Key Highlights:

- Mobile elevated work platforms (MEWPs) like scissor lifts are vital for safely raising personnel and materials in construction, maintenance, and warehousing.

- Electric scissor lifts are preferred for indoor use due to their quiet operation and zero emissions, comprising 68.7% of the market revenue in 2024.

- Diesel scissor lifts are designed for outdoor applications, providing power and stability on rough terrain, with a projected growth rate of 7.8%.

- Rough terrain scissor platforms feature larger tyres and enhanced stability for safe operation in challenging outdoor conditions.

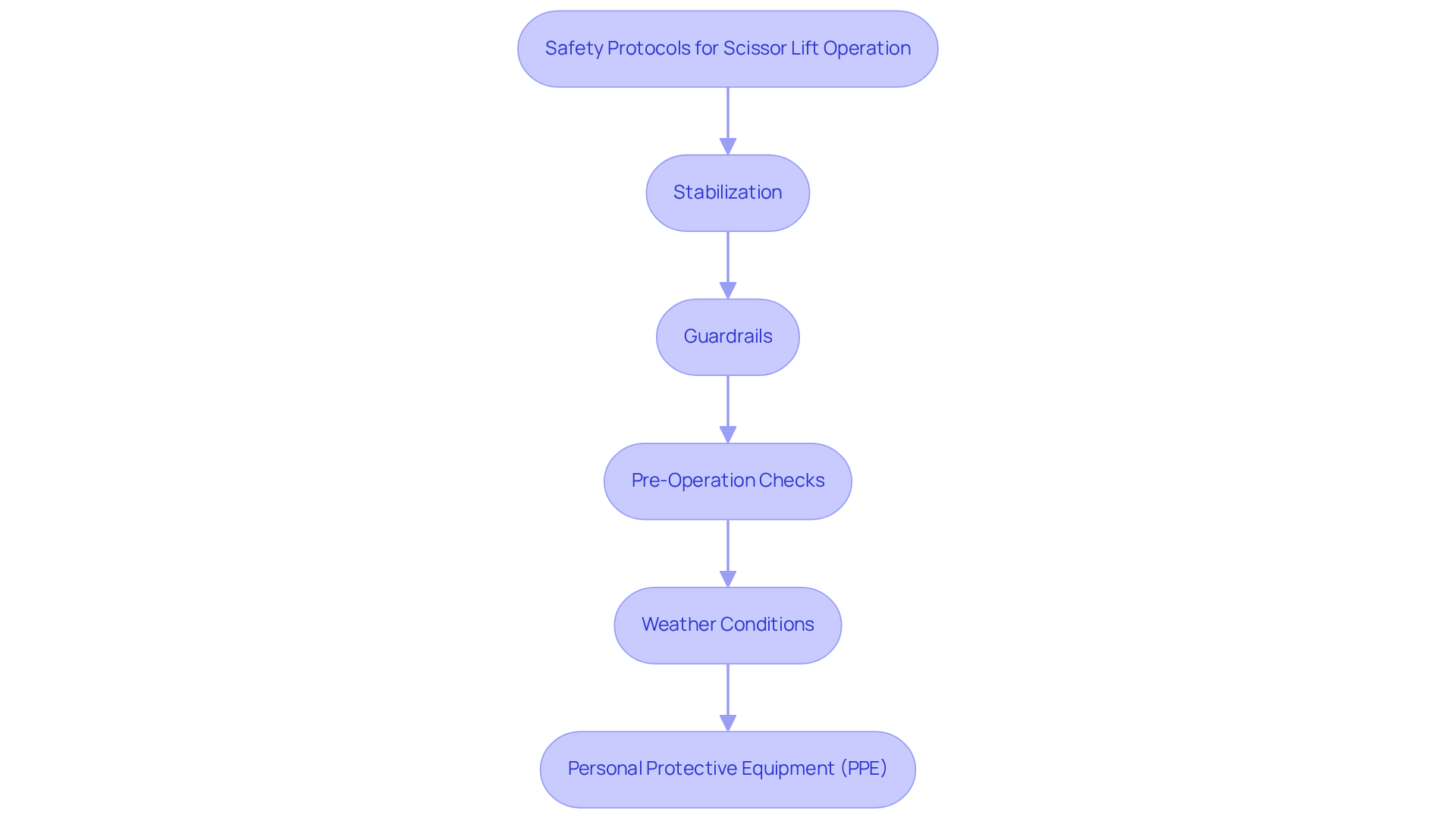

- Safety protocols for scissor lift operation include ensuring stabilisation on level surfaces, securing guardrails, conducting pre-operation checks, monitoring weather conditions, and wearing personal protective equipment (PPE).

- Adhering to safety protocols is crucial to prevent accidents, as evidenced by OSHA statistics linking inadequate stabilisation to fatalities and serious injuries.

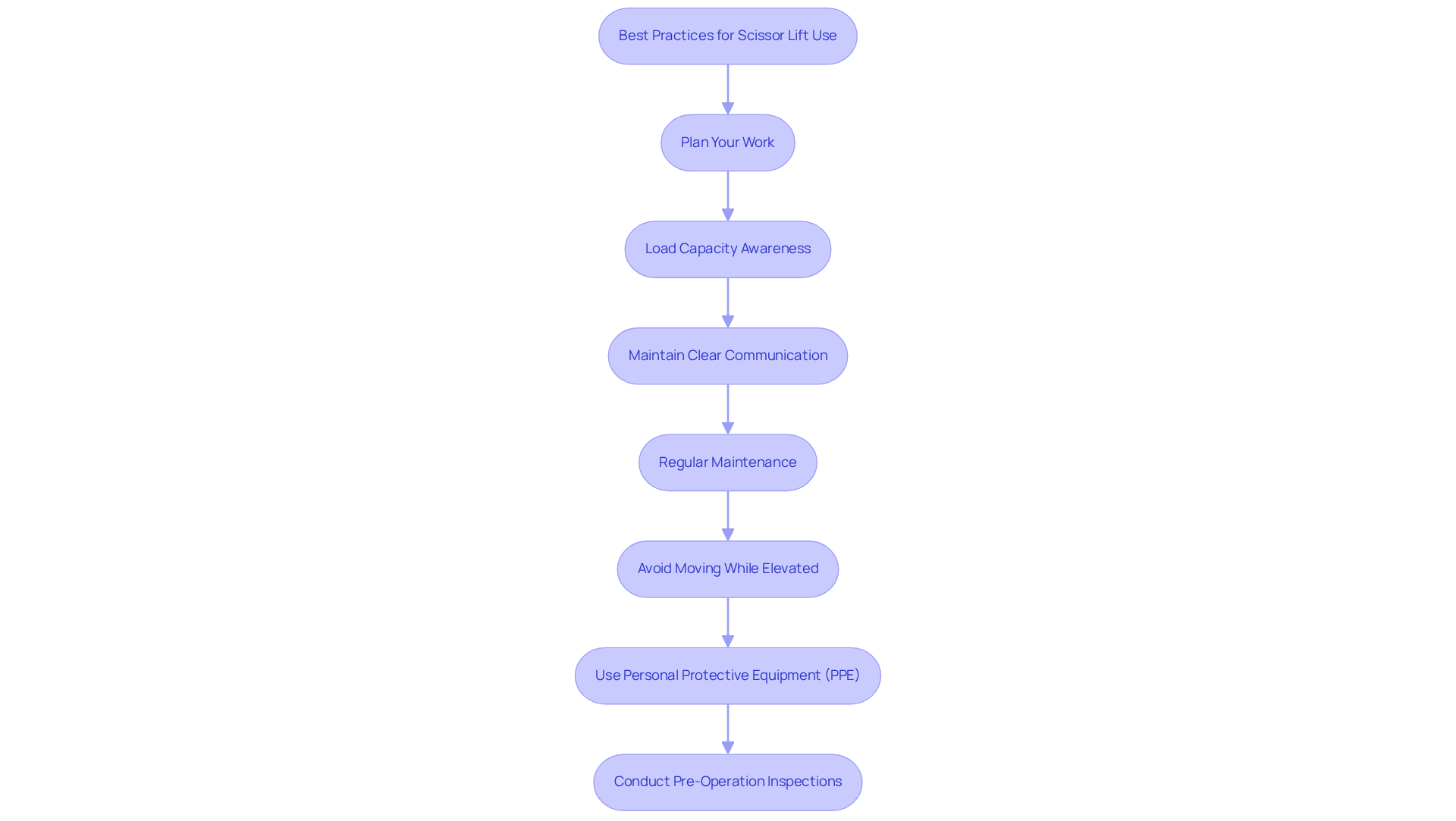

- Best practises for efficient scissor lift use include planning work, respecting load capacities, maintaining clear communication, scheduling regular maintenance, avoiding movement while elevated, and conducting pre-operation inspections.

- Training and certification are essential for scissor lift operators to ensure compliance with OSHA regulations and reduce accident risks, emphasising practical instruction and continuous education.

- Regular assessment and evaluation of operator performance help maintain safety standards and promote a culture of accountability in the workplace.

Introduction

Understanding the complexities of scissor lifts is crucial for ensuring safety and efficiency across various industries, including construction and maintenance. These versatile mobile elevated work platforms (MEWPs) not only provide access to hard-to-reach areas but also come in various types tailored for specific environments. For instance, electric models are ideal for indoor use, while rugged versions excel outdoors.

However, the challenge remains: how can operators maximize the benefits of scissor lifts while minimizing risks? This article explores essential best practices, safety protocols, and training requirements that equip operators with the knowledge necessary to navigate the complexities of scissor lift operation effectively. By adhering to these guidelines, operators can enhance their efficiency and ensure a safer working environment.

Understand Scissor Lifts: Definition, Functionality, and Types

Mobile elevated work platforms (MEWPs) are essential tools designed to raise personnel and materials vertically, ensuring safety and efficiency in various tasks. These platforms utilize a crisscrossed beam mechanism that extends and retracts, allowing for smooth elevation and descent. Scissor lifts near me are particularly crucial in construction, maintenance, and warehousing, as they provide secure access to elevated areas for operators.

Electric Scissor Lifts are perfect for indoor applications, thanks to their quiet operation and zero emissions, making them compliant with environmental regulations. In fact, they accounted for 68.7% of the market revenue in 2024, reflecting a growing preference for eco-friendly solutions. Diesel Scissor Elevators, on the other hand, are designed for outdoor use, offering greater power and stability on rough terrain, which is vital for extensive construction projects. This engine-powered segment is projected to grow at a CAGR of 7.8%, driven by the increasing demand for robust lifting capabilities. Additionally, Rough Terrain Scissor Platforms come equipped with larger tires and enhanced stability features, ensuring safe operation in challenging outdoor conditions.

Understanding these differences is crucial for operators to select the right equipment for their specific tasks, ultimately enhancing security and efficiency. Utilizing scissor lifts near me, especially from a trusted supplier like EZ Equipment Rental, significantly reduces the risks associated with working at heights. The stable structures and protective elements of both boom hoists and platform elevating devices ensure a secure working environment, minimizing accidents and injuries. As the construction industry continues to expand, the demand for aerial platforms is expected to rise, with the market projected to reach USD 5.15 billion by 2030.

Don't compromise on safety and efficiency - choose the right equipment for your needs today!

Implement Safety Protocols: Essential Guidelines for Scissor Lift Operation

To ensure the safe operation of scissor lifts, operators must adhere to essential safety protocols:

-

Stabilization: Always operate elevating work platforms on firm, level surfaces to prevent tipping. Avoid areas with slopes, holes, or debris, as these conditions significantly increase the risk of accidents. OSHA documented 10 fatalities and 20 serious injuries linked to platform accidents over a one-year span, suggesting that inadequate stabilization is a primary factor in equipment-related deaths.

-

Guardrails: Ensure that guardrails are installed and secure before using the hoist. This is essential for avoiding falls, which are a frequent cause of injury and death for aerial and scissor operators. Regular inspections should confirm that guardrails meet safety standards and are free from damage.

-

Pre-Operation Checks: Conduct thorough inspections of the equipment before use, checking for any mechanical issues or hazards in the work area. This proactive approach can identify potential problems that could lead to accidents, reinforcing the importance of a comprehensive maintenance program.

-

Weather Conditions: Avoid using scissor lifts in high winds or adverse weather conditions that could affect stability. Bad weather can exacerbate risks, leading to tip-overs and falls. Operators should monitor weather forecasts and halt operations during inclement conditions.

-

Personal Protective Equipment (PPE): Operators should wear suitable PPE, including hard hats, goggles, and harnesses when necessary. Adherence to protective equipment guidelines is crucial, as it greatly decreases the chances of injury in the case of an accident.

By adhering to these protocols, not only is protection improved, but a culture of accountability is also encouraged among workers. This aligns with the significance of proper training and compliance with precautionary measures, as highlighted in revised guidelines for 2025.

Adopt Operational Best Practices: Tips for Efficient Scissor Lift Use

Maximize Efficiency and Safety in Scissor Lift Operations

To ensure the utmost efficiency and safety during scissor lift operations, it’s essential to follow these best practices:

-

Plan Your Work: Before using the lift, outline the tasks at hand and ensure all necessary tools and materials are within reach. This approach minimizes unnecessary movements and significantly boosts productivity.

-

Load Capacity Awareness: Always adhere to the manufacturer’s load capacity guidelines. Overloading is a leading cause of accidents, with violations contributing significantly to scissor platform incidents. Regularly reviewing these guidelines is crucial for maintaining compliance and safety.

-

Maintain Clear Communication: Establish effective communication with ground personnel through hand signals or radios. This practice ensures that everyone is aware of the lift's movements and operations, thereby reducing the risk of accidents.

-

Regular Maintenance: Schedule routine maintenance checks to keep the lift in optimal working condition. Address any mechanical issues promptly, as defective equipment can lead to serious accidents.

-

Avoid Moving While Elevated: Unless the lift is specifically designed for movement while elevated, refrain from moving it in this position. This practice helps prevent tipping and other accidents, which are common causes of injuries in aerial hoist operations.

-

Use Personal Protective Equipment (PPE): Always wear appropriate PPE, including hard hats, gloves, and harnesses, to mitigate hazards associated with aerial platforms.

-

Conduct Pre-Operation Inspections: Before using the lift, perform thorough inspections to verify that all controls are functioning correctly. This step is crucial for ensuring safety during operations.

By implementing these best practices, construction project managers can significantly enhance both the efficiency and safety of using scissor lifts near me, ultimately fostering a safer work environment.

Prioritize Training and Certification: Ensuring Competent Scissor Lift Operators

To ensure the safe and efficient use of elevating platforms, prioritizing training and certification for all operators is essential. OSHA Compliance is a critical aspect; operators must be well-versed in OSHA regulations regarding scissor platform usage, which include specific safety standards and training requirements. Adhering to these regulations significantly reduces risks associated with elevator activities. As OSHA states, "It’s a simple fact, uncertified aerial equipment operators are more likely to make mistakes."

Practical Instruction is another vital component. Implementing practical instruction that covers hoisting procedures, security guidelines, and emergency protocols equips operators with the necessary skills to handle real-world scenarios safely. This hands-on approach fosters confidence and competence in their abilities.

Certification programs play a crucial role in validating operators' expertise in the operation of scissor lifts near me. Encouraging operators to complete these programs not only demonstrates their competency but also aligns with OSHA's emphasis on proper training to reduce accident rates. Notably, the average scaffold-related death rate is 36 percent across all trades, underscoring the urgent need for effective training.

Continuous Education is key to maintaining safety standards. Providing ongoing training sessions keeps operators informed about new protective practices, equipment updates, and regulatory changes. This commitment to education promotes a culture of security and adaptability in the workplace.

Assessment and Evaluation are necessary for ensuring compliance and encouraging ongoing enhancement. Regularly evaluating operator performance and offering constructive feedback helps maintain high standards.

Additionally, OSHA guideline 3842, published in 2016, addresses aerial work platform accidents, including fatalities related to scissor lifts near me, emphasizing the regulatory framework surrounding scissor lift operation and training.

Investing in comprehensive training and certification not only enhances safety but also boosts operator confidence and efficiency on the job, ultimately leading to a safer work environment.

Conclusion

Ensuring the safe and efficient use of scissor lifts is crucial across various industries, especially in construction and maintenance. By comprehensively understanding the different types of scissor lifts, adhering to stringent safety protocols, and implementing operational best practices, operators can significantly improve their work environments. Proper training and certification are essential, equipping operators with the skills necessary to handle these powerful tools responsibly.

Selecting the right equipment based on specific needs is vital. Maintaining rigorous safety standards and fostering a culture of continuous training are key insights that emerge from this discussion. From stabilization and pre-operation checks to effective communication and load capacity awareness, each practice plays a critical role in minimizing risks and maximizing productivity. The expanding market for scissor lifts highlights the necessity for operators to stay informed about evolving best practices and safety guidelines.

Prioritizing safety and efficiency in scissor lift operations not only safeguards personnel but also enhances overall project success. Investing in training, adhering to safety protocols, and implementing best practices are essential steps toward creating a safer and more productive work environment. Embrace these guidelines to ensure scissor lifts are utilized to their fullest potential, contributing to safer job sites and successful operations.

Frequently Asked Questions

What are scissor lifts and what is their primary function?

Scissor lifts are mobile elevated work platforms (MEWPs) designed to raise personnel and materials vertically, ensuring safety and efficiency in various tasks.

How do scissor lifts operate?

Scissor lifts utilize a crisscrossed beam mechanism that extends and retracts, allowing for smooth elevation and descent.

In what industries are scissor lifts commonly used?

Scissor lifts are particularly crucial in construction, maintenance, and warehousing, providing secure access to elevated areas for operators.

What are the different types of scissor lifts?

The main types of scissor lifts are Electric Scissor Lifts, Diesel Scissor Elevators, and Rough Terrain Scissor Platforms.

What are the advantages of Electric Scissor Lifts?

Electric Scissor Lifts are ideal for indoor applications due to their quiet operation and zero emissions, making them compliant with environmental regulations.

What is the market trend for Electric Scissor Lifts?

Electric Scissor Lifts accounted for 68.7% of the market revenue in 2024, indicating a growing preference for eco-friendly solutions.

What are Diesel Scissor Elevators designed for?

Diesel Scissor Elevators are designed for outdoor use, providing greater power and stability on rough terrain, essential for extensive construction projects.

What is the projected growth rate for Diesel Scissor Elevators?

The Diesel Scissor Elevators segment is projected to grow at a CAGR of 7.8%, driven by increasing demand for robust lifting capabilities.

What features do Rough Terrain Scissor Platforms have?

Rough Terrain Scissor Platforms come equipped with larger tires and enhanced stability features, ensuring safe operation in challenging outdoor conditions.

Why is it important to understand the differences between scissor lift types?

Understanding these differences is crucial for operators to select the right equipment for their specific tasks, ultimately enhancing security and efficiency.

What is the projected market value for aerial platforms by 2030?

The market for aerial platforms is projected to reach USD 5.15 billion by 2030, driven by the expansion of the construction industry.

How can choosing the right equipment impact safety?

Utilizing scissor lifts from a trusted supplier significantly reduces the risks associated with working at heights, ensuring a secure working environment and minimizing accidents and injuries.