Key Highlights:

- Walk-behind excavators are compact, making them ideal for confined spaces in residential and landscaping projects.

- They feature intuitive controls, enabling ease of use for operators of all skill levels.

- Versatility is a key advantage, as these machines can perform various tasks with different attachments.

- Economic benefits include reduced rental and shipping costs, leading to improved cash flow for businesses.

- Safety practises include pre-operation checks, maintaining visibility, using proper techniques, and following protection protocols.

- Daily inspections and fluid maintenance are crucial for ensuring the longevity and reliability of the excavator.

- Scheduled maintenance by qualified technicians helps prevent significant issues and enhances equipment performance.

- Effective integration into project planning involves assessing needs, scheduling use, training operators, and monitoring performance.

Introduction

The walk-behind excavator represents a significant advancement in construction and landscaping, merging compact design with exceptional versatility. By mastering best practices for operating these machines, users can fully harness their potential, ensuring both safety and efficiency on the job site.

However, with numerous features and techniques available, operators may wonder how to navigate the complexities of effective usage. This understanding is crucial to avoiding common pitfalls and maximizing productivity.

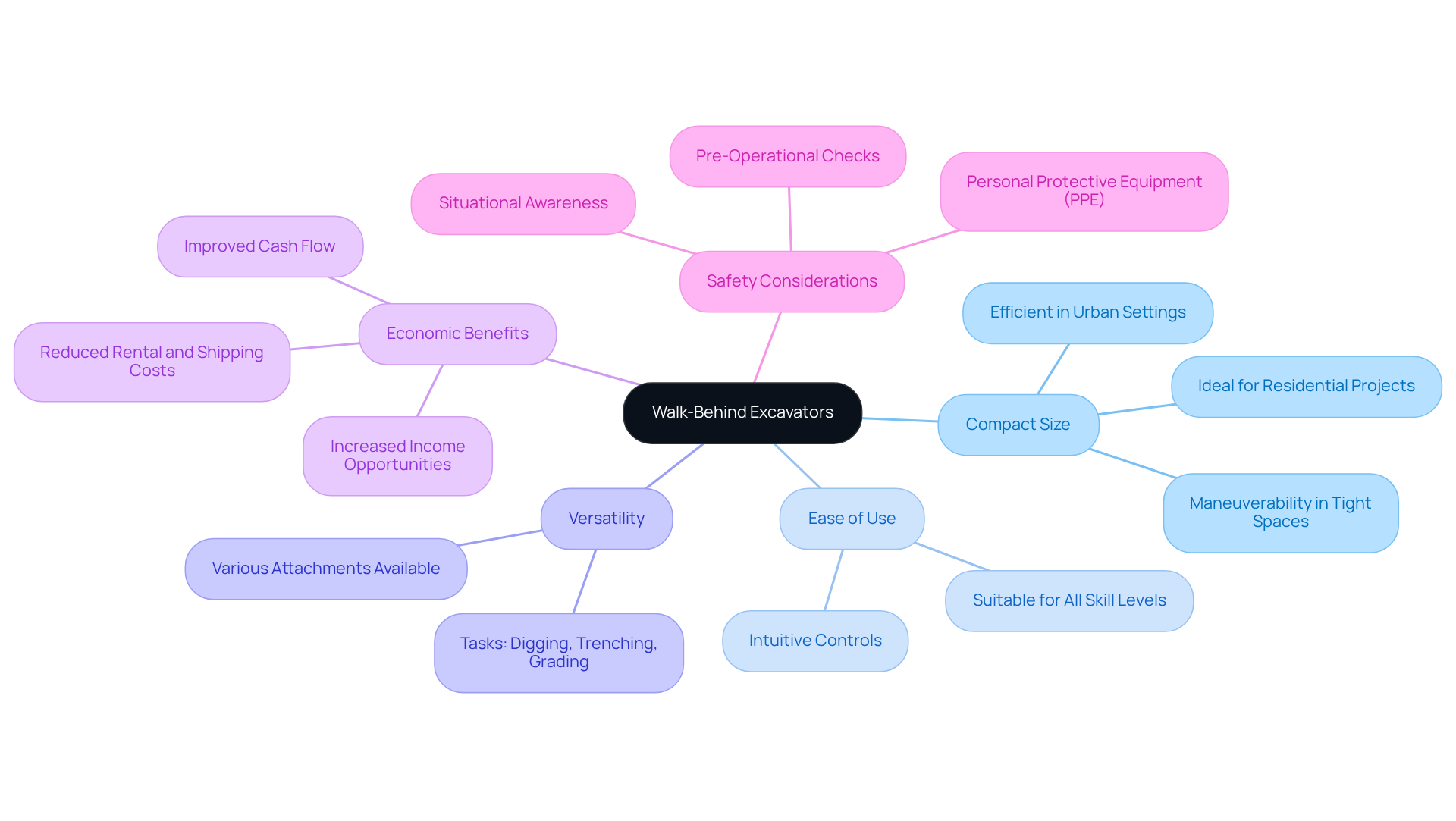

Understand Walk-Behind Excavators: Features and Benefits

The walk behind excavator is a compact, versatile machine designed for a variety of excavation tasks, particularly in confined areas. Their key features include:

- Compact Size: With a smaller footprint, these machines excel in maneuverability within tight spaces, making them ideal for residential projects and landscaping. Mini diggers, for example, have proven invaluable in urban settings, where their ability to navigate narrow pathways allows for efficient work without the need for larger equipment.

- Ease of Use: Crafted for operators of all skill levels, the walk behind excavator features intuitive controls that simplify operation. This ensures that even less experienced users can manage them effectively.

- Versatility: These machines can be equipped with various attachments, enabling them to perform tasks such as digging, trenching, and grading. This adaptability enhances their utility on job sites, allowing for seamless transitions between different tasks.

- Economic Benefits: The use of mini diggers can lead to significant financial gains for construction and landscaping firms, as they decrease the necessity for larger machinery, thus reducing rental and shipping expenses.

- Safety Considerations: Operators must prioritize safety by adhering to guidelines such as wearing suitable personal protective gear (PPE) and conducting pre-operational checks to minimize risks on the job site.

Typically, a walk behind excavator consumes less fuel than its larger counterparts, making it a cost-effective option for short-term projects. This efficiency not only reduces operational costs but also contributes to improved cash flow for businesses.

Understanding these features empowers operators to select the right machine for their specific needs, ensuring both efficiency and effectiveness in their work. Recent advancements in compact machinery, such as improved engine performance and ergonomic designs, further enhance their appeal in the construction and landscaping sectors. As industry specialist Michael Carter notes, "Simplifying complex mechanical concepts to enhance understanding and effectiveness in the field is my area of expertise," underscoring the importance of grasping device characteristics for optimal performance.

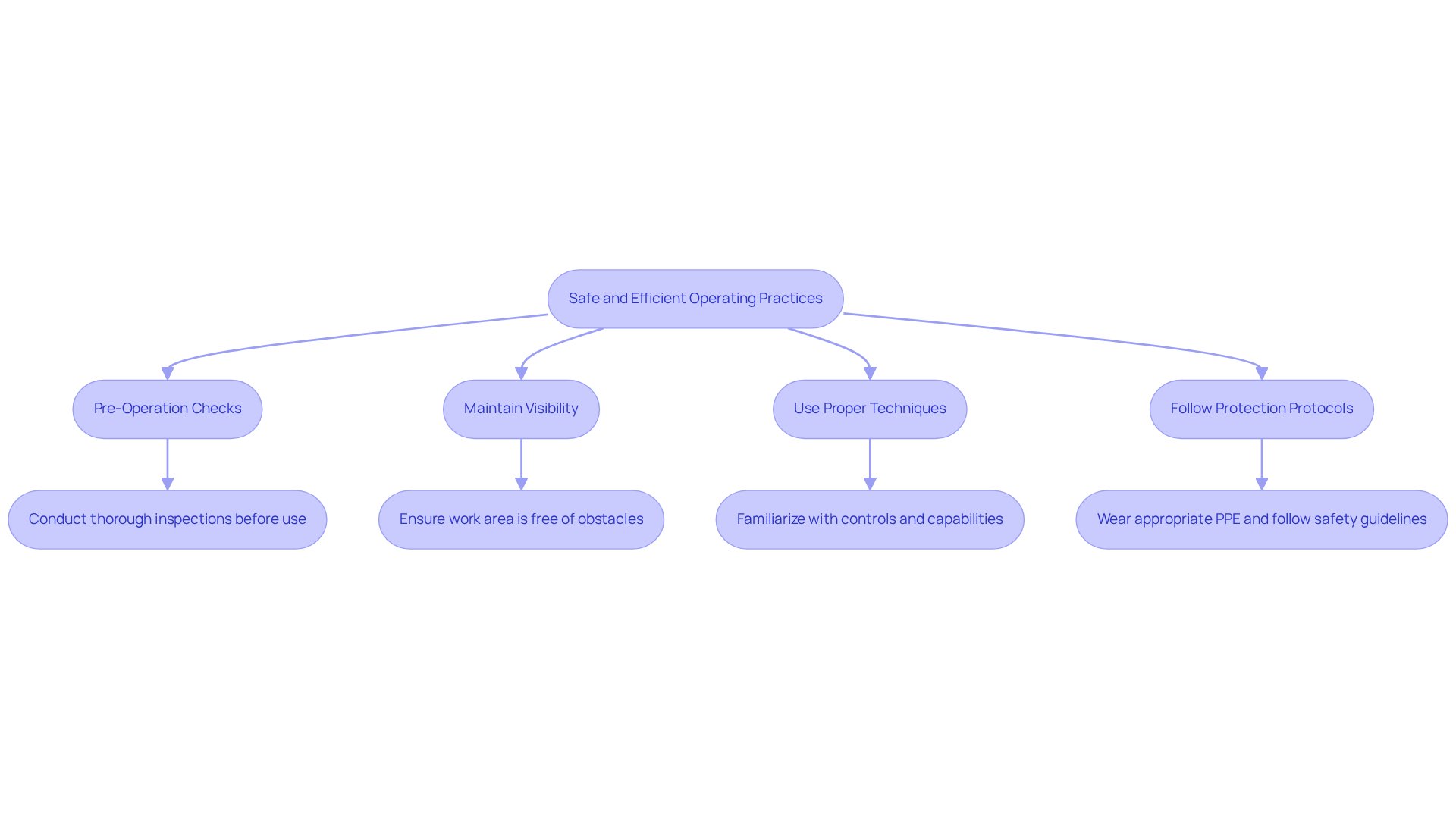

Implement Safe and Efficient Operating Practices

To operate a walk-behind excavator safely and efficiently, it is essential to adhere to several best practices:

Pre-Operation Checks: Conduct a thorough inspection before use. This includes checking fluid levels, brakes, and the condition of tracks and attachments. Spending ten minutes prior to each shift on these inspections can significantly enhance safety outcomes while improving equipment reliability.

Maintain Visibility: Ensure the work area is free of obstacles to provide the operator with a clear line of sight. This practice is crucial for avoiding accidents and ensuring the safety of both the operator and nearby workers. Operators must also remain aware of surrounding personnel while operating the machinery to prevent incidents.

Use Proper Techniques: Familiarize yourself with the specific controls and capabilities of the excavator. Practice basic movements, such as raising and lowering the boom and extending the arm. Smooth, controlled movements not only reduce wear on the machine but also enhance operational precision. Continuous training is vital for safe excavator operation, regardless of the operator's experience level.

Follow Protection Protocols: Always wear appropriate personal protective equipment (PPE) and adhere to established safety guidelines. Employ observers when necessary to direct activities in confined areas, ensuring that all precautionary measures are in place.

By implementing these practices, operators can significantly enhance safety and efficiency while operating a walk-behind excavator, leading to successful project outcomes.

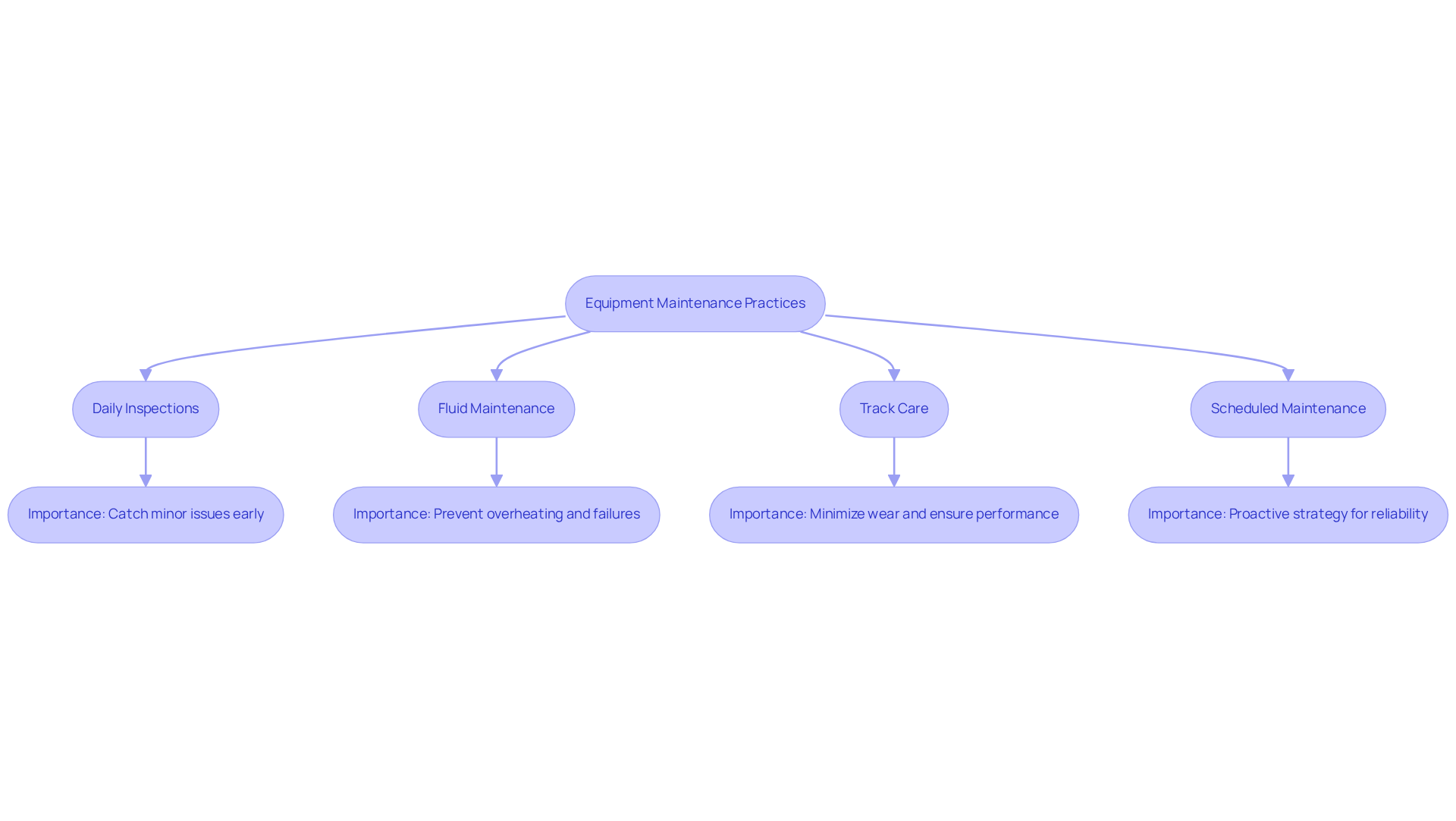

Maintain Equipment for Longevity and Reliability

To maximize the longevity and reliability of the walk behind excavator, adopting effective maintenance practices is essential.

Daily Inspections: Conduct thorough daily checks for leaks, wear, and damage, particularly focusing on hydraulic lines and the undercarriage. Regular inspections can catch minor issues before they escalate, preventing costly repairs and ensuring operational efficiency. Industry experts emphasize that consistent daily inspections are vital for preserving machinery health and preventing unexpected failures.

Fluid Maintenance: Adhere to the manufacturer's recommendations for checking and changing hydraulic fluid, engine oil, and coolant. This practice is crucial to avoid overheating and mechanical failures, which can significantly diminish the lifespan of machinery. Research indicates that regular fluid maintenance can lead to a reduction in downtime by up to 15%.

Track Care: Maintain clean tracks free of debris to minimize wear. Regularly inspect for signs of damage and adjust tension as necessary to ensure optimal performance. Neglecting track care can lead to increased wear and costly repairs.

Scheduled Maintenance: Implement a structured maintenance schedule that includes routine servicing by qualified technicians. This proactive strategy addresses potential issues before they evolve into significant problems, thereby improving overall reliability. Documented inspection records serve as proof of compliance during audits and can reduce liability in case of accidents.

By prioritizing these maintenance practices, operators can significantly enhance the performance and lifespan of their walk behind excavator, ensuring it remains a dependable asset on the job site. Incorporating these strategies not only boosts equipment reliability but also fosters a proactive safety culture among workers.

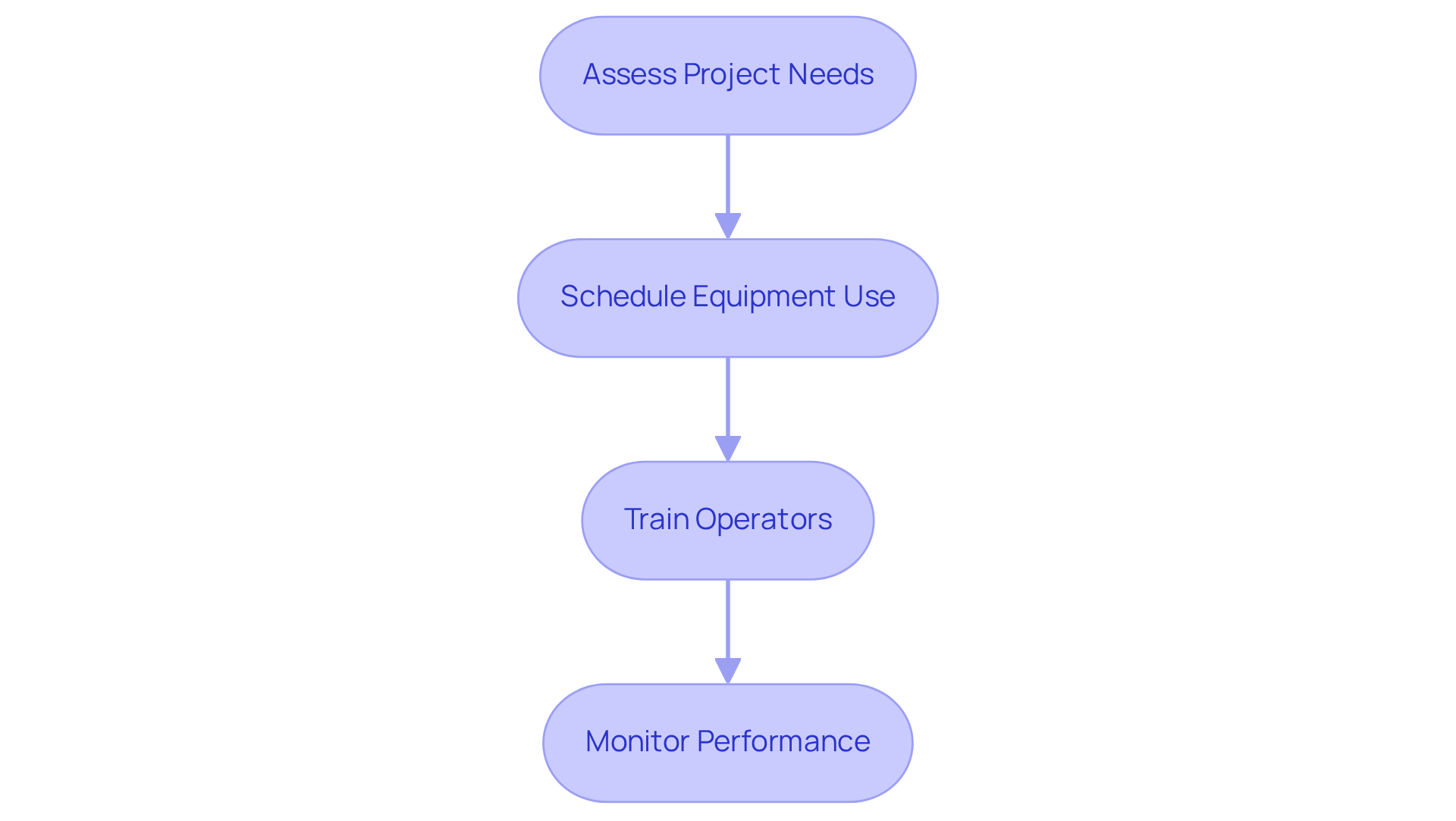

Integrate Excavators into Project Planning and Management

To effectively integrate walk-behind excavators into project planning and management, consider the following strategies:

- Assess Project Needs: Evaluate the specific excavation requirements of the project to determine the appropriate size and type of excavator needed.

- Schedule Equipment Use: Arrange the utilization of diggers in coordination with other activities to reduce downtime and ensure that tasks are accomplished effectively.

- Train Operators: Ensure that all operators are adequately trained on the specific type of machinery being used, including safety protocols and operational techniques.

- Monitor Performance: Track the performance of the digging machine throughout the endeavor to identify any issues early and adjust plans as necessary to maintain efficiency.

By strategically integrating excavators into project management, teams can enhance productivity and ensure that projects are completed on time and within budget.

Conclusion

The effective use of walk-behind excavators relies on a solid understanding of their unique features and the implementation of best practices that enhance safety, efficiency, and longevity. By recognizing the advantages of these compact machines, operators can effectively leverage their versatility across various excavation tasks, particularly in confined spaces.

Key insights from this article emphasize the necessity of:

- Thorough pre-operation checks

- Maintaining visibility

- Employing proper techniques

- Adhering to established safety protocols

Regular maintenance, including daily inspections and fluid management, is essential for ensuring the reliability of the equipment. Furthermore, integrating excavators into project planning and management can significantly enhance workflow and productivity, ultimately leading to successful project outcomes.

Embracing these best practices not only maximizes the performance of walk-behind excavators but also cultivates a culture of safety and efficiency on job sites. By prioritizing training, maintenance, and strategic planning, operators can ensure that their excavators remain dependable assets, propelling projects forward with confidence and precision. This commitment to best practices underscores the value of walk-behind excavators in modern construction and landscaping, establishing them as indispensable tools for achieving exceptional results.

Frequently Asked Questions

What is a walk-behind excavator?

A walk-behind excavator is a compact, versatile machine designed for various excavation tasks, particularly in confined areas.

What are the key features of walk-behind excavators?

Key features include a compact size for maneuverability in tight spaces, ease of use with intuitive controls, versatility with various attachments for different tasks, economic benefits by reducing the need for larger machinery, and safety considerations for operators.

How does the compact size of walk-behind excavators benefit their use?

The smaller footprint allows for excellent maneuverability within tight spaces, making them ideal for residential projects and landscaping, especially in urban settings.

Are walk-behind excavators easy to operate?

Yes, they are designed for operators of all skill levels with intuitive controls that simplify operation, enabling even less experienced users to manage them effectively.

What tasks can walk-behind excavators perform?

They can perform various tasks such as digging, trenching, and grading, thanks to their ability to be equipped with different attachments.

What are the economic benefits of using walk-behind excavators?

They can lead to significant financial gains for construction and landscaping firms by decreasing the necessity for larger machinery, thus reducing rental and shipping expenses.

How does fuel consumption of walk-behind excavators compare to larger machines?

Walk-behind excavators typically consume less fuel than larger counterparts, making them a cost-effective option for short-term projects.

What safety considerations should operators keep in mind?

Operators should prioritize safety by wearing suitable personal protective gear (PPE) and conducting pre-operational checks to minimize risks on the job site.

How have recent advancements improved walk-behind excavators?

Recent advancements include improved engine performance and ergonomic designs, enhancing their appeal in the construction and landscaping sectors.

List of Sources

- Understand Walk-Behind Excavators: Features and Benefits

- 10 Awesome Ways to Use Mini Excavators - TYPHON Machinery (https://typhonmachinery.com/10-awesome-ways-to-use-mini-excavators?srsltid=AfmBOooAuAV7hYA7UaAHqCyaleXK2I7KdrPR4D2GJ9sMTeTseEnLwxip)

- Implement Safe and Efficient Operating Practices

- Inspirational Safety Quotes to Share with Your Workers (https://ehsinsight.com/blog/inspirational-safety-quotes-to-share-with-your-workers)

- Excavator Safety Tips | Bourne, MA | Excavator Dealer (https://bobcatofcapecod.com/blog/crucial-safety-measures-for-operating-an-excavator--93929)

- Excavator Safety Best Practices | Bridgewater, MA | Equipment Dealer (https://bobcatofsouthshore.com/blog/ensuring-excavator-safety-key-measures-for-operators--101409)

- Contact Us | Outside US & Canada | Damotech (https://damotech.com/blog/inspirational-quotes-warehouse-safety)

- Maintain Equipment for Longevity and Reliability

- 5 "Genius" Quotes to Inspire Better Facilities Maintenance (https://brightlysoftware.com/blog/5-genius-quotes-to-inspire-better-facilities-maintenance)

- Lean Manufacturing Quotes to Drive Efficient Industrial Operations (https://mapcon.com/blog/2014/07/11-lean-manufacturing-quotes-to-inspire-you)

- Seven Tips for Mastering Summer Excavator Maintenance | DEVELON (https://na.develon-ce.com/en/news-stories/news/seven-tips-for-mastering-summer-excavator-maintenance)

- 10 Wise Quotes For Anyone Who Works In Facility Maintenance (https://linkedin.com/pulse/10-wise-quotes-anyone-who-works-commercial-building-natalia-chaaito)

- Why Regular Equipment Inspections Are Important | RPM (https://rpmmachinery.com/importance-of-regular-equipment-inspections)

- Integrate Excavators into Project Planning and Management

- 25 Project Management Statistics to Guide Your Plans in 2025 - PM 360 Consulting (https://pm360consulting.ie/25-project-management-statistics-to-guide-your-plans-in-2025)

- Project management statistics you need to know (2026) (https://breeze.pm/blog/project-management-statistics)

- 40 Construction Quotes to Motivate Your Team (https://projectmanager.com/blog/construction-quotes)

- 10 Construction Quotes to Inspire Your Project (https://horstconstruction.com/10-wise-construction-quotes-to-inspire-your-next-project-2)

- AI Agents for Construction (Key Statistics) (https://datagrid.com/blog/ai-agent-construction-statistics)