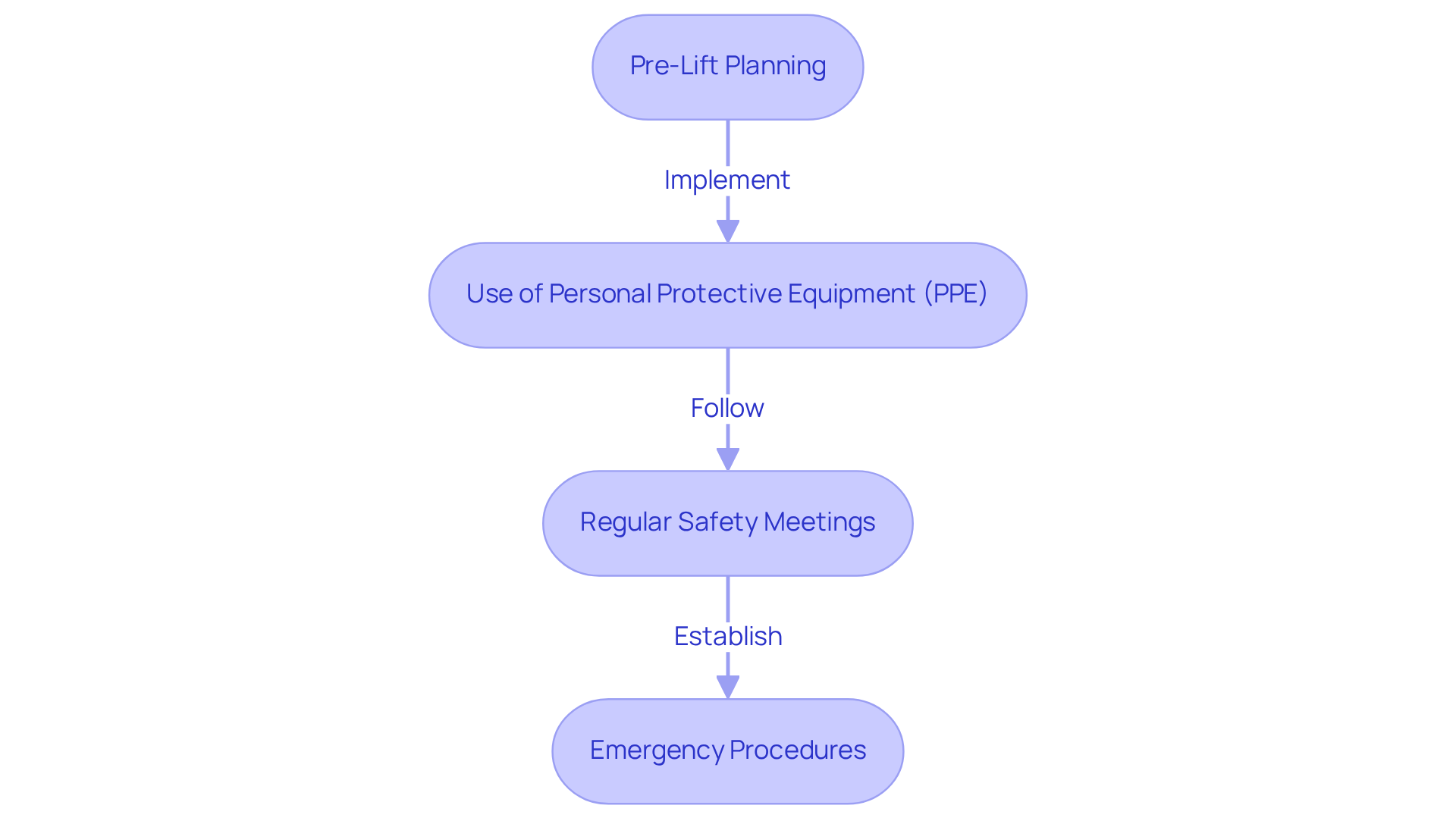

- Safety protocols include pre-lift planning, use of PPE, regular safety meetings, and clear emergency procedures to enhance workplace safety.

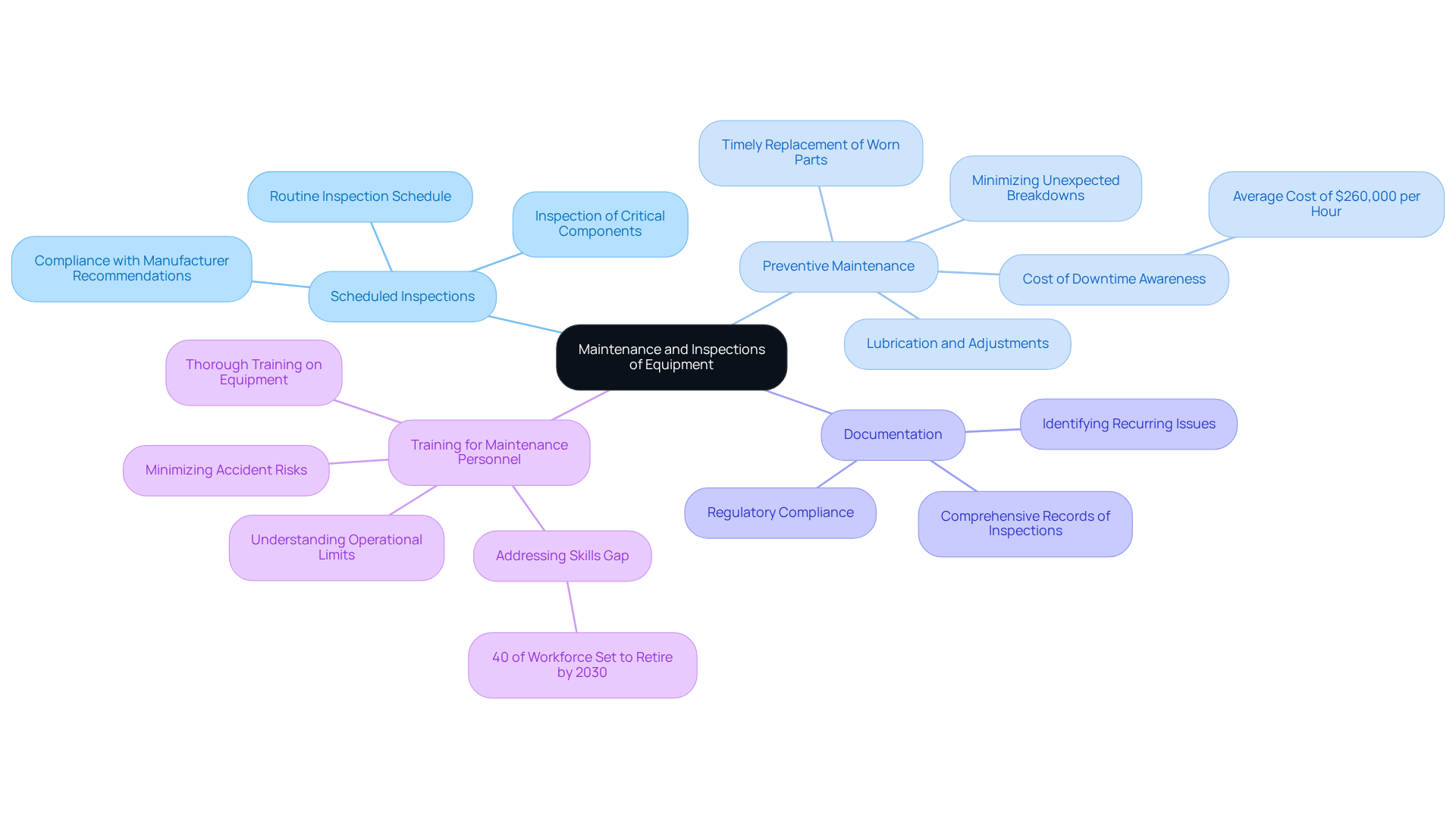

- Regular maintenance and inspections should follow manufacturer recommendations, with a focus on preventive measures to reduce downtime costs, which can reach $260,000 per hour.

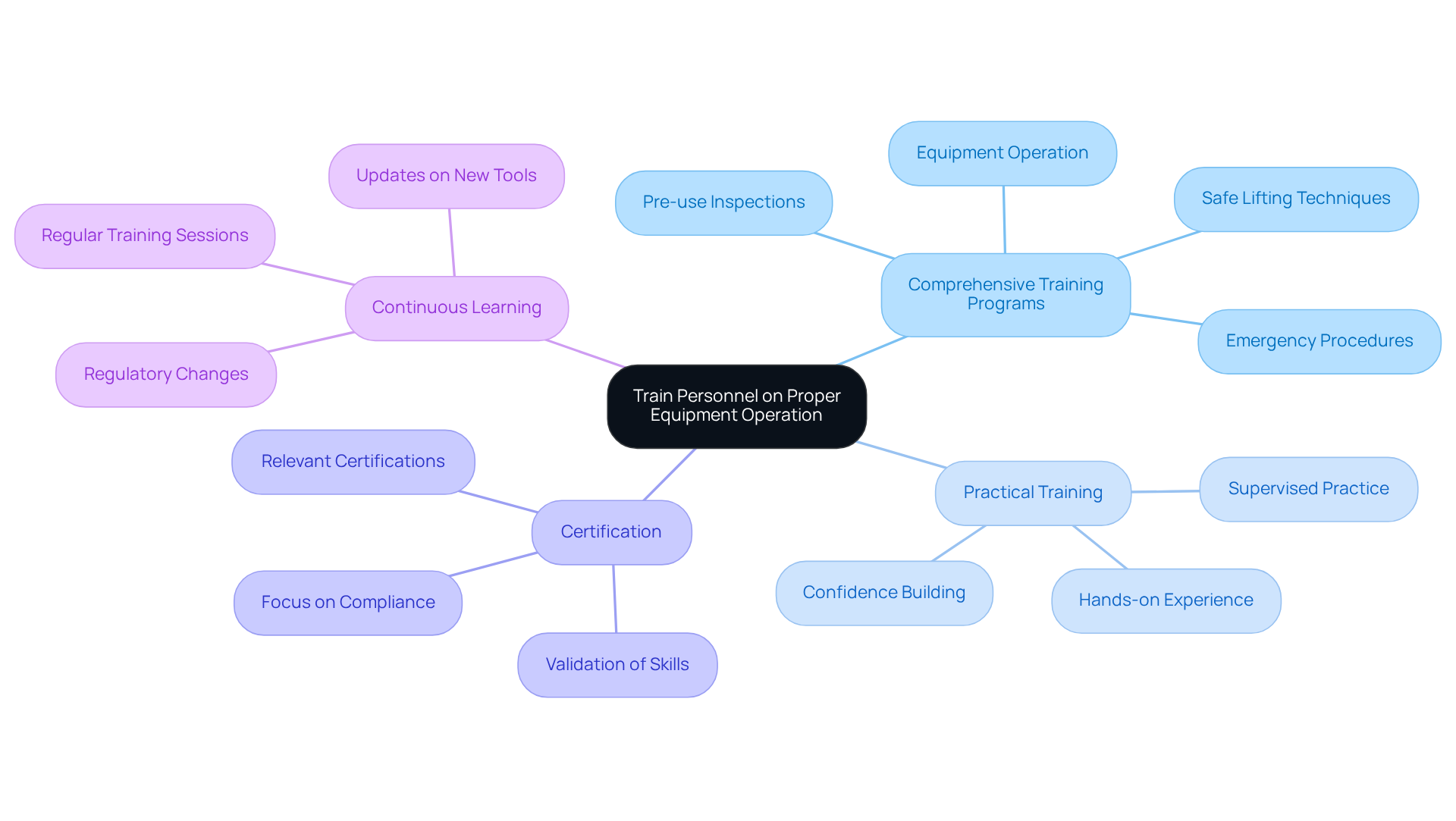

- Training programmes must cover comprehensive equipment operation, practical training, certification, and continuous learning to ensure safe and effective use of lifting tools.

Introduction

Choosing the right lifting equipment is crucial for the success of any construction project. With diverse load capacities, varying site conditions, and different operator skill levels, the importance of safety and efficiency cannot be overstated. As the construction industry faces growing demands for productivity and compliance, managers must navigate the complexities of lifting equipment services effectively. This article explores best practices that enhance operational effectiveness while prioritizing worker safety, ultimately laying the groundwork for successful project execution.

Select Appropriate Lifting Equipment for Project Needs

Choosing the right lifting equipment services is essential for the success of any construction project. Begin by assessing the specific requirements, including the weight and dimensions of the loads to be lifted. Key considerations include:

- Load Capacity: Ensure that the equipment can support the maximum weight of the load, taking into account dynamic forces that may occur during lifting. In 2026, the average weight of loads lifted in construction projects can vary significantly, making precise calculations crucial for safety.

- Type of Lift: Different projects may require various lifting solutions, such as cranes, hoists, or forklifts. Evaluate the nature of the lift needed based on the environment and the characteristics of the load.

- Site Conditions: Analyze the terrain and any spatial constraints. For example, rough terrain may require specialized tools like rough-terrain cranes, while compact lifts are ideal for tight spaces.

- Operator Skill Level: Match the machinery with the skill level of your operators. More complex machinery often requires certified operators to ensure safety and compliance with regulations.

By carefully selecting the appropriate hoisting tools and leveraging lifting equipment services, construction managers can significantly enhance safety, efficiency, and productivity on their sites. Notably, crane-related incidents underscore the importance of proper load assessments and operator training, as human error accounts for approximately 90% of crane accidents. Therefore, investing in the right equipment and training is not merely a compliance issue; it is a critical factor in protecting both workers and the project's success.

Implement Safety Protocols for Lifting Equipment Usage

Safety protocols are crucial for protecting workers and ensuring compliance with regulations during hoisting operations. Implementing the following key protocols can enhance safety:

- Pre-Lift Planning: Thorough planning is essential before any lift. This involves assessing the load, determining the lift path, and identifying potential hazards.

- Use of Personal Protective Equipment (PPE): It is vital that all personnel involved in hoisting operations wear appropriate PPE, including hard hats, gloves, and protective footwear.

- Regular Safety Meetings: Conduct regular safety briefings to discuss lifting operations, review safety protocols, and address any team concerns.

- Emergency Procedures: Establish clear emergency procedures for accidents or equipment failures, ensuring all team members are familiar with these protocols.

By implementing these protective measures, you can significantly reduce the risk of accidents and foster a safer working environment.

Conduct Regular Maintenance and Inspections of Equipment

Regular maintenance and inspections are essential for the safe operation of lifting equipment services in construction. By adhering to best practices, safety and reliability can be significantly enhanced:

- Scheduled Inspections: Establish a routine inspection schedule that aligns with manufacturer recommendations and regulatory standards. Inspections should encompass all critical components, including hoists, slings, and protective devices, ensuring optimal performance and compliance.

- Preventive Maintenance: Develop a preventive maintenance program that includes lubrication, adjustments, and timely replacements of worn parts. This proactive approach minimizes unexpected breakdowns and extends equipment lifespan, ultimately reducing the average cost of maintenance, which can reach approximately $260,000 per hour of downtime. This statistic highlights the financial impact of operational disruptions, making preventive maintenance crucial.

- Documentation: Maintain comprehensive records of all inspections and maintenance activities. This documentation is vital for regulatory compliance and can help identify recurring issues, enabling teams to address them proactively and improve overall operational efficiency.

- Training for Maintenance Personnel: Ensure that maintenance personnel receive thorough training on performing inspections and repairs. This training should cover the equipment's operational limits and protective features, such as guardrails and emergency stop buttons, enabling staff to effectively handle hoisting equipment and minimize accident risks. With 40% of the manufacturing workforce set to retire by 2030, preparing the current workforce is essential to mitigate the skills gap in the industry.

Utilizing a boom lift significantly reduces the risks associated with working at heights. The stable platform and safety features create a secure working environment for operators, minimizing accidents and injuries. By prioritizing these maintenance and inspection practices, building teams can enhance the reliability and security of their hoisting operations, ultimately leading to more efficient project execution with the help of lifting equipment services.

Train Personnel on Proper Equipment Operation

Training staff in the proper use of hoisting tools is essential for ensuring safety and productivity on construction sites. Implementing key strategies can significantly enhance training effectiveness:

-

Comprehensive Training Programs: Establish training programs that cover all aspects of equipment operation, including pre-use inspections, safe lifting techniques, and emergency procedures. This comprehensive approach prepares operators for various scenarios they may encounter, ensuring they are well-equipped to handle challenges.

-

Practical Training: Conduct practical training sessions where operators can practice using hoisting tools under supervision. This hands-on experience is crucial for building both confidence and competence, significantly reducing the likelihood of accidents. As Mahatma Gandhi wisely stated, "Live as if you were to die tomorrow. Learn as if you were to live forever," highlighting the importance of continuous learning in safety practices.

-

Certification: Encourage operators to obtain relevant certifications, which validate their skills in managing specific types of hoisting machinery. As of 2026, only 30% of construction workers are certified in operating lifting machinery, underscoring the need for increased focus on this area to enhance safety and compliance with industry standards.

-

Continuous Learning: Regular training sessions should be conducted to keep operators informed about new tools, protective measures, and regulatory changes. Ongoing education not only fosters a culture of safety but also enhances professionalism within the workforce. As Phil Collins noted, "In learning you will teach, and in teaching you will learn," reinforcing the value of continuous education.

Investing in these training initiatives ensures that personnel are well-prepared to operate lifting equipment safely and effectively, which is vital for the success of lifting equipment services in construction projects.

Conclusion

Selecting the right lifting equipment services is crucial for the success of construction projects. By addressing the specific needs of each project, construction managers can enhance safety, efficiency, and productivity. Key considerations include understanding load capacity, the type of lift required, site conditions, and operator skill levels. These factors are essential for making informed decisions that improve operational outcomes.

This article highlights four best practices:

- Selecting appropriate equipment

- Implementing safety protocols

- Conducting regular maintenance

- Training personnel

Each element is vital for mitigating risks and ensuring compliance with industry standards. Regular inspections and a proactive maintenance approach not only ensure equipment reliability but also reduce costly downtimes. Moreover, comprehensive training programs provide operators with the skills and knowledge necessary to handle lifting equipment safely and effectively.

In conclusion, prioritizing these best practices transcends mere regulatory compliance; it fosters a culture of safety and professionalism within the construction industry. By committing to optimal equipment choices, robust safety measures, diligent maintenance routines, and thorough training initiatives, construction teams can significantly enhance their operational efficiency and safeguard the well-being of their workforce. Embracing these principles will lead to safer and more successful construction projects in the future.

Frequently Asked Questions

Why is it important to select appropriate lifting equipment for construction projects?

Selecting the right lifting equipment is essential for the success of construction projects as it enhances safety, efficiency, and productivity on site.

What should be assessed when choosing lifting equipment?

Key assessments include the weight and dimensions of the loads to be lifted, load capacity, type of lift required, site conditions, and the skill level of operators.

How does load capacity impact the selection of lifting equipment?

Load capacity is crucial as the equipment must support the maximum weight of the load, considering dynamic forces that may occur during lifting to ensure safety.

What types of lifting solutions might be needed for different projects?

Different projects may require various lifting solutions such as cranes, hoists, or forklifts, depending on the nature of the lift and the characteristics of the load.

How do site conditions affect the choice of lifting equipment?

Site conditions, such as terrain and spatial constraints, influence the selection of equipment; for instance, rough terrain may require rough-terrain cranes, while compact lifts are suitable for tight spaces.

Why is operator skill level important in selecting lifting equipment?

The skill level of operators must match the complexity of the machinery, as more complex equipment often requires certified operators to ensure safety and compliance with regulations.

What role does operator training play in lifting equipment safety?

Proper operator training is critical in preventing accidents, as human error accounts for approximately 90% of crane incidents. Investing in training is vital for protecting workers and ensuring project success.

List of Sources

- Select Appropriate Lifting Equipment for Project Needs

- Important Crane Safety Statistics From 2026 (https://oshaoutreachcourses.com/blog/crane-safety-statistics)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- 15 of the Most Inspiring Quotes about Construction - Digital Builder (https://autodesk.com/blogs/construction/inspiring-construction-quotes)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- Get Motivated with 20 Classic Quotes About Construction (https://planhub.com/resources/get-motivated-with-20-classic-quotes-about-construction)

- Implement Safety Protocols for Lifting Equipment Usage

- Important Crane Safety Statistics From 2026 (https://oshaoutreachcourses.com/blog/crane-safety-statistics)

- Crane Safety Statistics 2025: Facts You Must Know (https://360osha30.com/blog/crane-safety-statistics)

- Fatal Occupational Injuries Involving Cranes (https://bls.gov/iif/factsheets/fatal-occupational-injuries-cranes-2011-17.htm)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Common Types of Crane Accidents & Injury Statistics (https://heavyequipmentcollege.edu/common-types-of-crane-accidents-injury-statistics)

- Conduct Regular Maintenance and Inspections of Equipment

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- Manufacturing Maintenance Statistics & Data You Need to Know (https://caisoft.com/resources/manufacturing-maintenance-statistics)

- 25 Maintenance Stats, Trends, And Insights For 2026 (https://getmaintainx.com/blog/maintenance-stats-trends-and-insights)

- Maintenance statistics and trends 2025 • Infraspeak Blog (https://blog.infraspeak.com/maintenance-statistics-trends-challenges)

- Train Personnel on Proper Equipment Operation

- Training Inspiration Meets eLearning: 15+ Quotes About Training & Insights (https://elmlearning.com/blog/quotes-about-training)

- 18 of Our Favorite Quotes About the Power of Training & Development - Abilitie (https://abilitie.com/blog/2018-7-6-18-of-our-favorite-quotes-about-the-power-of-training-development)

- 22 Workplace Safety Quotes From Leaders and Experts - AlertMedia (https://alertmedia.com/blog/workplace-safety-quotes)

- Inspirational Learning and Training Quotes | SkyPrep (https://skyprep.com/2013/07/29/15-inspiration-learning-and-training-quotes)

- 65 Quotes About Workplace Learning & Development (https://growthengineering.co.uk/65-quotes-about-workplace-learning)