Key Highlights:

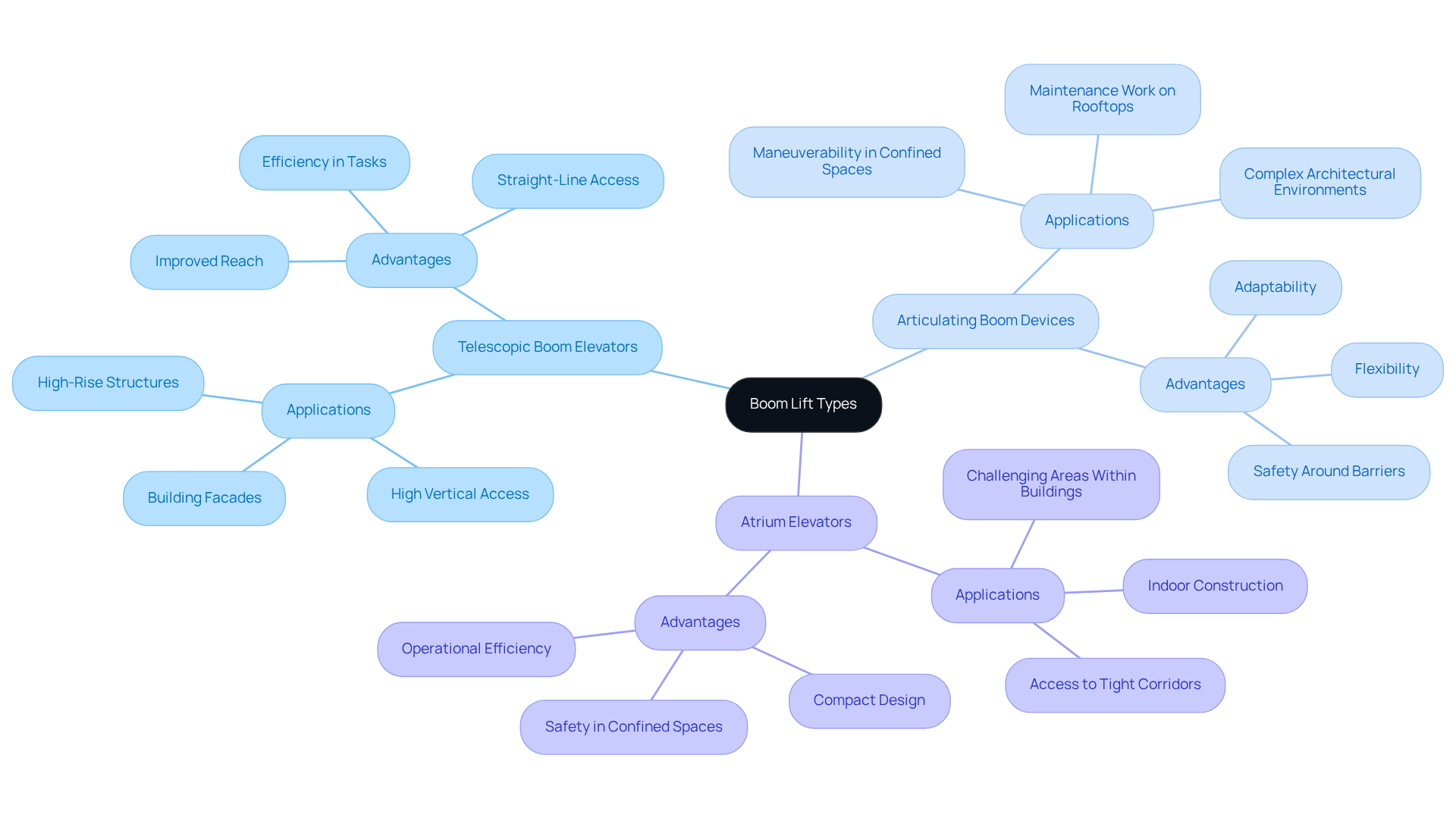

- Boom lifts are categorised into three types: telescopic, articulating, and atrium elevators, each serving different construction needs.

- Telescopic boom lifts offer direct vertical access, preferred in 40% of projects for high reach tasks.

- Articulating boom lifts, or knuckle booms, are favoured in 60% of projects for their manoeuvrability in confined spaces.

- Atrium elevators are designed for indoor use, accessing tight areas within buildings.

- Key terminologies like 'working height' and 'load capacity' are crucial for safe equipment selection and operations.

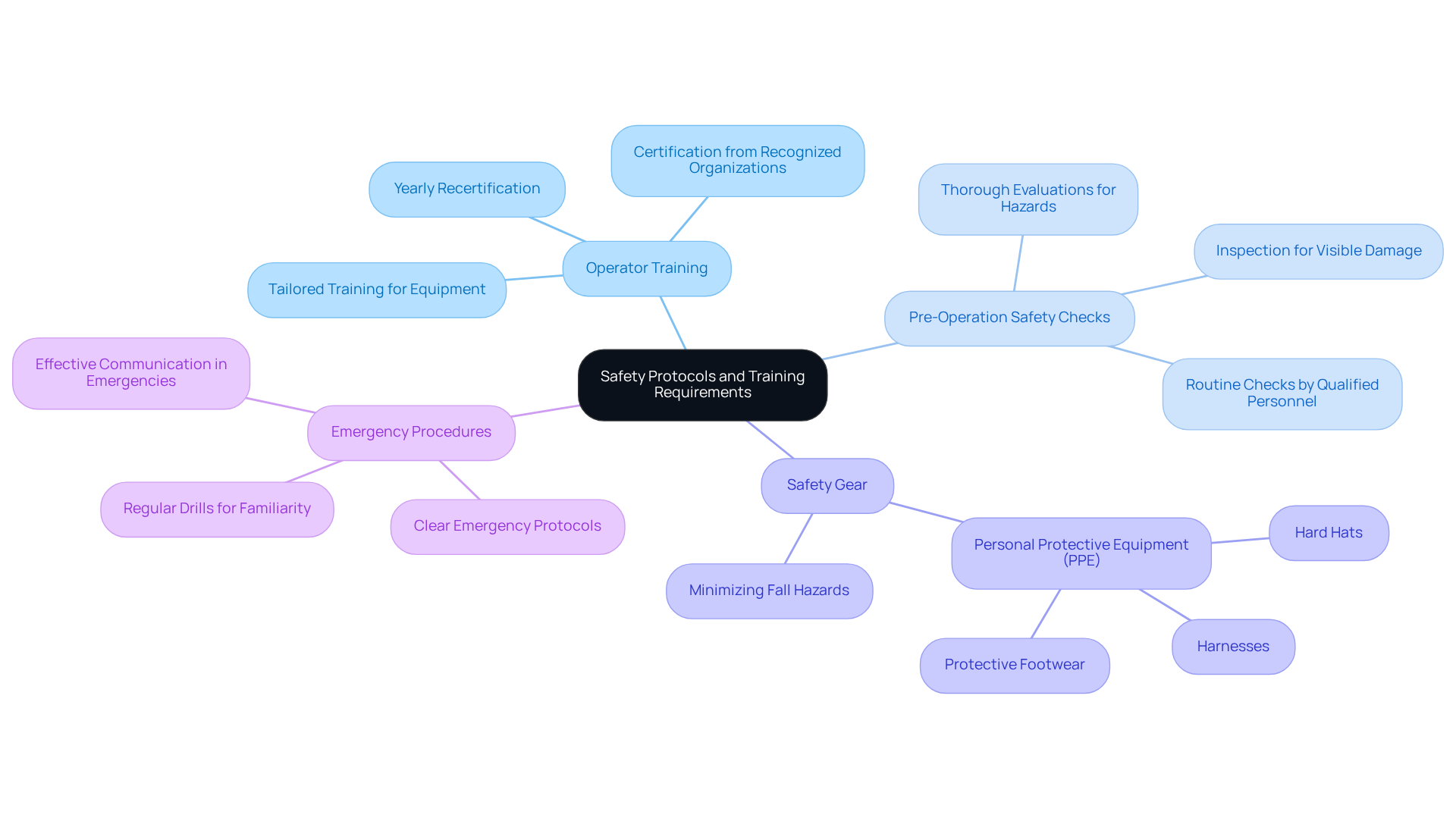

- Operator training is essential, with certification from recognised organisations like OSHA being a requirement.

- Pre-operation safety checks must be conducted to identify hazards and ensure equipment readiness.

- Personal protective equipment (PPE) is necessary for operators and personnel to minimise injury risks.

- Emergency procedures should be established and regularly practised to enhance readiness during incidents.

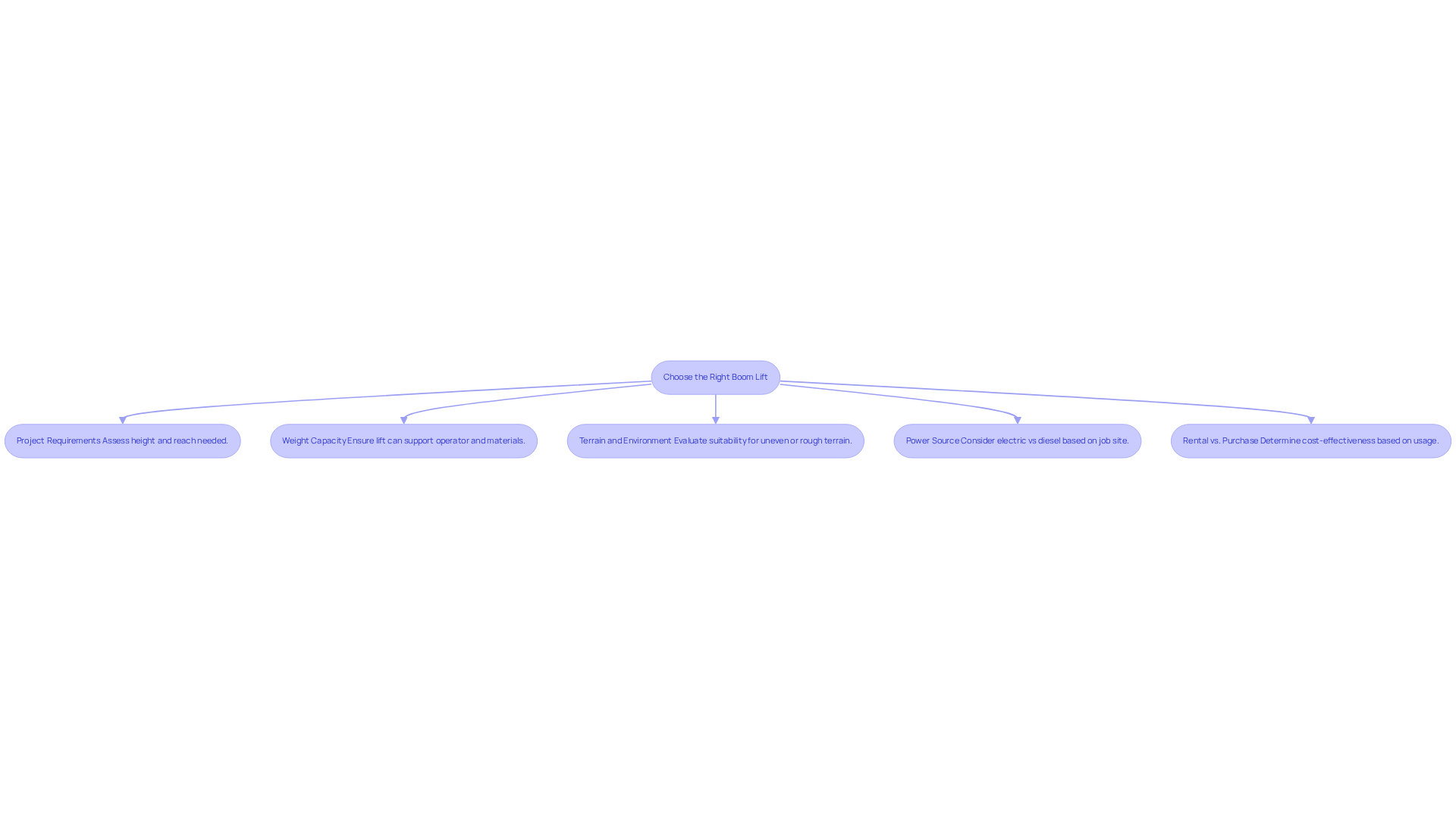

- Selecting the right boom lift involves assessing project requirements, weight capacity, terrain, power source, and cost-effectiveness.

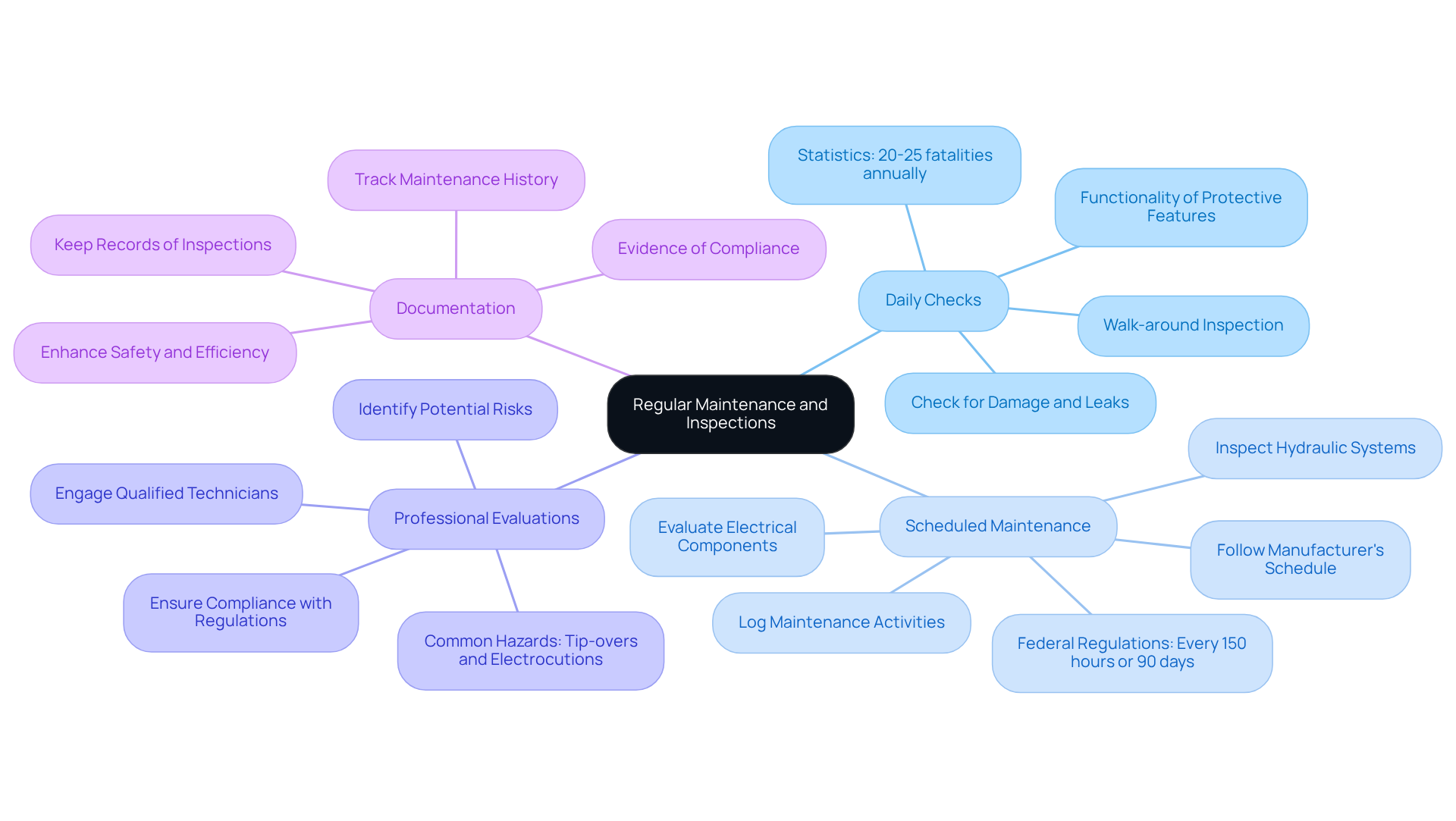

- Regular maintenance and inspections, including daily checks and scheduled evaluations, are vital for safety and compliance.

- Documentation of maintenance activities is essential for regulatory compliance and incident readiness.

Introduction

Understanding the complexities of boom lift operations is essential in the construction industry, where safety and efficiency are critical. This article explores best practices for ensuring safe boom lift operations, providing insights into:

- Equipment selection

- Operator training

- Maintenance protocols

As construction sites grow increasingly intricate, it raises an important question: how can workers effectively navigate the challenges of using boom lifts while minimizing risks and maximizing productivity?

Understand Boom Lift Types and Terminology

Boom lift construction platforms are categorized into distinct types, each designed for specific applications in construction and maintenance. The primary categories include:

-

Telescopic Boom Elevators: These devices extend straight out, making them ideal for reaching high, vertical areas. In boom lift construction projects, they are frequently utilized to provide direct vertical access, such as for building facades and high-rise structures. Approximately 40% of construction projects prefer boom lift construction due to their improved reach and straight-line access abilities, facilitating efficient tasks such as painting and repairs.

-

Articulating Boom Devices: Commonly referred to as knuckle booms, these mechanisms feature joints that enable them to bend and navigate around obstacles. Their design is particularly advantageous for tasks requiring maneuverability in confined spaces, such as maintenance work on rooftops or in complex architectural environments. Boom lift construction is favored in approximately 60% of projects where adaptability is essential, ensuring security and efficiency when maneuvering around barriers.

-

Atrium Elevators: Designed specifically for indoor applications, atrium elevators boast a compact design that allows access to challenging areas within buildings, such as atriums and tight corridors. Their ability to operate in confined spaces makes boom lift construction invaluable for interior construction and maintenance tasks.

Familiarity with key terminologies, including 'working height' and 'load capacity', is vital for selecting the appropriate equipment and ensuring safe operations on site. As construction risk specialists highlight, understanding these terms not only assists in equipment selection, such as boom lift construction, but also enhances overall site security, reducing the likelihood of accidents and ensuring adherence to regulations. Real-world applications of boom lift construction include their use in high-rise construction, where they assist in the installation of windows and exterior cladding, showcasing their effectiveness in achieving high output quickly and safely.

Implement Safety Protocols and Training Requirements

To ensure safe boom lift construction operations, implementing comprehensive safety protocols and training requirements is essential.

Operator Training: All operators must complete training tailored to the specific boom lift construction equipment they will be using. This training should encompass operational techniques, precautionary measures, and emergency procedures. Certification from recognized organizations, such as OSHA, is crucial, as it ensures operators possess the necessary knowledge to handle the equipment safely. Yearly recertification is often adopted as a best practice for aerial equipment certification, underscoring the importance of continuous training to uphold compliance and security standards.

Pre-Operation Safety Checks: Operators are required to conduct thorough pre-operation evaluations to identify potential hazards or equipment malfunctions. This involves inspecting for visible damage, confirming that protective features are operational, and validating that the apparatus is suitable for the intended task. Routine checks of aerial platforms should be performed by a qualified, experienced team member, typically a supervisor, as mandated by OSHA, emphasizing the importance of diligence in ensuring equipment security.

Safety Gear: It is essential that operators and personnel working near boom lift construction wear appropriate personal protective equipment (PPE). This includes hard hats, harnesses, and protective footwear to minimize the risk of injury. Fall hazards are the primary cause of aerial equipment injuries, underscoring the importance of adhering to PPE guidelines as a critical element of workplace protection, especially in environments where boom lift construction is taking place.

Emergency Procedures: Establishing clear emergency procedures for scenarios such as equipment failure or accidents is vital. Regular drills should be conducted to ensure all personnel are familiar with these protocols, enhancing readiness and response times in emergencies. Effective communication and training in emergency protocols can significantly reduce the risks associated with aerial platform operations. As workplace safety expert Jason Hessom states, "Diligence saves lives, and compliance saves companies from significant fines.

Choose the Right Boom Lift for Your Project Needs

Selecting the appropriate boom lift requires careful consideration of several key factors.

-

Project Requirements: Begin by assessing the height and reach necessary for your project. If the task involves accessing high ceilings or rooftops, a telescopic platform may be essential to meet those demands.

-

Weight Capacity: It is crucial to ensure that the chosen aerial platform can safely support the combined weight of the operator, tools, and materials. Exceeding the weight limit can lead to equipment failure and pose serious safety risks.

-

Terrain and Environment: Evaluate the work environment as well. For uneven or rough terrain, an articulating boom lift may be more suitable due to its enhanced ability to navigate obstacles effectively.

-

Power Source: Consider whether an electric or diesel-powered lift is more appropriate based on the job site conditions and the expected duration of use. Electric lifts are often preferred for indoor applications due to their lower emissions and reduced noise levels.

-

Rental vs. Purchase: Finally, determine whether renting or purchasing the lift is more cost-effective, taking into account the frequency of use and the duration of the project. This decision can significantly impact your overall budget.

Conduct Regular Maintenance and Inspections

Regular maintenance and inspections are vital for the safe operation of boom lift construction equipment.

Daily Checks: Operators must conduct a thorough walk-around inspection before each use. This includes checking for visible damage, fluid leaks, and the functionality of protective features. Such proactive measures help identify potential issues early, significantly reducing the risk of accidents. Notably, statistics indicate that 20 to 25 fatalities occur annually due to aerial lift-related accidents, underscoring the importance of vigilance in these operations.

Scheduled Maintenance: Following the manufacturer's recommended maintenance schedule is crucial for safety and performance. This typically involves inspections of hydraulic systems, electrical components, and structural integrity. Maintaining a detailed log of all maintenance activities not only tracks service history but also helps identify recurring issues that may need attention. Federal regulations mandate evaluations every 150 hours of operation or every 90 days, whichever comes first, to ensure compliance and safety.

Professional Evaluations: It is essential to engage qualified technicians for comprehensive assessments at regular intervals. These professionals ensure compliance with regulations and can pinpoint potential risks before they develop into serious problems. Common hazards associated with boom lift construction include tip-overs and electrocutions, highlighting the necessity of routine evaluations.

Documentation: Keeping meticulous records of all inspections and maintenance activities is essential for regulatory compliance. This documentation can prove crucial in the event of an incident, providing evidence of adherence to protocols and maintenance practices. Regular inspections and thorough documentation significantly enhance the overall safety and efficiency of boom lift construction operations.

Conclusion

Understanding best practices for safe boom lift construction operations is essential for improving workplace safety and efficiency. By grasping the various types of boom lifts and their specific applications, operators can make informed decisions that meet project requirements and ensure optimal safety measures are implemented.

Key points discussed in this article include:

- The necessity of thorough training for operators

- The importance of implementing safety protocols

- The critical role of regular maintenance and inspections

Each of these elements significantly contributes to minimizing risks associated with boom lift operations, ultimately protecting personnel and maintaining project integrity.

As the construction industry evolves, prioritizing safety through education, proper equipment selection, and diligent maintenance practices remains crucial. By adhering to these best practices, construction teams can enhance operational efficiency and foster a culture of safety that protects workers while promoting compliance with regulations. Emphasizing these principles ensures that boom lift construction operations are executed smoothly and securely, paving the way for successful project outcomes.

Frequently Asked Questions

What are the main types of boom lifts used in construction?

The main types of boom lifts used in construction are Telescopic Boom Elevators, Articulating Boom Devices (knuckle booms), and Atrium Elevators.

What is the purpose of Telescopic Boom Elevators?

Telescopic Boom Elevators extend straight out and are ideal for reaching high, vertical areas, commonly used for direct vertical access in building facades and high-rise structures.

In what percentage of construction projects are boom lifts preferred for their reach and access abilities?

Approximately 40% of construction projects prefer boom lifts due to their improved reach and straight-line access abilities.

What are Articulating Boom Devices designed for?

Articulating Boom Devices, or knuckle booms, have joints that allow them to bend and navigate around obstacles, making them suitable for tasks in confined spaces, such as maintenance work on rooftops.

How frequently are Articulating Boom Devices used in construction projects?

Articulating Boom Devices are favored in about 60% of construction projects where adaptability is essential.

What is the purpose of Atrium Elevators?

Atrium Elevators are designed for indoor applications with a compact design that allows access to challenging areas within buildings, such as atriums and tight corridors.

Why is it important to understand key terminologies like 'working height' and 'load capacity'?

Understanding key terminologies such as 'working height' and 'load capacity' is vital for selecting appropriate equipment and ensuring safe operations on site, enhancing overall site security and reducing the likelihood of accidents.

What are some real-world applications of boom lifts in construction?

Boom lifts are used in high-rise construction to assist in the installation of windows and exterior cladding, showcasing their effectiveness in achieving high output quickly and safely.

List of Sources

- Understand Boom Lift Types and Terminology

- Boom Lifts Market Size, Share, Trends & Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/boom-lifts-market-report)

- Boom Lifts Market 2025 - Growth And Opportunities to 2034 (https://thebusinessresearchcompany.com/report/boom-lifts-global-market-report)

- Boom Lift Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/boom-lift-rental-market)

- Boom Lifts Market Size, Share And Forecast Report, 2033 (https://imarcgroup.com/boom-lifts-market)

- Boom Lifts Market Size, Share & Global Industry 2035 (https://marketresearchfuture.com/reports/boom-lifts-market-27050)

- Implement Safety Protocols and Training Requirements

- Aerial Lift Operator Safety Training. Northern Training trains your operators (https://northern-training.com/aerial-lift-operator-training)

- Onsite Forklift & Aerial Lift Certification & Training for Employers (https://forkliftcomply.com/post/aerialliftcertification)

- Does OSHA Require Training for Aerial Lifts? (https://safetyvideos.com/does-OSHA-require-training-for-aerial-lifts?srsltid=AfmBOop5rMVnebG1C_ZIkg_mW5cQSWd0ReC4CGs1JXI1eFrhcQUE085w)

- eLCOSH : Deaths From Aerial Lifts (https://elcosh.org/document/1417/d000484/deaths-from-aerial-lifts.html)

- Choose the Right Boom Lift for Your Project Needs

- Boom Lifts Market Size, Share, Trends & Growth Report, 2030 (https://grandviewresearch.com/industry-analysis/boom-lifts-market-report)

- The Boom Lift: Everything You Need To Know (https://dozr.com/blog/boom-lift)

- Boom Lift Work Platform Market, Global Outlook and Forecast 2026-2034 (https://statsmarketresearch.com/global-boom-lift-work-platform-forecast-market-8069111)

- Boom Lift Rental Market | Global Market Analysis Report - 2035 (https://factmr.com/report/boom-lift-rental-market)

- Boom Lift Sizes Guide: Heights, Reach & Best Uses (https://zumasales.com/blogs/boom-lifts/boom-lift-sizes?srsltid=AfmBOoq9thuiQBQs2oEcUEp6hZHz_us5u2lZdZZeCmKKwnWfUTTWZAnw)

- Conduct Regular Maintenance and Inspections

- Aerial Lift Hazards and What to Watch Out For 2026 (https://certifymeonline.net/blog/top-5-aerial-lift-hazards-avoid)

- Buying vs. Renting a Boom Lift: What’s Right for You? (https://widespreadrentals.com/buying-vs-renting-a-boom-lift-what-makes-sense-for-you)

- eLCOSH : Deaths From Aerial Lifts (https://elcosh.org/document/1417/d000484/deaths-from-aerial-lifts.html)

- What Is The Recommended Frequency For Aerial Lift Inspection? (https://cnclifttruck.com/blog/what-is-the-recommended-frequency-for-aerial-lift-inspection--64474)

- How Do Accidents Happen on Aerial Lifts? (https://aerialliftcertification.com/blog/accidents-happen-aerial-lifts)