Key Highlights:

- Vibratory plate compactors are essential for compacting soil, gravel, and asphalt in construction and landscaping.

- There are two main types of vibratory plate compactors: forward and reversible models, each suited for different tasks.

- Forward plate compactors are best for larger areas, while reversible compactors excel in tight spaces and manoeuvrability.

- Choosing the right compactor affects project efficiency, with forward models ideal for open areas and reversible models for intricate work sites.

- The gasoline-powered segment of vibratory plate compactors holds a 60.1% market share in 2024, with significant market growth projected.

- Key factors in selecting a compactor include project size, soil type, density depth, weight and size, and engine type.

- Safety best practises for operating compactors include wearing PPE, conducting pre-start inspections, and maintaining steady operation.

- Regular maintenance, including daily inspections and fluid level checks, is crucial for prolonging the lifespan and performance of compactors.

Introduction

Vibratory plate compactors are essential tools in the construction and landscaping sectors, specifically engineered to improve the density of soil, gravel, and asphalt. Recognizing the differences among various types of compactors and their intended applications can greatly influence project efficiency and outcomes.

With numerous models available and key factors to consider - such as project size, soil type, and maintenance practices - how can operators ensure they are optimizing both performance and safety?

This article explores best practices for effectively utilizing vibratory plate compactors, offering valuable insights that contribute to successful project execution.

Understand Vibratory Plate Compactors: Types and Functions

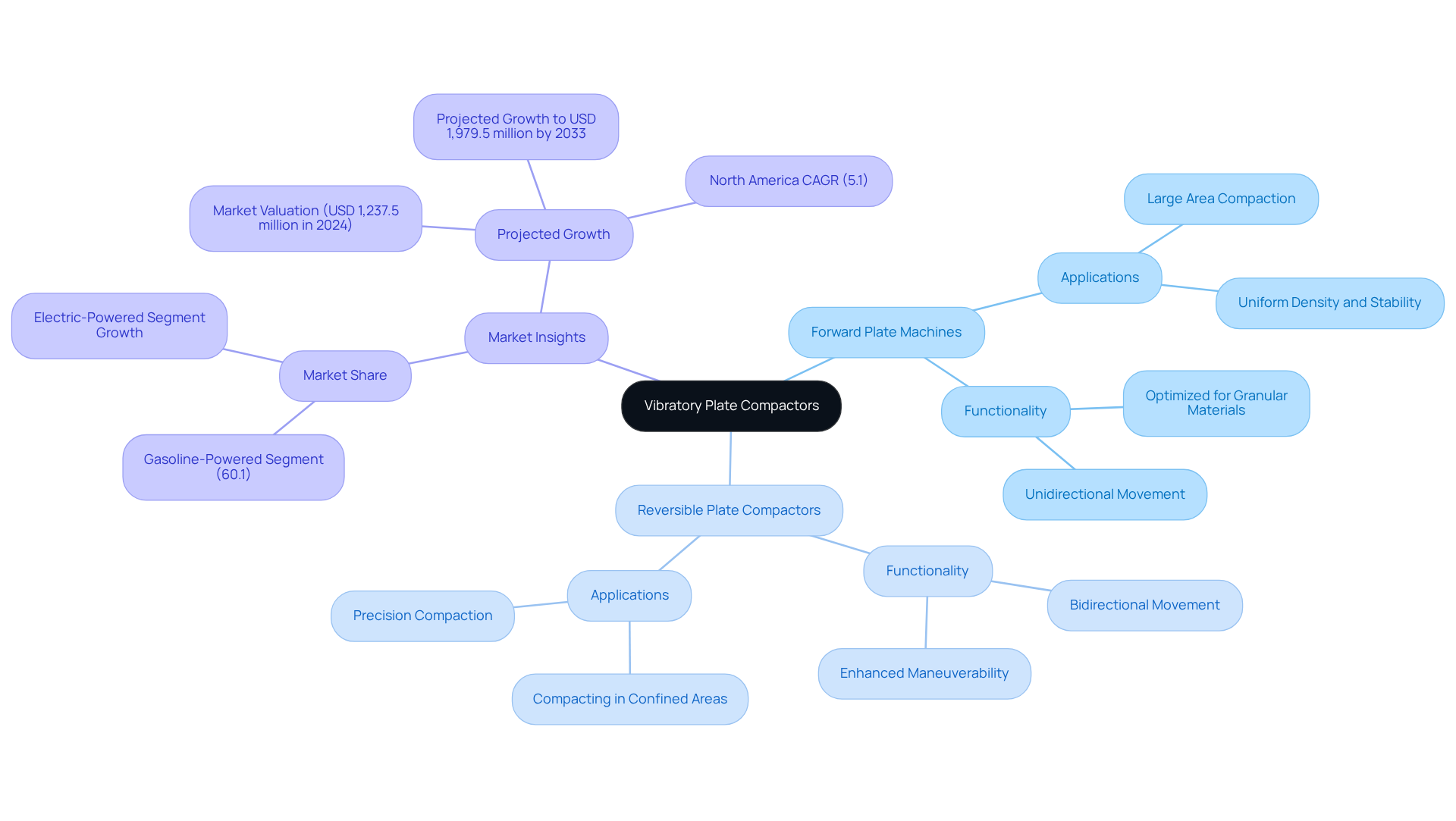

Vibratory plate compactors play a crucial role in construction and landscaping, designed to compact soil, gravel, and asphalt effectively. They are primarily categorized into two types: forward and reversible models, each tailored for specific functions.

-

Forward Plate Machines: These machines are optimized for compacting granular materials over larger areas. Their unidirectional movement makes them ideal for straightforward compaction tasks, ensuring uniform density and stability in the material being compacted.

-

Reversible Plate Compactors: In contrast to forward models, reversible machines can move both forward and backward, providing enhanced maneuverability in tight spaces. This capability is particularly beneficial for compacting in confined areas, such as trenches or around obstacles, where precision is essential.

Choosing between forward and reversible vibratory plate compactors significantly influences project efficiency. For example, forward compactors excel in open areas, while reversible compactors are vital for intricate work sites. Recognizing these distinctions enables operators to select the most suitable equipment, including a vibratory plate compactor, maximizing performance and ensuring effective soil compaction.

As the vibratory surface compressor market evolves, the gasoline-powered segment remains dominant, holding a 60.1% market share in 2024. Furthermore, the global vibratory plate machine market was valued at USD 1,237.5 million in 2024 and is projected to reach USD 1,979.5 million by 2033, reflecting a broader trend towards sustainable construction practices. The North American market is expected to expand at a CAGR of 5.1%, driven by infrastructure investments and the increasing demand for effective compression solutions. This growth underscores the importance of selecting the appropriate machine for specific applications, as experts increasingly recognize the advantages of efficient soil densification.

Select the Right Vibratory Plate Compactor for Your Project Needs

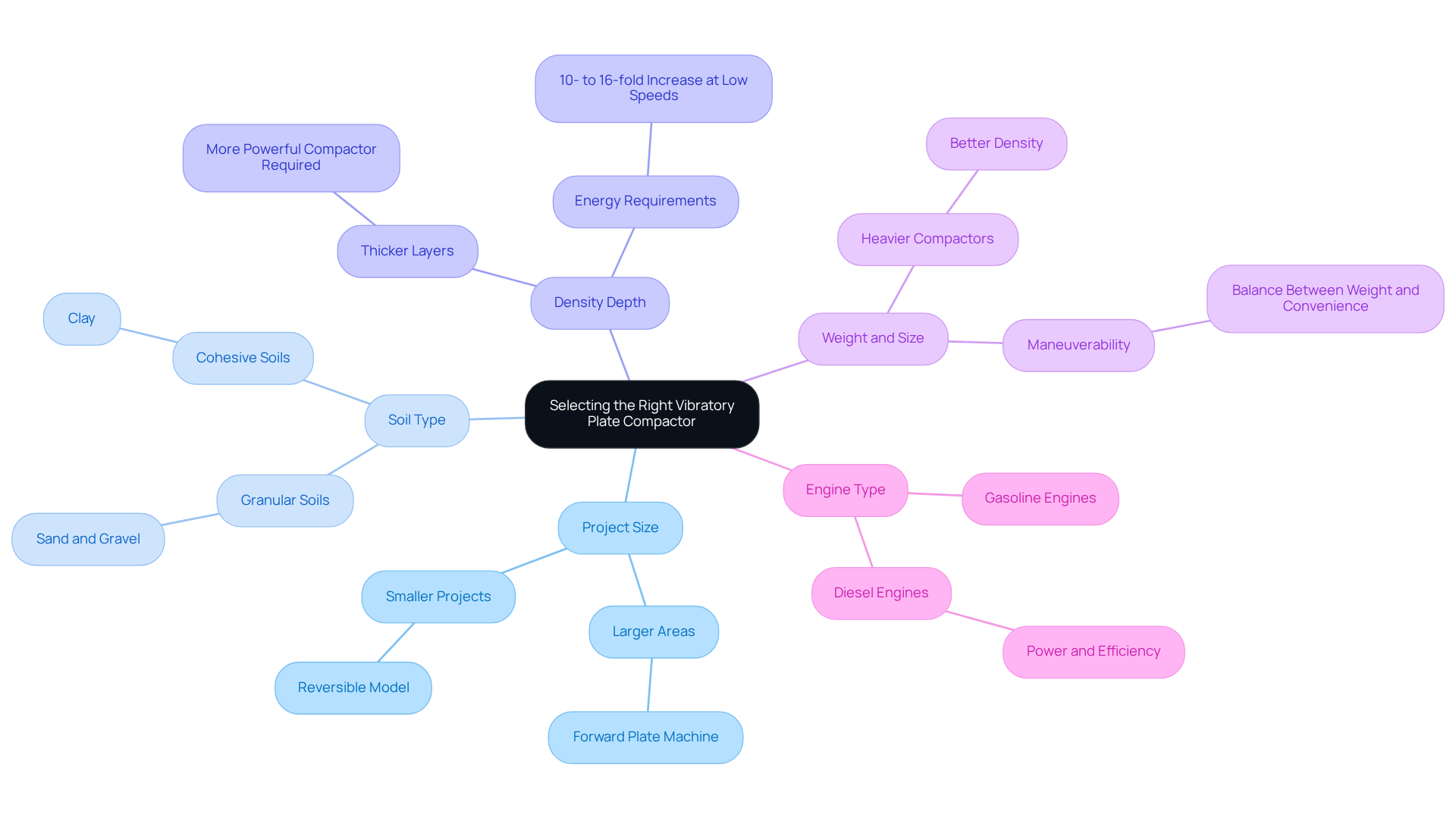

Selecting the appropriate vibratory plate compactor is crucial for achieving optimal compaction results. Here are the key factors to consider:

-

Project Size: For larger areas, a forward plate machine is generally more efficient, allowing for quicker coverage. In contrast, smaller projects may benefit from a reversible model, which provides enhanced maneuverability in tight spaces. A project manager from Caterpillar emphasizes, "Choosing the right compactor based on project size can significantly impact efficiency and overall project timelines."

-

Soil Type: The effectiveness of densification varies significantly with soil type. Granular soils, including sand and gravel, respond well to a vibratory plate compactor, achieving high density. Conversely, cohesive soils, like clay, may require different consolidation methods to ensure adequate density and stability. Research indicates that compacted soils can demand considerably more energy for tillage activities, underscoring the importance of selecting the appropriate equipment for deeper soil density requirements.

-

Density Depth: Assessing the necessary density depth is crucial. For thicker layers, a more powerful compactor is required to achieve the desired density. A study on soil density revealed that energy requirements can increase by 10- to 16-fold at low speeds for compacted soils, highlighting the necessity for appropriate equipment selection.

-

Weight and Size: Heavier compactors typically provide better density but can be challenging to handle. It is vital to strike a balance between the machine's weight for effective compression and its dimensions for convenience in the project setting. A common pitfall is underestimating the difficulty of maneuvering heavier models in tight spaces, which can lead to inefficiencies.

-

Engine Type: The choice between gasoline and diesel engines can influence power levels and operational efficiency. Selecting the right engine type based on project requirements and fuel availability can enhance performance and reduce operational costs. Liebherr states, "The appropriate engine selection can enhance both power and efficiency, guaranteeing that the machine meets the requirements of the project."

By thoroughly evaluating these factors, operators can select the most suitable vibratory plate compactor for their specific project needs, ensuring effective and efficient results. A case study on the 'Impact of Soil Density on Crop Yields' illustrates that improper density choices can lead to significant yield reductions, reinforcing the importance of making informed decisions.

Implement Best Practices for Operating Vibratory Plate Compactors Safely and Effectively

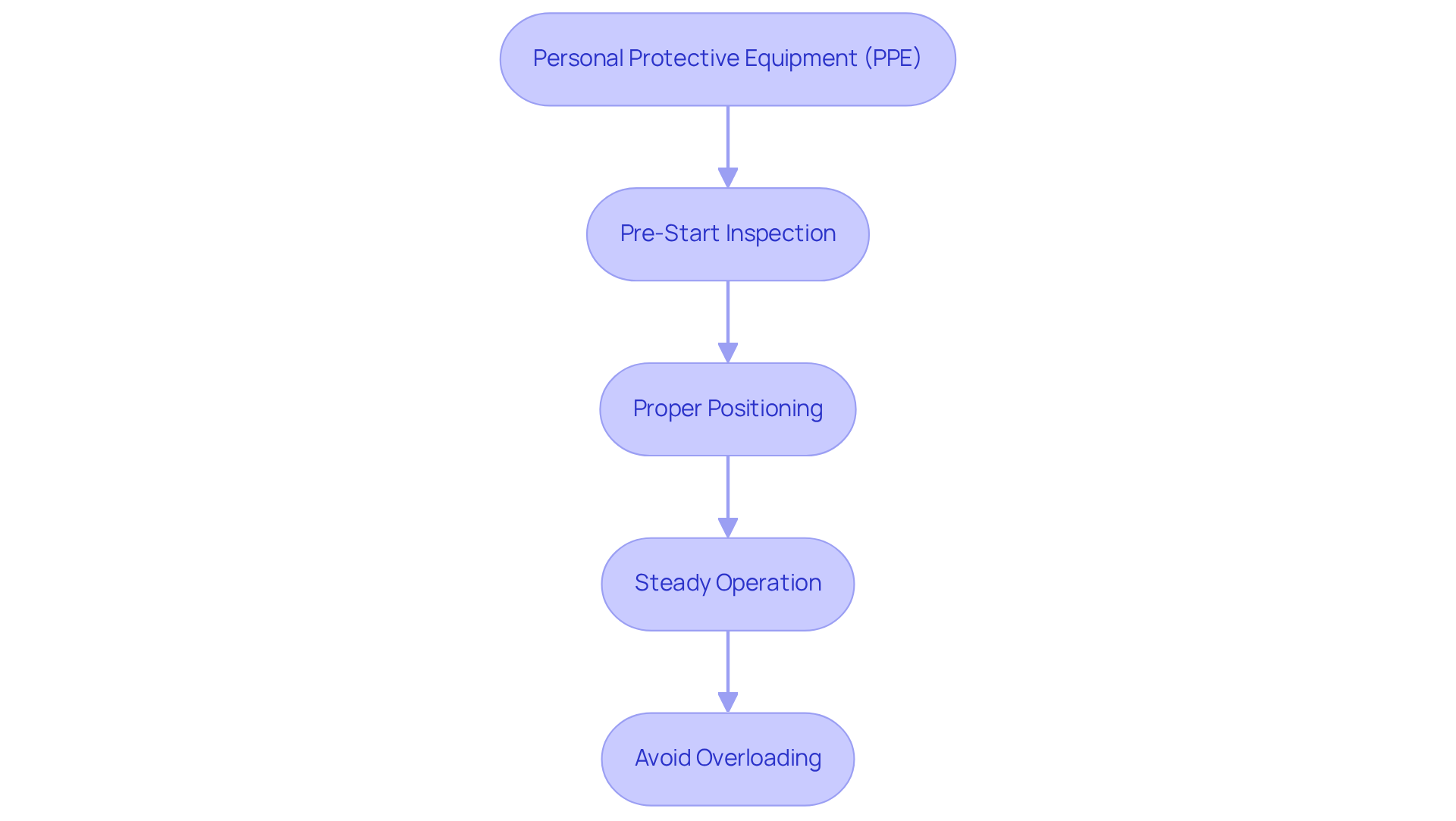

To operate vibratory plate compactors safely and effectively, it is essential to follow these best practices:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety glasses, and steel-toed boots, to protect against potential hazards.

- Pre-Start Inspection: Conduct a thorough inspection before use. Check fuel levels, fluid levels, and ensure all components are functioning correctly.

- Proper Positioning: Stand with feet shoulder-width apart and maintain a firm grip on the handles. This stance provides stability and control during operation.

- Steady Operation: Keep the compactor moving at a steady pace to ensure uniform compaction. Avoid sudden jerks or stops, which can lead to uneven surfaces.

- Avoid Overloading: Do not attempt to compact too much material at once. Follow guidelines for lift thickness to achieve optimal results.

By adhering to these practices, operators can maximize the effectiveness of their vibratory plate compactor while ensuring their safety.

Maintain Your Vibratory Plate Compactor for Longevity and Performance

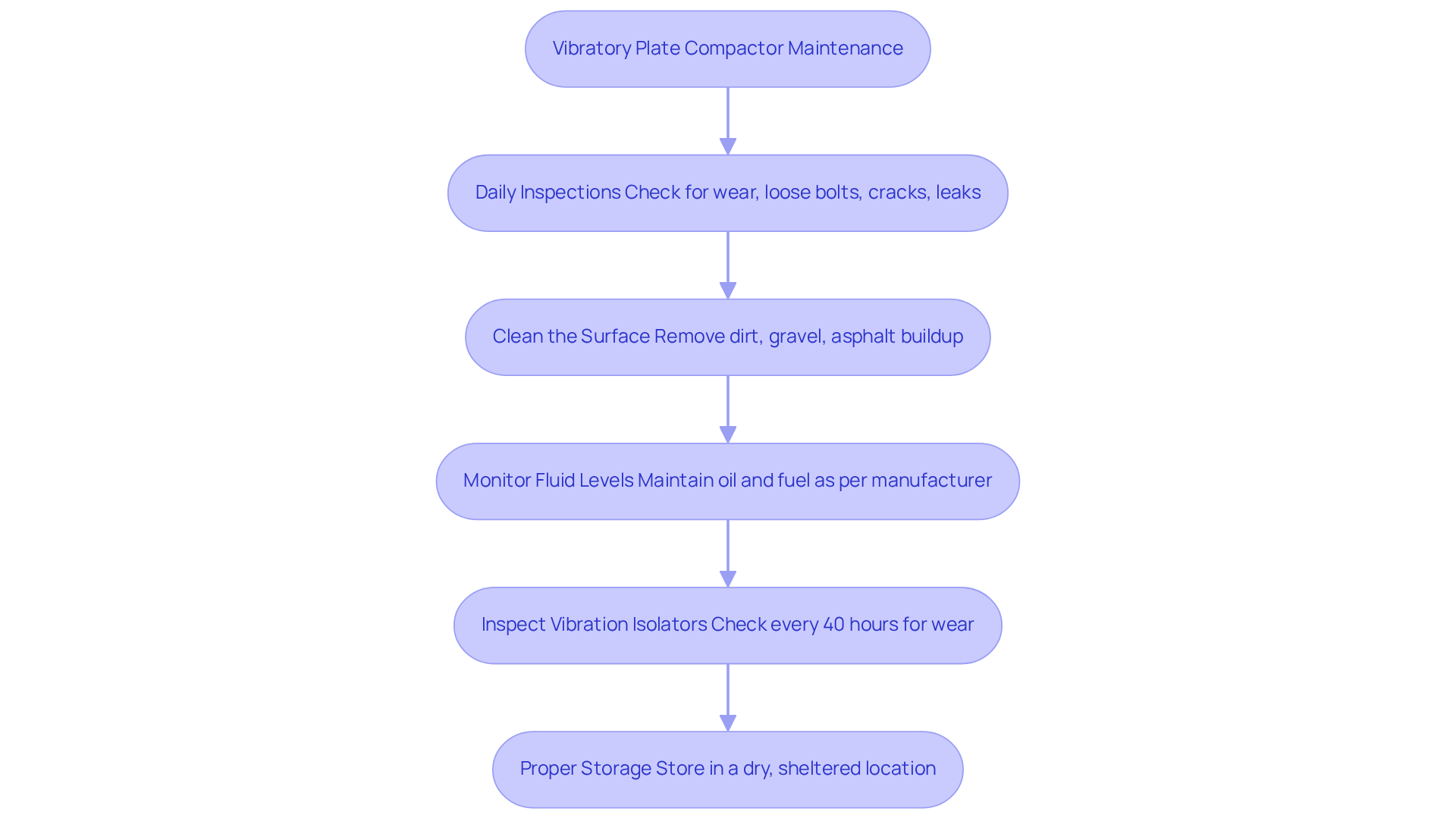

Regular maintenance of the vibratory plate compactor is essential for optimizing its performance and extending its lifespan. This is particularly important in a developing market projected to grow from USD 1,140.30 million in 2026 to USD 1,942.90 million by 2034. Implementing the following key practices can significantly enhance equipment longevity:

- Daily Inspections: Conduct daily checks for signs of wear or damage. Inspect for loose bolts, cracks, or leaks, as these can undermine the machine's effectiveness. Research indicates that regular inspections can lead to a 20% increase in equipment longevity.

- Clean the Surface: After each use, thoroughly clean the compression surface to eliminate dirt, gravel, and asphalt buildup. This prevents material adhesion and ensures optimal compaction outcomes, which is crucial in competitive markets like India, where government initiatives are driving rapid growth in the vibratory equipment sector.

- Fluid Levels: Consistently monitor and maintain proper fluid levels, including oil and fuel. Adhere to the manufacturer's recommendations for oil changes to ensure smooth engine operation; neglecting this can lead to costly repairs.

- Vibration Isolators: Inspect vibration isolators every 40 operating hours for signs of wear. Timely replacement is crucial for maintaining peak performance and reducing operator fatigue, which can significantly impact overall productivity.

- Storage: Store the compactor in a dry, sheltered location to protect it from environmental factors. Covering the equipment helps prevent dust and debris accumulation, further safeguarding its condition.

By adhering to these maintenance practices, operators can significantly prolong the life of their vibratory plate compactors, ensuring that these machines remain reliable and efficient throughout their operational lifespan. Given the challenges of high maintenance costs in the industry, these practices are not just beneficial but essential for sustaining equipment performance.

Conclusion

Selecting and operating a vibratory plate compactor effectively is crucial for achieving optimal results in construction and landscaping projects. By understanding the various types of compactors and their specific functions, operators can make informed choices that enhance efficiency and ensure successful soil compaction.

Key considerations include:

- Project size

- Soil type

- Required density depth

- Machine weight and size

- Engine type

Evaluating these factors enables operators to select the most suitable equipment for their specific tasks. Furthermore, implementing best practices for operation and maintenance maximizes performance and extends the equipment's lifespan, ensuring reliability over time.

The importance of using the right vibratory plate compactor cannot be overstated. As the market continues to evolve, adopting these best practices will improve project outcomes and contribute to the overall efficiency and sustainability of construction efforts. For those involved in construction or landscaping, prioritizing the selection, operation, and maintenance of vibratory plate compactors is a strategic decision that yields lasting benefits.

Frequently Asked Questions

What are vibratory plate compactors used for?

Vibratory plate compactors are used in construction and landscaping to compact soil, gravel, and asphalt effectively.

What are the two main types of vibratory plate compactors?

The two main types are forward plate machines and reversible plate compactors.

What is the function of forward plate machines?

Forward plate machines are optimized for compacting granular materials over larger areas and are ideal for straightforward compaction tasks due to their unidirectional movement.

How do reversible plate compactors differ from forward models?

Reversible plate compactors can move both forward and backward, providing enhanced maneuverability in tight spaces, making them suitable for compacting in confined areas such as trenches or around obstacles.

Why is it important to choose the right type of vibratory plate compactor?

Choosing the right type significantly influences project efficiency; forward compactors excel in open areas, while reversible compactors are essential for intricate work sites.

What is the market share of gasoline-powered vibratory plate compactors in 2024?

Gasoline-powered vibratory plate compactors hold a 60.1% market share in 2024.

What was the value of the global vibratory plate machine market in 2024, and what is its projected growth?

The global vibratory plate machine market was valued at USD 1,237.5 million in 2024 and is projected to reach USD 1,979.5 million by 2033.

What factors are driving the growth of the vibratory plate compactor market in North America?

The growth is driven by infrastructure investments and the increasing demand for effective compression solutions, with an expected CAGR of 5.1%.

List of Sources

- Understand Vibratory Plate Compactors: Types and Functions

- Vibratory Plate Compactor Market | Industry Report, 2033 (https://grandviewresearch.com/industry-analysis/vibratory-plate-compactor-market-report)

- Case Study on Output/Productivity of Pneumatic Tired Vibratory Roller (Earth Compaction Equipment) under Different Job and Management Conditions (https://academia.edu/30825942/Case_Study_on_Output_Productivity_of_Pneumatic_Tired_Vibratory_Roller_Earth_Compaction_Equipment_under_Different_Job_and_Management_Conditions)

- Select the Right Vibratory Plate Compactor for Your Project Needs

- How to choose the right plate compactor for your project? | WHC Hire Services (https://whchire.com/resources/how-to-choose-the-right-plate-compactor-for-your-project)

- Construction Equipment Market Size, Analysis Report 2034 (https://gminsights.com/industry-analysis/construction-equipment-market)

- Buyer's Guide: What to Look for in a Vibratory Plate Compactor (https://mbw.com/buyers-guide-what-to-look-for-in-a-vibratory-plate-compactor)

- Soil compaction (https://extension.umn.edu/soil-management-and-health/soil-compaction)

- U.S. Construction Industry Data (Updated January 2026) (https://constructioncoverage.com/data/us-construction-spending)

- Implement Best Practices for Operating Vibratory Plate Compactors Safely and Effectively

- Vibratory Plate Compactor Market | Industry Report, 2033 (https://grandviewresearch.com/industry-analysis/vibratory-plate-compactor-market-report)

- Best Practices For Using Hydraulic Plate Compactors In 2025 - DeKai Attachment (https://dekaiattachment.com/best-practices-for-using-hydraulic-plate-compactors-in-2025)

- Personal Protective Equipment (PPE) Statistics To Know In 2025 (https://oshagear.com/blog/ppe-statistics)

- Soil Compactor Safety Stats and Facts (https://bhhcsafetycenter.com/soil-compactor-safety-stats-and-facts?print=pdf)

- Safety First: Guidelines for Operating Compactor Equipment Safely (https://bladesdirect.net/blogs/news/safety-first-guidelines-for-operating-compactor-equipment-safely?srsltid=AfmBOopyOthUgVN90yvNo2yRfjFfR3Pp9kLZeAftAQENwdfC_eUr3mBK)

- Maintain Your Vibratory Plate Compactor for Longevity and Performance

- Vibratory Plate Compactor Market | Industry Report, 2033 (https://grandviewresearch.com/industry-analysis/vibratory-plate-compactor-market-report)

- Vibratory Plate Compactor Market Size, Share & Trends [2034] (https://fortunebusinessinsights.com/vibratory-plate-compactor-market-109056)