Key Highlights:

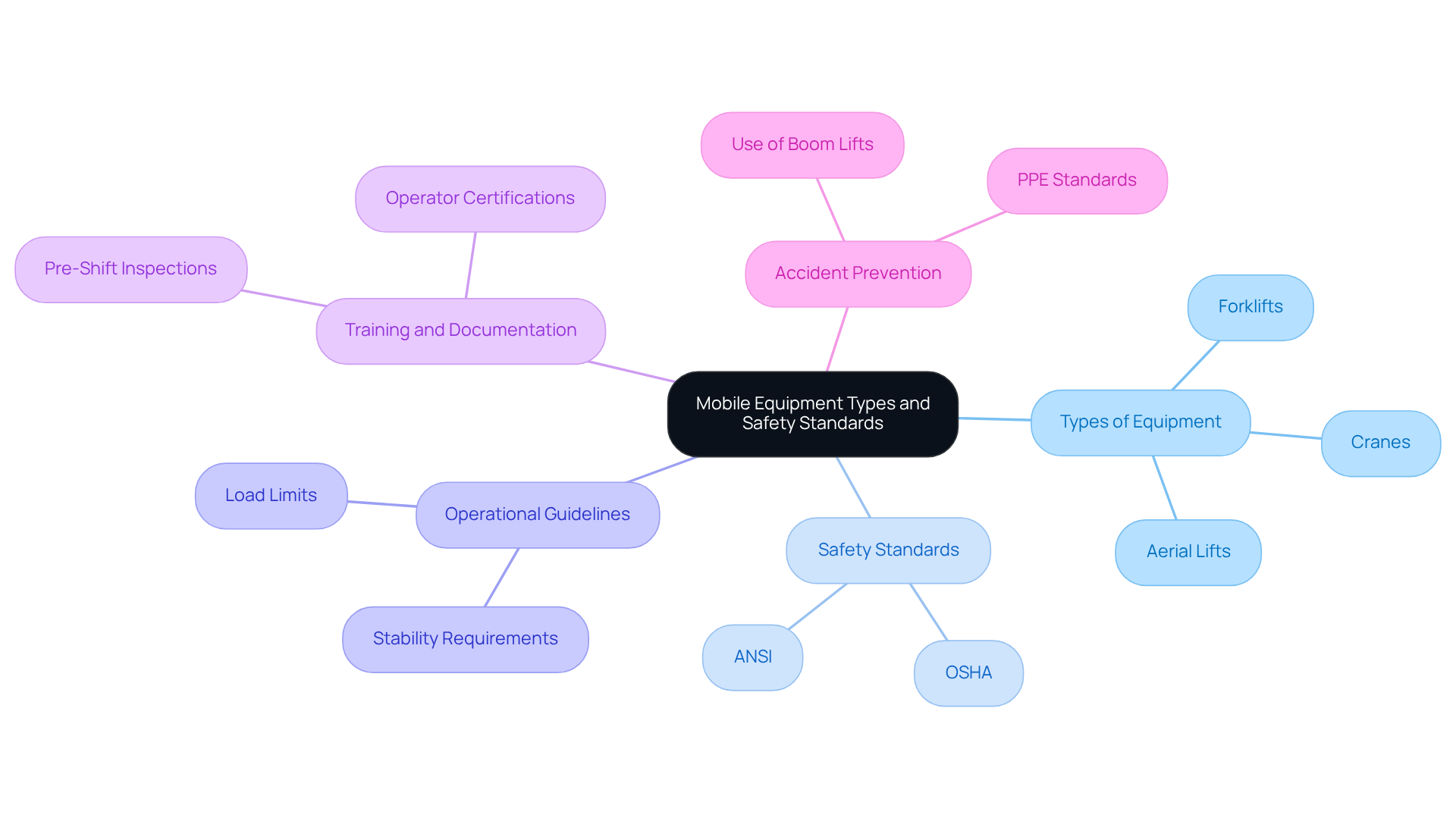

- Mobile machinery includes forklifts, cranes, and aerial lifts, each governed by specific safety standards from OSHA and ANSI.

- Understanding load limits and stability is crucial for preventing accidents and ensuring efficient operation.

- As of 2026, OSHA has introduced stricter regulations requiring comprehensive training and documentation of operational practises.

- Boom lifts provide a safer working environment at heights with features like guardrails and emergency stop buttons.

- In 2023, there were 5,283 fatal work injuries, highlighting the critical need for adherence to safety standards.

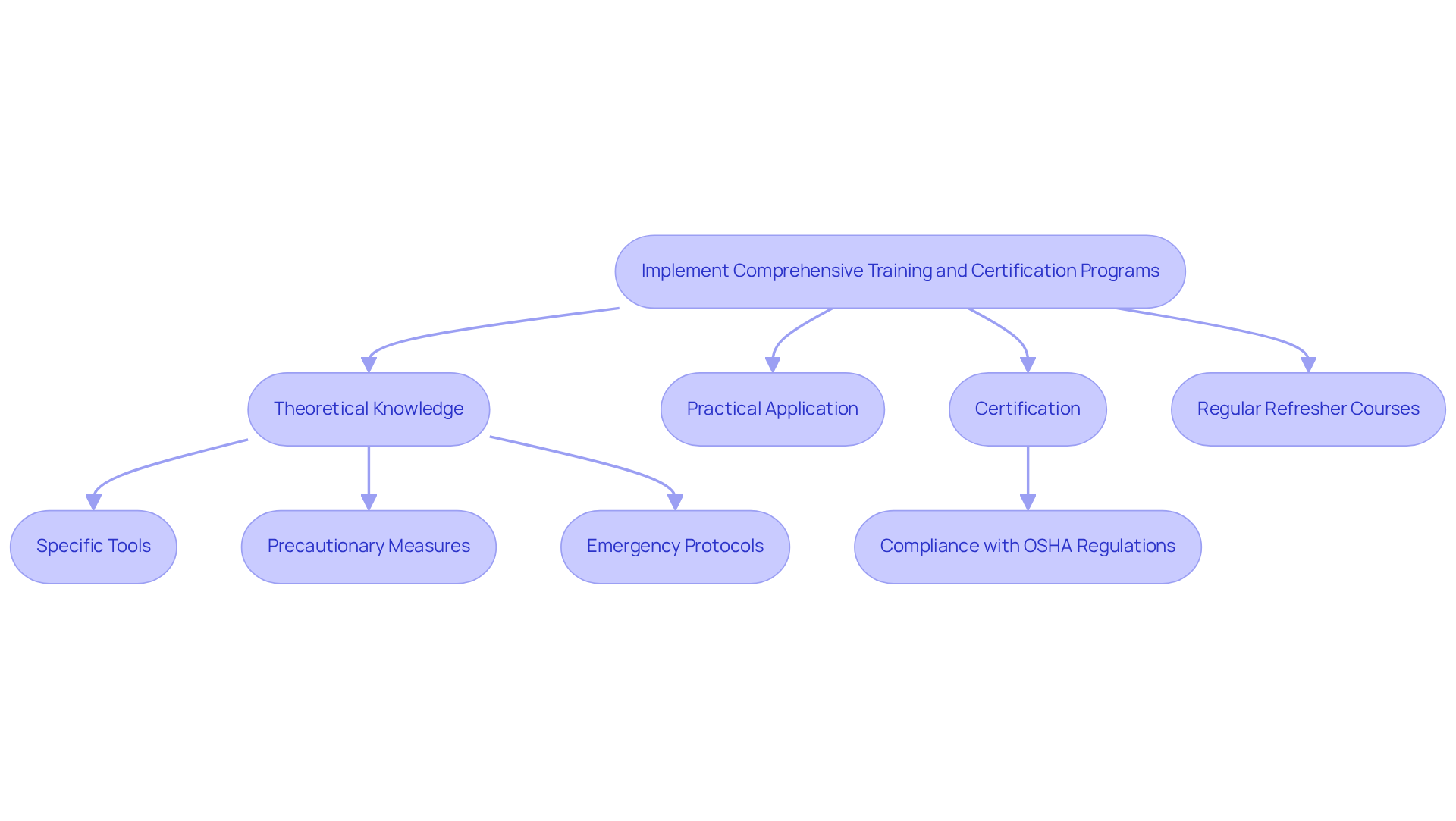

- Comprehensive training and certification programmes must blend theoretical knowledge with practical application for effective operator education.

- Regular refresher courses are essential to keep operators updated on evolving safety standards.

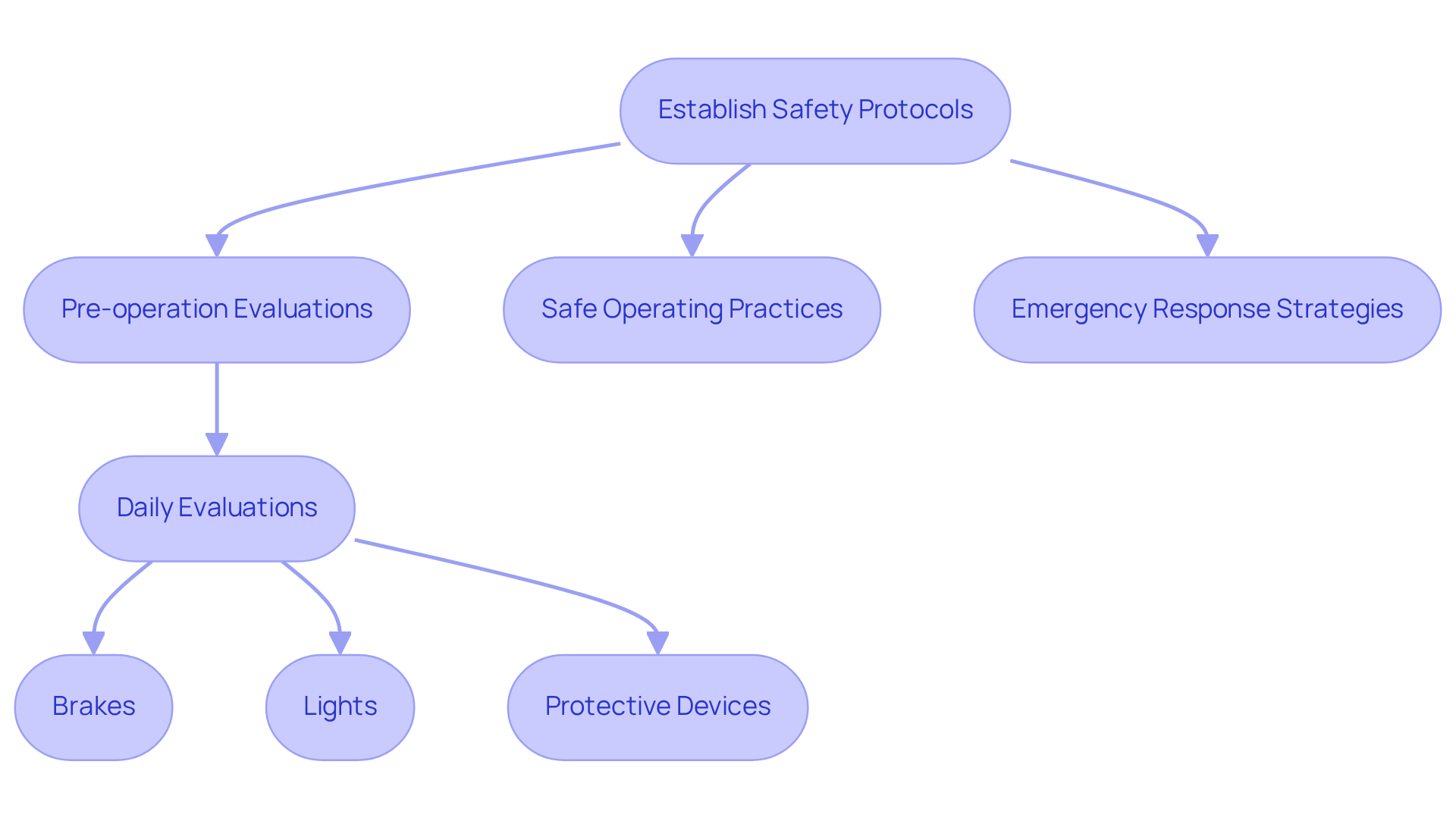

- Daily evaluations of mobile equipment are mandated by OSHA to prevent accidents related to human error.

- Establishing clear communication strategies is vital for coordinating movements and preventing incidents.

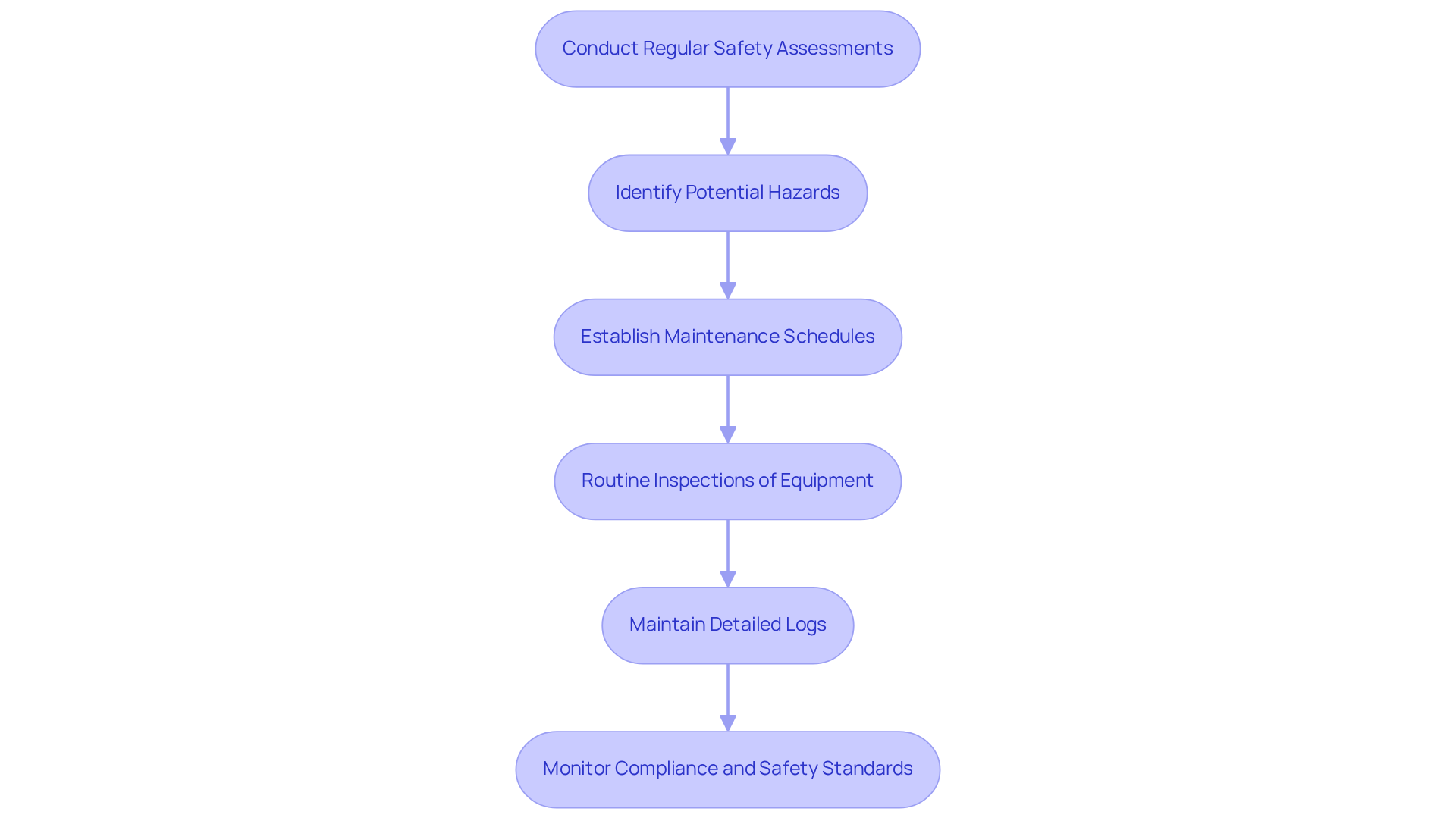

- Regular safety assessments and maintenance are crucial for identifying hazards and ensuring optimal equipment performance.

- Proactive maintenance is more cost-effective than reactive upkeep, leading to improved safety outcomes and operational efficiency.

Introduction

Understanding the complexities of mobile equipment operation is essential in today’s dynamic industrial environment, where safety standards are continually evolving. This article explores four best practices that not only enhance operational safety but also ensure compliance with rigorous regulations. As organizations face increasing costs associated with non-compliance and concerning injury statistics, the critical question arises: how can operators effectively implement these practices to protect themselves and their teams?

Understand Mobile Equipment Types and Safety Standards

Mobile machinery encompasses a wide range of devices used in construction and industrial settings, including forklifts, cranes, and aerial lifts. Each type of equipment is subject to specific operational guidelines and safety standards set by organizations such as OSHA and ANSI. Understanding these standards is essential for ensuring safe operations. Operators must be knowledgeable about load limits and stability requirements, as these factors are critical for preventing accidents and ensuring efficient performance. Regularly evaluating and adhering to these standards not only ensures compliance but also significantly enhances safety across work sites.

As of 2026, OSHA has implemented stricter regulations, highlighting the importance of comprehensive training and documentation of all operational practices. This includes maintaining electronic records of pre-shift inspections and operator certifications, which are vital for fostering a culture of safety and accountability in operations involving mobile equipment. Utilizing a boom lift notably reduces the risks associated with working at heights. The stable platform and safety features, such as guardrails and emergency stop buttons, create a secure working environment for operators, thereby minimizing accidents and injuries. Consequently, boom lifts are a crucial rental option at EZ Equipment Rental for elevated work tasks.

The rising costs of non-compliance, coupled with the alarming statistic of 5,283 fatal work injuries recorded in 2023, underscores the importance of adhering to safety standards and the value of using boom lifts to enhance protection on job sites.

Implement Comprehensive Training and Certification Programs

To ensure the safe operation of mobile equipment, it is essential to implement comprehensive training and certification programs. These programs should encompass the specific tools in use, detailed precautionary measures, and emergency protocols. Training must effectively blend theoretical knowledge with practical application, enabling operators to acquire vital hands-on experience. Certification should be mandatory, ensuring that only qualified individuals are entrusted with the operation of mobile equipment.

Regular refresher courses are crucial for maintaining skills and keeping knowledge up to date, particularly as safety standards evolve. According to the Bureau of Labor Statistics, an average of 42 crane-related deaths occurred each year from 2011 to 2017, with over 50% of these fatalities involving workers struck by objects or machinery. This statistic highlights the importance of rigorous training and certification.

Moreover, compliance with OSHA regulations, such as ensuring adequate ground conditions and utilizing personal protective equipment (PPE), is vital for mitigating risks associated with crane operations. Implementing these measures not only enhances safety but also protects workers and minimizes potential liabilities.

Establish Safety Protocols and Operational Procedures

Creating robust precautionary measures and operational protocols is vital for minimizing hazards associated with the operation of mobile equipment. These protocols should include comprehensive guidelines for:

- Pre-operation evaluations

- Safe operating practices

- Emergency response strategies

Operators are required to conduct daily evaluations to ensure that machinery is in secure working order, focusing on critical components such as:

- Brakes

- Lights

- Protective devices

According to OSHA, all heavy machinery must undergo daily examinations to ensure safety, which aligns with the statistic that 90% of crane accidents are attributed to human error. A case study highlights that regular inspections can prevent minor issues from escalating into costly repairs, thereby enhancing performance and extending the machinery's lifespan.

Moreover, establishing a clear communication strategy for signaling and coordinating movements is essential to prevent incidents involving ground staff and machinery. This proactive approach not only fosters a culture of safety but also empowers operators to make informed decisions, significantly reducing the likelihood of incidents. As industry leaders emphasize, a commitment to thorough pre-operation evaluations and operational procedures is crucial for ensuring the safety and reliability of mobile equipment in construction environments. Additionally, a cultural shift towards proactive hazard mitigation is necessary to address persistent risks within the industry.

Conduct Regular Safety Assessments and Equipment Maintenance

Regular safety evaluations and equipment upkeep are vital components of a robust safety program in construction. Routine inspections not only help identify potential hazards but also prevent accidents before they occur. Establishing maintenance schedules based on manufacturer recommendations and usage patterns is crucial. For example, operators should routinely examine hydraulic systems, brakes, and protective features to ensure optimal performance.

Maintaining detailed logs of inspections and maintenance activities is essential; these records serve as evidence of compliance during audits and assist in monitoring adherence to safety standards. Organizations that prioritize these practices often experience improved safety outcomes and enhanced operational efficiency, underscoring the importance of a proactive maintenance culture.

According to Nick Darlage, Director of Projects, "Reactive upkeep is always more costly than preventive equipment care," which highlights the cost-effectiveness of regular servicing. Furthermore, organizations that engage in more preventive maintenance report greater cost savings on maintenance technology investments, emphasizing the financial advantages of a proactive approach.

Conclusion

Understanding and implementing effective practices for the safe operation of mobile equipment is essential for ensuring a secure work environment in construction and industrial settings. By emphasizing compliance with safety standards, comprehensive training, established operational protocols, and regular maintenance, organizations can significantly mitigate the risks associated with mobile machinery.

Key insights from this discussion underscore that familiarity with equipment types and their specific safety regulations is crucial for operators. Comprehensive training programs, mandatory certifications, and ongoing evaluations are vital for enhancing skills and ensuring that operators are well-prepared for the challenges they may encounter. Furthermore, establishing robust safety protocols and conducting regular assessments not only reduce hazards but also cultivate a culture of safety within the workforce.

As the industry continues to evolve, maintaining a commitment to safety must remain a top priority. Organizations should actively pursue the implementation of these best practices, not only to comply with regulations but also to protect their workers and enhance operational efficiency. By prioritizing safety in mobile equipment operations, businesses can foster a more secure environment that ultimately benefits all stakeholders involved.

Frequently Asked Questions

What types of mobile equipment are commonly used in construction and industrial settings?

Common types of mobile equipment include forklifts, cranes, and aerial lifts.

Why is it important to understand safety standards related to mobile equipment?

Understanding safety standards is essential for ensuring safe operations, preventing accidents, and ensuring efficient performance.

What organizations set the operational guidelines and safety standards for mobile equipment?

Organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) set the operational guidelines and safety standards.

What are some critical factors operators must be knowledgeable about when using mobile equipment?

Operators must be knowledgeable about load limits and stability requirements to prevent accidents and ensure safe operations.

What new regulations did OSHA implement as of 2026?

OSHA implemented stricter regulations emphasizing comprehensive training and documentation of all operational practices, including maintaining electronic records of pre-shift inspections and operator certifications.

How do boom lifts enhance safety for elevated work tasks?

Boom lifts provide a stable platform and include safety features such as guardrails and emergency stop buttons, which create a secure working environment and minimize the risk of accidents and injuries.

Why are boom lifts considered a crucial rental option at EZ Equipment Rental?

Boom lifts are considered crucial because they significantly reduce the risks associated with working at heights, enhancing safety for elevated work tasks.

What are the consequences of non-compliance with safety standards?

The rising costs of non-compliance and the statistic of 5,283 fatal work injuries recorded in 2023 highlight the importance of adhering to safety standards to ensure worker safety.

List of Sources

- Understand Mobile Equipment Types and Safety Standards

- OSHA Updates 2025: New Regulations Affecting Heavy Equipment Operators - Associated Training Services (https://operator-school.com/blog/osha-updates-2025-new-regulations-affecting-heavy-equipment-operators)

- Construction Equipment Market 2025–2032: Infrastructure Expansion, Urbanization, and Technology-Driven Equipment Modernization | MMR Statistics (https://mmrstatistics.com/reports/641062/construction-equipment-market)

- 10 Statistics About Construction Equipment You Need to Know (https://gocodes.com/construction/equipment-statistics)

- Operating Mobile Equipment - Safety Alert (https://msha.gov/news-and-updates/alerts-hazards/filter/operating-mobile-equipment-safety-alert)

- Mobile Construction Cranes Market Share and Statistics - 2035 (https://factmr.com/report/2299/mobile-construction-cranes-market)

- Implement Comprehensive Training and Certification Programs

- Common Types of Crane Accidents & Injury Statistics (https://heavyequipmentcollege.edu/common-types-of-crane-accidents-injury-statistics)

- Mobile Equipment Safety Tips Every Contractor Should Know - Contractors Insurance Agency (https://contractorsinsuranceagency.com/mobile-equipment-safety-tips-every-contractor-should-know)

- Establish Safety Protocols and Operational Procedures

- Important Crane Safety Statistics From 2026 (https://oshaoutreachcourses.com/blog/crane-safety-statistics)

- The Importance of Equipment Inspections | MacAllister Machinery (https://macallister.com/importance-of-equipment-inspections)

- Crane Accidents: Facts and Statistics (https://blockotoole.com/ny-construction-accidents/crane-accidents-facts-and-statistics)

- Operating Mobile Equipment - Safety Alert (https://msha.gov/news-and-updates/alerts-hazards/filter/operating-mobile-equipment-safety-alert)

- Top 10 Most Common Forklift Accidents [With Statistics] | Conger (https://conger.com/forklift-accidents)

- Conduct Regular Safety Assessments and Equipment Maintenance

- Why Regular Equipment Inspections Are Important | RPM (https://rpmmachinery.com/importance-of-regular-equipment-inspections)

- Maintenance Management Guide: Overview, Trends & Key Statistics | Accruent (https://accruent.com/resources/blog-posts/maintenance-management-guide-overview-trends-key-statistics)

- A New Era of Equipment Preventive Maintenance - Engineered Rigging (https://engineeredrigginggroup.com/tech-talk/a-new-era-of-equipment-preventive-maintenance)

- The Importance of Regular Machinery Assessments for Workplace Safety and Efficiency (https://threesixtysafety.com/the-importance-of-regular-machinery-assessments-for-workplace-safety-and-efficiency)

- 30 Key Maintenance Statistics & Facts Highlighting 2026 Trends (https://coastapp.com/blog/maintenance-metrics-statistics-facts)